Manufacturing method of shell and shell

A manufacturing method and a technology for a shell, which are applied to devices that apply liquid to surfaces, special surfaces, coatings, etc., can solve problems such as poor wear resistance of paint layers, and achieve the effect of increasing hardness and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

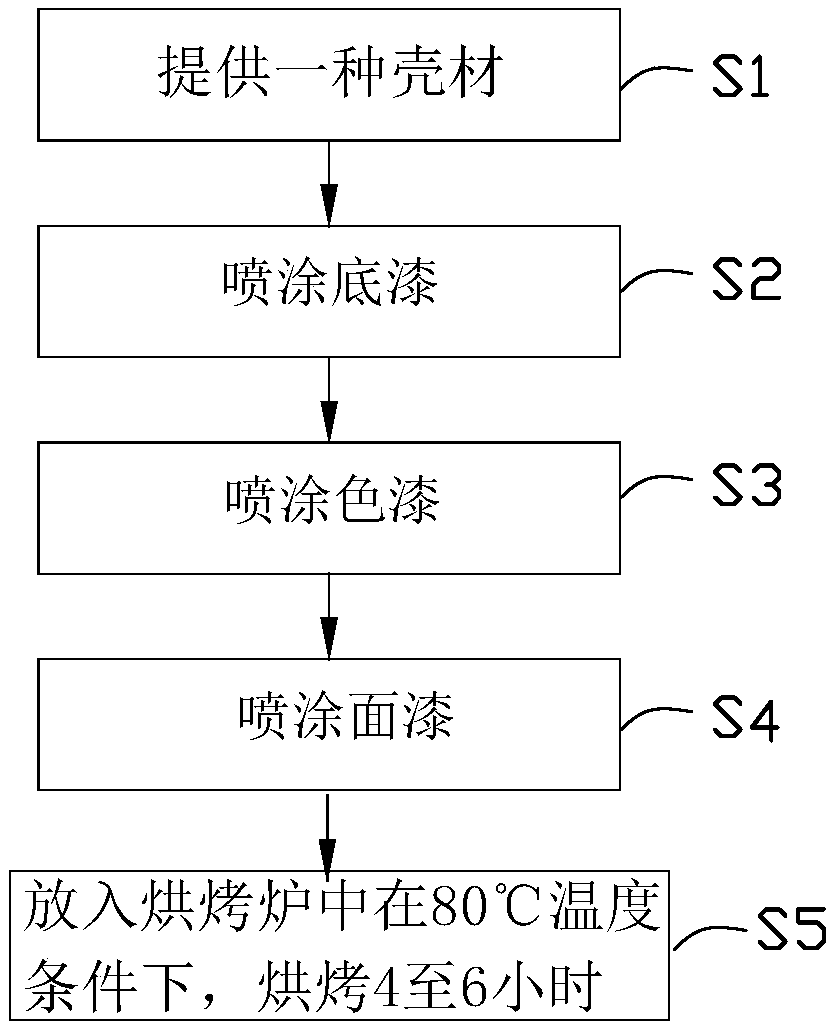

[0025] See figure 1 , figure 1 It is a manufacturing method of a shell provided by the first embodiment of the present invention, wherein the shell can be applied to any electronic device with a shell, such as a mobile phone, a computer, a tablet computer, a notebook computer, a personal digital assistant, a mobile Internet device Or wearable devices, etc. The manufacturing method of the shell includes:

