ABS/POK alloy spraying-free material and preparation method thereof

A spray-free and alloy technology, applied in the field of ABS/POK alloy spray-free materials and their preparation, can solve the problems of poor product weight, non-spray materials are not resistant to scratches, and the application range is narrow, and achieves low motion resistance and high toughness. , the effect of improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

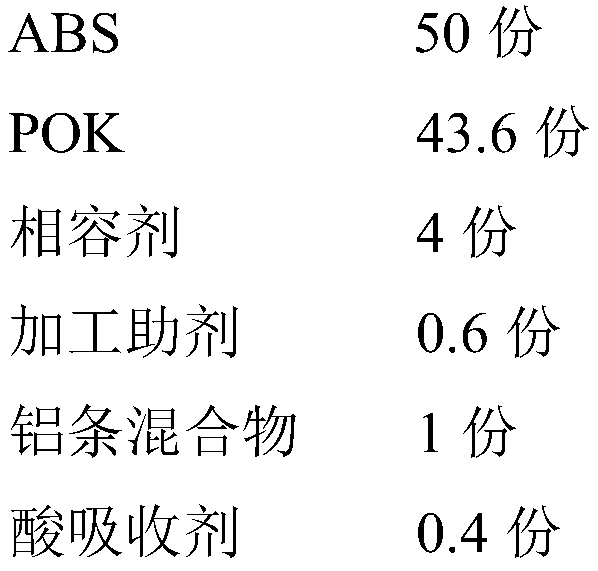

Examples

Embodiment 1~5

[0041] The preparation method of embodiment 1~5 is as follows:

[0042] (1) The raw materials ABS and POK are first placed in an oven to dry, and the moisture content of the raw materials is determined to be below 0.01%;

[0043] (2) After mixing the aluminum strip mixture corresponding to the weight portion with the lubricating dispersant, place it in a constant temperature box for use;

[0044] (3) Put the dry base materials in step (1) into the mixer together, stir at low speed (400-600r / min) for 1min, add compatibilizer while stirring, and stir at high speed (1300-1500r / min) for 1 minute Stir at low speed (400-600r / min) for 1 minute, then stir at low speed (400-600r / min) for 1 minute, add all the baked processing aids and acid absorbents, and add white oil; Stir at high speed (1300~1500r / min) for 1 minute, then turn to low speed (400~600r / min) and stir for 2 minutes;

[0045] (4) Within 5 minutes after the end of stirring, add the mixed raw materials into the twin-screw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com