Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "With metallic texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

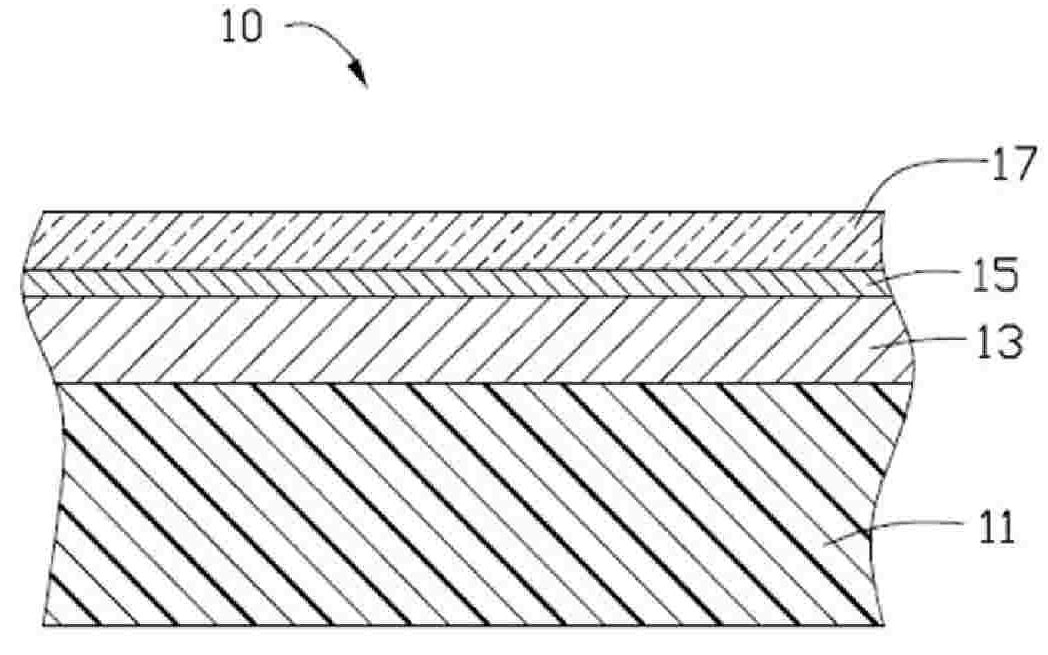

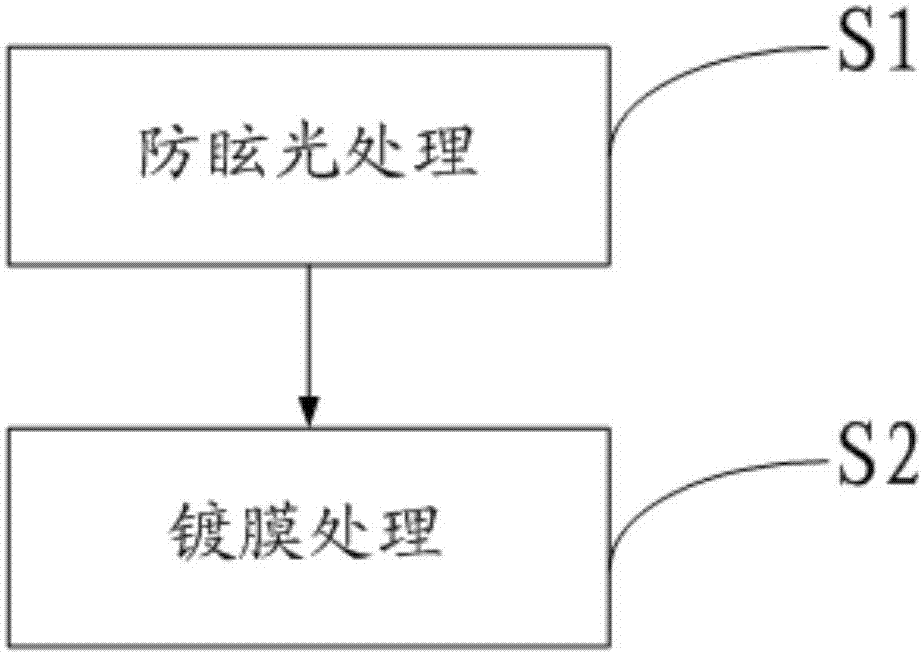

Electronic device housing, and electronic device and housing manufacturing technology

ActiveCN108724858ASolve the glare problemStrong textureLamination ancillary operationsSynthetic resin layered productsManufacturing technologyEngineering

