Vacuum coating layer and coating method thereof

A vacuum coating and coating technology, which is applied in the field of coatings, can solve problems such as difficulty in satisfying hardness and wear resistance, affect UV curing effect, and affect photoinitiator absorption, etc., to achieve excellent adhesion, excellent weather resistance, and good hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the sample in following examples 1~5 is as follows:

[0049] (1) Preparation of primer: Add aliphatic urethane acrylic resin, urethane modified epoxy acrylate and trimethylolpropane triacrylate in turn to the container, add 1 / 3 of the solvent in the formula, and turn it at about 700 rpm Disperse fully and evenly at a speed of 1 / min; then add surface wetting agent, and then continue to disperse at about 700 rpm; dissolve the photoinitiator with 1 / 3 of the organic solvent, and add the dissolved mixture to the container to disperse together , then disperse evenly at about 1000 rpm, continue to disperse for about 25 minutes, then add the remaining solvent to adjust the viscosity (8.5-12s, Iwata No. 2 cup, 25°C) to obtain an ultraviolet (UV) primer, use Filter with 400 mesh filter cloth and pack.

[0050] (2) Preparation of intermediate paint (the first main agent): put hydroxyacrylate A and epoxy resin modified hydroxyacrylic resin into the contai...

Embodiment 1

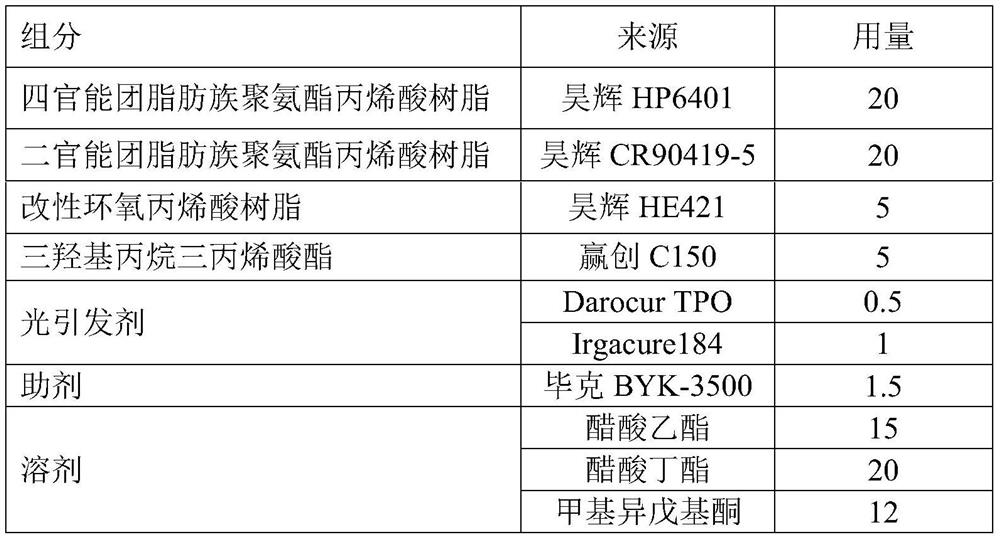

[0059] Table 1 primer raw material:

[0060]

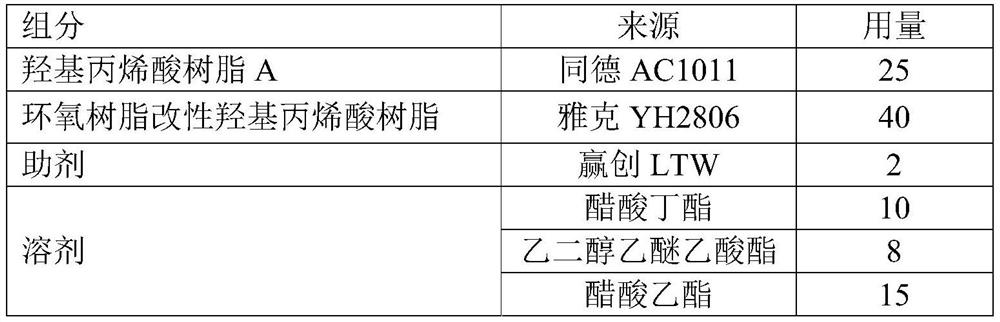

[0061] Paint in Table 2 (the first main agent)

[0062]

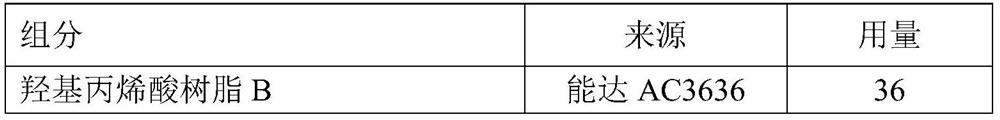

[0063] Table 3 Topcoat (second main agent)

[0064]

[0065]

Embodiment 2

[0067] Table 4 primer raw materials:

[0068]

[0069] Paint in Table 5 (the first main agent)

[0070]

[0071] Table 6 Topcoat (second main agent)

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com