Alloy composite material and preparing method thereof

A composite material and alloy technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of poor weather resistance, poor mechanical strength and unstable preparation process of alloy composite materials, etc. Achieve the effect of improving the utilization rate of the target material, not easy to be oxidized, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

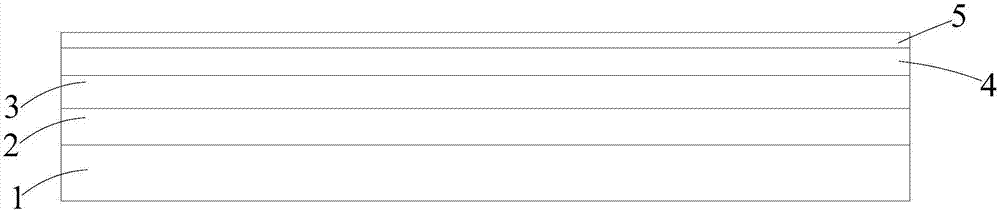

[0028] This embodiment provides an alloy composite material, including a soft substrate 1, on the surface of the soft substrate 1, a first metal layer 2, a second metal layer 3, a third metal layer 4 and The fourth metal layer 5 .

[0029] Wherein, the first metal layer 2 is a copper layer, the second metal layer 3 is a nickel layer, the third metal layer 4 is a stainless steel layer, and the fourth metal layer 5 is a zinc layer. The soft substrate 1 is polyimide (PI).

[0030] Wherein, the thickness of the first metal layer 2 is 110nm, the thickness of the second metal layer 3 is 90nm, the thickness of the third metal layer 4 is 66nm, the thickness of the fourth metal layer 5 is 90nm, the central alloy layer of the soft body substrate 1 The thickness is 355nm.

[0031] The invention has good adhesion between layers, good mechanical strength, stable preparation process, strong metal texture, good weather resistance, and the film layer is not easily oxidized when exposed to t...

Embodiment 2

[0033] The difference from Example 1 is that the first metal layer 2 is a copper layer, the second metal layer 3 is a copper-nickel alloy layer, the third metal layer 4 is a copper-nickel steel alloy layer, and the fourth metal layer 5 is a copper-nickel steel-zinc layer. alloy layer. The soft substrate 1 is polyethylene terephthalate (PET).

[0034] Among them, the thickness of the first metal layer is 113nm, the thickness of the second metal layer is 93nm, the thickness of the third metal layer is 67nm, the thickness of the fourth metal layer is 92.5nm, and the thickness of the central alloy layer of the soft substrate is 365nm .

[0035] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0037] This embodiment provides an alloy composite material, including a soft substrate 1, on the surface of the soft substrate 1, a first metal layer 2, a second metal layer 3, a third metal layer 4 and The fourth metal layer 5 .

[0038] Wherein, the first metal layer 2 is a copper layer, the second metal layer 3 is a nickel layer, the third metal layer 4 is a stainless steel layer, and the fourth metal layer 5 is a zinc layer. The soft base material 1 is polypropylene (PE).

[0039] Among them, the thickness of the first metal layer 2 is 115nm, the thickness of the second metal layer 3 is 91.3nm, the thickness of the third metal layer 4 is 67nm, and the thickness of the fourth metal layer 5 is 89.5nm. The thickness of the alloy layer was 370 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com