Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Good metal texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

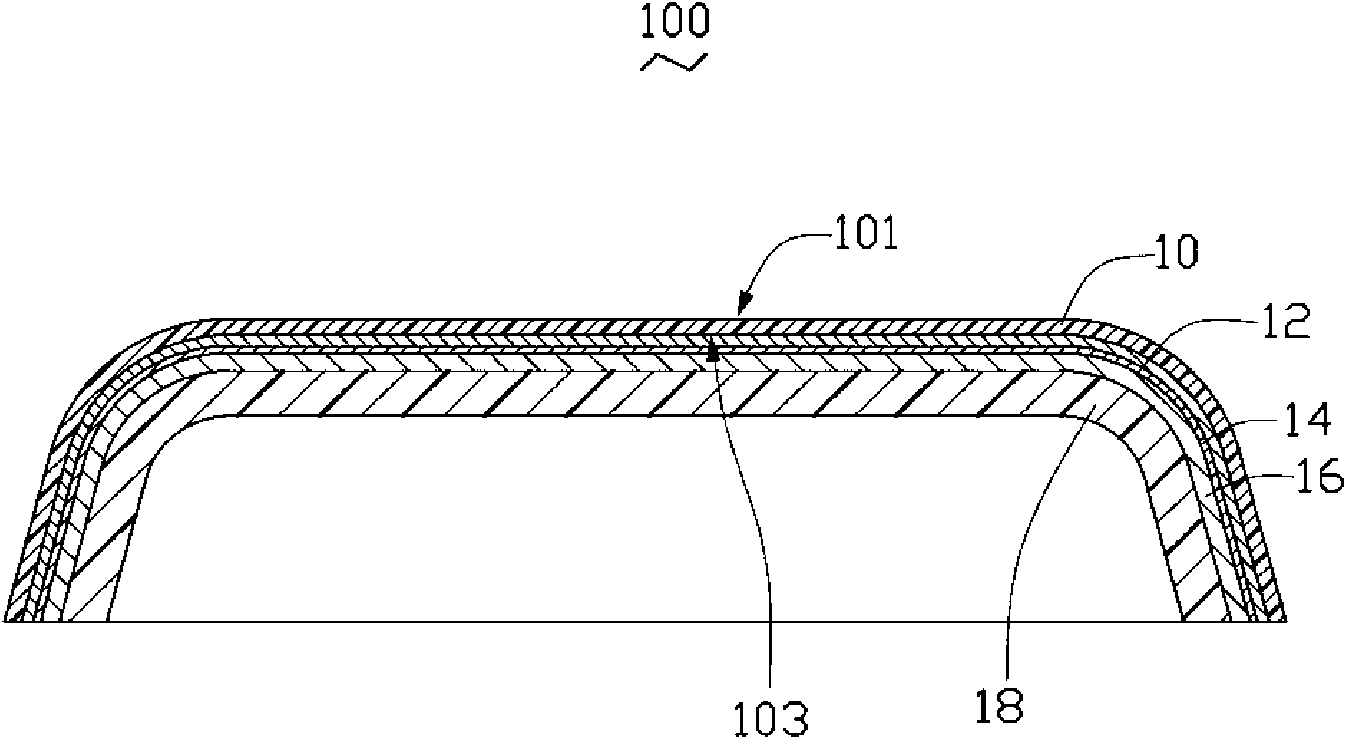

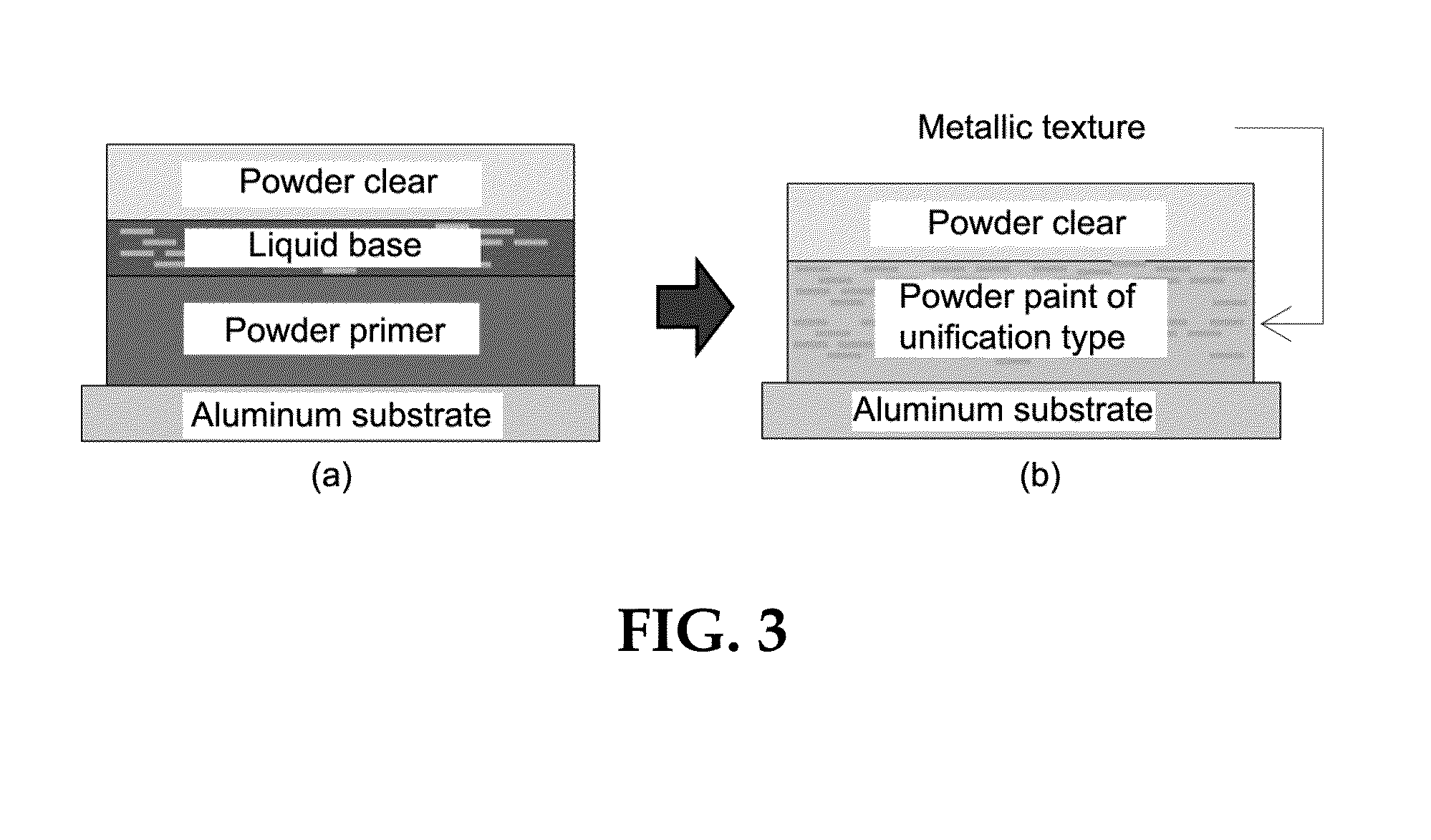

Manufacturing method of casing and casing manufactured therefrom

InactiveCN101554823AGood metal textureEasy to useDecorative surface effectsSynthetic resin layered productsOptoelectronicsCoating

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Free-spraying polyamide resin with metal effect, and preparation method thereof

The invention provides a free-spraying polyamide resin with metal effect, and a preparation method thereof. The free-spraying polyamide resin comprises, by mass, 70 to 95 parts of polyamide, 10 to 30 parts of a metal color pigment, 0.1 to 2 parts of a coupling agent, 0.1 to 0.2 part of zinc stearate, and 2 to 8 parts of a lubricating agent. The preparation method comprises following steps: the raw materials are mixed, are delivered into an extruder for melt blending and extrusion, and then cooing, drying, and cutting are carried out so as to obtain the free-spraying polyamide resin with metal effect. According to the preparation method, the metal color pigment is added into polyamide, and accessory ingredients such as the coupling agent and zinc stearate are added, so that the compatibility and dispersity of polymer matrix with the metal color pigment are improved, spraying effect of metal effect of the obtained product is achieved after injection moulding, increasing of production cost and ecological environment pollution caused by spraying are avoided, defects of injection molding products, such as flow lines and weld bond, are reduced, cost is reduced, and application prospect is promising.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

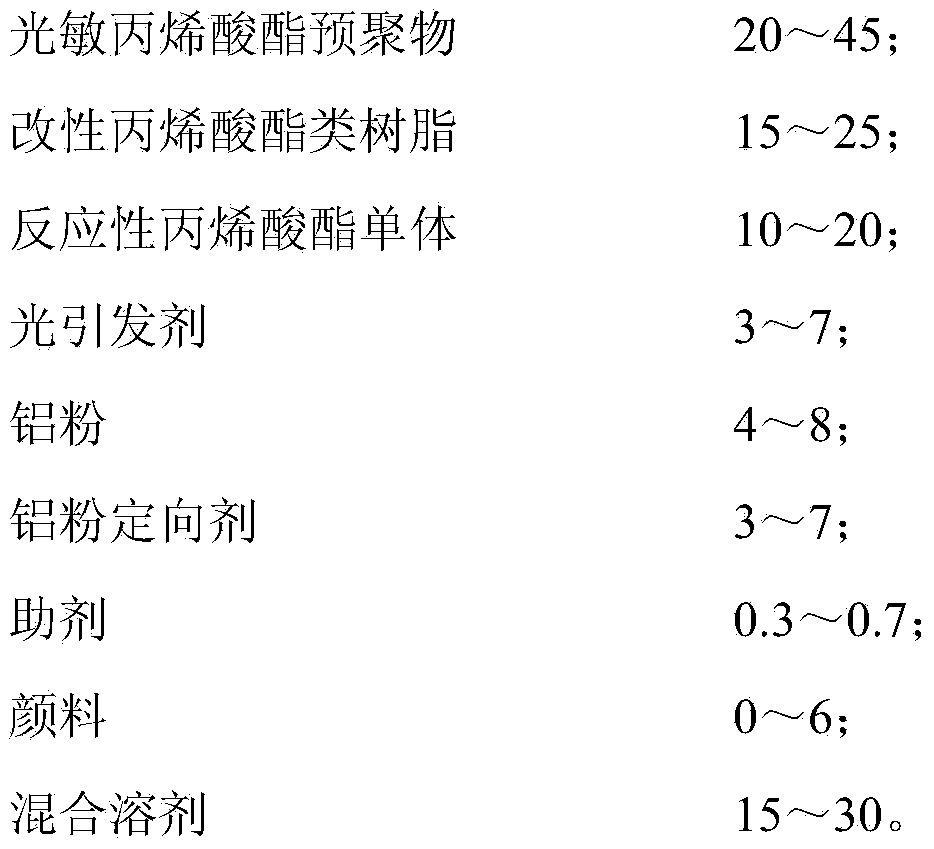

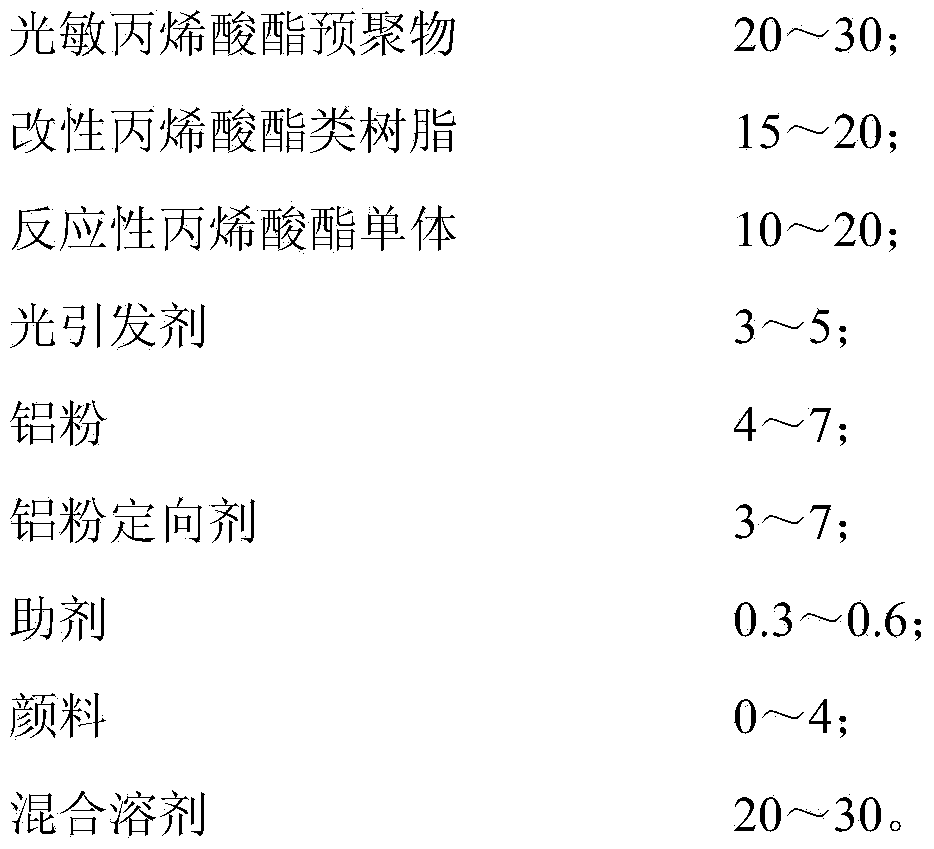

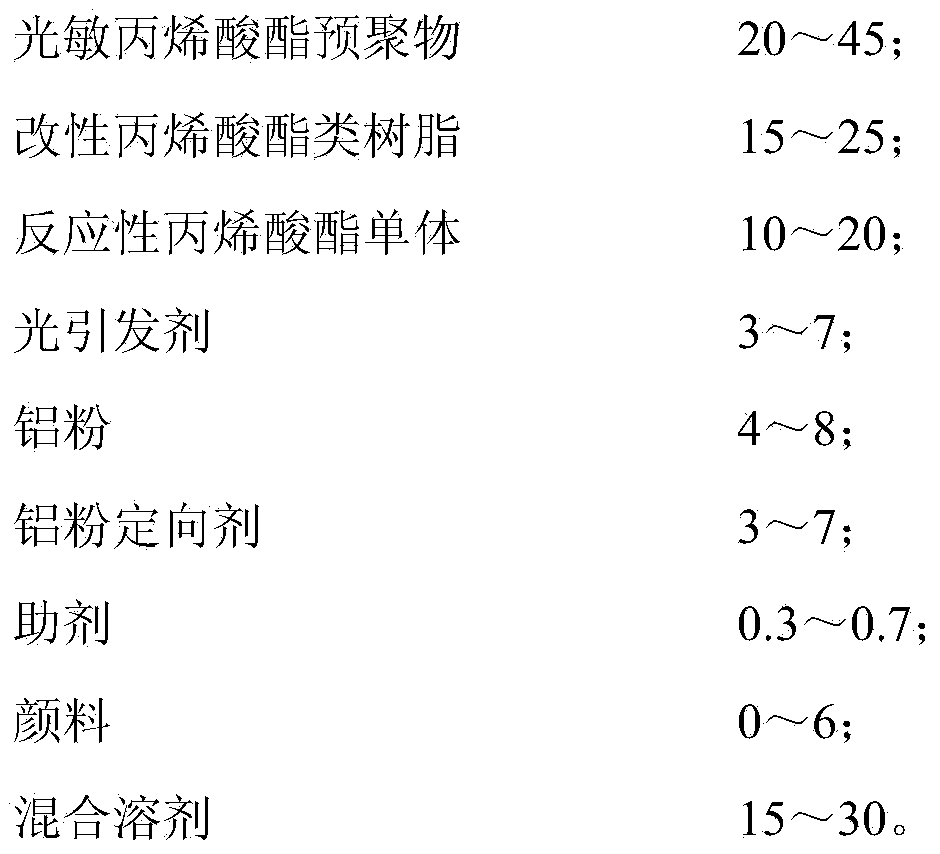

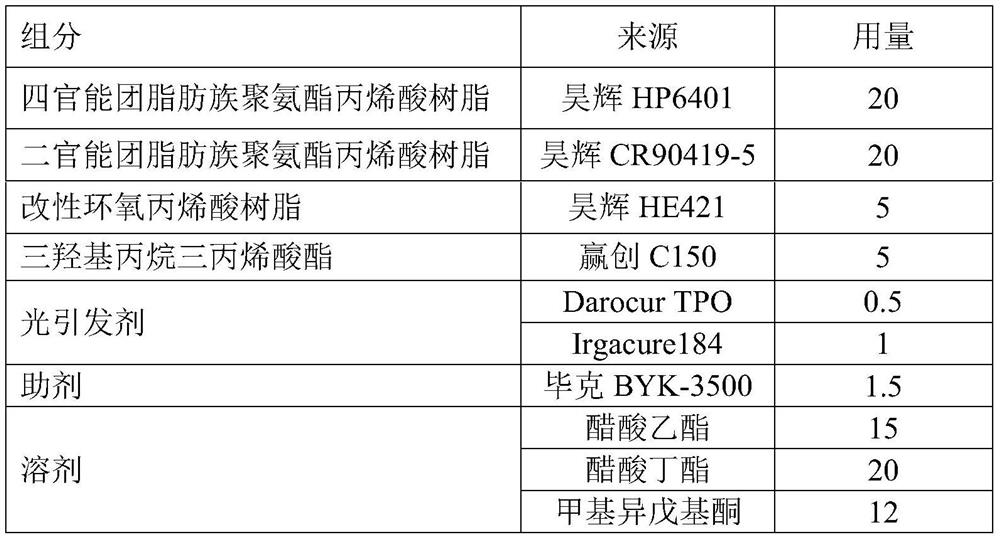

Recoatable UV-curing colored one-step-coating aluminum powder paint and preparation method thereof

ActiveCN104194613AImprove thermal stabilityLow refractive indexPolyurea/polyurethane coatingsPolyether coatingsPolymer sciencePolyvinyl chloride

The invention discloses a recoatable UV-curing colored one-step-coating aluminum powder paint and a preparation method thereof. The paint is prepared from the following components in parts by weight: 20-45 parts of photosensitive acrylate prepolymer, 15-25 parts of modified acrylate resin, 10-20 parts of reactive acrylate monomer, 3-7 parts of photoinitiator, 4-8 parts of aluminum powder, 3-7 parts of aluminum powder orienting agent, 0.3-0.7 part of assistant, 0-6 parts of pigment and 15-30 parts of mixed solvent. The paint can be used for ABS (acrylonitrile-butadiene-styrene), PC (polycarbonate), PE (polyethylene), PP (polypropylene), PVC (polyvinyl chloride) and other plastic substrates, and thus, has wide applicability; the paint has the characteristics of high UV curing speed, low VOC (volatile organic compound) content, energy saving and environment friendliness; the paint is simple in construction technique, does not need any additional curing agent, and can achieve the effects of favorable leveling property, orderly aluminum powder arrangement and the like; the coating has the advantages of high hardness, favorable wear resistance, favorable solvent resistance and bright and adjustable color, and can satisfy the demands for protection and decoration by one coating step; and the paint can be recoated repeatedly, and has excellent adhesive force and metal sensation.