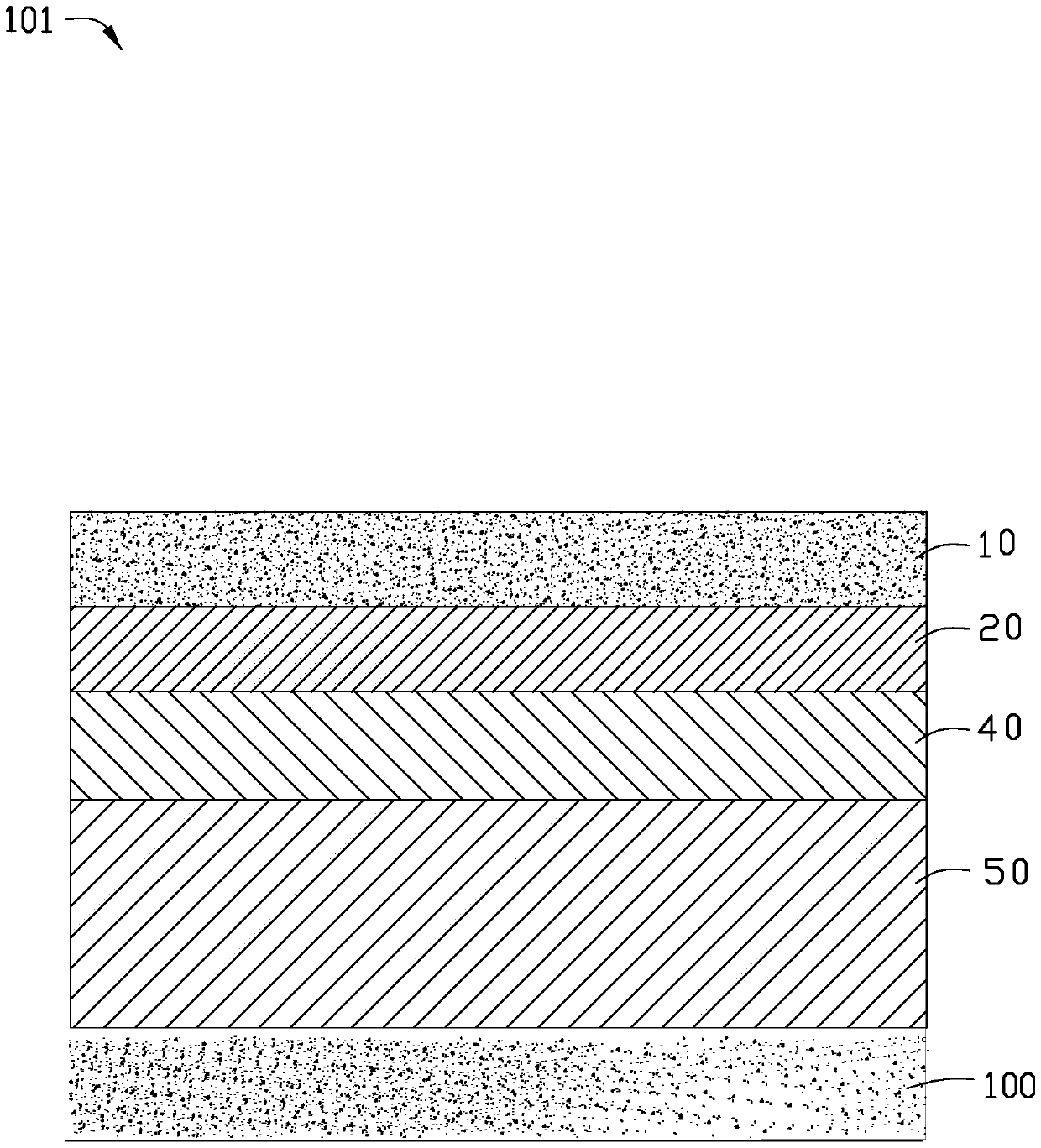

[0026] S1: Please refer to image 3 , provide a shell material 100, the shell material 100 can be made of alloy (such as aluminum alloy).

[0027] Preferably, the shell material 100 can also be pre-treated. Taking the shell material 100 as an example made of aluminum alloy, the pre-treatment steps of the shell material include:

[0028] S10: Cutting the aluminum alloy to the required size, and then processing the inner cavity and the positioning column on the aluminum alloy to obtain a shell material intermediate.