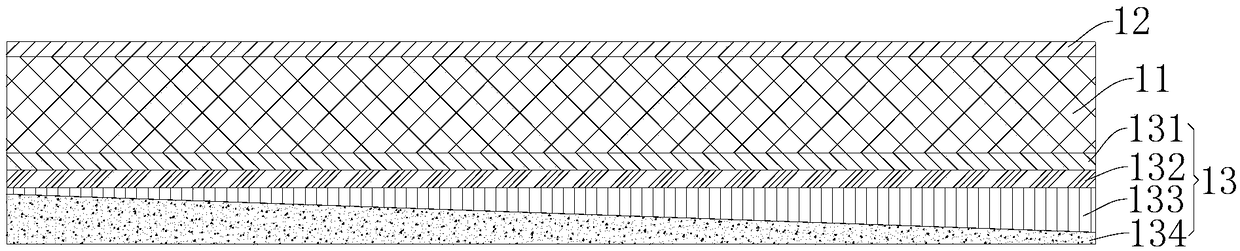

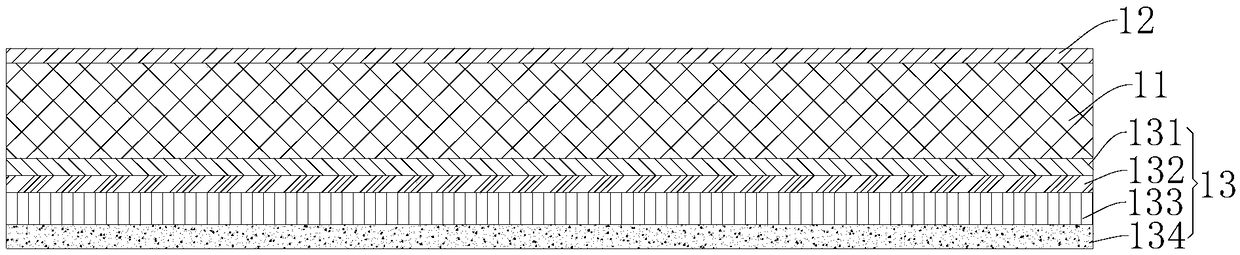

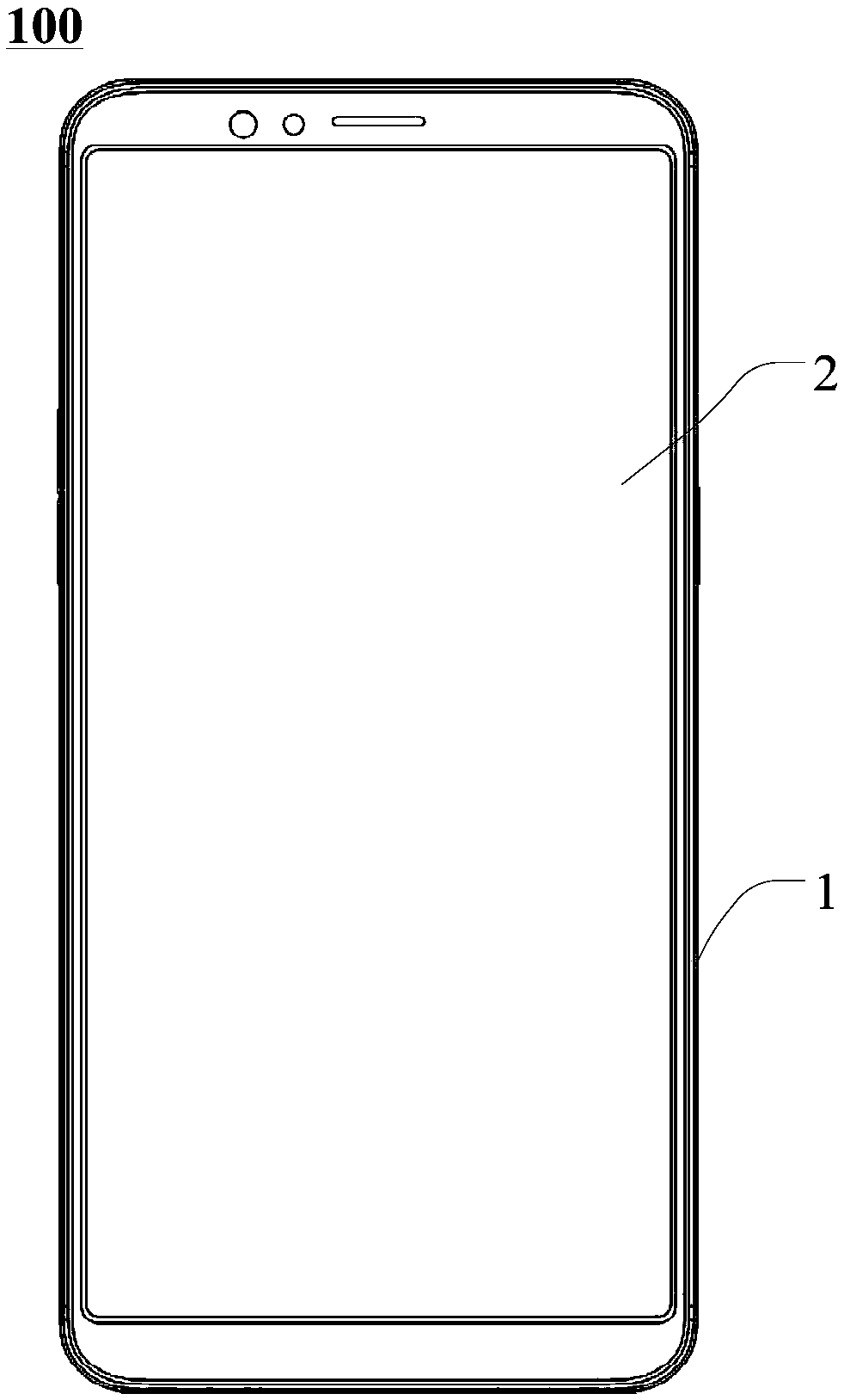

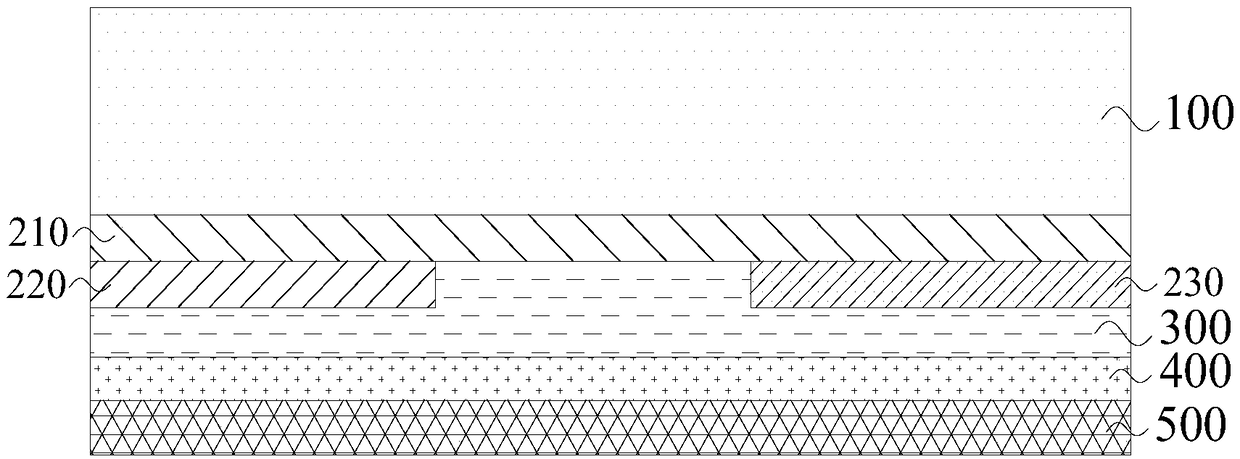

The invention discloses an electronic device housing, and electronic device and housing manufacturing technology. The electronic device housing comprises a glass substrate, a color function layer, andan anti-fingerprint film layer; the external surface of the glass substrate is an anti-dazzle surface; the color function layer is arranged on the internal surface of the glass substrate; the anti-fingerprint film layer is arranged on the external surface of the glass substrate. According to the electronic device housing, the external surface of the glass substrate is designed to be an anti-dazzle surface, so that dazzling caused by glass housings is avoided, and at the same time, the external surface of the housing is provided with better qualitative sense and business sense; the anti-fingerprint film layer is adopted on the surface of the anti-dazzle surface, so that anti-fingerprint function is improved further; the color function layer is adopted, so that the anti-dazzle surface of the housing is provided with certain color with certain metal qualitative sense, and the qualitative sense and the sense of beauty of the electronic device housing are improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Electronic product outer shell and manufacturing method thereof

ActiveCN101662899AExquisite appearanceWith metallic textureSynthetic resin layered productsDomestic articlesFiberCarbon fibers

The invention provides an electronic product outer shell comprising a shell body and a transparent window, wherein the transparent window is inlaid on the shell body, and the shell body is formed by hot-pressing at least one carbon fiber cloth layer presoaked by thermosetting resin. The invention also provides a manufacturing method of the electronic product outer shell. According to the electronic product outer shell, because the shell body is formed by hot-pressing at least one carbon fiber cloth layer presoaked by the thermosetting resin, the electronic product outer shell has stronger mechanical strength.

Owner:BYD CO LTD

Housing of electronic device, manufacturing method thereof, and electronic device

InactiveCN108966548AWith metallic textureIncrease metallic lusterNatural patternsOrnamental structuresGratingOptical coating

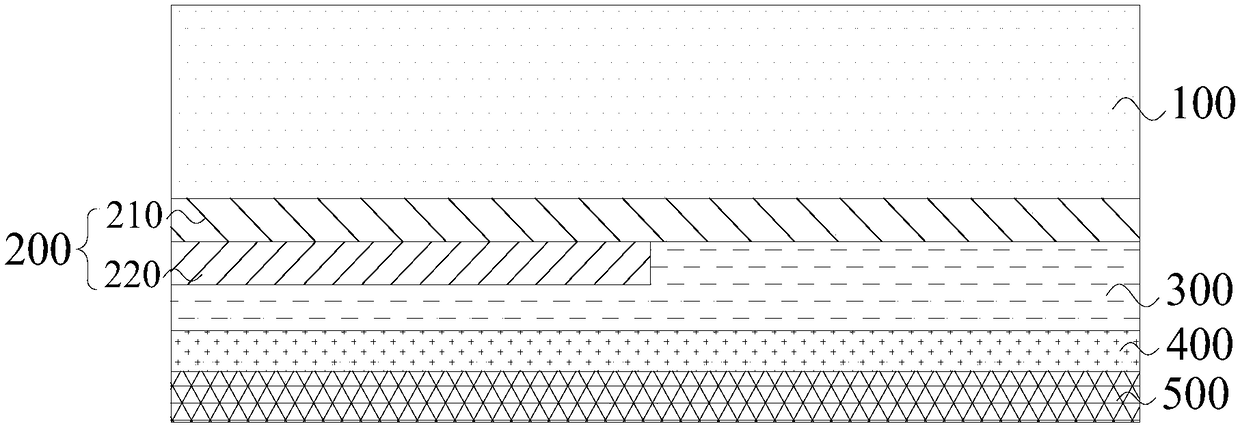

The invention provides a housing of an electronic device, a manufacturing method thereof, and an electronic device, wherein the housing of the electronic device comprises a transparent housing body, agradient color layer, a gloss oil layer, an optical texture layer and an optical coating layer which are stacked. The gradient color layer includes a first transparent color layer and a second transparent color layer which are stacked. The orthographic projection of the first transparent color layer on the transparent housing body completely covers the orthographic projection of the second transparent color layer on the transparent housing body. According to the housing of the electronic device of the present invention, the gradient color layer, the optical texture layer and the optical coating layer are disposed on a side of the transparent housing body. Viewed from the other side of the transparent housing body, the housing has an appearance with more than two uniformly and gradually varied colors and with high metallic gloss having a grating effect, so that the appearance of the electronic device can satisfy a consumer's demand for the variable appearance of the electronic device.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

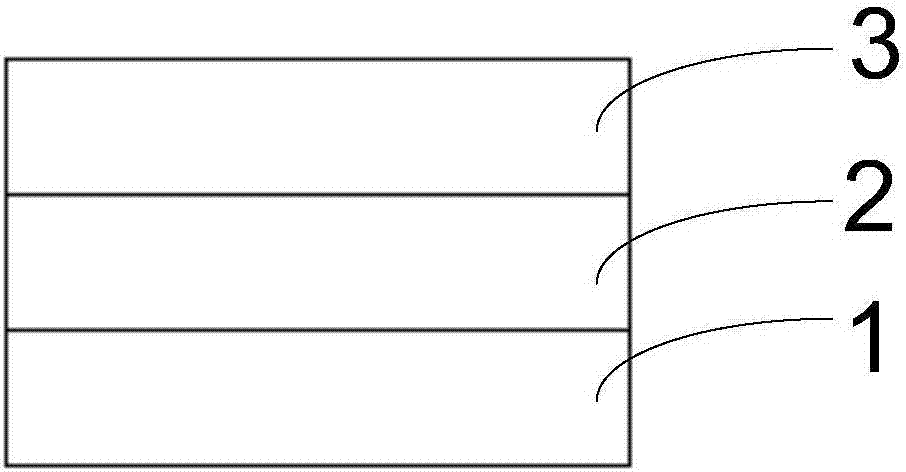

Casing of electronic device

InactiveCN1419404AWith metallic textureStrong corrosion resistanceMolten spray coatingSurface reaction electrolytic coatingAnodizingMetal

A casing of electronic devices comprises a plastic casing, a metal coating and an oxidized layer formed on the surface of the metal coating by anodizing. The method for manufacturing the casing of electronic devices, including the following steps: (1) ejecting and forming the above plastic casing; (2) forming in metal coating on the surface of the plastic casing; (3) anodizing the plastic casing with the metal coating. In such a way, the casing of electronic devices has a metal sense and a strong erosion resistance. The method can continue the tinctorial processing after the step (3) to acquire the required color or pattern.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Glaze material with metal texture for ceramic, preparation method thereof and ceramic prepared from the same

InactiveCN101148369ASimple preparation processProcess conditions are easy to controlProcess conditionsUltimate tensile strength

The present invention discloses one kind of ceramic glaze material with metal texture. The ceramic glaze material includes one kind of base metal facing glaze material of metal oxide mixture and one kind of covering printed glaze material. The ceramic product with the ceramic glaze has metal luster and metal texture as well as improved physical and chemical performances, and raised mechanical strength, abrasive strength and other mechanical performance, and is beautiful and durable. In addition, the ceramic glaze material has relatively simple preparation process and is suitable for industrial production. The present invention also discloses the preparation process of the ceramic glaze material and the ceramic product.