Owner:YIXING HONGTAI CHEM

Pretreatment technology for electroplating of automobile door handle

InactiveCN105951142AGood lookingImprove adhesionLiquid/solution decomposition chemical coatingChlorideBiological activation

The present invention relates to a pretreatment process of electroplating for automobile door handles. The pretreatment process includes seven processes of degreasing, roughening, reduction, pre-soaking, activation, degumming and electroless nickel plating. Secondary roughening, and increase the roughening concentration, reduction concentration and pre-dipping concentration; and the activation solution is a mixture of hydrochloric acid, metal palladium and stannous chloride. The invention has the advantages that: the pretreatment process solves the problem that the existing electroplating pretreatment activation process is easy to corrode the base material, which seriously affects the appearance effect and adhesion of electroplating, and ensures that the automobile door handle has good adhesion during electroplating treatment , so that the car door handle shows an excellent metal texture after electroplating, which improves the appearance effect.

Owner:南通柏源汽车零部件有限公司

Metal facing tile productive technology

The invention relates to a decorative plate for building decoration, in particular to a surface coverage board for decoration; especially, the invention discloses a metal facing tile productive technology which is characterized in that: the technology comprises the following steps: (1) a tile basic layer is ground; (2) mixture of adhesives and metal powder is sprayed on the surface of the tile; (3) the tile is dried; (4) the dried tile is ground; (5) the tile is cleaned by stearol removing agent; (6) a protective layer for preventing oxidation of metal surface is sprayed. The method has simple manufacturing mode and is blended with the traditional process of the surface spraying and the like, thereby having special surface decorative effect.

Owner:EVERSTONE BUILDING MATERIALS QINGDAO

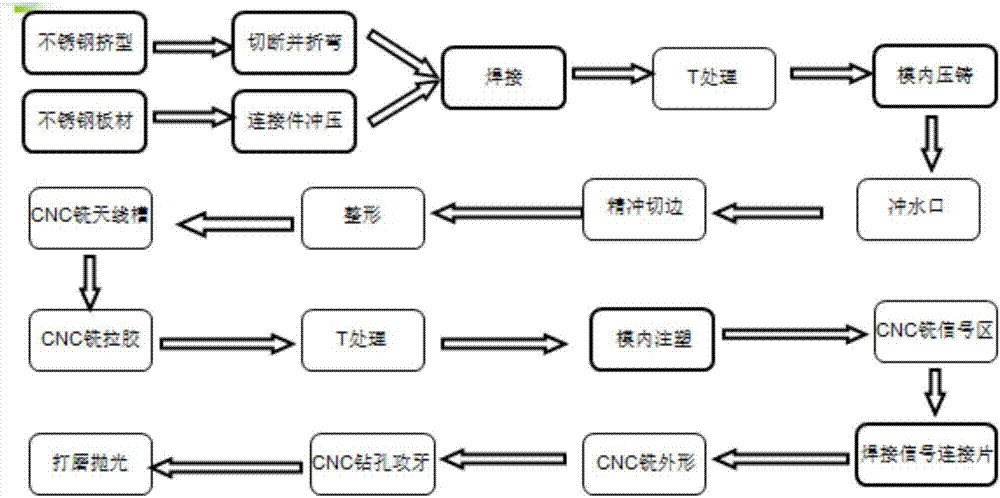

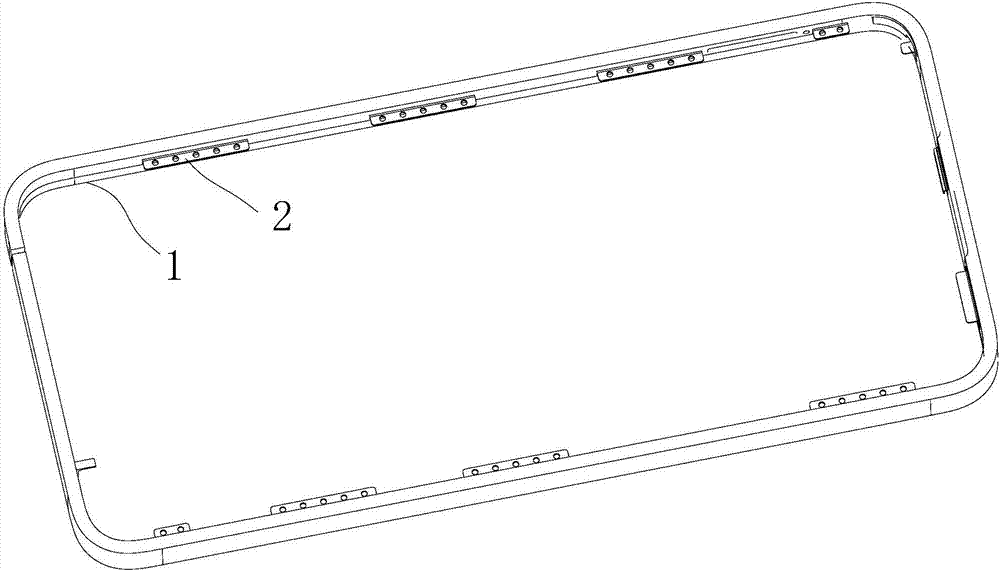

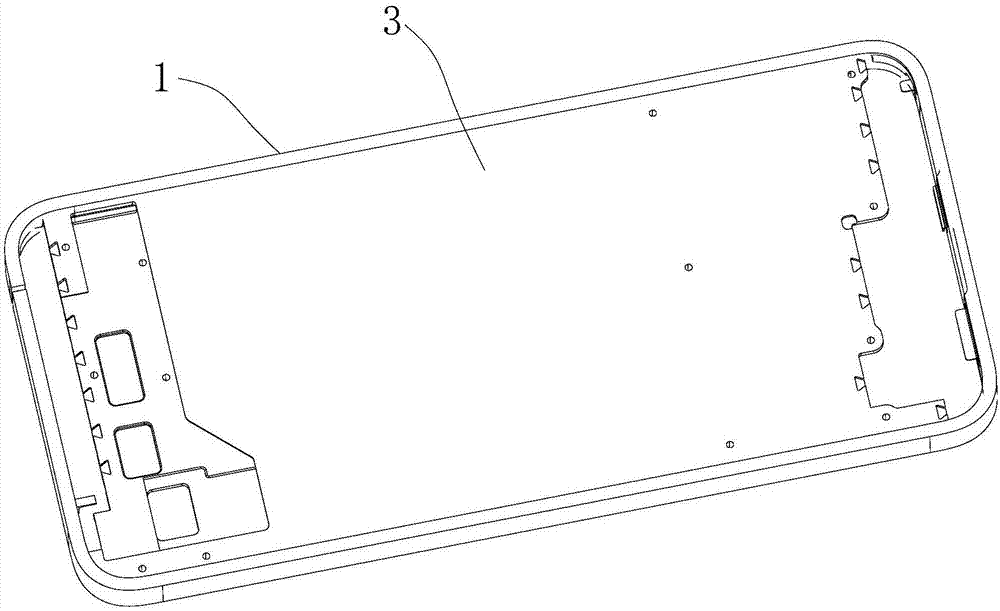

Mobile phone shell forming method

InactiveCN107088987AHigh strengthGood metal textureDomestic articlesPressure castingAgricultural engineering

The invention discloses a mobile phone shell forming method. The mobile phone shell forming method comprises the steps that a metal strip is welded into a rectangular frame body through bending, and a mobile phone frame is made; then a plurality of connecting pieces are welded and formed on the two inner sides of the mobile phone frame; and the mobile phone frame is arranged in a pressure casting die, and a middle plate is formed on the inner side of the mobile phone frame in a pressure casting mode. The connecting strength of the middle plate and the mobile phone frame is strengthened through the connecting pieces, and therefore, the strength of a mobile phone is strengthened; in addition, the mobile phone frame is formed by the metal strip through bending and welding, the production cost of the mobile phone frame can be reduced, and the strength of the mobile phone frame can be made higher than that of a mobile phone frame formed through machining according to the material mechanics and the material forming streamline science; and meanwhile, the appearance of the mobile phone has the good metal texture.

Owner:王强

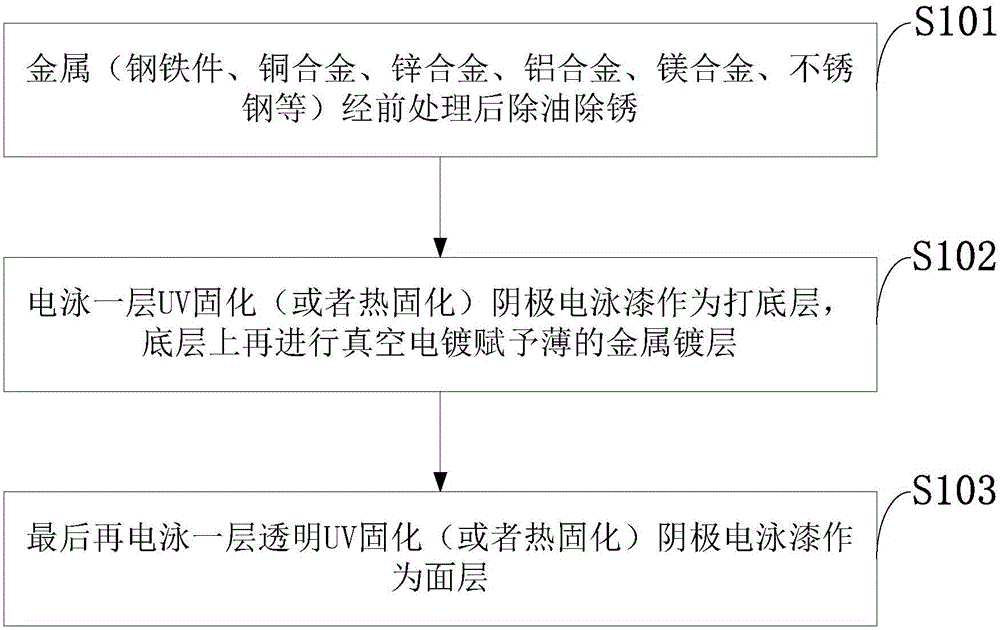

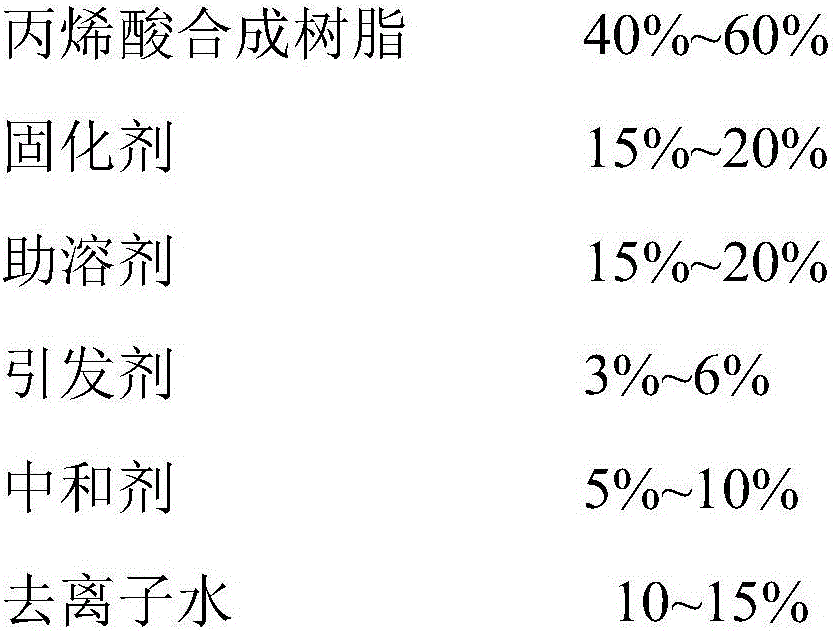

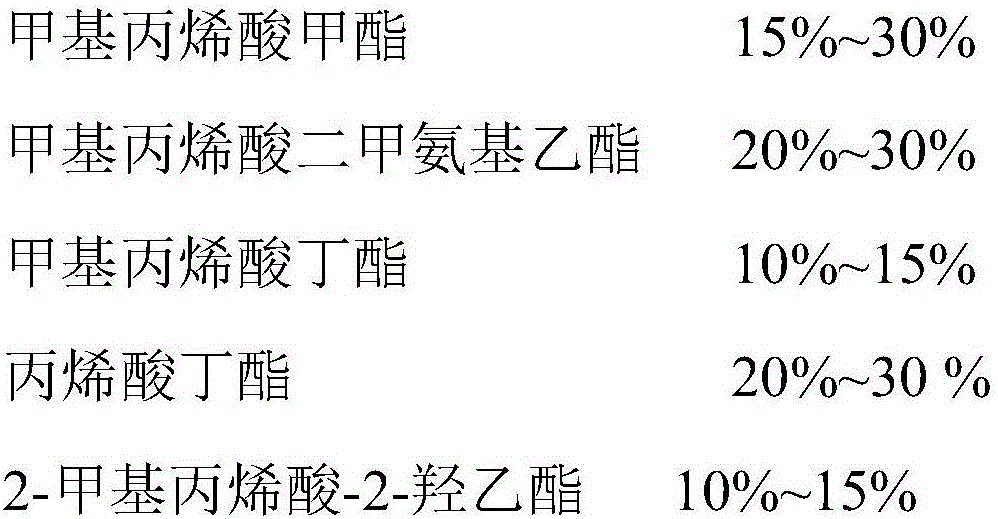

Acrylic acid cathode electrophoretic paint for producing composite coating and application thereof

InactiveCN106497372AStrong metal textureGood metal textureElectrophoretic coatingsPolyurea/polyurethane coatingsSolventBinding force

The invention discloses acrylic acid cathode electrophoretic paint for producing a composite coating and an application thereof. The acrylic acid cathode electrophoretic paint consists of the following components in percentage by mass: 40-60% of acrylic acid synthetic resin, 15-20% of curing agent, 15-20% of cosolvent, 3-6% of initiator, 5-10% of neutralizer and 10-15% of deionized water, wherein the curing agent is closed polyisocyanate; the cosolvent is an alcohol ether organic solvent; the initiator is azodiisobutyronitrile; the neutralizer comprises lactic acid and glacial acetic acid. The electrophoretic paint disclosed by the invention has the advantages of good leveling property, high throwing power, strong covering power against a base material and good binding force with the base material while the obtained film layer has good flexibility; a pulse magnetron sputtering vacuum coating method is adopted for vacuum plating; the adopted target materials include aluminum, titanium, zinc, chromium or alloy thereof, and the deposition speed is high; the film layer is silver white, can reach mirror plane brightness and has strong metal texture; the film layer is 1-2mum thick, the thickness is uniform and the phenomenon of skip plating is avoided; and moreover, the electrical conductivity is good, and a good foundation is laid for follow-up secondary electrophoresis.

