Deep treatment system of membraneless industrial organic wastewater

A technology for organic wastewater and advanced treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problems of high pollutant concentration and poor biodegradability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

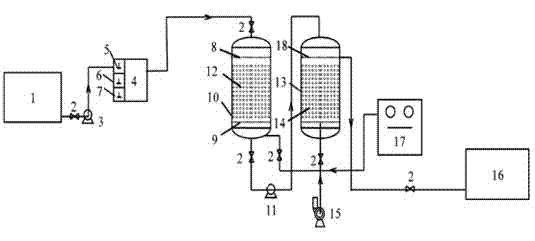

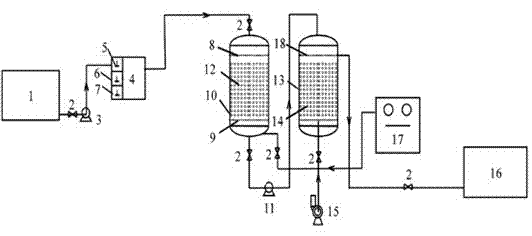

Image

Examples

Embodiment 1

[0038] After the industrial organic wastewater undergoes secondary biochemical treatment, the COD concentration is often reduced to below 300mg / L. The supernatant of the secondary sedimentation tank 1 enters the wastewater property improvement pool 4 through the valve 2 and the lift pump 3. In the waste water property improvement pool 4, according to the water quality Features Dosing different water quality improving agents, when there are organic matter mainly composed of branched chain units in the wastewater, and the average molecular weight is higher than 2 million, choose to use the improvement formula of potassium permanganate, polyferric sulfate and polyacrylamide (corresponding to The first reaction tank 5, the second reaction tank 6, the third reaction tank 7), when the main component of the organic matter in the wastewater is benzene series, the improved formula of adding ferrous hydroxide, aluminum sulfate and polyacrylamide (corresponding to The first reaction t...

Embodiment 2

[0041] A landfill is the largest landfill in Asia, the COD concentration of the leachate is as high as 30000~50000mg / L, the B / C ratio is less than 0.3, the chromaticity is 2000 times, the ammonia nitrogen concentration is 1000~1400mg / L, and the COD concentration is 216 ~242mg / L, the concentration of ammonia nitrogen is 8mg / L, and the chromaticity is 200~300 times. The biochemical effluent enters the wastewater property improvement pool, and is treated with potassium permanganate, polyferric sulfate and polyacrylamide. The concentration of potassium permanganate is 10mg / L, and the concentration of polyferric sulfate is 80mg / L. The dosing concentration is 5mg / L, the wastewater properties are improved, and the pool effluent can oxidize organic matter to the form of aldehydes and alcohols by using ozone, which fully improves biodegradability and reduces chromaticity and COD. In the case of ozone concentration: COD=1:1, The COD concentration of the effluent is 98~108mg / L, the am...

Embodiment 3

[0043] A pharmaceutical factory biological fermentation (gentamicin) wastewater, secondary biochemical effluent COD effluent 160~200mg / L, chroma 100~150 times, BOD / COD less than 0.1, in order to meet the reuse requirements, the effluent COD concentration is less than 50mg / L L, the chroma is less than 30 times, and the waste water property improvement pool adopts ferrous hydroxide (50mg / L), aluminum sulfate (150mg / L), dicyandiamide formaldehyde polymer (50mg / L), and the COD removal rate reaches 35~ 40%, the chroma removal rate is 50%, the effluent COD is at 80~100mg / L, when the ozone concentration and the COD influent concentration of the ozone contact tower are 1:1, the effluent COD concentration is less than 70mg / , and the chroma is less than 25 times. The B / C ratio reaches 0.3. After being treated by the biological aerated filter, the COD concentration of the effluent is less than 45mg / L, and the chromaticity is less than 25 times, which meets the requirements for reuse a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com