Owner:毛海燕

Electronic device shell and manufacturing method thereof

InactiveCN102448263AWith metallic textureIncrease brightnessDecorative surface effectsSpecial ornamental structuresHigh luminanceBrightness perception

The invention provides an electronic device shell which comprises a plastic matrix, a primer layer, a metal color vacuum coating layer and a transparent finish paint layer, wherein the primer layer is formed on the outer surface of the matrix; the vacuum coating layer is formed on the primer layer; a pattern is formed on the vacuum coating layer and on the electronic device shell; and the finish paint layer is formed on the vacuum coating layer and on the primer layer which is not covered by the vacuum coating layer. The invention also provides a method for manufacturing the electronic device shell. The pattern such as a mark, the pattern or characters on the surface of the electronic device shell not only has high luminance brightness, but also has metal texture and has an obvious visual effect.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Method for processing magnesium alloy surface

ActiveCN101294283AImprove corrosion resistanceImprove the decorative effectVacuum evaporation coatingSputtering coatingIonElectroless plating

The invention relates to a method for the surface treatment of magnesium alloy. The method includes that a metal coating is formed on the surface of the magnesium alloy, wherein, the method for forming metal coating on the surface of the magnesium alloy comprises the following steps: first, a zinc layer is coated on the surface of the magnesium alloy through electroless plating, then at least a layer of metal layer is electrocoated on the zinc layer of electroless plating, and at least a layer of metal or metal compound is coated on the electrocoated metal layer by adopting an ion plating method. After the zinc layer of electroless plating is treated by the method, electroplating is performed to the magnesium alloy first by the method of combining the electroplating and ion plating; the plating layer obtained after ion plating is performed to the electrocoated metal layer has uniform thickness; the plating layer is smooth; the corrosion resistance is remarkably improved; and the binding power between the base material of the magnesium alloy and the plating layer is also better. The magnesium alloy after through surface treatment can integrate good corrosion resistance and good decoration effect, and at the same time, can meet the requirements of high performance and high aesthetics of various industries for the magnesium alloy products, such as the automobile industry, the electronic industry, etc.

Owner:BYD CO LTD

Housing of electronic device

InactiveCN102098887AWith metallic textureHigh glossDecorative surface effectsSemiconductor/solid-state device detailsRefractive indexSilicon dioxide

The invention provides a housing of an electronic device. The housing of the electronic device comprises a substrate and a metal oxide film formed on the substrate surface. The roughness value of the substrate surface is below 60 nm. The metal oxide film comprises oxide layers which have different reflective indexes and are arranged alternatively. The oxide layers with different reflective indexes may be a combination of a Ta2O5 oxide layer and a SiO2 oxide layer or a combination of an Nb2O5 oxide layer and a ZrO oxide layer. The surface glossiness value of the housing is 100 to 200 glossiness units.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Method for making casing of electronic device

InactiveCN1419403AWith metallic textureStrong corrosion resistancePretreated surfacesCoatingsMetal coatingAnodizing

The present invention provides a method for manufacturing the casing of electronic device, including the following steps: (1) ejecting and forming the plastic casing having a specific shape; (2) forming a metalk coating on the surface of the plastic casing; (3) anodizing the plastic casing with the metal coating. In such a way, the casing of electronic devices has a metal sense and a strong erosion resistance. The method can continue the tinctoiral processing after the step (3) to acquire the required color or pattern.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Metal plating piece and preparation method thereof

InactiveCN105063619AWith metallic textureImprove corrosion resistanceLiquid/solution decomposition chemical coatingSuperimposed coating processPotential differenceCopper

The invention discloses a metal plating piece which comprises a metal base material, a chemical nickel layer, a semi-finished nickel layer and an acid copper layer. The chemical nickel layer, the semi-finished nickel layer and the acid copper layer are sequentially arranged on the metal base material. The between-layer potential differences of the metal plating piece are high, the corrosion resistance is high, and ultrahigh metal texture is achieved. The invention further discloses a preparation method of the metal plating piece. The preparation method includes the following steps that the metal base material is provided or prepared; the chemical nickel layer is plated on the metal base material; the semi-finished nickel layer is plated on the chemical nickel layer; the acid copper layer is plated on the semi-finished nickel layer; and the metal plating piece of the metal base material / chemical nickel layer / semi-finished nickel layer / acid copper layer structure is obtained. The metal plating piece manufactured according to the preparation method of the metal plating piece is good in metal texture and high in corrosion resistance.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Production process of composite board mobile phone rear cover

InactiveCN111031160ALow costIncrease productivityOther printing apparatusTelephone set constructionsSilver inkOptical coating

The invention discloses a production process of a composite board mobile phone rear cover. The production process comprises the following steps of: preparing a composite board substrate, cutting the composite board substrate to obtain a composite board base material, acquiring pattern printing, optical coating, mirror surface silver ink printing, UV transfer glue printing, first color ink layer printing and second color ink layer printing in a printing step, obtaining a semi-finished product of the composite board mobile phone rear cover in a high-pressure forming step, acquiring a hardened film in a step of spraying a strengthening liquid, pasting a film for protection, and conducting CNC cutting machining to obtain the composite board mobile phone rear cover finished product. The composite board material is used for production and processing; a curved surface effect which cannot be achieved by conventional injection molding is achieved; the problem of unstable binding between UV glueand glass in the prior art is solved; the prepared composite board mobile phone rear cover not only achieves the hardness of the glass, but also has the toughness of plastic, can tolerate stronger impact and is ultrathin, and the production process of the composite board mobile phone rear cover is lower in cost and higher in production efficiency.

Owner:SHENZHEN ATES SCI & TECH CO LTD

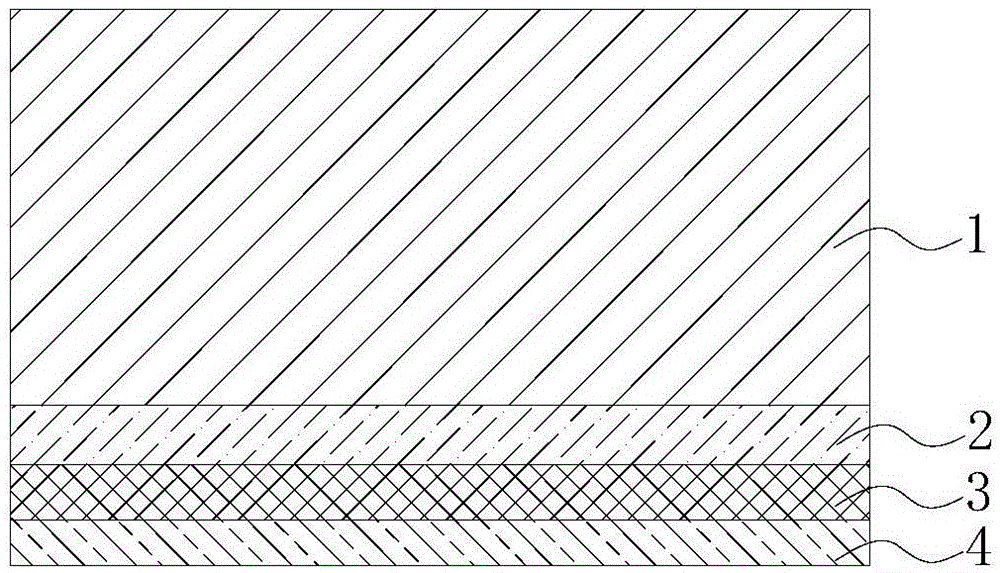

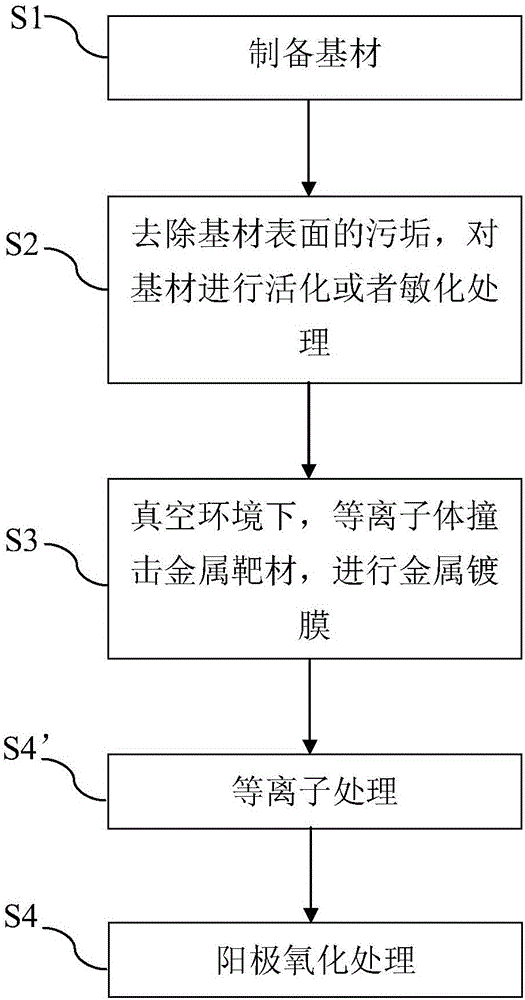

Shell with metal texture, manufacturing method of shell and electronic product

ActiveCN106048517AWith metallic textureGood adhesionAnodisationVacuum evaporation coatingMetallurgyBiological activation

The invention discloses a shell with metal texture, a manufacturing method of the shell and an electronic product. The manufacturing method of the shell with the metal texture includes the following steps that S1, a base material is prepared, wherein the base material is a material capable of being used for surface plating; S2, dirt on the surface of the base material is removed, and activation or sensitization is conducted on the base material; S3, under the vacuum environment, metal steam is generated by striking a metal target material through plasmas, the metal steam is deposited on the surface of the base material in a nanometer layer manner, and a metal coating film is formed on the surface of the base material; and S4, anodic oxidation treatment is conducted on the base material with the metal coating film formed on the surface, and an anodic oxidation film layer is formed on the metal coating film layer of the base material. According to the manufacturing method, the selectivity of the base material is large, and the material cost of products can be effectively reduced; and meanwhile, the technological process is simple, and the manufacturing cost is low.