Owner:东莞市霖辉金属表面处理材料有限公司 +1

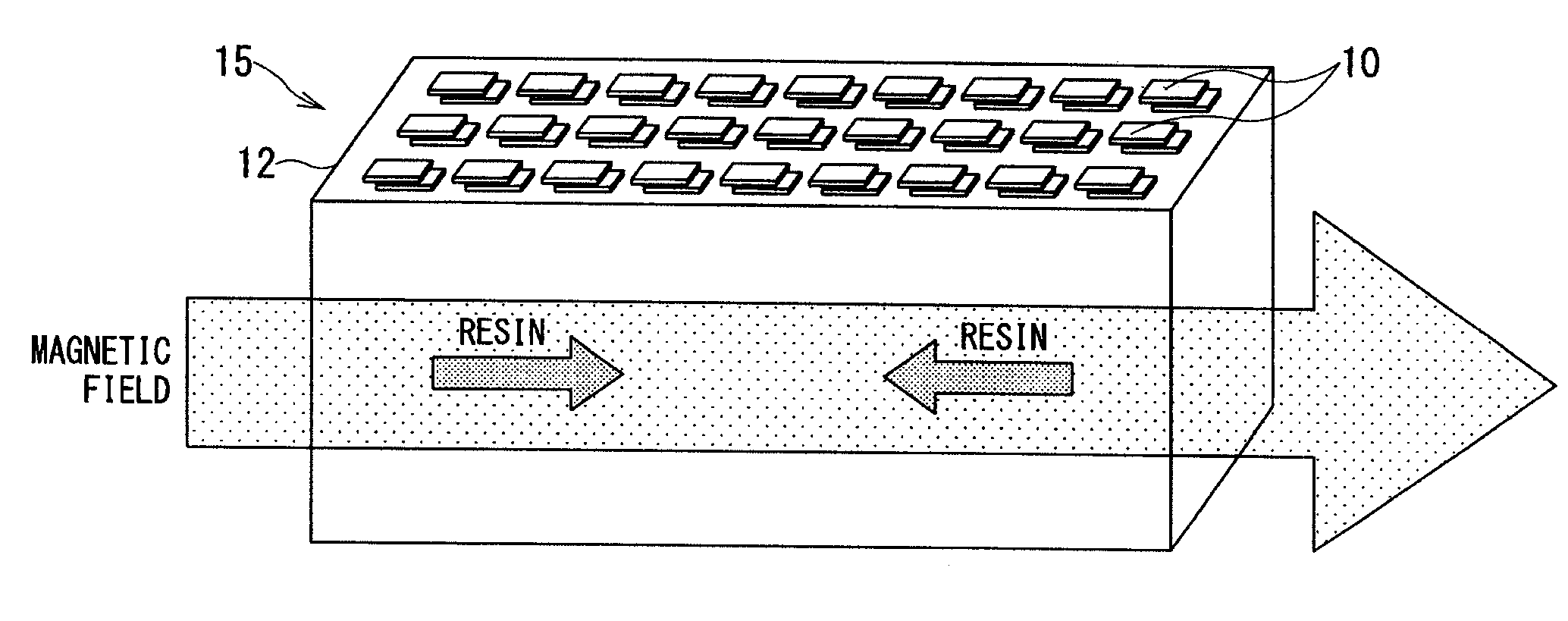

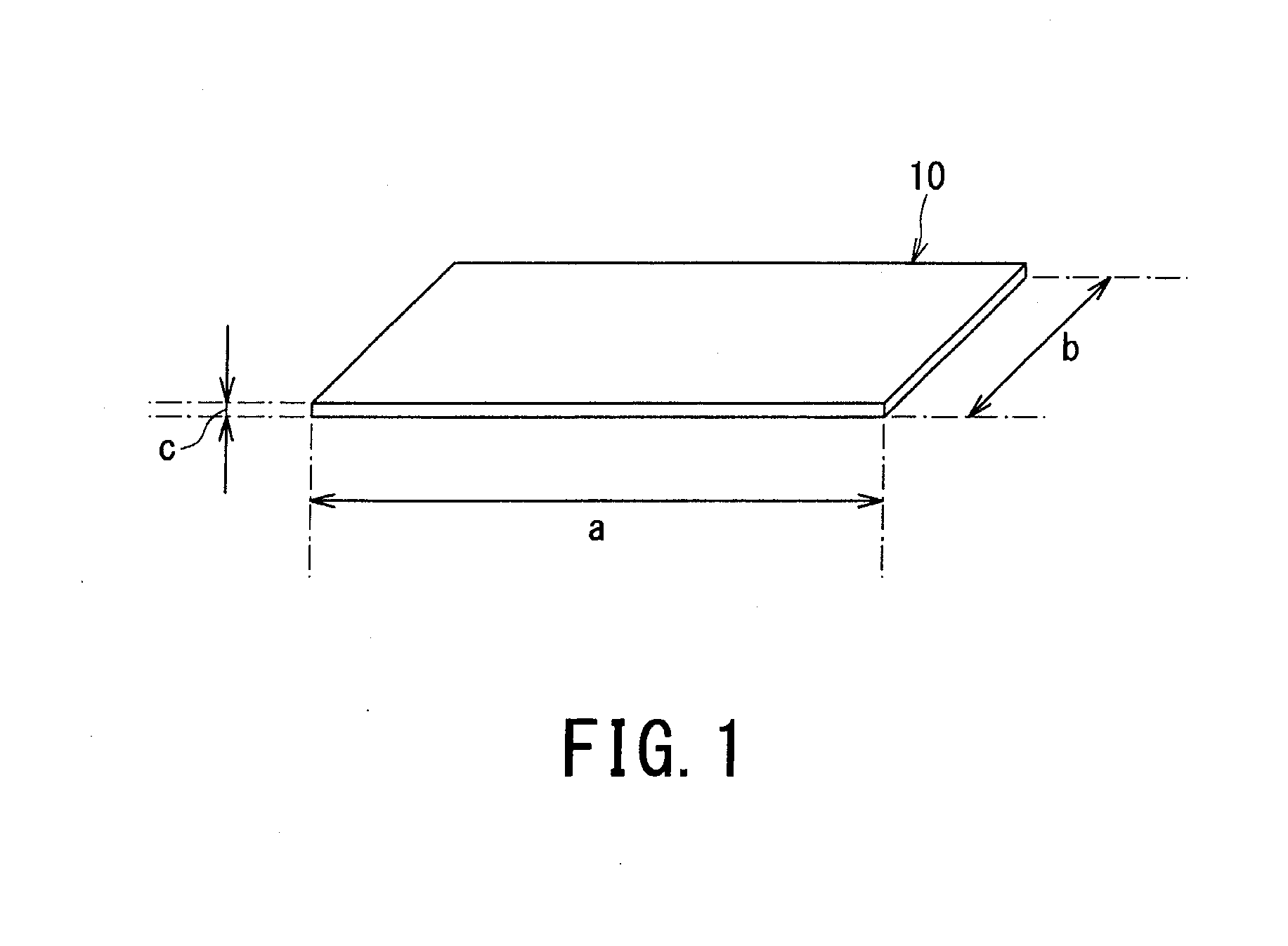

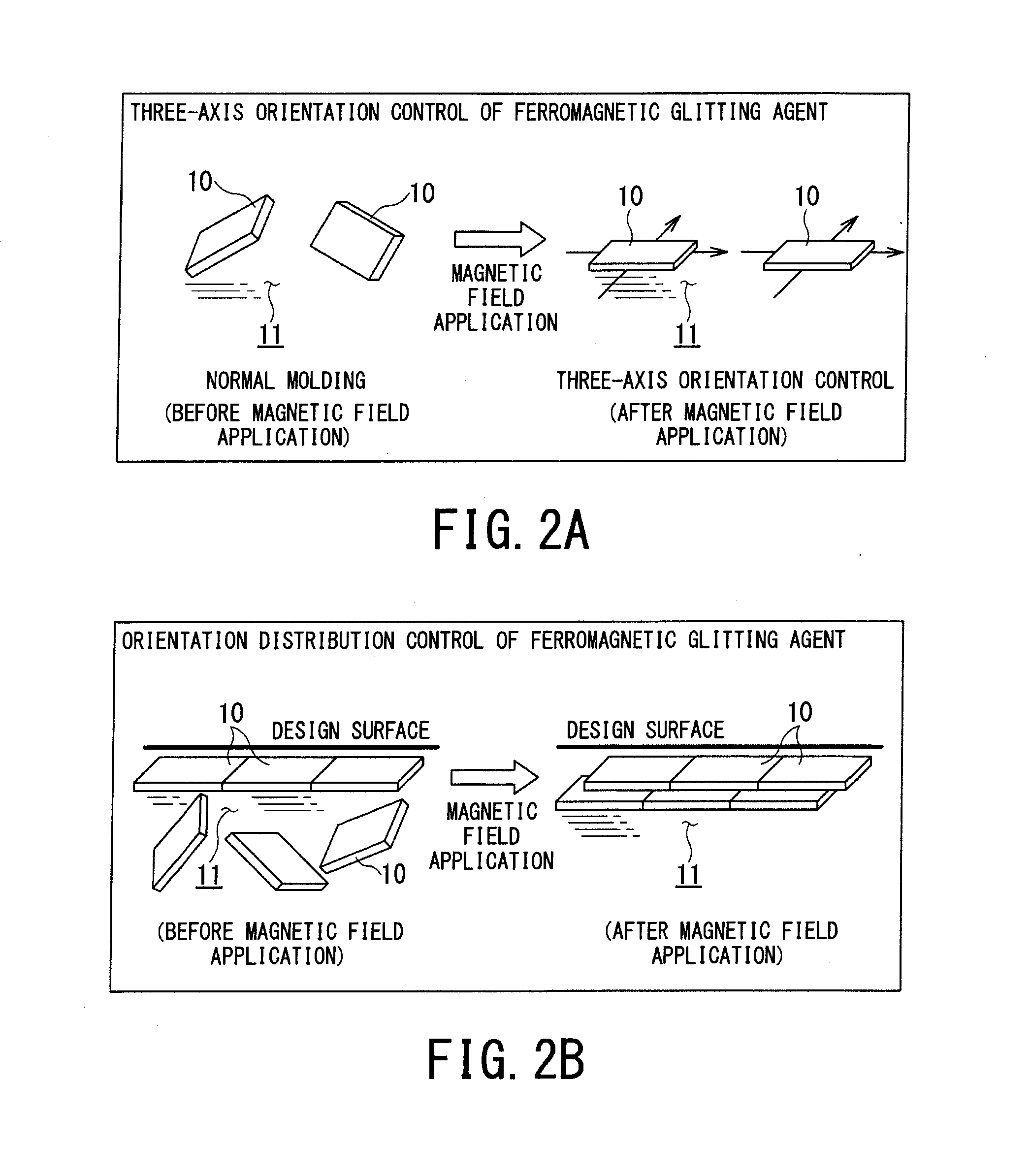

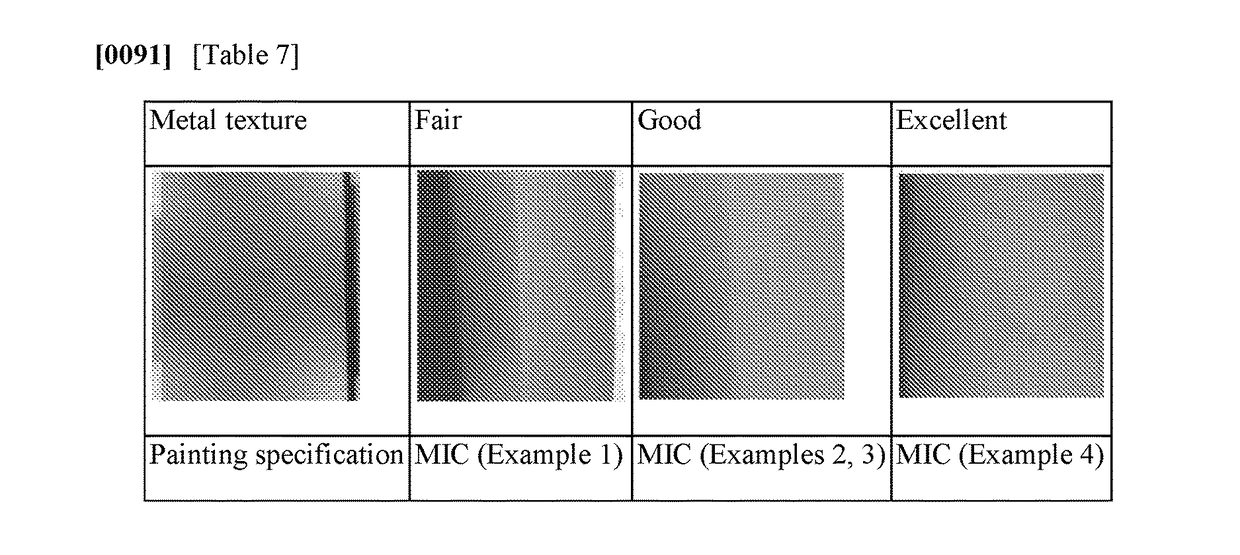

Resin molded body and method of manufacturing same

InactiveUS20130309488A1Suppress problemGood metal textureRecord information storageAnimal housingDistribution controlPolyresin

A resin molded body includes a polymeric material, such as one of a thermoplastic resin, a thermosetting resin, elastomer, and rubber, to which a required amount of ferromagnetic glittering agent having shape anisotropy is added. At a time when the polymeric material is in a molten resin state inside of a mold cavity, the polymeric material is subjected to the three-axis orientation control and orientation distribution control performed by applying a rotating magnetic field to the molten resin at a required position, adjusting an orientation of the ferromagnetic glittering agent mixed in the molten resin, and shifting the ferromagnetic glittering agent mixed in the molten resin in a required direction, and the ferromagnetic glittering agent mixed in the molten resin is then shifted to a design surface side to be thereby concentratedly distributed for orientation.

Owner:SUZUKI MOTOR CO LTD

3D material additive manufacturing process

InactiveCN106738888AReduce processing costsImprove processing efficiencyManufacturing enclosuresManufacturing heating elementsMaterials scienceMetal

The invention discloses a 3D material additive manufacturing process. The 3D material additive manufacturing process is characterized by comprising the following steps: step 1, heating materials to a semi-molten state; step 2, extruding the materials into strip-shaped blank in a mode of enabling an extruding head to fit with a mould surface of a mould; and step 3, repeating the step 2, enabling adjacent strip-shaped blank to splice or stack with each other, performing a molten-state or semi-molten-state jointing on a joint of adjacent strip-shaped blank to obtain a prefabricated part or welding through friction stir welding to obtain the prefabricated part. The 3D material additive manufacturing process is suitable for thermoplastic nonmetal materials and metal materials, and has the advantages of a wide range of application, low cost and good mechanical performances of workpieces obtained by manufacturing.

