Manufacturing method of casing and casing manufactured therefrom

A manufacturing method and casing technology, applied in chemical instruments and methods, casing/cabinet/drawer parts, and technology for producing decorative surface effects, etc., can solve the problem of easy to be worn, easy to fall off, metal layer To solve problems such as weak bonding force, achieve good wear resistance and better use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

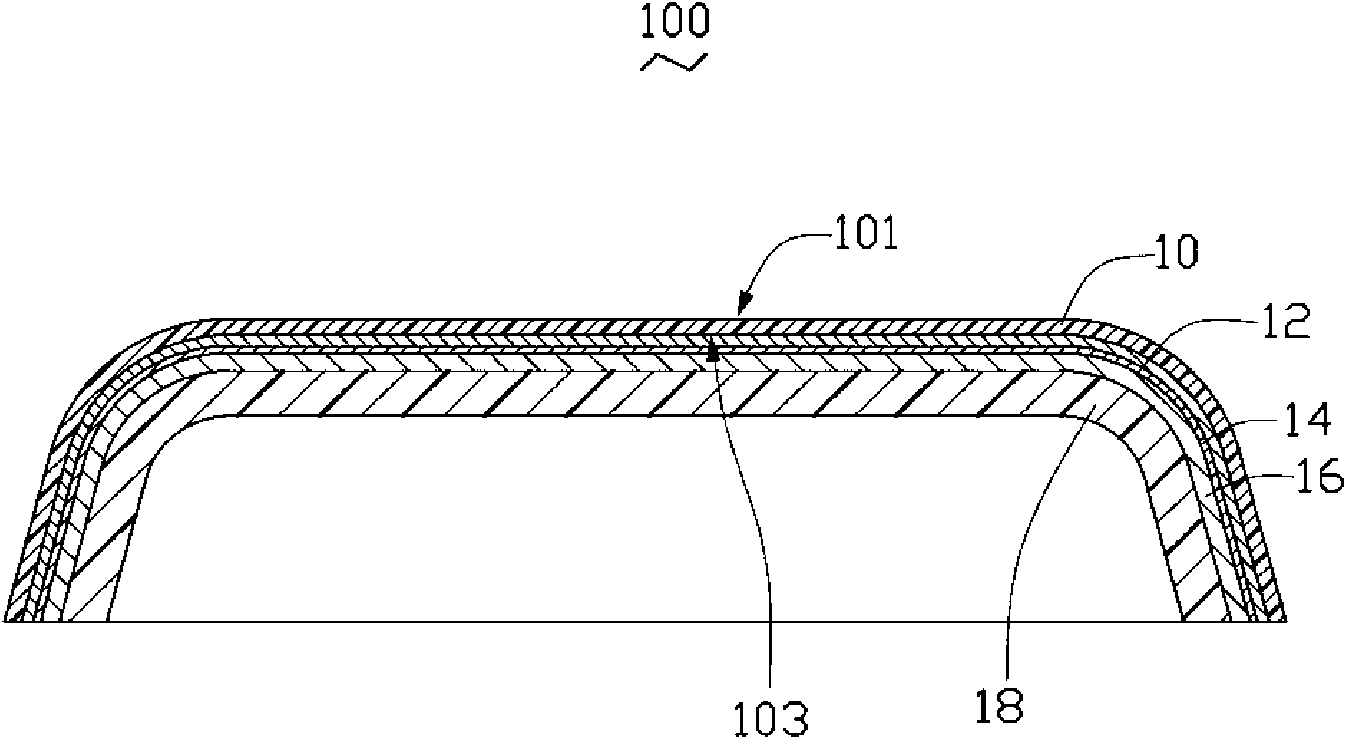

[0013] The manufacturing method of the casing of the preferred embodiment of the present invention comprises the following steps:

[0014] A transparent film is provided. The film can be made of plastic material, such as polyethylene terephthalate (PET) plastic or polycarbonate (PC) plastic. The film made of polyethylene terephthalate or polycarbonate has good abrasion resistance and high surface hardness.

[0015] A transparent or translucent decorative layer is formed on one surface of the transparent film. The decoration layer can be a transparent or translucent ink layer, which can be formed on the surface of the film by screen printing. The decorative layer can also be a transparent or translucent baking varnish layer, which can be formed on the surface of the film by means of paint spraying. The decorative layer can be colorless or colored.

[0016] A coating layer is plated on the decoration layer. The coating layer can be a coating layer with metal texture. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com