Owner:GUANGDONG JANUS SMART GRP CO LTD

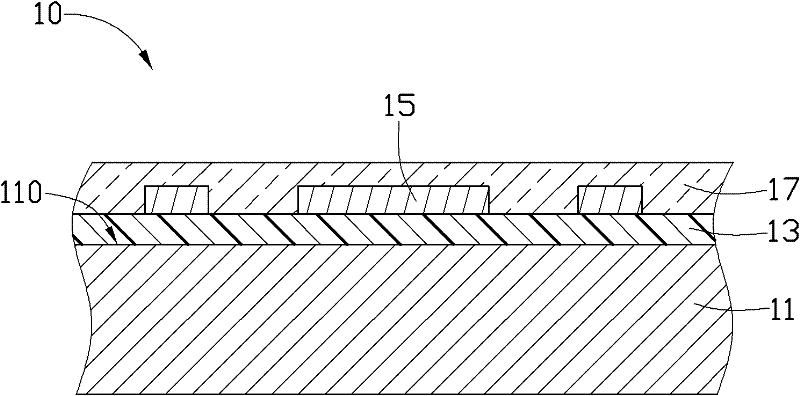

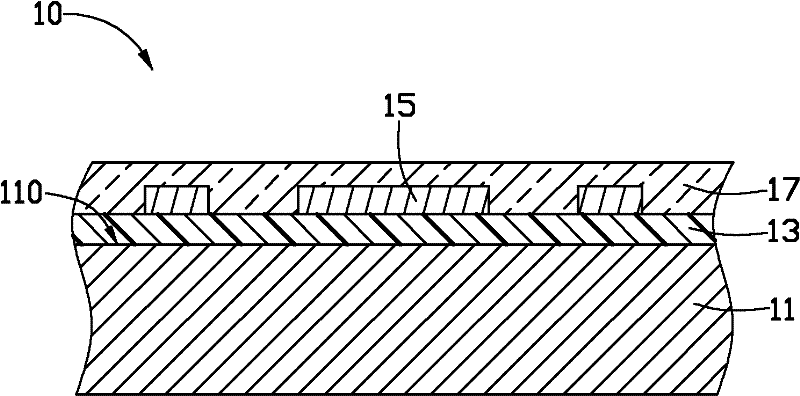

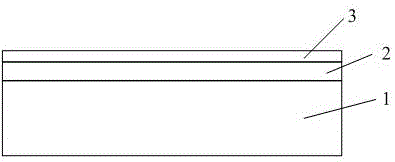

Shell and manufacturing method thereof

InactiveCN102762042AWith metallic textureNatural patternsElectrical apparatus casings/cabinets/drawersMetallurgyVacuum coating

The invention provides a shell comprising a transparent base body, a semi-transparent first vacuum coating layer formed on the outer surface of the base body, a semi-transparent first pattern layer formed on the first vacuum coating layer, a semi-transparent second pattern layer formed on the inner surface of the base body, and a second vacuum coating layer formed on the second pattern layer, wherein the first vacuum coating layer covers a part of the outer surface; the first pattern layer and the first vacuum coating layer are in the same shape and are superposed with the first vacuum coating layer; and the second pattern layer covers a part of the inner surface. The second vacuum coating layer covers the second pattern layer and the part of the inner surface which is uncovered by the second pattern layer. The invention further provides a manufacturing method of the shell.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Plastic cover plate of electronic equipment and manufacturing method thereof

InactiveCN107148187AWith metallic textureImprove textureCasings/cabinets/drawers detailsEngineeringMetal

The invention discloses a plastic cover plate of electronic equipment, which comprises a plastic cover plate body, and is characterized in that the side, which faces outward, of the plastic cover plate body is sequentially provided with a frosted effect layer and a coating layer from the inside out, the structure of the frosted effect layer corresponds to the structure of a surface material of the corresponding simulated metal, and the coating layer corresponds the surface material of the simulated metal in reflectance for light. According to the plastic cover plate, the structure surface of a metal material is simulated through enabling the structure of the frosted effect layer to correspond to the structure of the surface material of the corresponding simulated metal, and the plastic cover plate is enabled to have a corresponding metal color through enabling the coating layer to correspond to the surface material of the simulated metal in reflectance for light, so that the plastic cover plate is enabled to have a metal texture, and the texture of the plastic cover plate is improved. In addition, the invention further discloses a manufacturing method of the plastic cover plate of the electronic equipment.

Owner:TRULY OPTO ELECTRONICS

Machining method for stainless steel mobile phone rear cover

InactiveCN104690504AHigh strengthReduce weightSubstation equipmentAgricultural engineeringUltimate tensile strength

The invention discloses a machining method for a stainless steel mobile phone rear cover, belongs to the field of machining methods for mobile phone parts, and aims to solve the problems of high machining cost, lower strength and the like of the conventional mobile phone rear cover. The machining method at least comprises the step of etching a material strip of the mobile phone rear cover to reduce the weight of the mobile phone rear cover. The step is used for reducing the weight of the mobile phone rear cover and improving the binding force of intra-mold injection, the material strip of the mobile phone rear cover is made of a stainless steel material of 0.4-0.8mm, and the etching depth of the material strip of the mobile phone rear cover is 0.2-0.5mm. According to the machining method, the machining procedure is simple, and the machining cost is lower. The mobile phone rear cover machined according to the method is attractive, elegant and higher in strength.

Owner:AOJIE HARDWARE JIANGSU

Mobile phone rear cover with metal texture and preparation method thereof

ActiveCN106790791AWill not act as a shieldWith metallic textureTelephone set constructionsThermal sprayingTouch Senses

The invention disclose a mobile phone rear cover with a metal texture, which comprises a mobile phone rear cover matrix and a metal compound coating. A mainboard electronic component is arranged in the mobile phone rear cover matrix, and the mobile phone rear cover matrix is prepared from zirconia; the metal compound coating is prepared by the following method of: spraying a metal material on the surface of the mobile phone rear cover matrix by magnetron sputtering, thermal spraying of electric arc heat, supersonic thermal spraying or plasma thermal spraying so as to form a metal thin film; and oxidizing the metal thin film by corrosion treatment so as to form a metal compound, wherein a thickness of the metal compound occupies for 70 to 80% of a thickness of the metal thin film. Correspondingly, the invention further discloses a preparation method of the mobile phone rear cover. By adopting the mobile phone rear cover and the preparation method thereof, which are disclosed by the invention, not only is an effect that appearance of a metal housing has the unique texture and touch sense of metal achieved, but also a thickness of a mobile phone is reduced by one fifth, cost of the mobile phone is reduced by two thirds, and radio transmission efficiency of the mobile phone is improved by over 2 times.