Owner:肖仁旺

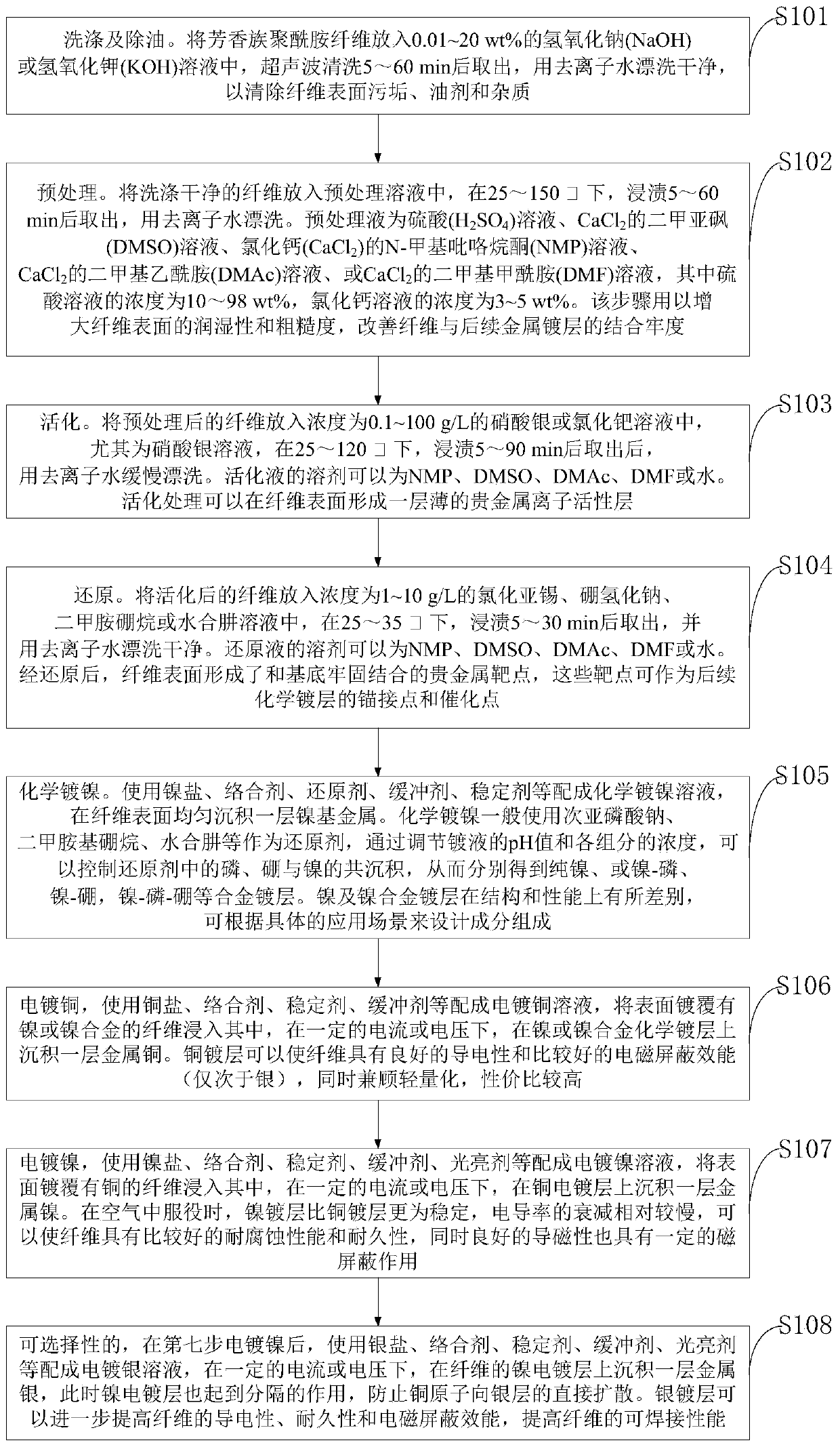

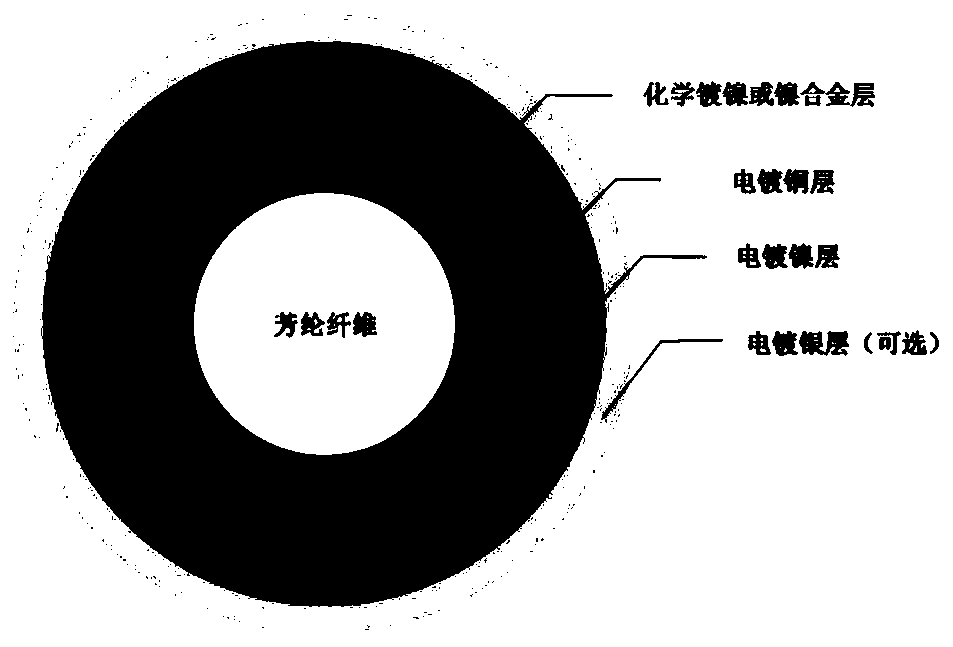

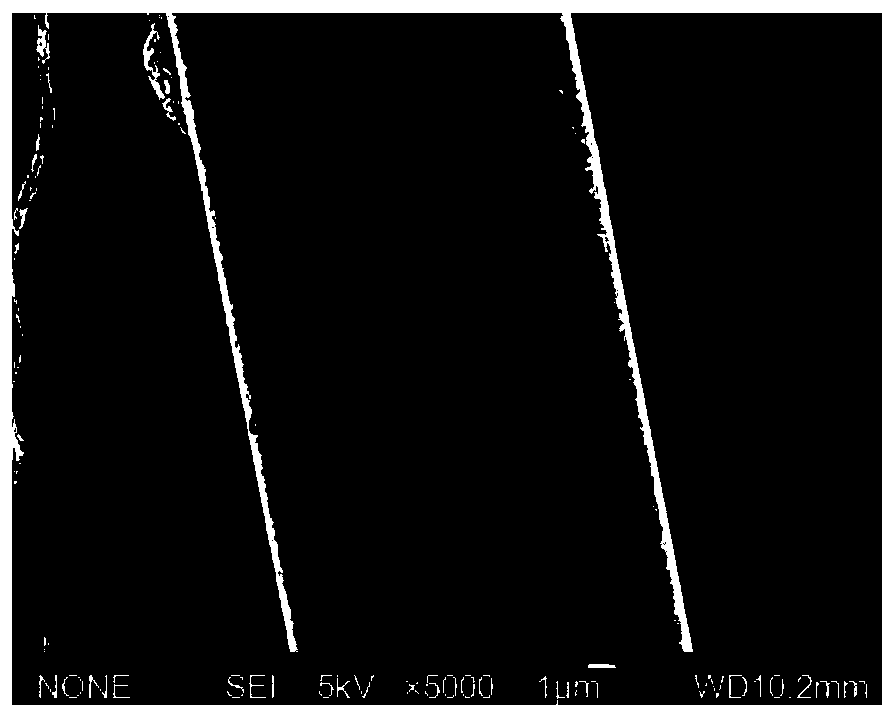

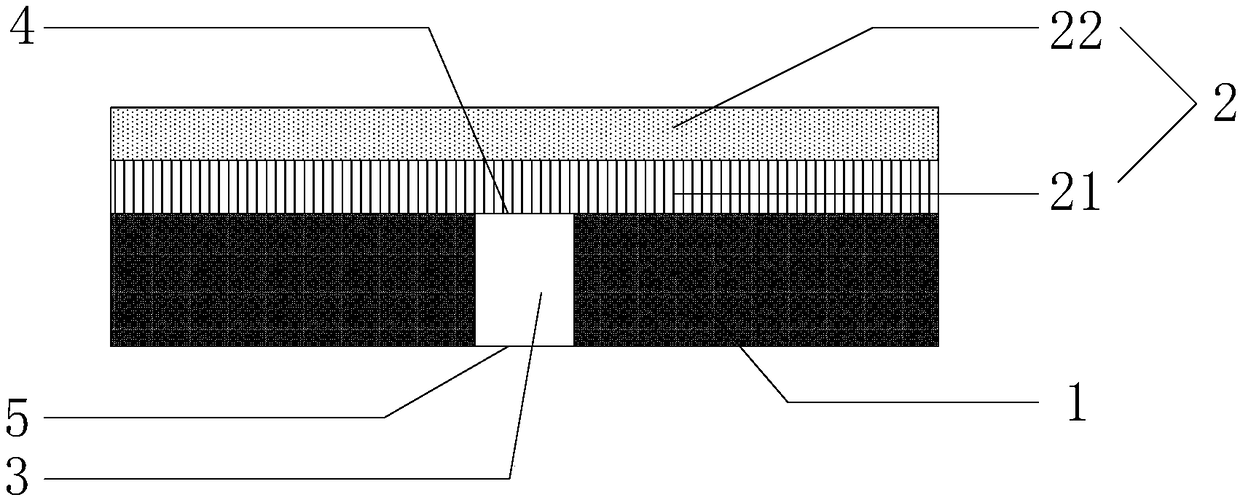

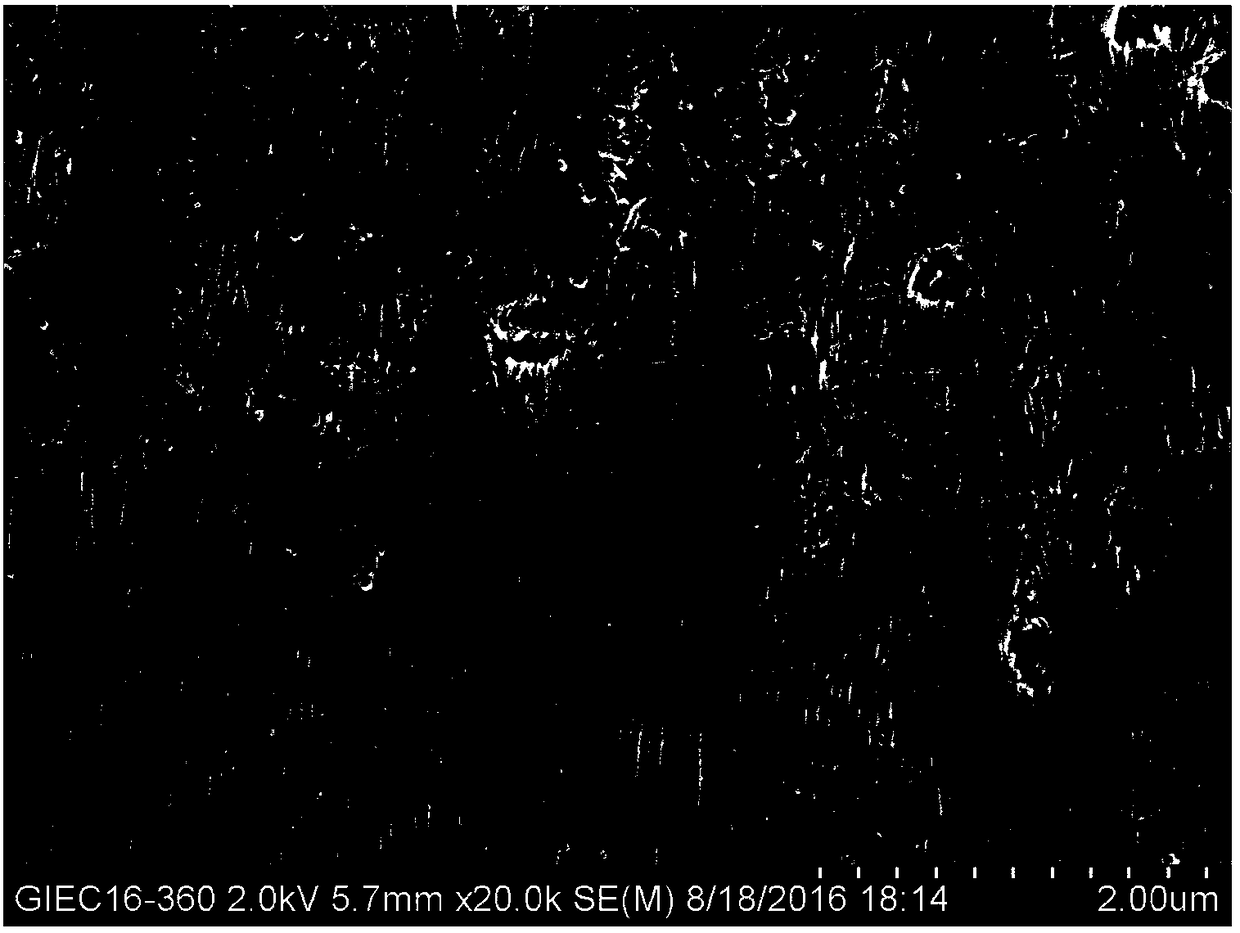

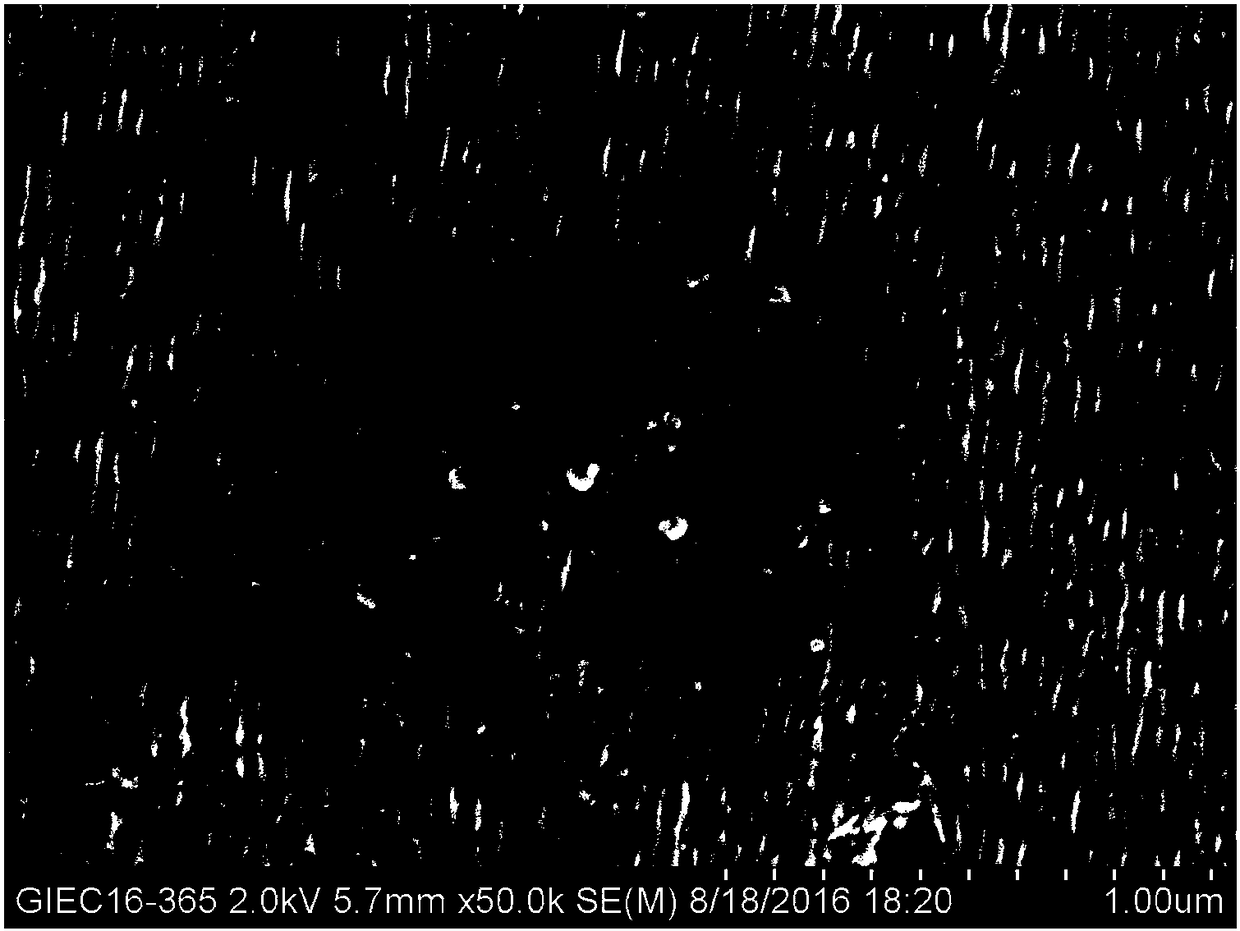

Conductive aromatic polyamide fiber with composite metal plating structure

ActiveCN110983764ALight weightImprove conductivityFibre typesLiquid/solution decomposition chemical coatingChemical platingConductive materials

The invention belongs to the technical field of electromagnetic shielding materials and conductive materials, and discloses a conductive aromatic polyamide fiber with a composite metal plating structure. A chemical nickel-plating or nickel alloy layer is deposited on a substrate of aromatic polyamide synthetic fibers; an electroplated copper metal layer is deposited on the substrate of the chemical nickel-plating or nickel alloy layer; an electroplated nickel metal layer is deposited on the substrate of the electroplated copper metal layer; and an electroplated silver metal layer is selectively deposited or not deposited on the substrate of the electroplated nickel metal layer. The preparation method of the conductive aromatic polyamide fiber with the composite metal plating structure includes the steps of washing and degreasing, pretreatment, activation, reduction, chemical plating, and electroplating. According to the invention, the chemical plating can give the fiber continuous conductivity, and the subsequent electroplating can effectively avoid the shortcomings of the chemical plating, which can improve the production efficiency. The conductive aromatic polyamide fiber prepared by the method has the characteristics of conductivity, light weight, high strength and flame retardancy, and has broad application prospects in the field of electromagnetic shielding.

