Biomass water-based decorative coating with metal texture and preparation method

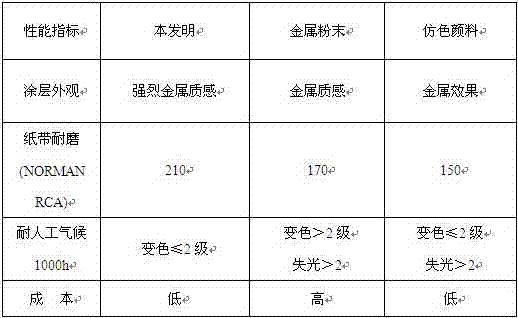

A metal texture and decorative coating technology, applied in the direction of coating, can solve the problems of weak metallic luster of pigment and easy oxidation of metal powder, and achieve the effect of excellent scratch resistance, strong adhesion and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

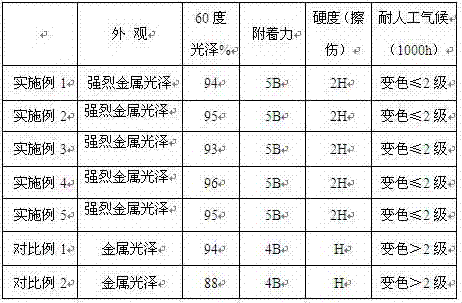

Examples

Embodiment 1

[0030] (1) The fish scales in this example are a mixture of crucian carp, grass carp, and silver carp scales. In order to obtain a better metallic luster effect, fresh fish scales are preferred. Clean the fish scales, set the power of the ultrasonic cleaner to 280W, and the ultrasonic frequency to 100KHz, clean the fish scales in the ultrasonic cleaner for 30 minutes, remove the impurities on the surface of the fish scales, take them out, rinse them again with clean water, drain them, put them in a drying box, and dry them Carry out low-temperature pulverization, the refining temperature of low-temperature pulverization is -60°C, and the particle size of the pulverized fish scale powder is 20 microns, which is filtered through a sieve to obtain fish scale powder;

[0031] (2) Take 30 parts by mass of fish scale powder, 20 parts of mica powder with particle size of 150 microns, 20 parts of water-based fluorocarbon emulsion (solid content 50%), 20 parts of acrylic emulsion (solid...

Embodiment 2

[0035] (1) In this embodiment, the fish scales are carp scales. In order to obtain a better metallic luster effect, fresh fish scales are used. Clean the fish scales, set the power of the ultrasonic cleaner to 320W, and the ultrasonic frequency to 80KHz. Clean the fish scales in the ultrasonic cleaner for 30 minutes to remove impurities on the surface of the fish scales, remove them, rinse them again with clean water, drain them, put them in a drying box, and dry them. Carry out low-temperature pulverization, the refining temperature of low-temperature pulverization is -20°C, and the particle size of the pulverized fish scale powder is 20 microns, which is filtered through a sieve to obtain fish scale powder;

[0036] (2) Take 15 parts by mass of fish scale powder, 10 parts of mica powder with particle size of 50 microns, 20 parts of water-based fluorocarbon emulsion (solid content 50%), 30 parts of acrylic emulsion (solid content 50%), particle size of 50 - 10 parts of 180 mi...

Embodiment 3

[0040] (1) The fish scales in this example are mixed with crucian carp, grass carp, and goldfish scales. In order to obtain a better metallic luster effect, fresh fish scales are preferred. Clean the fish scales, set the power of the ultrasonic cleaner to 300W, and the ultrasonic frequency to 85KHz, clean the fish scales in the ultrasonic cleaner for 45 minutes, remove the impurities on the surface of the fish scales, take them out, rinse them again with clean water, drain them, put them in a drying box, and dry them Carry out low-temperature crushing, the refining temperature of low-temperature crushing is -40°C, and the particle size of the refined fish scale powder is 70 microns, which is filtered through a sieve to obtain fish scale powder;

[0041] (2) Take 18 parts by mass of fish scale powder, 18 parts of mica powder with particle size of 120 microns, 20 parts of water-based fluorocarbon emulsion (solid content 55%), 20 parts of acrylic emulsion (solid content 50%), part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com