Owner:广东百工新材料科技有限公司

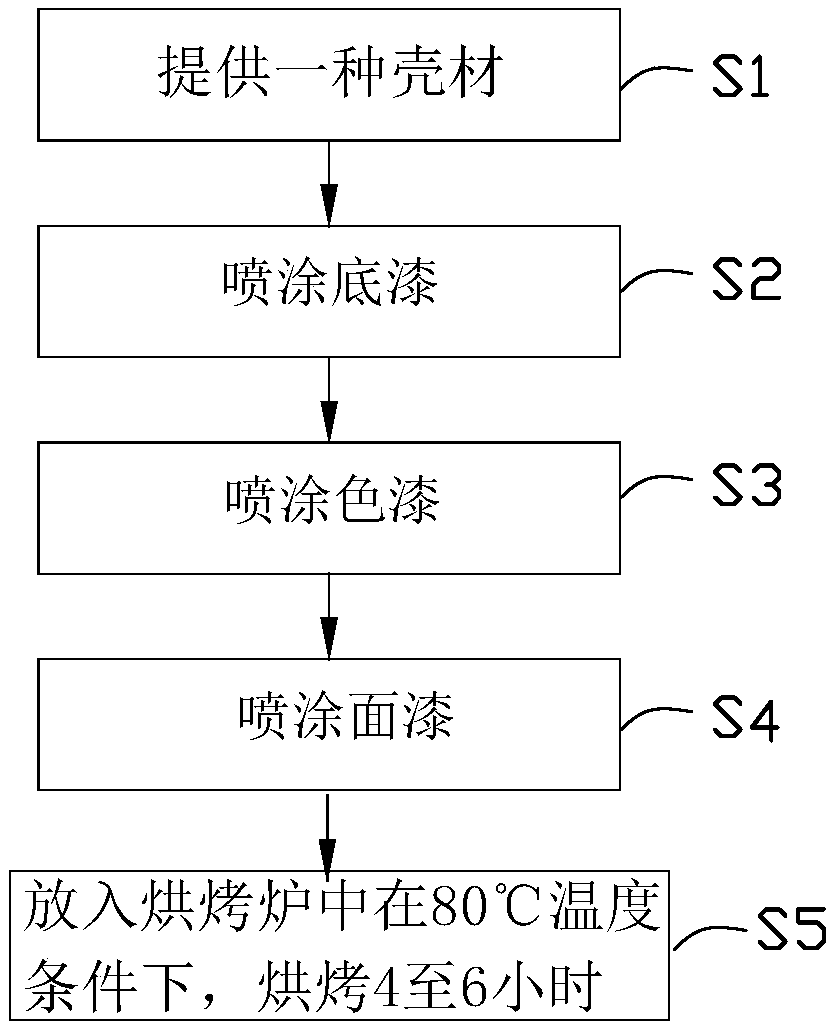

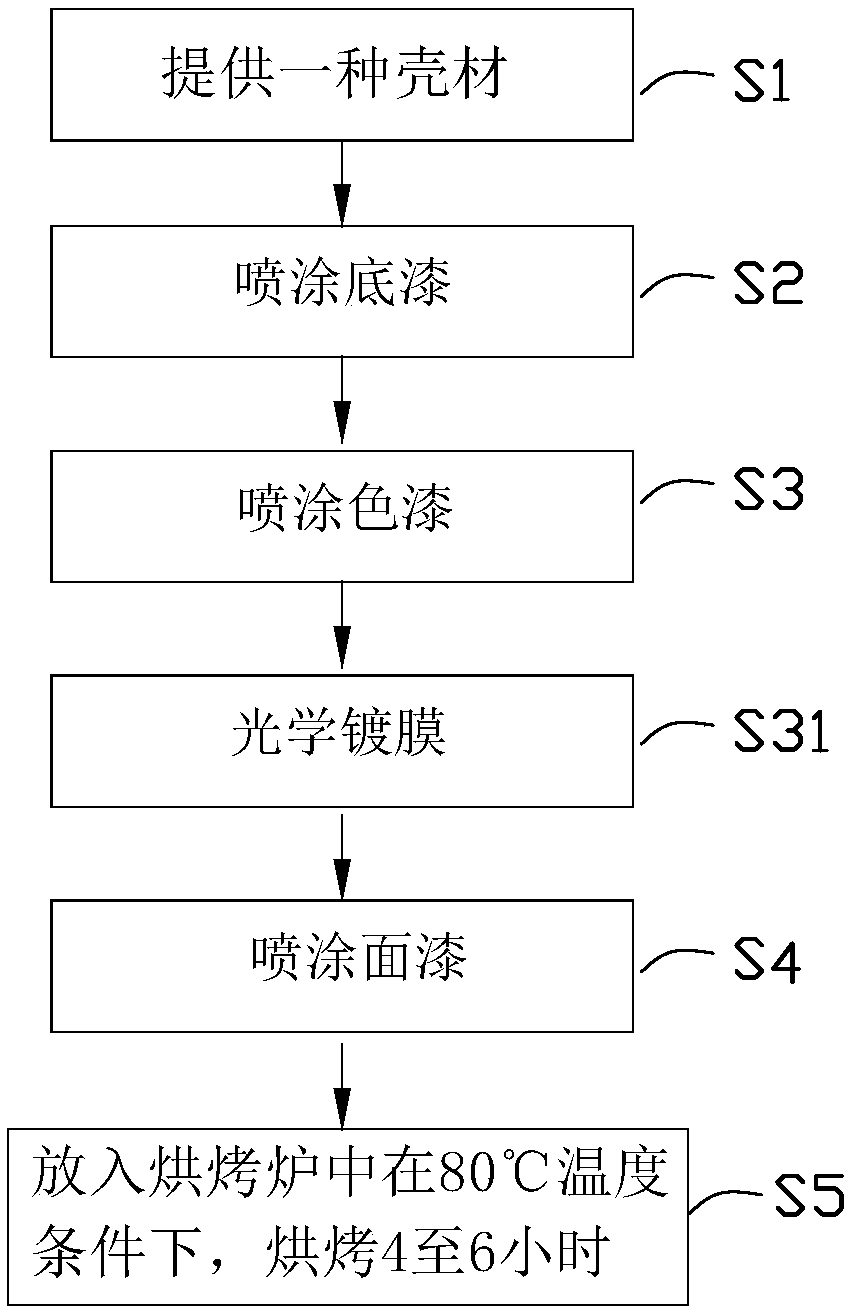

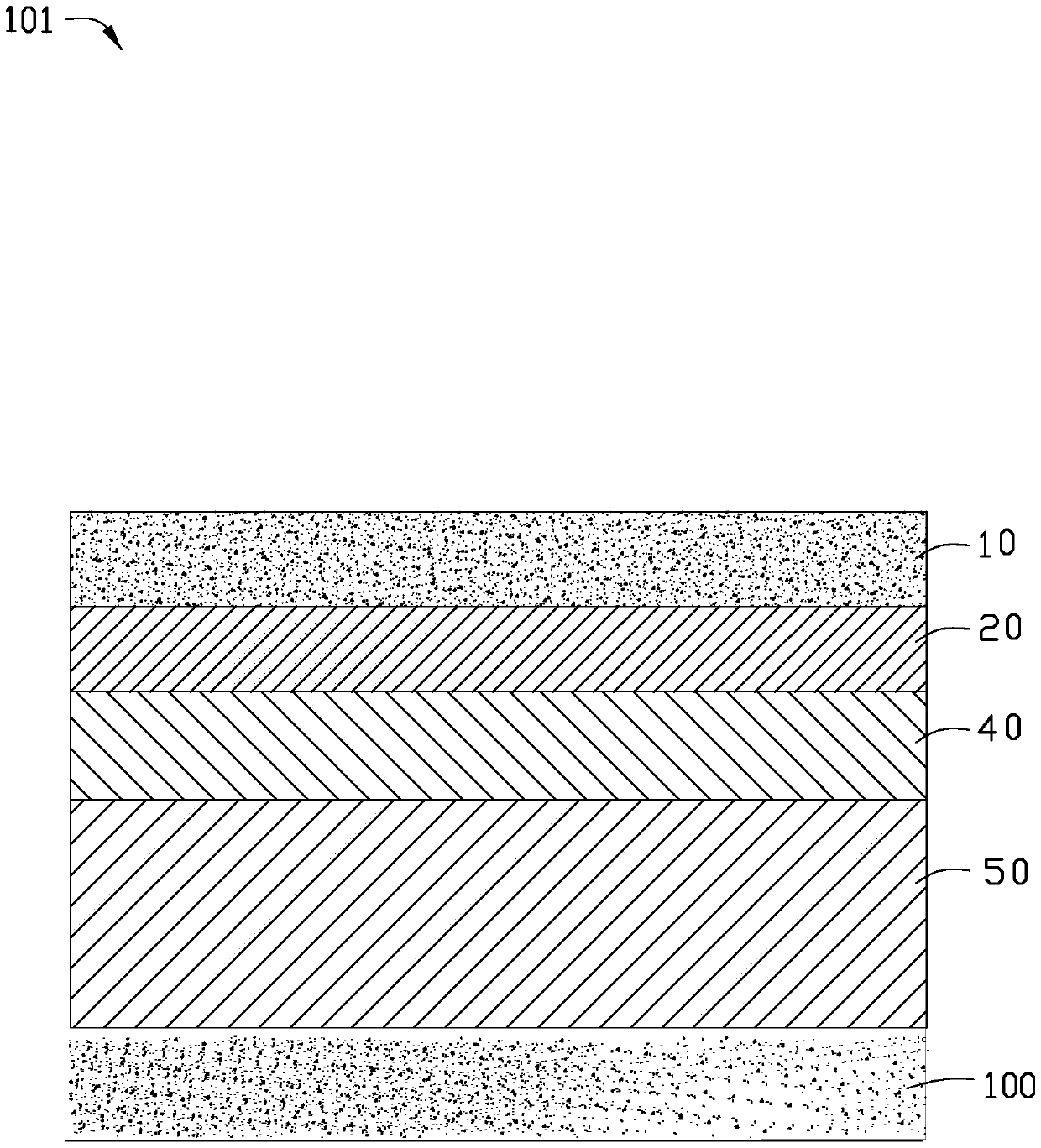

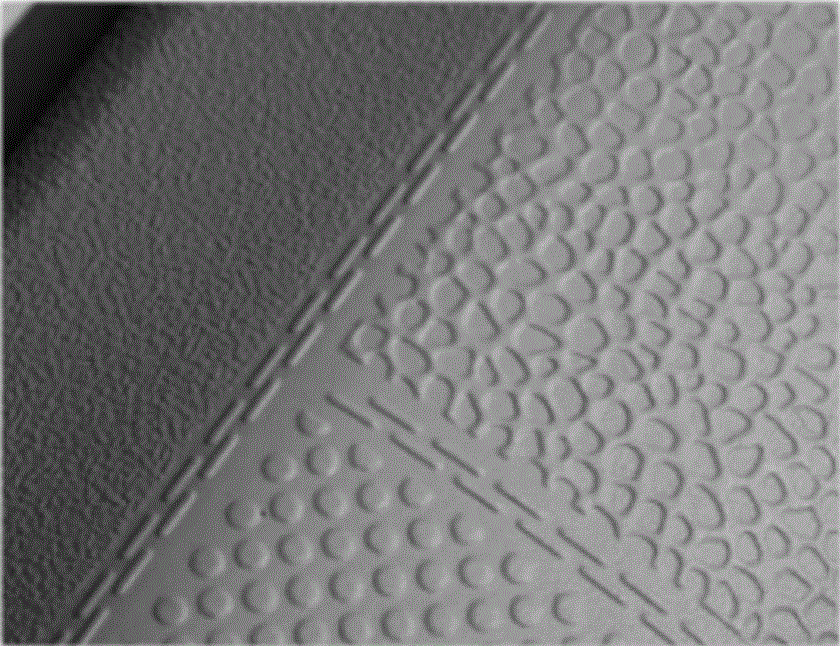

Manufacturing method of shell and shell

InactiveCN111097675AWith metallic textureHigh hardnessSpecial surfacesCoatingsZirconium oxideCeramic materials