Owner:SHANGHAI UNIV

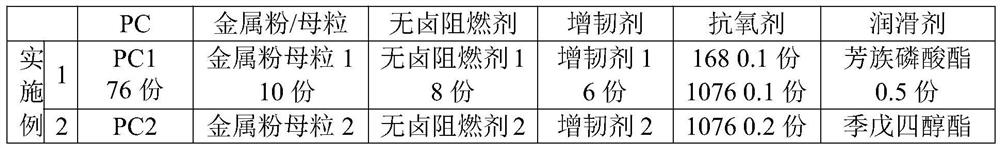

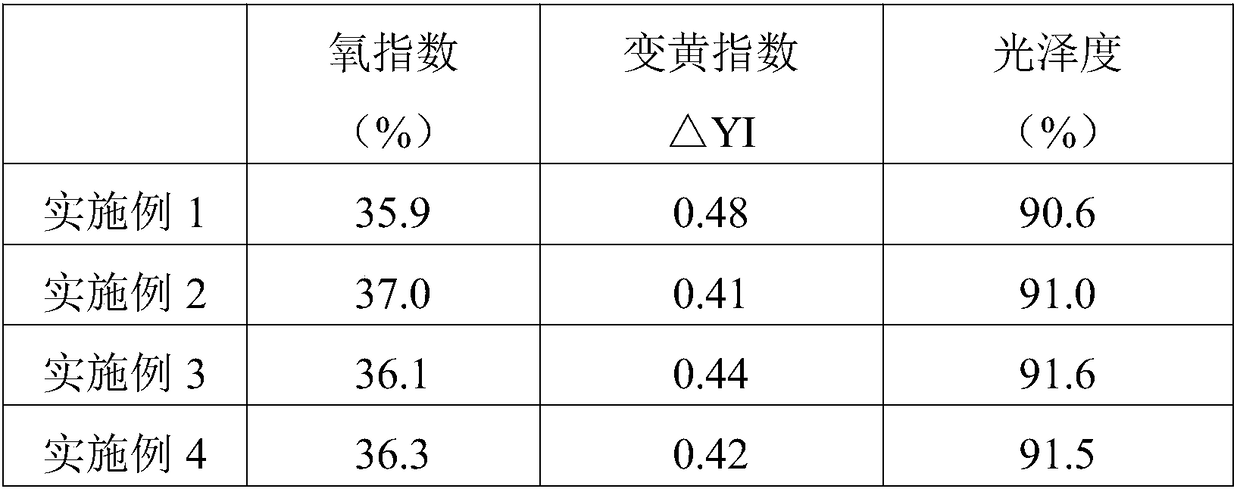

Spraying-free high-flowability high-impact flame-retardant PC material with metal texture and preparation method and application of material

The invention discloses a spraying-free high-flowability high-impact flame-retardant PC material with metal texture as well as a preparation method and application of the material. The material is prepared from 55 to 89 parts of PC resin, 1 to 25 parts of metal powder master batch, 5 to 10 parts of halogen-free flame retardant, 5 to 10 parts of flexibilizer, 0.1 to 0.5 part of antioxidant and 0.2 to 2 parts of lubricant; wherein the metal powder master batch is metal powder subjected to coating treatment by an MAH-St-MMA copolymer. The compatibility between the metal powder and PC is improved through MAH-St-MMA, the material performance and the metal texture are improved, and the technical problem that in the prior art, the flowability, the impact property and the flame retardant property of a metal texture PC material cannot be considered at the same time is solved through cooperative use of high-flowability PC, the metal powder master batch, the flexibilizer and the halogen-free flame retardant; meanwhile, the material has a good appearance effect, high flowability, impact resistance and flame retardance, is easy to form and meets the requirements of wall switches.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

Metal glazed tile and preparation method thereof

The invention discloses a metal glazed tile and a preparation method thereof. The metal glazed tile comprises a green body, a ground glaze layer, a cover glaze layer, a pattern layer arranged between the ground glaze layer and the cover glaze layer, a texture layer arranged between the pattern layer and the cover glaze layer, and a metal glaze layer arranged on the cover glaze layer; the ground glaze layer and the cover glaze layer are arranged on the green body; and the texture layer is used for enabling the cover glaze layer to form concave textures and enabling part of the metal glaze layer to be embedded in the concave textures. The ceramic tile has the effect that gold woven copper is inlaid in filaments, and is high in metal texture and good in stereoscopic impression and layering sense. The preparation method comprises the steps of preparing the green body, spraying ground glaze, printing the pattern layer and the texture layer, spraying cover glaze, spraying metal crystal glaze, firing and polishing; the preparation method is simple in steps and easy to implement, the ceramic tile with the effect that gold woven copper is inlaid in the filaments can be obtained, and the ceramic tile not only has metallic luster, but also is good in three-dimensional effect and strong in layering sense.

Owner:GUANGDONG NEWPEARL CERAMIC GRP CO LTD +4

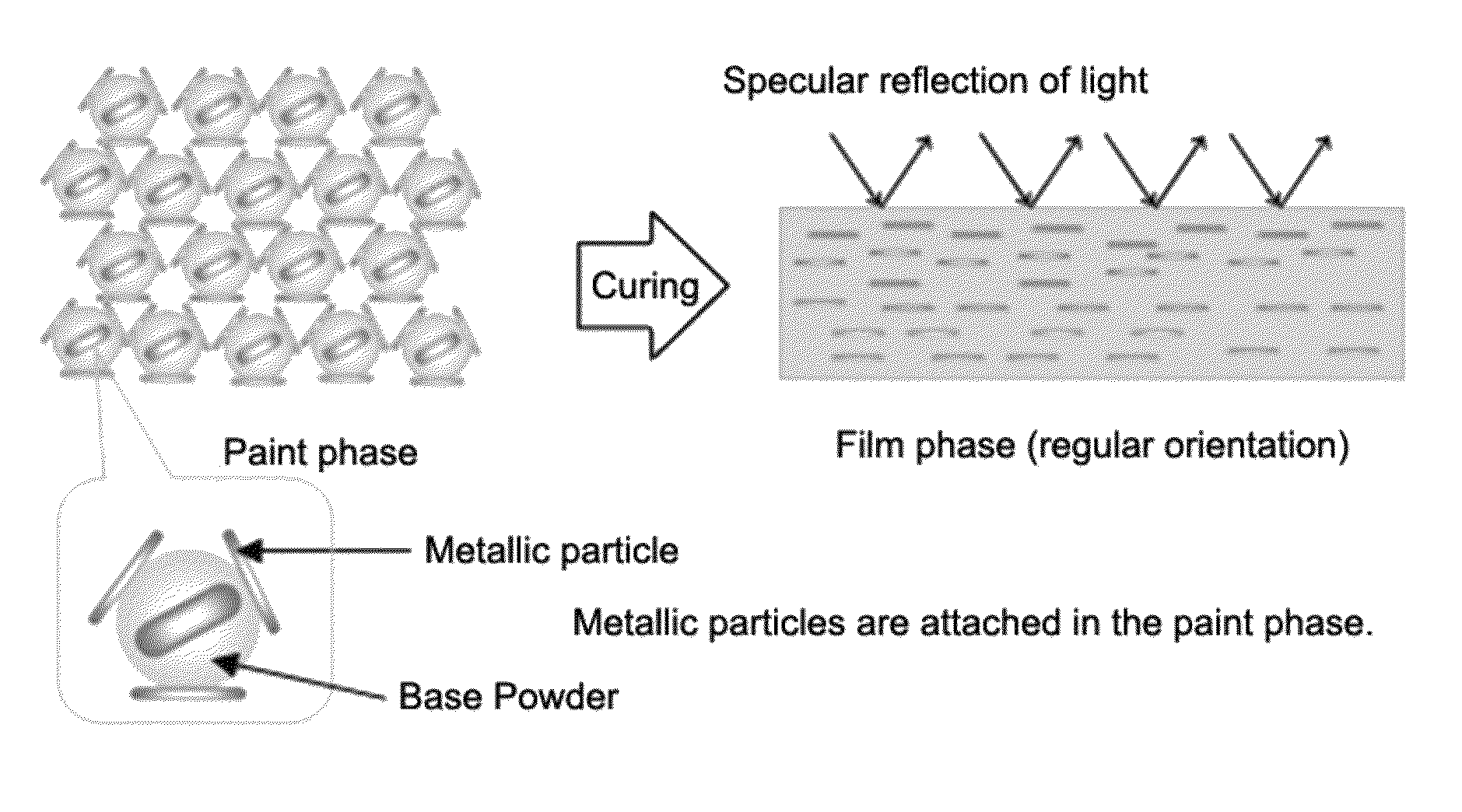

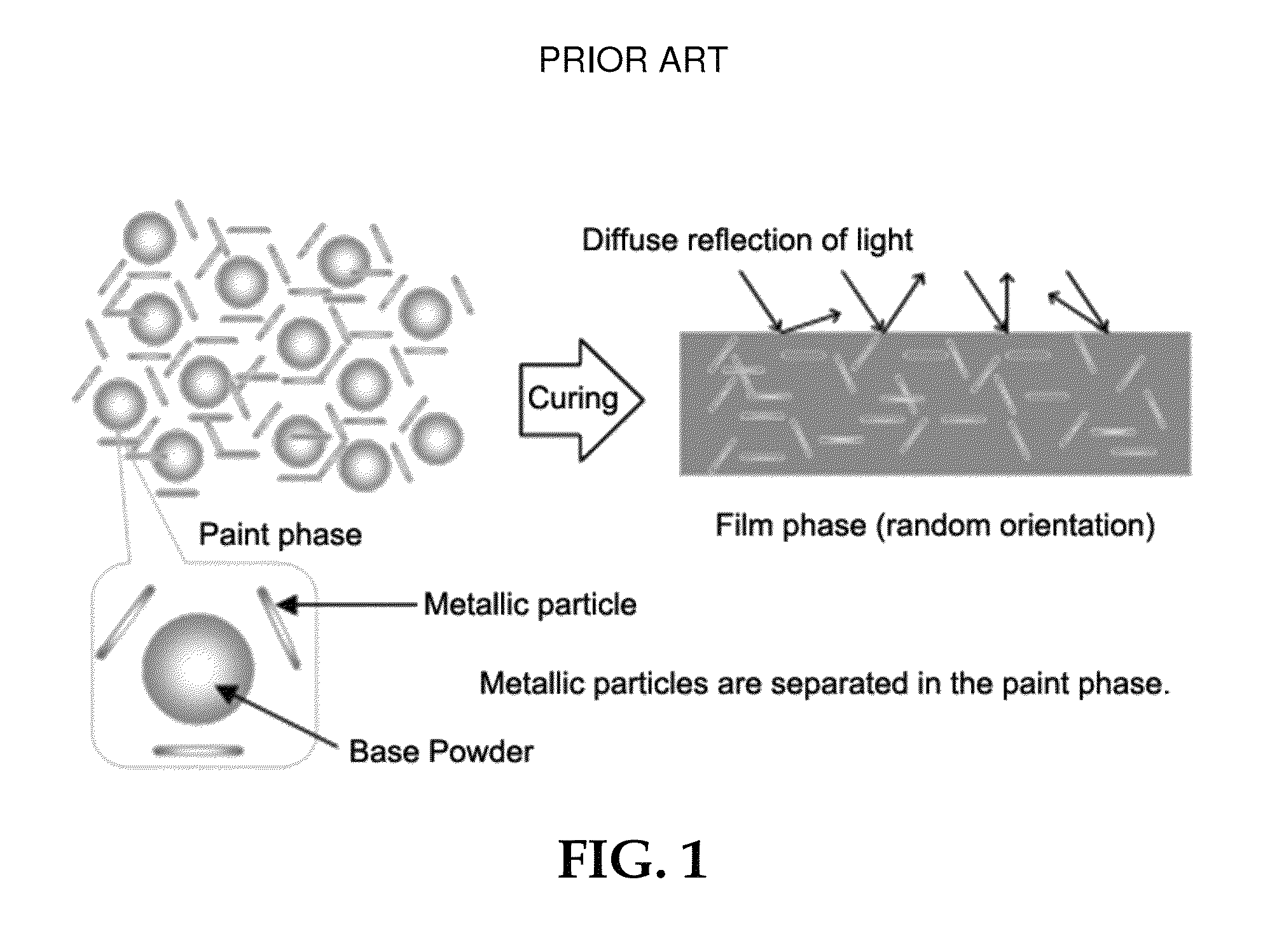

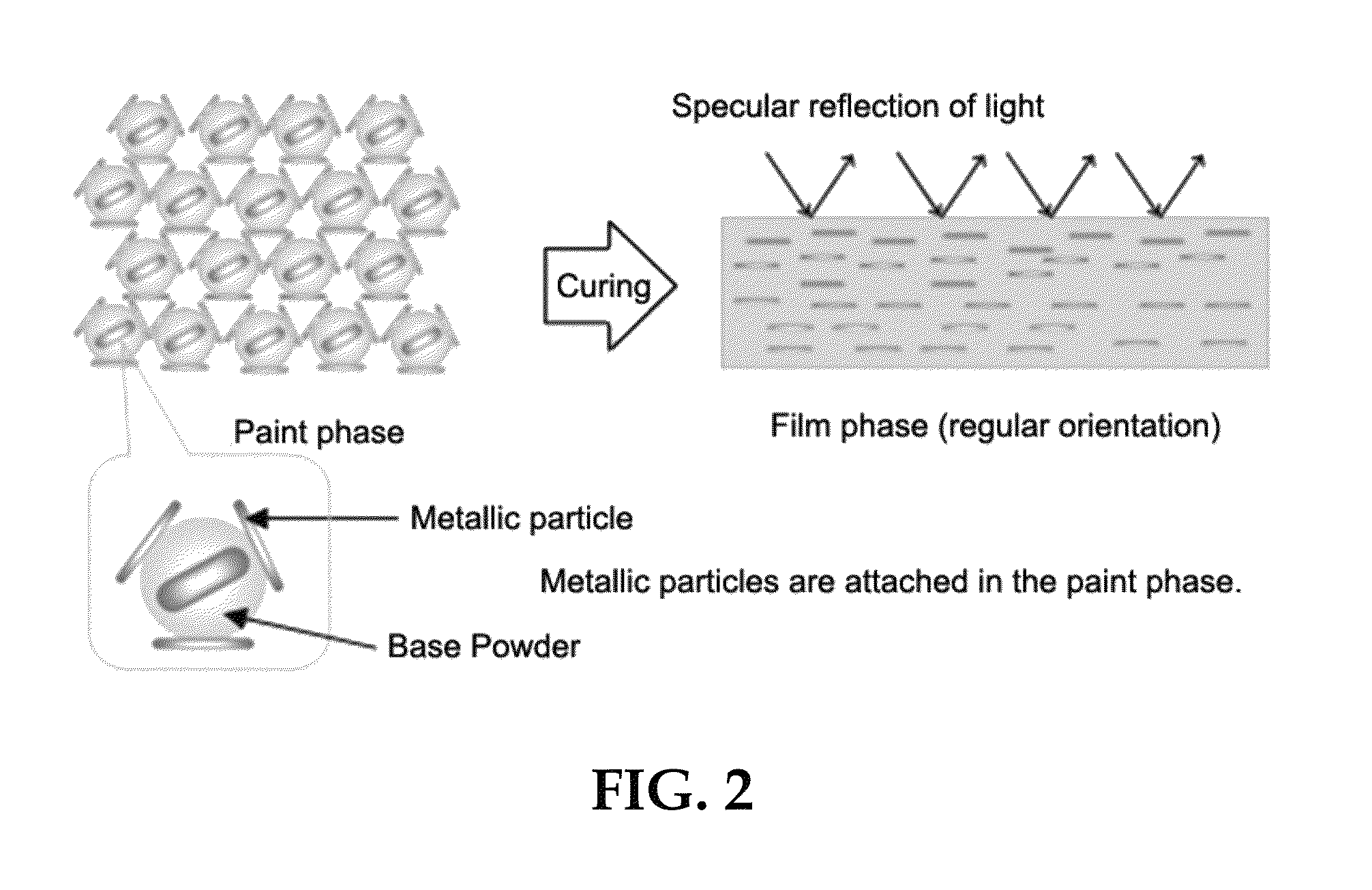

Powder paint composition and method for preparing same

ActiveUS20150064444A1Improve textureImprove corrosion resistanceLayered productsPretreated surfacesPowder coatingMaterials science

