Blending aid composition, synthetic resin, and polyolefin film/sheet

A synthetic resin and composition technology, applied in the field of polyolefin film processing, can solve problems such as easy delamination, poor adhesion of plating and coating, and achieve low odor function, high metallic luster, and excellent barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

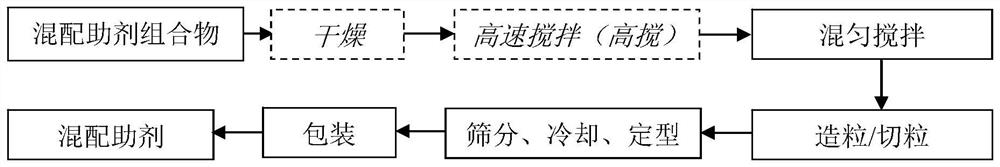

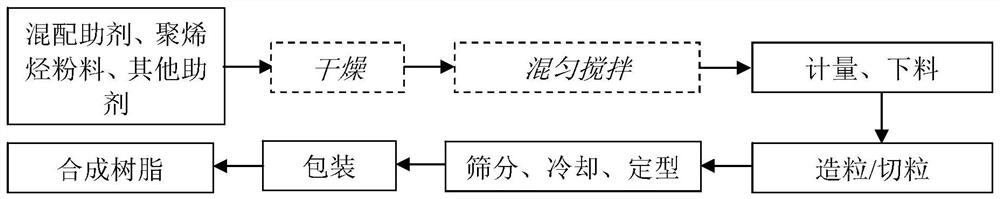

[0031] According to the present invention, figure 1 It is a schematic flow diagram of the preparation method of the compounding aid composition of the present invention, such as figure 1 As shown, the preparation method for preparing a compounding aid by using the compounding aid composition of the present invention comprises: drying, mixing and stirring the compounding aid composition (antioxidant, stabilizer and adhesion enhancer) , granulation / cutting, sieving, cooling, shaping, and packaging to obtain the compounding aid. Preferably, the mixing and stirring is carried out under high-speed stirring conditions.

[0032] Wherein, the drying conditions include: temperature 25-50° C., time ≥ 4 hours.

[0033] Stirring conditions include: mixing and stirring with a low-speed mixer for 15-30 minutes.

[0034] The conditions for sieving include: using a vibrating sieve with a sieve aperture of ≤5mm for sieving.

[0035] The conditions of setting treatment include: setting with...

Embodiment 1

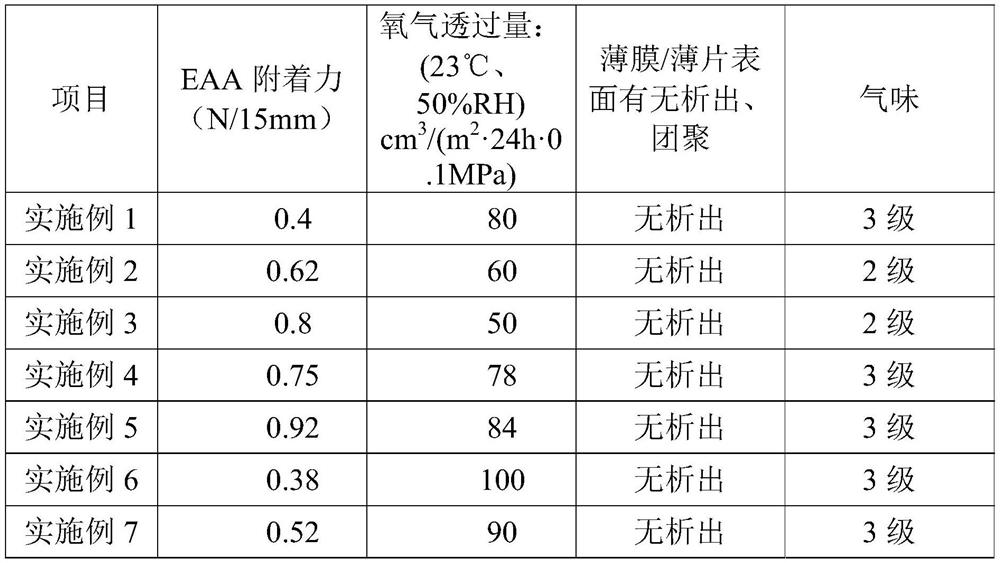

[0063] This example is intended to illustrate synthetic resin and polyolefin films / sheets prepared using the compounding aid composition of the present invention.

[0064] Compounding Auxiliary Composition:

[0065] The antioxidant is a compound of hydroxylamine antioxidant and phosphite antioxidant, with a weight ratio of 1:1;

[0066] The stabilizer is hydrotalcite, D 50 ≤150nm, MgO / Al 2 o 3 3:1;

[0067] Adhesion enhancers are specifically: ɑ-nucleating agent (brand is NX8000K), β-nucleating agent (brand is MT205-B), petroleum resin (specifically hydrogenated C9) and synergistic anti-blocking agent (specifically silicon dioxide) compound , The weight ratio of α-nucleating agent, β-nucleating agent, petroleum resin and synergistic opening agent is 0.005:0.005:1:0.5.

[0068] Wherein, based on the total weight of the compounding aid composition, the content of the antioxidant is 10% by weight, the content of the stabilizer is 10% by weight, and the content of the adhesio...

Embodiment 2

[0075] This example is intended to illustrate synthetic resin and polyolefin films / sheets prepared using the compounding aid composition of the present invention.

[0076] Synthetic resin and polyolefin film / sheet are prepared according to the same method as in Example 1, except that:

[0077] Compounding Auxiliary Composition:

[0078] The antioxidant is a compound of hydroxylamine antioxidant and phosphite antioxidant, with a weight ratio of 1:1;

[0079] The stabilizer is hydrotalcite, D 50 ≤150nm, MgO / Al 2 o 3 3:1;

[0080] The adhesion enhancer is specifically a compound of α-nucleating agent (specifically NX8000K), β-nucleating agent (specifically MT205-B), petroleum resin (specifically hydrogenated C9) and synergistic anti-blocking agent (specifically silicon dioxide), The weight ratio of α-nucleating agent, β-nucleating agent, petroleum resin and synergistic opening agent is 0.005:0.005:1:0.5.

[0081] Wherein, based on the total weight of the compounding aid com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com