The invention provides a manufacturing method of a shell. The manufacturing method comprises the following steps of providing a shell material, and spraying primer on the shell material to form a primer layer; spraying colored paint on the primer layer to form a colored paint layer; and spraying finish paint on the colored paint layer to form a finish paint layer so as to obtain the shell with high glossiness. The shell is made of metal or a complex of metal and plastic; the primer layer and the colored paint layer contain zirconium oxide powder; the mass percentages of the zirconium oxide powder in the primer and the colored paint are 1%-5% and 0.1%-1% correspondingly; and the primer layer, the colored paint layer and the finish paint layer are repeatedly sprayed and cured for at least three times. The invention further provides the shell manufactured according to the method, and the shell has high glossiness and metallic luster.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

3D printing modified polypropylene composition and preparation method thereof

PendingCN110157101AIncreased crystallization temperature and crystallization rateImprove melt strengthAdditive manufacturing apparatusPolypropyleneCrystallization rate

The invention discloses a 3D printing modified polypropylene composition and a preparation method thereof. The 3D printing modified polypropylene composition is prepared from the following componentsby weight: 75-85 parts of polypropylene random copolymer, 0.1-0.3 part of a nucleating agent, 0.3-0.5 part of a hyperdispersant, 15-25 parts of AS resin, 0.5-1.5 parts of aluminum powder, 2-5 parts ofa cross-linking agent and 0.5 part of a heat stabilizer. According to the 3D printing modified polypropylene composition provided by the invention, by adding the nucleating agent and cross-linking agent into the system, the crystallization temperature and crystallization rate of the polypropylene material are enhanced, and the melt strength is improved, so that the material can achieve faster andmore stable shaping. At the same time, the metal powder and compound hyperdispersant system are added into the polypropylene matrix to make the metal powder disperse evenly in the polymer and endow the material with metal texture, thus improving the aesthetics of printed products, and further improving the melt strength of the polypropylene composition at the same time.

Owner:HEFEI GENIUS NEW MATERIALS

Preparation method of metal feeling low-luster automotive interior material

PendingCN106380616AThermoplasticSolve the disadvantages of plastic feelingPolyurea/polyurethane coatingsPaints with free metalsQuality levelPolyurethane coating

The invention discloses a preparation method of a metal feeling low-luster automotive interior material. The preparation method comprises 1, film material preparation: S101, uniformly mixing polypropylene, rubber, a solubiliser, an inorganic filler and color master batches, putting the uniform mixture into a double-roller open mill, carrying out open milling and preparing a film material with the thickness of 1-10mm and S102, carrying out corona treatment on the film material obtained by the step S101 so that surface polarity of the film subjected to corona treatment is improved, 2, preparing an aqueous polyurethane coating material and 3, coating the surface of the film material with a uniform polyurethane coating and carrying out drying to obtain the metal feeling low-luster automotive interior material. The preparation method solves the problem of plastic feeling of the existing injection molding plastic, is free of a later paint spraying process and satisfies requirements of low VOC, scratch resistance, low luster and high quality level provided by the automobile manufacturer on automotive interiors.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

Metal and PA-12 composite material for 3D printing and preparation method of metal and PA-12 composite material

InactiveCN105670278AImprove mechanical propertiesLow shrinkageAdditive manufacturing apparatusFlexural strengthCopper

The invention belongs to the technical field of 3D printing and particularly relates to a metal and PA-12 composite material for 3D printing and a preparation method of the metal and PA-12 composite material. The metal and PA-12 composite material for 3D printing is prepared from raw materials in parts by weight as follows: 250-330 parts of copper powder, 670-750 parts of PA-12 nylon material, 2-5 parts of a coupling agent, 5-15 parts of a dispersing agent, 5-10 parts of a lubricant and 18-25 parts of a flexibilizer. Printed articles have metallic texture through improvement of the PA-12 nylon material, meanwhile, the mechanical properties of the material is improved effectively, the tensile strength and the bending strength of the printed articles are improved, and warpage produced during printing is reduced.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

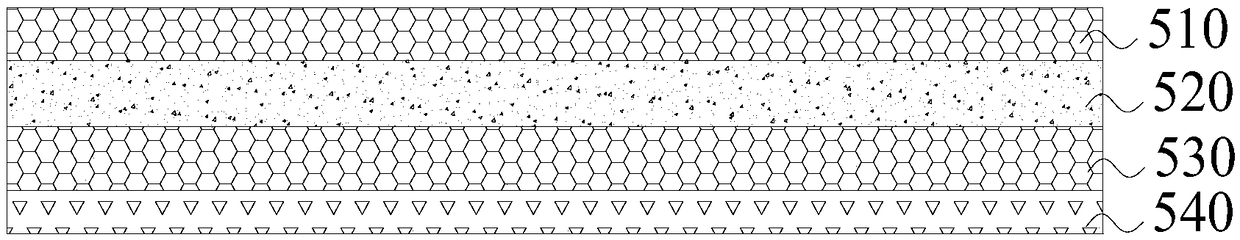

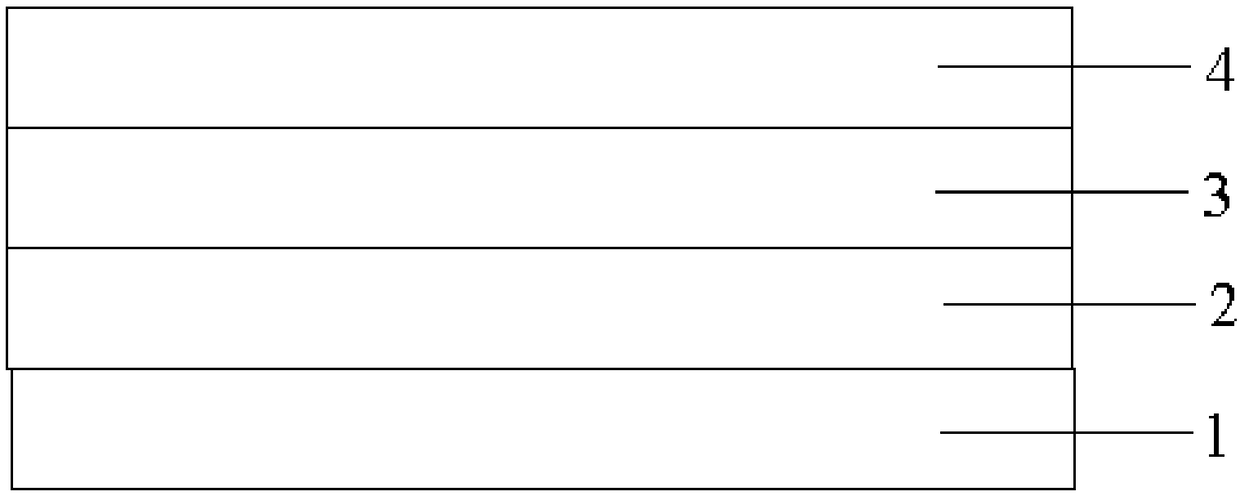

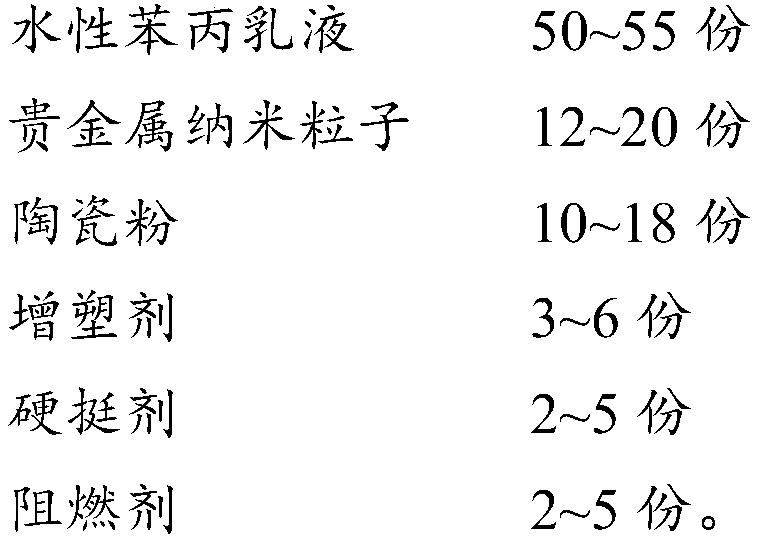

Functional layer coating for projection screen, projection screen and manufacturing method of projection screen

The invention discloses a functional layer coating for a projection screen. The coating is prepared from the following components in parts by weight: 50-55 parts of aqueous styrene-acrylic emulsion, 12-20 parts of noble metal nanoparticles, 10-18 parts of ceramic powder, 3-6 parts of a plasticizer and 2-5 parts of a stiffening agent. The projection screen comprises a base layer as well as a glassfiber layer, a protective layer and a functional layer which are arranged on one side of the base layer sequentially. The projection screen has high optical efficiency, high screen brightness, 1.04 brightness gain and wide viewing angle range. Besides, the projection screen is provided with the protective layer for blocking water vapor, and can be prevented from damage caused by moisture.