[0029] S11: slotting the shell material intermediate to...

no. 2 example

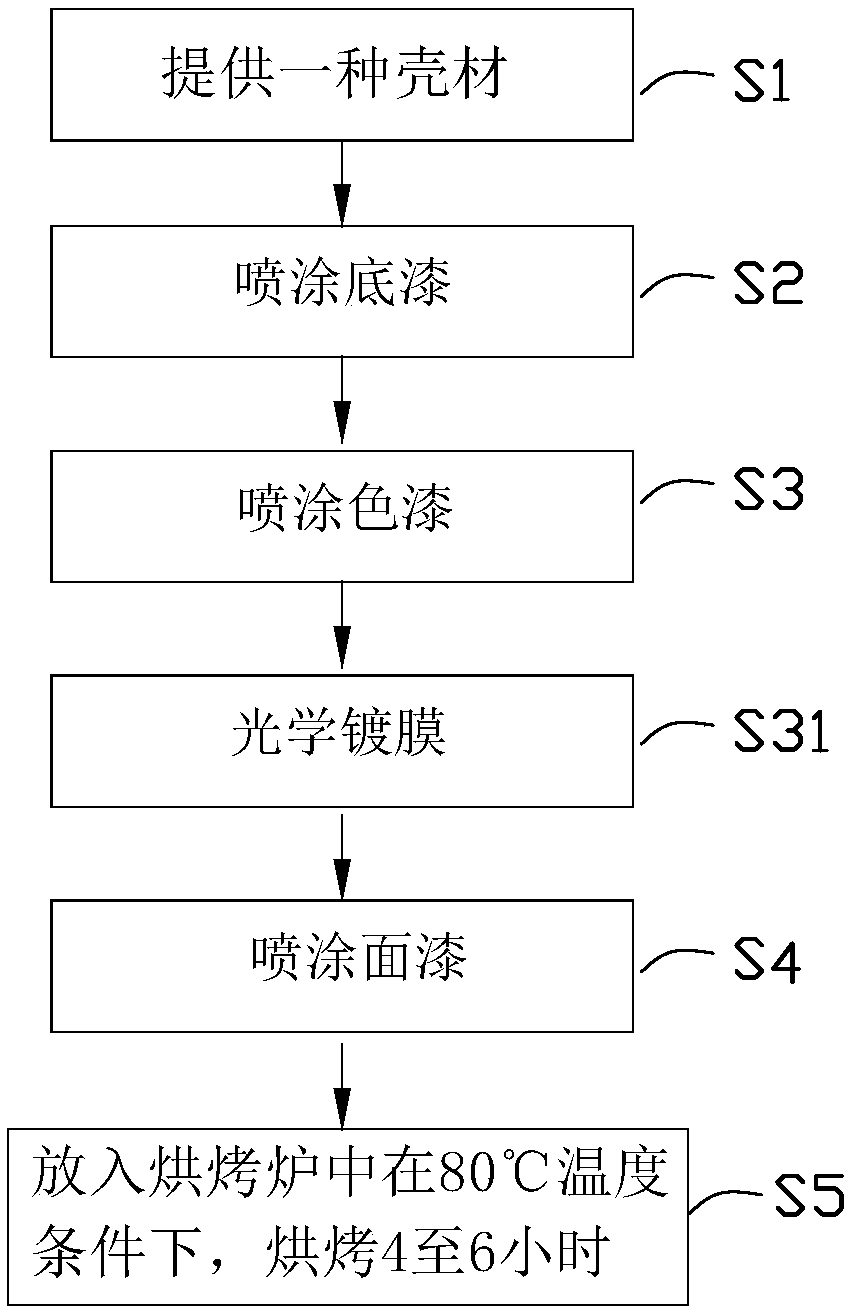

[0046] Please refer to figure 2 , figure 2 It is a method of manufacturing a casing provided by the second embodiment of the present invention. The difference from the first embodiment is that between steps S3 and S4:

[0047] S31: In the optical coating machine, alternately coat 3-6 layers of different coating materials on the color paint layer 40 according to the preset reflectance and transmittance, thereby forming an optical coating layer 30 . The optical coating layer 30 is used to increase the metallic luster of the shell material 100 . The material of the optical coating layer 30 is any one of titanium dioxide and silicon dioxide. The thickness of each layer of the optical coating layer 30 is 20-30 μm.

[0048] Preferably, in order to enhance the bonding force between the optical coating layer 30 and the color paint layer 40, a coating primer layer 60 can also be sprayed between the optical coating layer 30 and the color paint layer 40 Similarly, in order to enhan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com