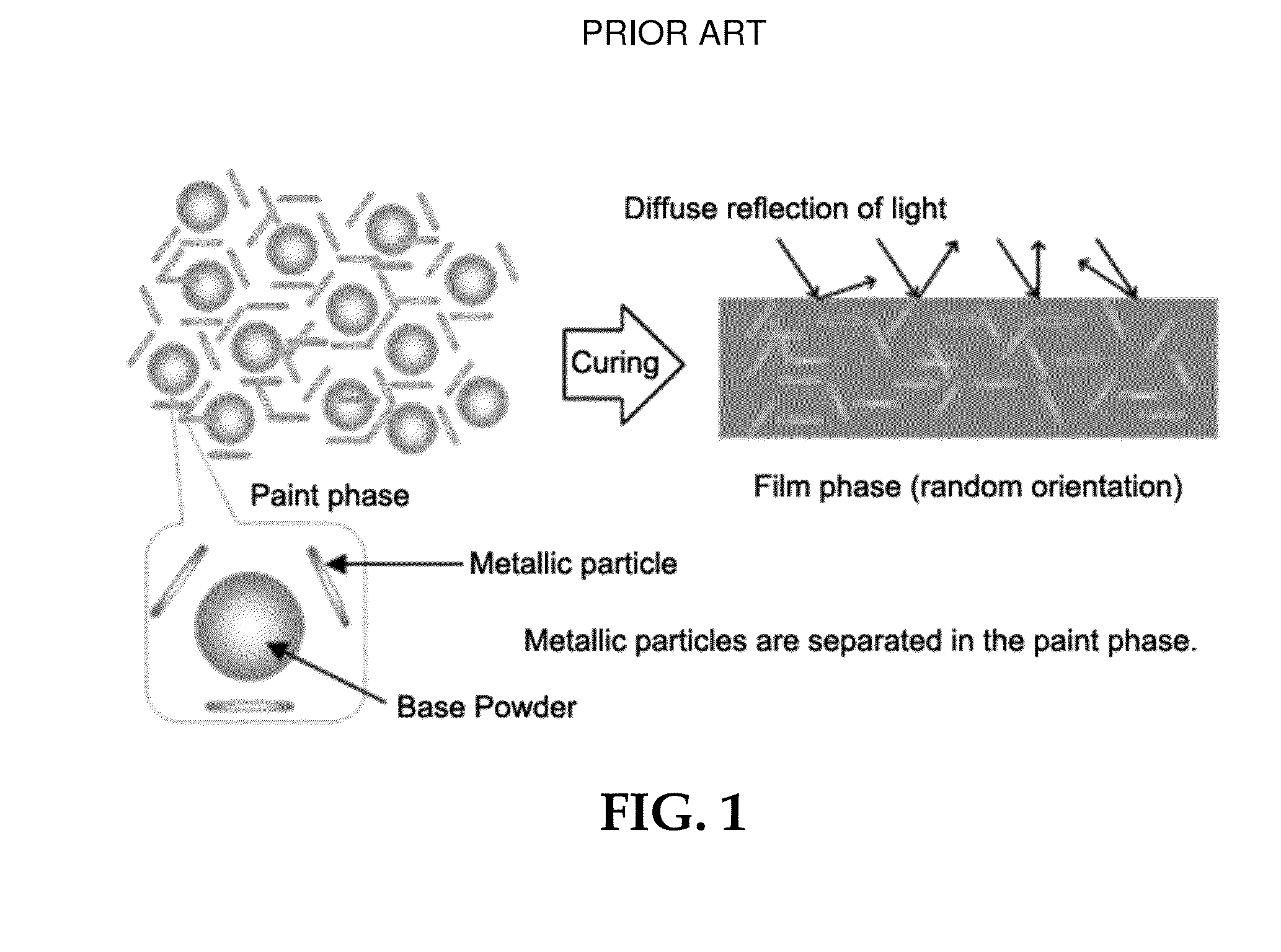

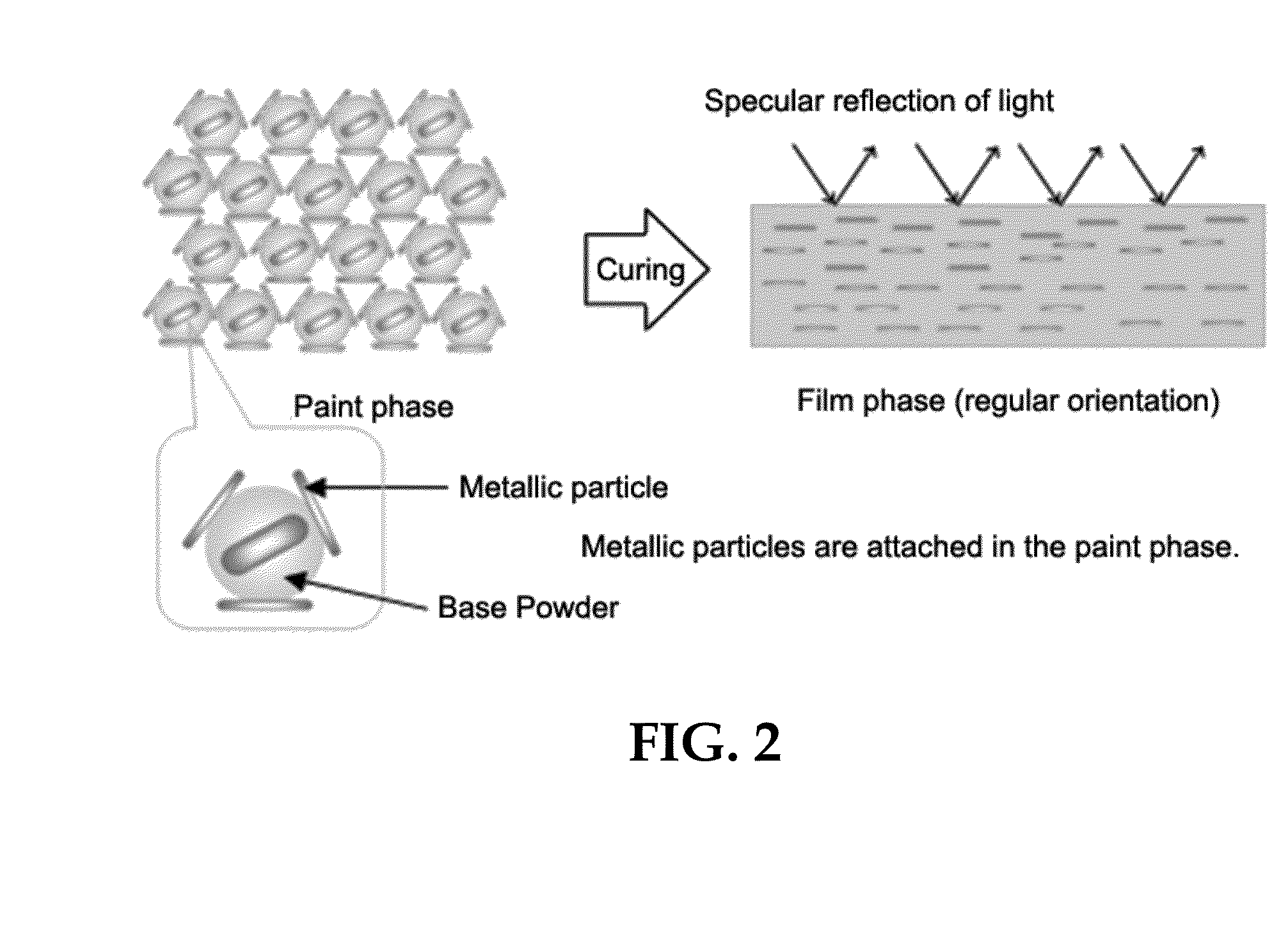

Disclosed is a powder paint composition of and a method for preparing the same. More particularly, the present invention relates to a powder paint composition including a powder paint prepared by physically attaching metallic particles to a powder resin, which exhibits no separation or aggregation of metallic particles when coated and significantly improves metallic texture owing to orientation of the metallic particles, and a method for preparing the same.

Owner:HYUNDAI MOTOR CO LTD

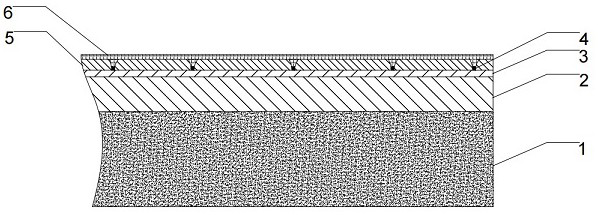

Wallboard for integral bath room and preparation method of wallboard

ActiveCN105694795ASolve the surface is not bright enoughSolve the problem of not being full enoughCovering/liningsNon-macromolecular adhesive additivesCompound aWear resistant

The invention discloses a wallboard for an integral bath room and a preparation method of the wallboard. A substrate is an SMC sheet-shaped molding compound molded plate, a panel is a glue film veneered thin aluminum plate, and the glue film veneered thin aluminum plate is obtained by compounding a glue film and a thin aluminum plate through film laminating. The preparation method of the wallboard comprises the following steps: compounding the glue film with the aluminum plate to obtain a panel material; and paving the panel material on the surface of a mold, feeding the substrate into the mold, laminating the substrate to the back of the panel material, heating the panel material and the substrate to 125-145 DEG C, and carrying out once pressure forming in the mold, wherein the front surface of the panel material faces to the mold. A polyurethane hot melt adhesive is utilized, when the temperature is 100-120 DEG C, isocyanate groups of polyurethane are maintained at a closed state, when the temperature is 125-145 DEG C during in-mold forming, double bonds of isocyanate are opened at about 130 DEG C and are bonded with hydroxyl groups in SMC sheets, and then the thin aluminum plate and the SMC substrate are firmly bonded together through polyurethane glue. The wallboard has excellent metal texture, is plump and wear resistant and is unlikely to be scratched.

Owner:SUZHOU COZY HOUSE EQUIP

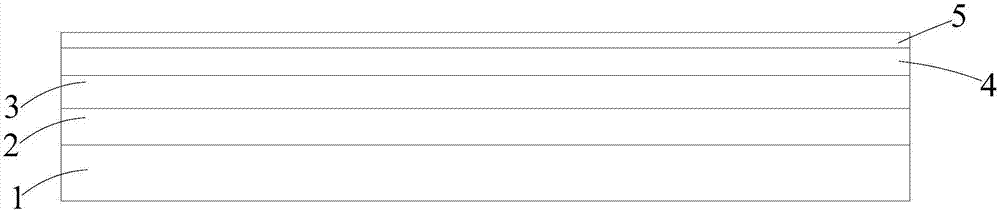

Vacuum coating layer and coating method thereof

InactiveCN113845834AWith metallic textureImprove the level ofFireproof paintsVacuum evaporation coatingMetal coatingPolymer science

The invention relates to the technical field of paint, in particular to a vacuum coating layer and a coating method thereof. The vacuum coating layer comprises a primer layer, a metal coating layer, a middle paint layer and a finish paint layer which are sequentially stacked, the middle paint layer is made of hydroxyl acrylic resin with a low hydroxyl value; the finish paint layer is made of acrylic resin with a high hydroxyl value; the hydroxyl value of the acrylic resin with the low hydroxyl value is not higher than 3wt%, and the hydroxyl value of the acrylic resin with the high hydroxyl value is not lower than 3.5 wt%. Through interaction of the primer layer, the metal coating layer, the middle paint layer and the finish paint layer, the coating layer which is good in hardness, wear-resistant, weather-resistant and excellent in high-temperature and high-humidity resistance and has metal texture is prepared. Wherein the middle paint layer serves as an adhesion promoting layer, the adhesion between the middle paint layer and the metal coating layer is excellent, it can be guaranteed that the finish paint layer can be stably attached to the metal coating layer , and nano color paste can be added to make the coating layer achieve the metal texture and have the colorful effect at the same time.