Owner:张家港宝视特影视器材有限公司

Trademark label and manufacturing method thereof

The invention relates to a trademark label and a manufacturing method thereof. The trademark label comprises a processing fabric, an upper part label template, a lower part trademark template, a metal film, a sealing sleeve fabric and a through hole, wherein a plurality of penetrating holes with sizes corresponding to the shape of trademarks are formed in positions corresponding to the trademarks on the processing fabric; the upper part of the processing fabric is provided with the upper part trademark template corresponding to the through hole; the lower part of the processing fabric is provided with the lower part trademark template corresponding to the through holes; a layer of metal film with the same size and form with the upper part trademark plate is compounded on the upper part trademark template; a layer of sealing cover fabric is pasted on the lower part trademark template. The manufacturing method of the trademark label comprises the following steps that an injection molding mold is processed; meanwhile, the fabrics are processed; shaping processing is performed; injection molding is started; the metal film is pasted. The trademark label and the manufacturing method provided by the invention have the advantages that the technical problem of difficulty in the technical level in aspects of cutting, grinding, polishing and the like of metal materials and the like in the prior art can be solved; in addition, when the products are installed, the trademarks are softer and lighter; the use and the installation are more convenient; the trademark label has good metal texture; the trade mark label is made of flexible and easy-to-bend materials, so that the installation is proper.

Owner:尹银爱

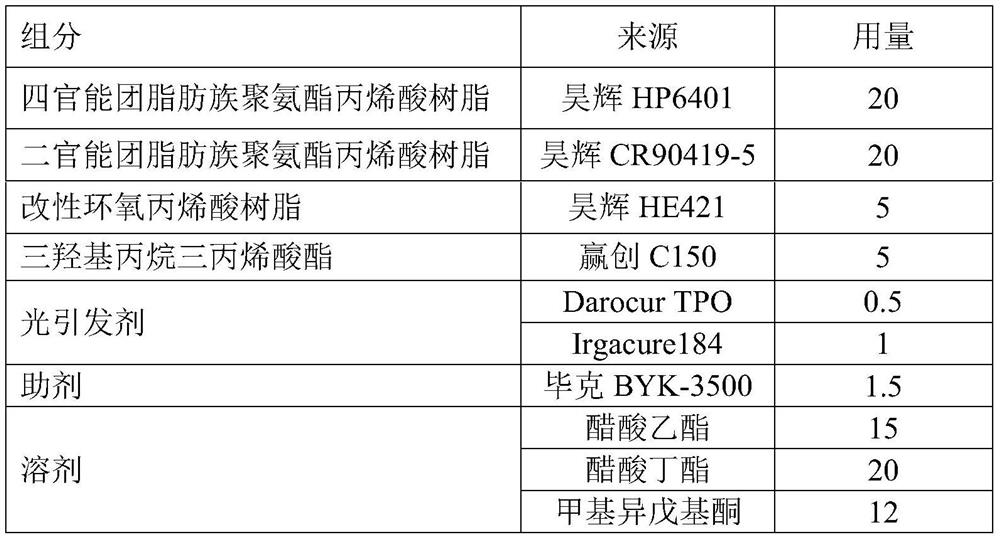

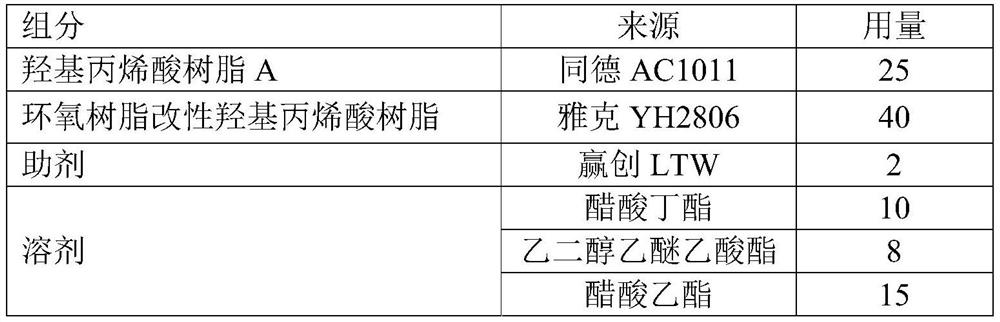

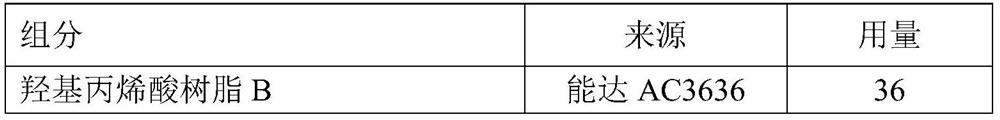

Vacuum coating layer and coating method thereof

InactiveCN113845834AWith metallic textureImprove the level ofFireproof paintsVacuum evaporation coatingMetal coatingPolymer science

The invention relates to the technical field of paint, in particular to a vacuum coating layer and a coating method thereof. The vacuum coating layer comprises a primer layer, a metal coating layer, a middle paint layer and a finish paint layer which are sequentially stacked, the middle paint layer is made of hydroxyl acrylic resin with a low hydroxyl value; the finish paint layer is made of acrylic resin with a high hydroxyl value; the hydroxyl value of the acrylic resin with the low hydroxyl value is not higher than 3wt%, and the hydroxyl value of the acrylic resin with the high hydroxyl value is not lower than 3.5 wt%. Through interaction of the primer layer, the metal coating layer, the middle paint layer and the finish paint layer, the coating layer which is good in hardness, wear-resistant, weather-resistant and excellent in high-temperature and high-humidity resistance and has metal texture is prepared. Wherein the middle paint layer serves as an adhesion promoting layer, the adhesion between the middle paint layer and the metal coating layer is excellent, it can be guaranteed that the finish paint layer can be stably attached to the metal coating layer , and nano color paste can be added to make the coating layer achieve the metal texture and have the colorful effect at the same time.

Owner:HUIZHOU FEIKAI NEW MATERIAL CO LTD

Aqueous metal paints preparation and paints therefrom

InactiveCN1439681AGood weather resistanceImprove stain resistanceEmulsion paintsNano sio2Carboxylate

A process for preparing metallic water paint includes such steps as proportionally mixing deionized water, acrylate, potassium salt of acrylic copolymer, hydroxyethyl carboxylate cellulose, nano SiO2, metallic water flashing powder, organic silica oil, ZH-10 and anti-mildew bactericiding agent, stirring, proportionally adding BCS, propanediol, thicking agent, alkoxide 12 and pH regulator, and stirring. Its advantages are rich colors, strong metallic feeling, high weatherability, durability and resistance to pollution and brush, and no environmental pollution.

Owner:TUYIDE COATING MFG GUANGZHOU CITY

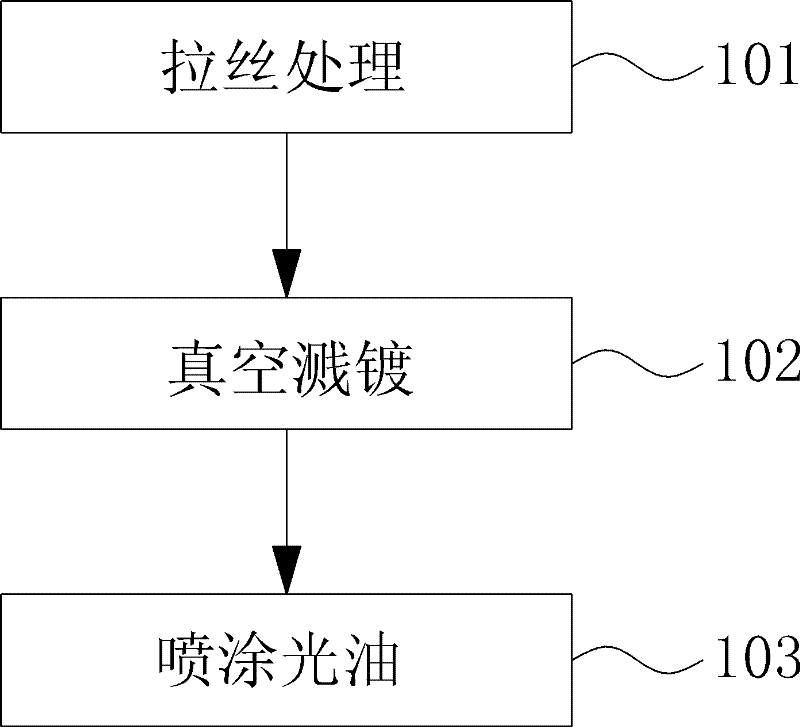

Surface treatment method for magnesium alloy

InactiveCN102650038AWith metallic textureVacuum evaporation coatingSputtering coatingSputteringMetal

The invention provides a surface treatment method for a magnesium alloy. The surface treatment method is characterized by comprising the steps as follows: (1) drawing treatment: a drawing treatment is carried out for the surface of a magnesium alloy piece; (2) vacuum sputtering: a layer of metallic film is coated on the surface of the magnesium alloy piece in a vacuum sputtering manner; and (3) gloss oil spraying: a gloss oil is sprayed on the metallic film on the magnesium alloy piece. Compared with the prior art, the surface treatment method for the magnesium alloy, which is provided by the invention, adopts a technique integrating the drawing treatment, the vacuum sputtering and the gloss oil spraying, thus the surface of the treated magnesium alloy is provided with metallic tactile sensation and can meet demands.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Electronic communication device with metal shell and processing method of metal shell

InactiveCN105744015AWith metallic textureDoes not affect antenna performanceTelephone set constructionsElectronic communicationElectroplating

The invention discloses an electronic communication device with a metal shell and a processing method of the metal shell. The objective of the invention is to make the surface of an electronic communication device has an overall metal texture under the premise that antenna performance is not affected. The electronic communication device comprises the metal shell and a first non-conductive layer; the metal shell includes an insulation separation portion and a plurality of metal portions which are separated by the insulation separation portion; the first non-conductive layer is arranged at the outer surface of the insulation separation portion; and the first non-conductive layer includes an non-conductive layer which is formed by performing electrical conductivity-removing treatment on a first metal layer which is plated on the outer surface of the insulation separation portion. With the above technical schemes of the invention adopted, the surface of the electronic communication device has an overall metal texture under the premise that antenna performance is not affected.

Owner:XIAOMI INC

PVC composite material based on self-drying water-based aluminum powder coating as well as preparation method and application thereof

ActiveCN112064367AHigh transparencyImprove water resistanceProjectorsTextiles and paperWeather resistanceAluminium powder

The invention discloses a PVC composite material based on a self-drying water-based aluminum powder coating as well as a preparation method and application thereof. The PVC composite material comprises a PVC material and the self-drying water-based aluminum powder coating, and the coating comprises the following components in percentage by mass: 50-60% of water-based resin, 20-25% of water-based aluminum powder and 5-15% of a water-based additive. The water-based coating is used for replacing oil-based coating, water is used as a solvent, the cost is reduced, safety and environmental protection are achieved, and environmental protection and physical health of constructors are greatly reduced; and a dry film has good transparency, water resistance, weather resistance and yellowing resistance, the coating can be cleaned with water or a cleaning agent after being used for a long time, the corrosion of water to the dry film is avoided, and the influence of humidity in air on the weather resistance and yellowing resistance of the dry film is also avoided.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

Method of manufacturing construction abrasion-resistance coating with metal as filling

The invention discloses a making method of architectural abrasion-proof paint based on metal as fill, which comprises the following steps: (1) blending phenoxypropyl emulsion, copper powder and silver powder with weight rate at 1:0.3:0.05-0.1; (2) adding fitful adjuvant in the mixture of step (1); stirring evenly to obtain the product.

Owner:SHENYANG JIANZHU UNIVERSITY

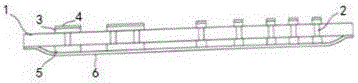

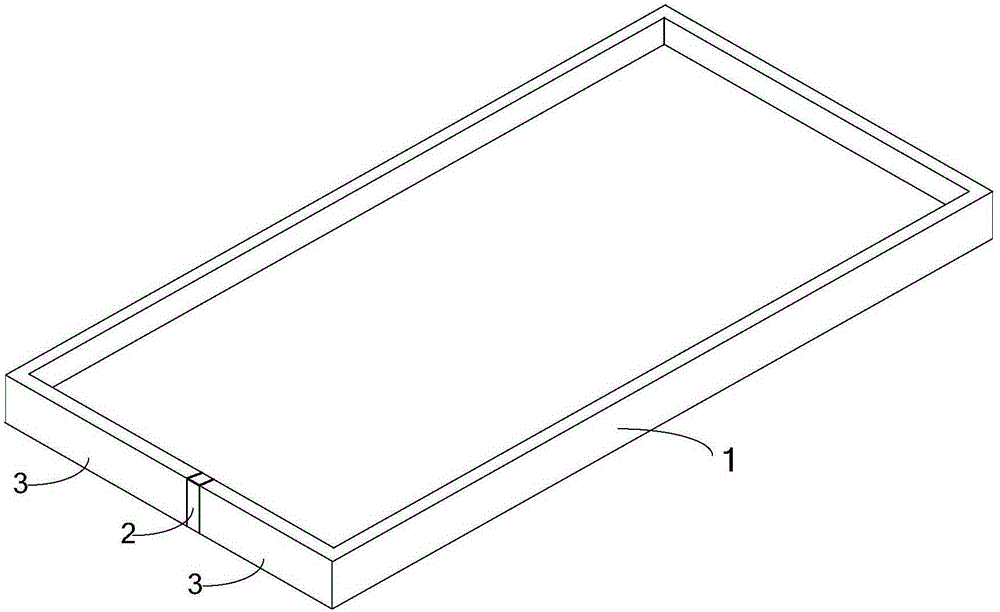

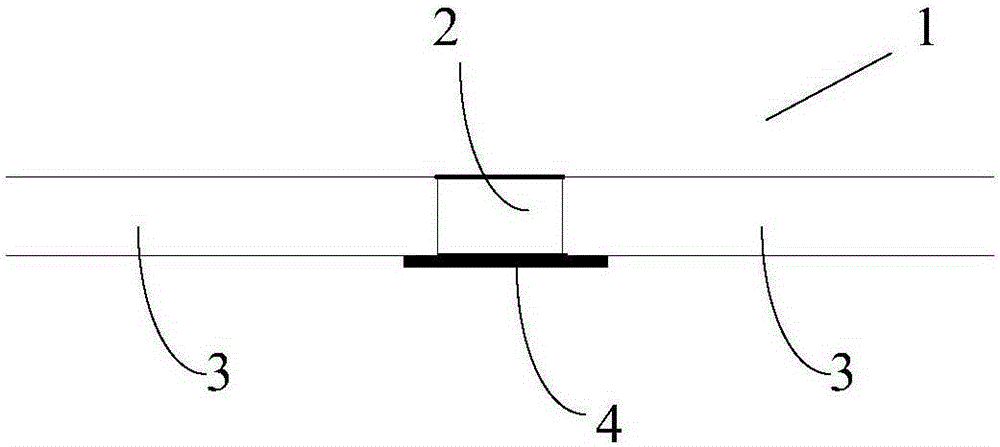

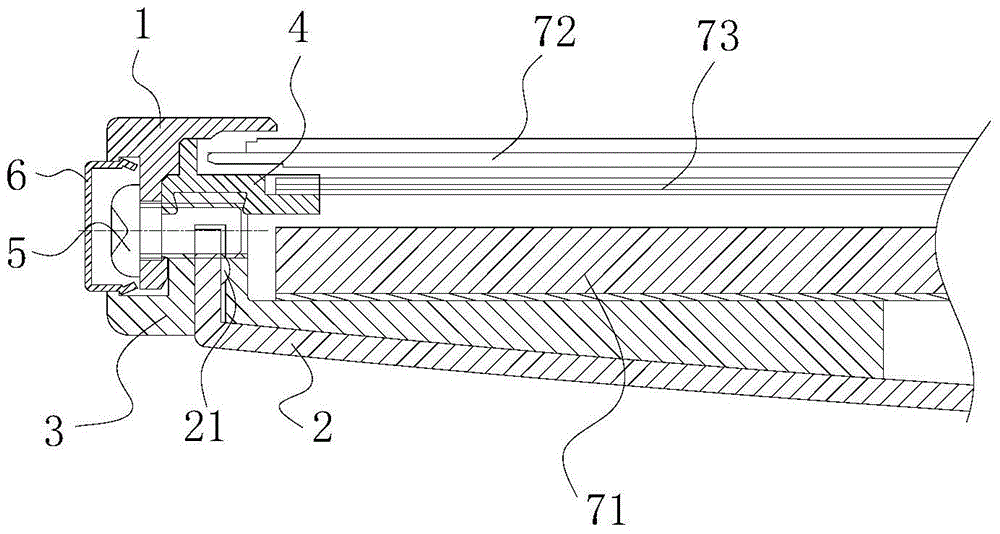

Display device

InactiveCN104575274AEasy to assembleHigh strengthCasings/cabinets/drawers detailsIdentification meansDisplay deviceEngineering

The invention discloses a display device, which comprises a front frame, a metal rear cover, a display module, a structure-reinforcing plate, a middle frame and a locking part, the structure-reinforcing plate is matched with the metal rear cover and used for enhancing the strength of the metal rear cover, the middle frame is matched with the structure-reinforcing plate and the front frame, and the locking part is used for connecting the front frame, the middle frame and the structure-reinforcing plate together; the display module comprises a backlight module, a display screen and a diaphragm, the backlight module is arranged between the structure-reinforcing plate and the middle frame, and the display screen and the diaphragm are arranged sequentially from the top down between the front frame and the middle frame. The strength of the metal rear cover and the whole display device is enhanced by the arrangement of the structure-reinforcing plate, the structure-reinforcing plate and the metal rear cover are connected together by the arrangement of the front frame and the middle frame, so that the whole display device is convenient to assemble, the locking of the locking part ensures that the whole assembled display device is stable and reliable, and the display device is structurally simple, is convenient to assemble, and is metallic.

Owner:AOJIE HARDWARE JIANGSU

UV raindrop glass production process

InactiveCN106976345ASolve the defect of poor decorative artStrong Art Deco EffectSpecial ornamental structuresBase oilElectroplating

The invention relates to an UV raindrop glass production process. The shortcoming of poor decorative artistry of lines formed on a glass surface or sanding decoration in the exiting glass decoration is overcome. The production process comprises the steps of firstly printing and curing UV concentrated oil on the glass surface to form raindrop base oil; secondly, printing and curing UV raindrop gloss oil on the raindrop base oil surface. The UV raindrop gloss oil is printed on the cured UV concentrated oil surface to form a raindrop shape after being cured, with high artistic decoration effect; an electroplating process is combined while printing the UV raindrop gloss oil, so that the raindrop has metal texture, and transparent raindrops become "metallic particles"; the artistic effect is better.

Owner:YIWU HUAHONG CULTURE CREATIVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com