Owner:HUIZHOU FEIKAI NEW MATERIAL CO LTD

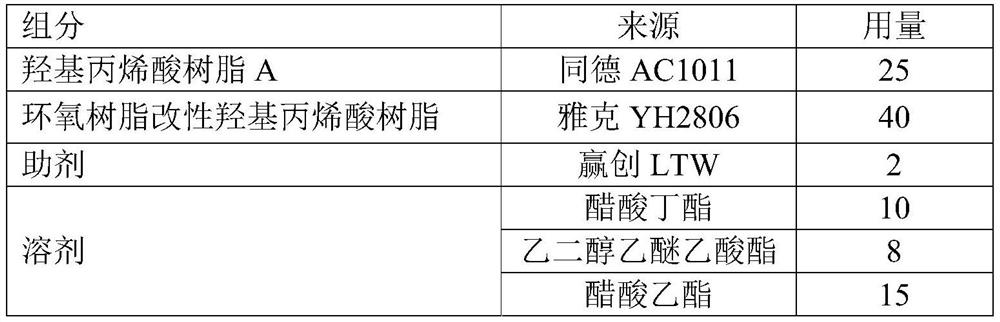

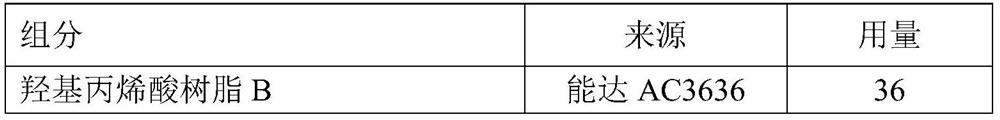

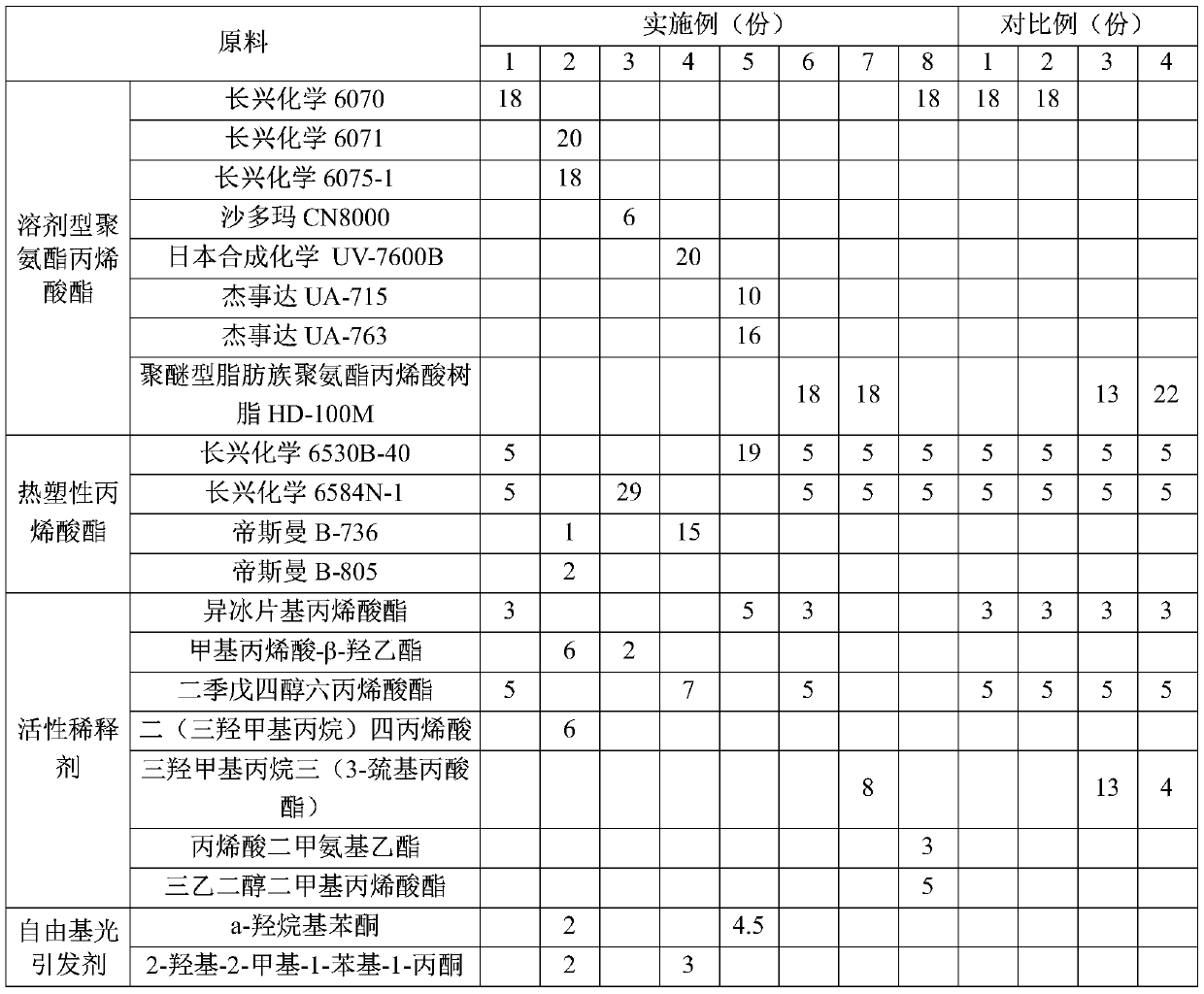

Ultraviolet-curing gradient color electroplating intermediate paint

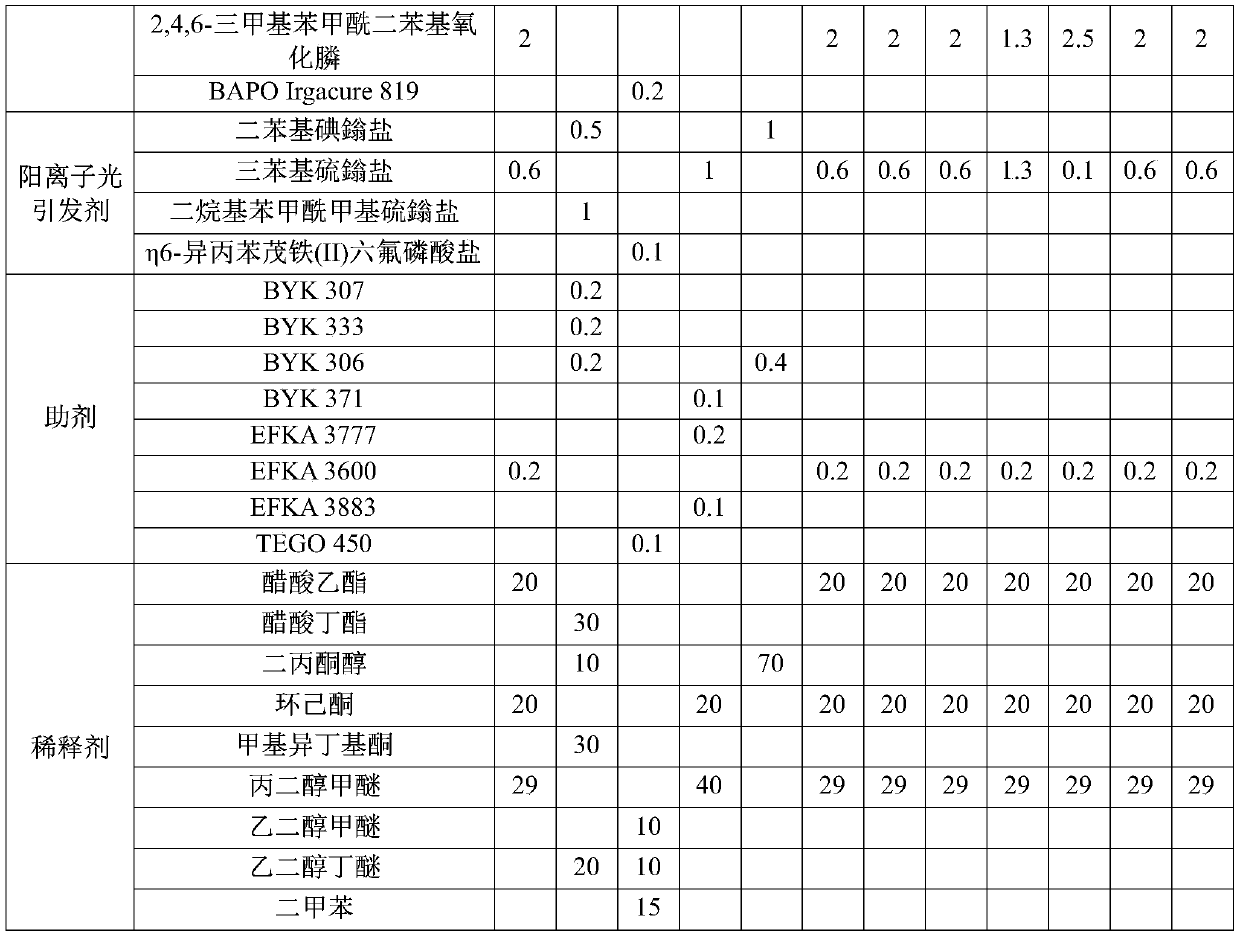

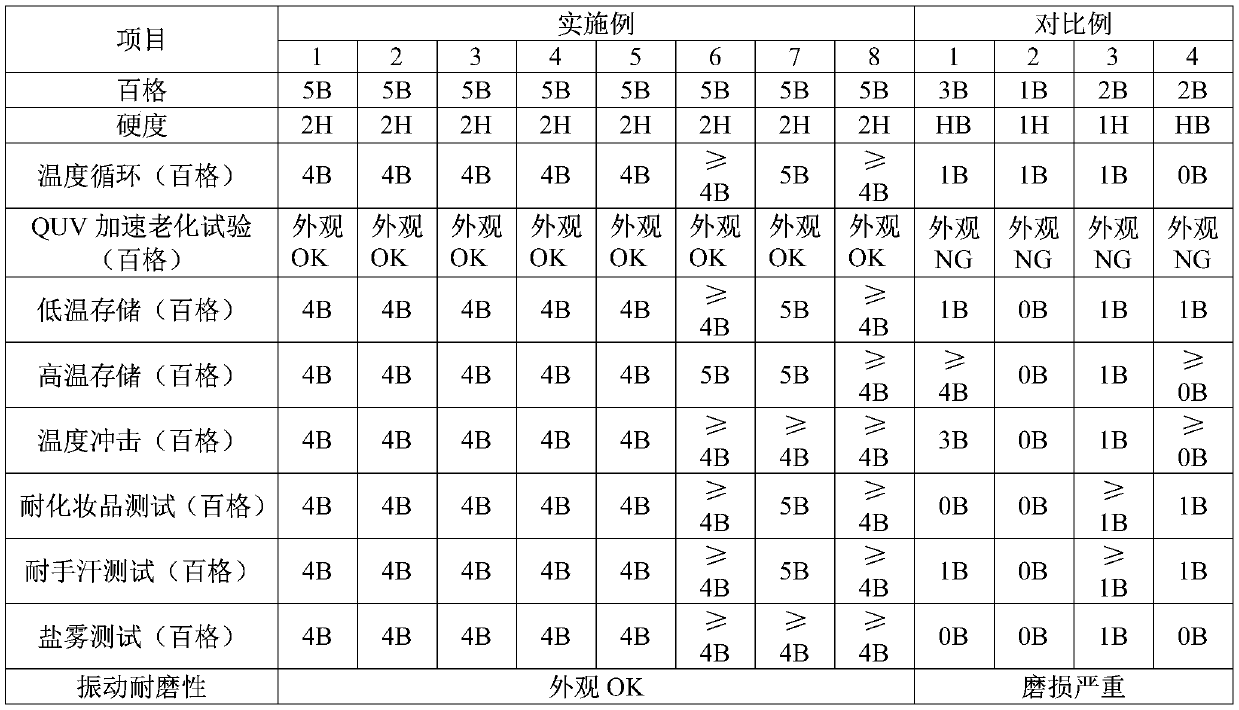

InactiveCN109897529AImprove coloring flowersImprove dark spotsAnti-corrosive paintsPolyurea/polyurethane coatingsColor effectLacquer

The invention belongs to the field of coatings, and concretely relates to an ultraviolet-curing gradient color electroplating intermediate paint. The ultraviolet-curing gradient color electroplating intermediate paint comprises, by weight, 6-36 parts of solvent-type polyurethane acrylate, 3-29 parts of thermoplastic acrylate, 0.8-12 parts of a reactive diluent, 0.5-8 parts of a nanometer color paste, 0.2-5.5 parts of an initiator, 0.1-0.6 part of an assistant and 35-90 parts of a diluent. The ultraviolet-curing gradient color electroplating intermediate paint effectively improves the dyeing defect, color spots and metal texture of a metal coating layer and different gradient color effects of the same metal coating surface; a free radical photoinitiator and a cationic photoinitiator are compounded to ensure the curing speed by the free radical photoinitiator and ensure deep curing by the cationic photoinitiator; and thiol acrylate cooperates with polyether polyurethane acrylate, and thesynergistic action of the two components ensures the sufficient curing of a film and reduce the sensitivity of the surface of the film to gases, water steam and outside impurities, so the prepared film has good aging resistance.

Owner:YIXING HONGTAI CHEM

Alloy composite material and preparing method thereof

InactiveCN106868462AGood adhesionGood mechanical strengthVacuum evaporation coatingSputtering coatingBatch productionPhysical vapor deposition

The invention belongs to the technical field of alloy materials, and particularly relates to an alloy composite material. A first metal layer, a second metal layer, a third metal layer and a fourth metal layer are sequentially precipitated on the surface of a soft base material through a physical vapor deposition method. Compared with the prior art, the adhesive force between layers is good, the mechanical strength resistance is good, the preparing process is stable, the metal texture is high, the weather fastness is good, and a film is not likely to oxidization even when the film is exposed to air for a long time; and meanwhile, the alloy composite material further has the low and high frequency electromagnetism radiation-proof function and is suitable for batch production.

Owner:东莞市航晨纳米材料有限公司

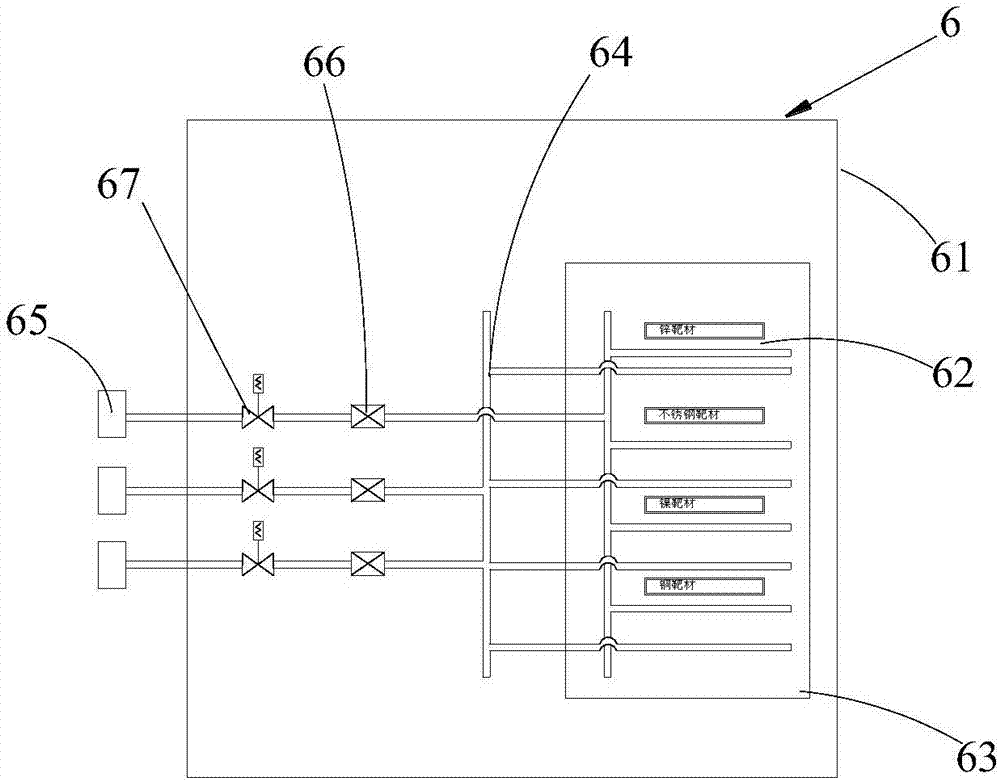

Electroplating apparatus

ActiveCN109537031AMeet the appearance quality requirementsAchieve protective effectCellsElectrodesEngineeringElectroplating

An apparatus for electroplating which is applicable to the electroplating of workpiece is disclosed. The apparatus includes: an electroplating solution container, a target, an absorbent piece, and a power supply. All the electroplating solution, workpiece, absorbent piece, and target are placed inside the electroplating solution container with at least partial portions of each workpiece, absorbentpiece and target submerged in the electroplating solution. The positive electrode of the power supply is electrically connected to the target while its negative electrode is electrically connected tothe workpiece and absorbent piece simultaneously. When the power supply imposes a current through the circuit, the target releases metal ions into the electroplating solution and metal ions reduce and a metal coating is formed on the workpiece. In the meantime, carbocations in the electroplating solution are adsorbed on the absorbent piece.

Owner:MING CHI UNIVERSITY OF TECHNOLOGY

Spray-free polypropylene material for automotive exterior decorations and preparation technology thereof

The invention relates to a spray-free polypropylene material for automotive exterior decorations and a preparation technology thereof. The spray-free polypropylene material for the automotive exteriordecorations is prepared from the following raw materials in percent by mass: 1.5-3% of a metal powder , 0.5-2% of a pearl powder, 5-15% of a talcum powder, 0.1-0.4% of triethylene glycol ether-bis(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate, 0.2-0.4% of N, N'-ethylene bisstearamide, 3-8% of a flame retardant, 0.1-0.3% of 1-bromo-5, 5-dimethylhydantoin, 0.1-0.4% of an ultraviolet absorbent and the balance of polypropylene. The spray-free polypropylene material for the automotive exterior decorations has good luster and metal texture, and the appearance effect thereof is similar to the painting effect; the process is greatly simplified; the preparation technology is simple; the equipment requirements are low; the product yield rate is high; the surface quality of the spray-free material is obviously improved; the problems of surface blurring, gas mark and skin layering phenomena in the injection moulding process thereof are solved; the using requirements thereof in automotive interior and exterior decorations are met.

Owner:陈昭

Aluminum alloy shell and preparation method and individual electronic equipment

ActiveCN108265322AImprove wear resistanceImprove seismic performanceAnodisationCasings/cabinets/drawers detailsAlloy substrateAnode oxidation

Owner:BYD CO LTD

High-temperature glisten glaze and preparation method thereof

The invention discloses a high-temperature glisten glaze and a preparation method thereof. The glaze comprises, by mass, 1-16% of Al2O3, 50-75% of SiO2, 0.5-5% of CaO, 0-2% of MgO, 2-9% of K2O, 0-2% of Na2O, 2-16% of ZnO, 0-2% of PbO, 3-9% of ZrO2, 3-10% of CeO2 and 0.5-8% of B2O3. The glisten glaze is wide in application range, good in firing performance and high in stability and glisten strength; and the preparation method is reasonable and simple in technology.

Owner:威远县大禾陶瓷原料有限公司

Non-painting metallic polypropylene resin composition

ActiveUS20170335098A1Improve scratch resistanceMaintain mechanical propertiesSuperstructure subunitsDomestic articlesPolypropylenePolymer chemistry

A metallic polypropylene resin composition is provided herein. The metallic polypropylene resin composition provides appearance characteristics that are similar to those provided by painting, but without painting. The metallic polypropylene resin composition of the present invention has excellent physical properties such as scratch resistance, and thus may be applied to molding methods, such as a molded in color (MIC) method. The resin composition is useful as a material for automobile interior and exterior parts, as wells as electric and electronic products, which can be molded by the MIC method.

Owner:HYUNDAI MOTOR CO LTD +2

Preparation method of pug of stone gold purple sand utensil for softening water quality and accelerating sobering

The invention relates to a preparation method of mud of a stone gold purple sand utensil for softening water quality and accelerating sobering. The method comprises the following steps: manually selecting raw ore materials of the yellow stone scattered in a tender mud paragenic ore layer, airing and drying the weathered raw ore materials by adopting a winter-summer two-season open-air stacking natural weathering method, grinding by using a hard stone mill, crushing into 60-mesh and 80-mesh powder and 120-mesh fine powder, adding water, uniformly mixing and stirring, and sealing for ageing; andcarrying out sealed aging and three times of repeated vacuum pugging to prepare the purple sand pug of the purple sand utensil for softening water quality and accelerating sobering. According to themethod, the design color requirement is met through different firing temperatures and methods, the product quality is good, the utensil metal texture is achieved, the glass phase is extremely good, and the purpose of turning waste purple sand waste mineral aggregate into wealth can be achieved. The finished product can effectively soften the water quality, is sweet and pure to drink, improves thetaste, and has a certain health-care effect. The product can be used for quickly decanting wine drinks, and is mellow and soft in taste.

Owner:宜兴市天恩陶舍紫砂文化有限公司

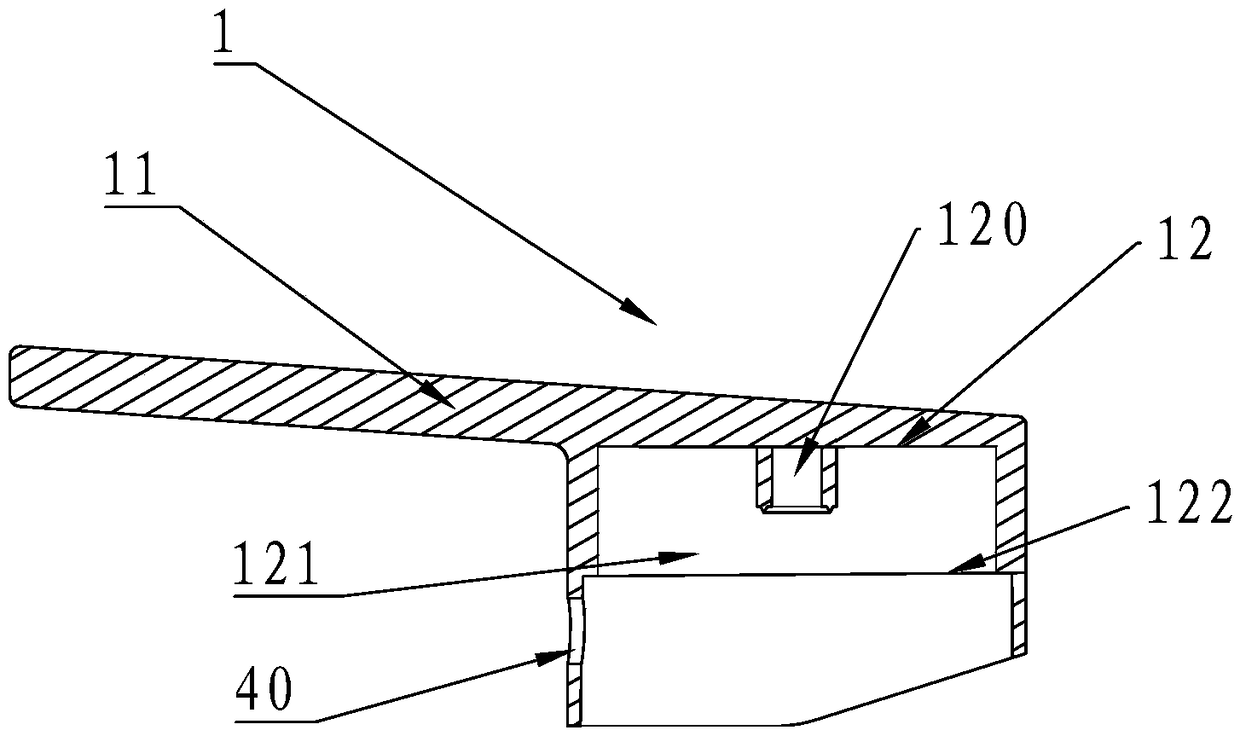

Faucet handle and machining and electroplating method thereof

InactiveCN108930833ASimple structureThe electroplating process is simpleOperating means/releasing devices for valvesEngineeringInjection moulding

The invention relates to a faucet handle. The faucet handle comprises a handle shell, a balance weight block and a fixed piece, wherein injection molding is adopted for the handle shell and the fixedpiece; the handle shell is provided with an installing hole, and comprises a handle and a faucet connection portion; the faucet connection portion is provided with a hollow containing portion; the balance weight block is arranged in the containing portion; a valve element connection head is arranged on the outer side of the fixed piece, and a positioning boss is arranged on the inner side; and thefixed piece is arranged in the containing portion on the outer side of the balance weight block and is welded to the handle shell in an interference manner. The faucet shell has the following beneficial effects that firstly, the structure is simplified, the electroplating process is simple, and cost is lower; secondly, the appearance face comprises a visible portion in the handle shell, and bothof them are very bright and clean, and the nearly perfect metal texture is achieved; thirdly, the fixed piece and the handle shell are in interference welding, so that gas tightness between the fixedpiece and the handle shell is better, and connection is more stable and reliable; and fourthly, the fixed piece is provided with an alignment groove, in the process of installing the fixed piece, thealignment groove is aligned with the installing hole, and the fixed piece can be accurately installed in place.

Owner:XIAMEN LIYE IND & TRADE CO LTD

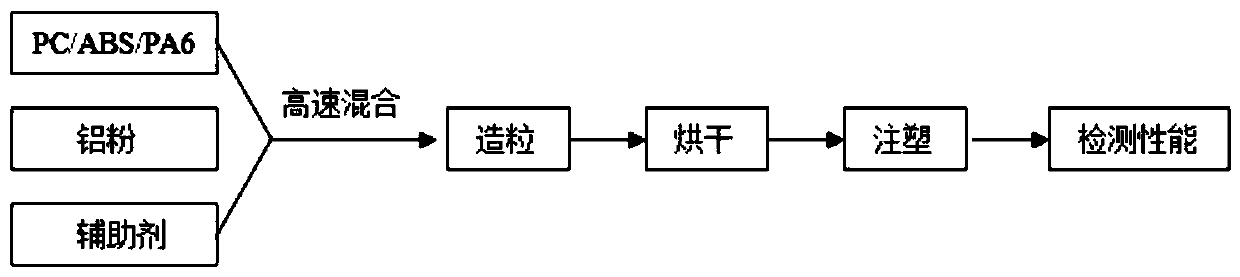

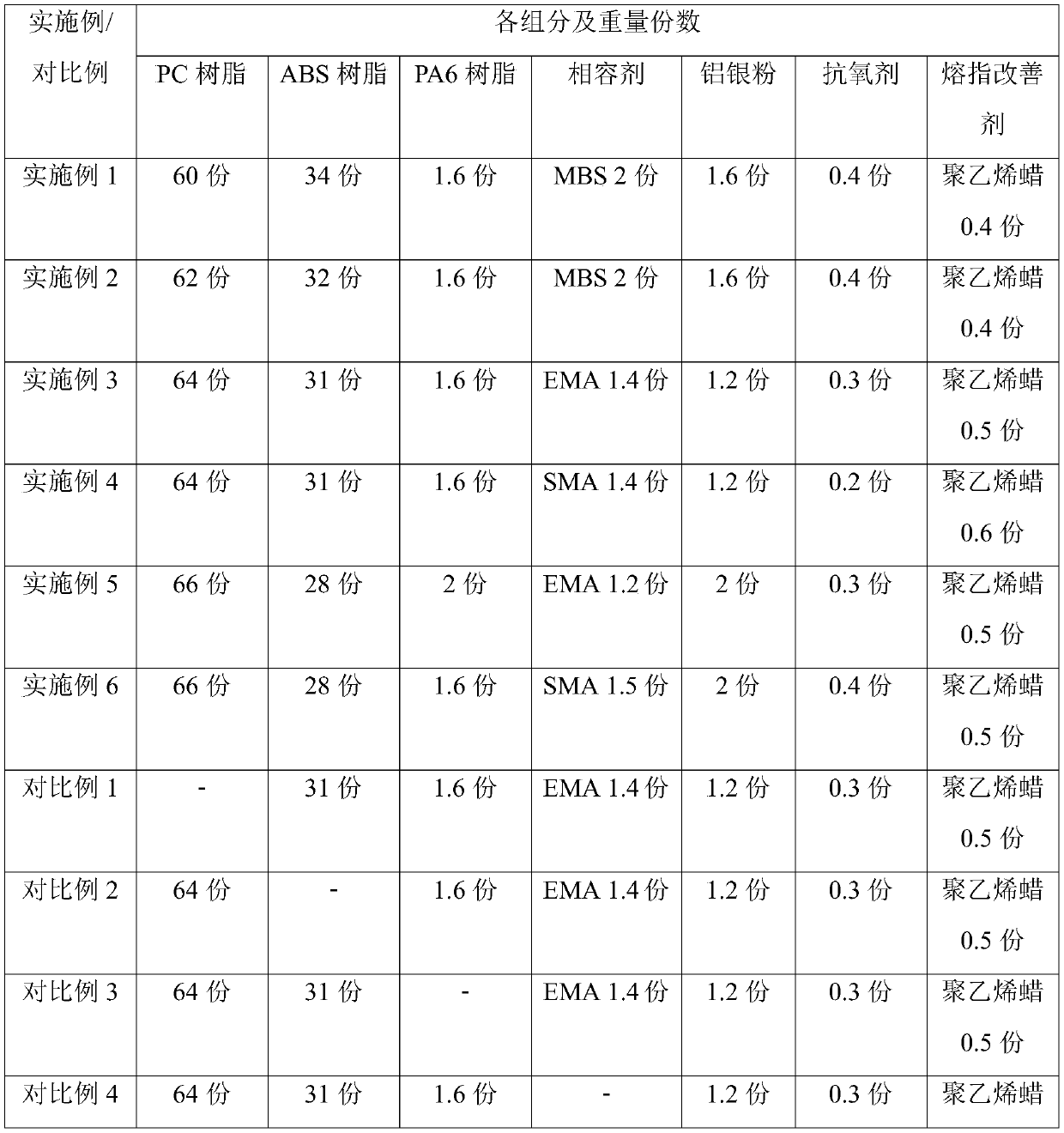

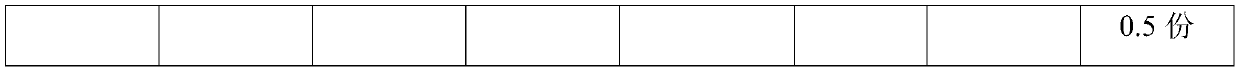

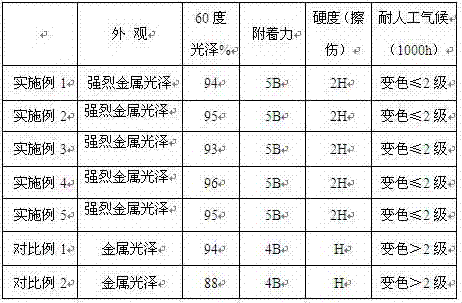

Spraying-free material and preparation method thereof

The invention provides a spraying-free material, which comprises the following components by weight: 60-70 parts of PC resin, 20-40 parts of ABS resin, 1-5 parts of PA6 resin, 1-4 parts of a compatilizer, 0.1-1 part of an antioxidant and 0.4-0.6 part of a melt index improver. The invention also provides a preparation method of the material, and the method includes: compounding the PC resin, ABS resin, PA6 resin and other auxiliary materials, and carrying out extrusion granulation. The material has the advantages of high glossiness, good metal texture, environmental protection, no toxicity andlow processing cost. Meanwhile, compared with spraying-free materials in the prior art, the material has good tensile strength and impact strength.

Owner:珠海格力绿色再生资源有限公司

Biomass water-based decorative coating with metal texture and preparation method

InactiveCN107880677ACoating Appearance AdvantagesAdvantages of wear resistanceCoatingsWater basedEmulsion

The invention provides a biomass water-based decorative coating with metal texture and a preparation method. Fish scale is dried and refined at the low temperature, the obtained fish scale and mica powder are subjected to centralized dispersion and homogenization in airflow, a biomass pigment is obtained and uniformly mixed with a water-based fluorocarbon emulsion, an acrylic emulsion, glass micropowder and water, and the biomass water-based decorative coating with metal texture is obtained. The method overcomes the defects that existing coatings with metal texture are prone to oxidation due to use of metal powder and have weak metal gloss due to use of pigments, the coating contains fish scale powder assisted with the mica powder and thus has excellent gloss and metal texture, the coatingis easy to bond with bottom surfaces, has excellent scratch resistance, has attractiveness and protection functions and has the characteristics of fullness, smoothness, high hardness, extremely highadhesion, yellowing resistance, water resistance and the like.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

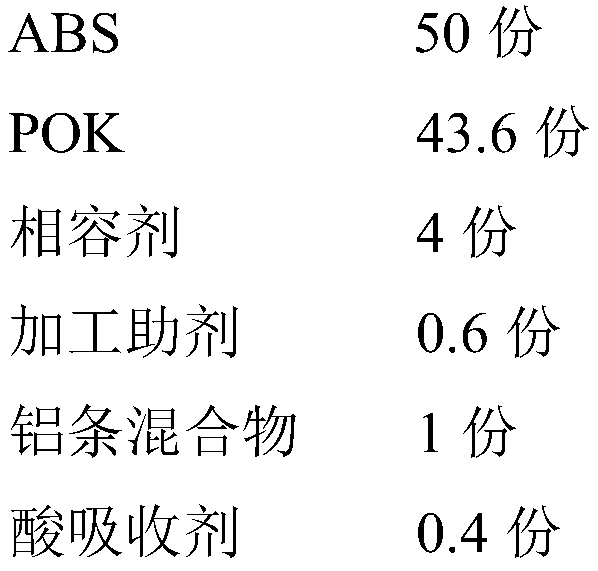

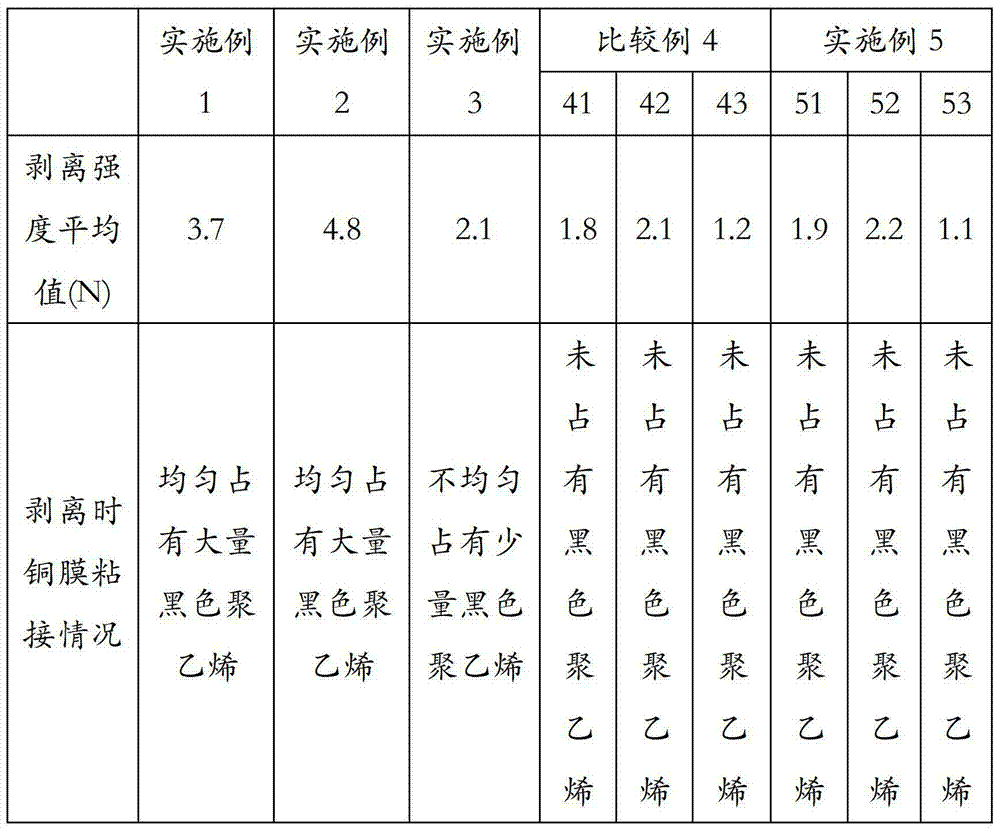

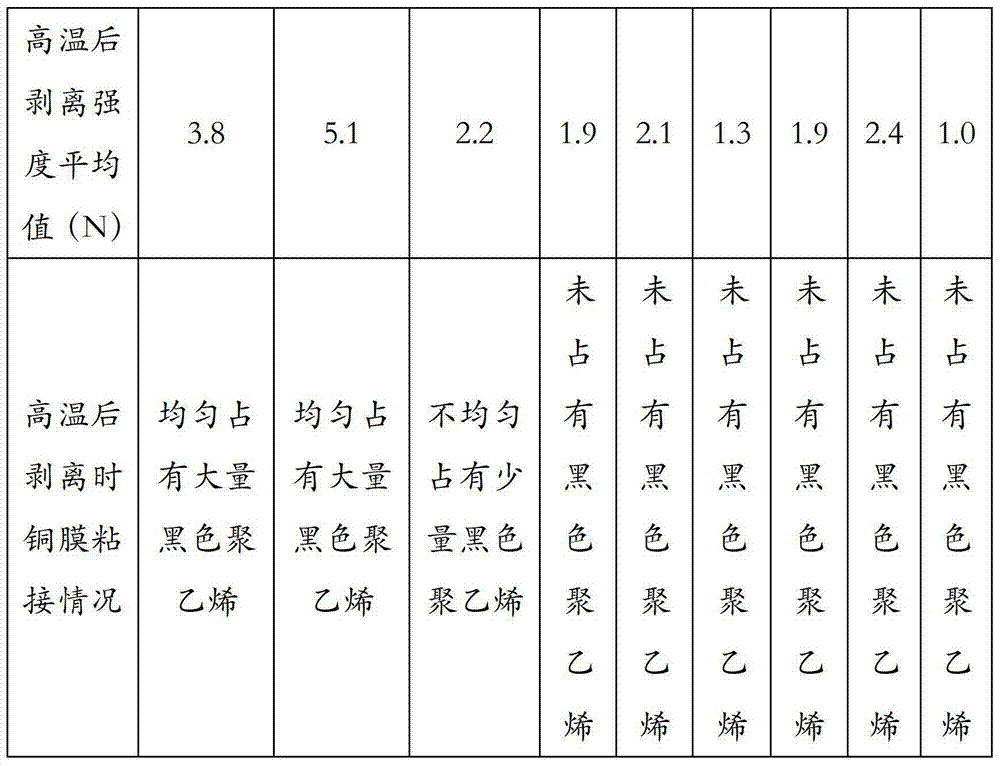

ABS/POK alloy spraying-free material and preparation method thereof

The invention discloses an ABS / POK alloy spraying-free material and a preparation method thereof, and solves the technical problems that an existing spraying-free material is not scratch-resistant, poor in product weight and narrow in application range. Every 100 parts by weight of the ABS / POK alloy spraying-free material comprises the following components: 49.5-65 parts of ABS, 30-44 parts of POK, 2-5 parts of a compatilizer, 0.2-1 part of a processing aid, 1-2 parts of an aluminum strip mixture, 0.3-0.6 part of an acid absorbent, 0.1-0.5 part of a lubricating dispersant and 0.1 part of whiteoil. The invention also provides a preparation method of the ABS / POK alloy spraying-free material.

Owner:威海联桥新材料科技股份有限公司

Method for improving joint strength of polyethylene and metalwork

ActiveCN103484028AImprove connection strengthImprove production efficiencyAdhesive processes with surface pretreatmentCross-linkPolymer science

The invention provides a method for improving joint strength of polyethylene and metalwork. The method comprises the following steps: a, subjecting polyethylene or a polyethylene compound to irradiation cross-linking; b, fusing the polyethylene or polyethylene compound having undergone irradiation cross-linking and subjecting the metalwork and the fused polyethylene or polyethylene compound to mould pressing and bonding; and c, slowly cooling to room temperature after mould pressing and bonding of the metalwork and the fused polyethylene or polyethylene compound. Or the method comprises the following steps: d, subjecting the polyethylene or polyethylene compound used for connection with the metalwork to irradiation cross-linking; and e, heating the metalwork and bonding the heated metalwork onto the surface of the polyethylene or polyethylene compound through pressurization or embedding the heated metalwork into the polyethylene or polyethylene compound. The method has the characteristics of high joint strength, high manufacturing efficiency, good product consistency, low manufacturing cost, economy, environment friendliness, etc.

Owner:SHENZHEN JINRUI ELECTRONICS MATERIAL

Plastic part metalizing process with hardware nanometer molding artwork line effect

The invention relates to a plastic part metalizing process with a hardware nanometer molding artwork line effect. The plastic part metalizing process comprises the following steps: step 1, taking a plastic base material, spraying priming paint on the surface of the plastic base material, baking, and thus obtaining a priming paint layer; step 2, spraying protective paint on the surface of the priming paint layer, baking, and thus forming a protective paint layer; step 3, spraying imitated anodized paint on the surface of the protective paint layer, baking, and thus forming a imitated anodizedpaint layer; and step 4, spraying cover paint on the surface of the imitated anodized paint layer, covering, and forming a cover paint layer. Thus, the shell of a mobile communication terminal has a good metal texture effect, the adhesive force between each coating and the plastic base material is good, and abrading and peeling are not easy. In addition, as a non-metallic material is used as the base material, the surface treatment steps of T treatment, nanometer molding, polishing, sand blasting, etc., are not needed, the processing technology is simplified, the production cycle is shortened,and further the production efficiency is improved. Moreover, the waste and overuse of metal materials are reduced.

Owner:广东以诺通讯有限公司

Powder paint composition and method for preparing same

ActiveUS9447290B2Improve textureImprove corrosion resistancePowdery paintsSpecial surfacesMaterials sciencePowder coating

Disclosed is a powder paint composition of and a method for preparing the same. More particularly, the present invention relates to a powder paint composition including a powder paint prepared by physically attaching metallic particles to a powder resin, which exhibits no separation or aggregation of metallic particles when coated and significantly improves metallic texture owing to orientation of the metallic particles, and a method for preparing the same.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com