Quincunx-shaped elastic element and preparation method thereof

An elastic element and quincunx-shaped technology, which is applied in the field of material science, can solve the problems of low temperature brittleness and long-term heat resistance, long molding cycle of cast nylon elastomer, broken elastomer drum, etc., to achieve low production cost, The effect of widening application and adjustable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

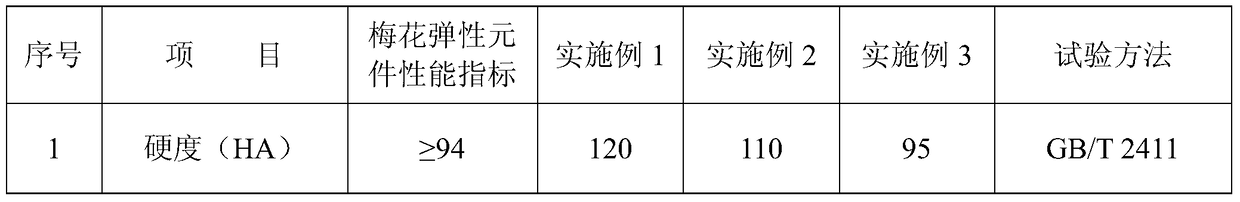

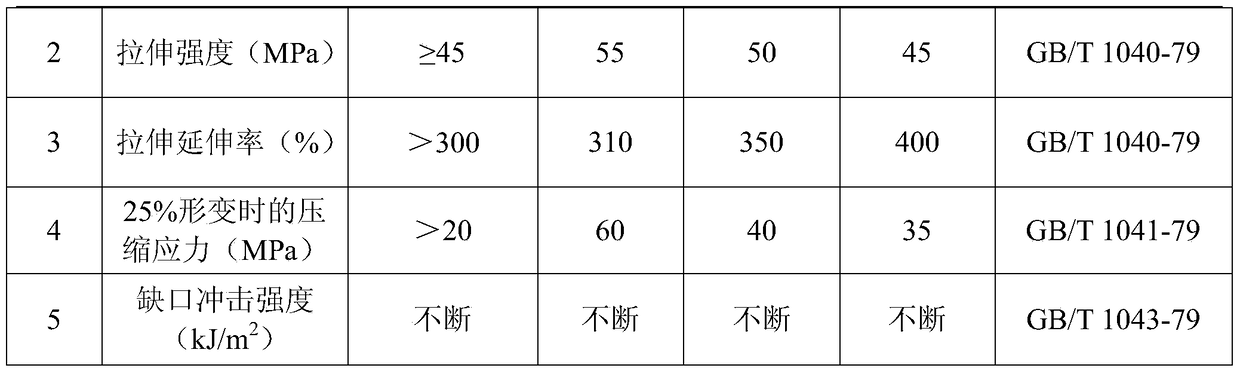

Embodiment 1

[0025] A quincunx-shaped elastic element of the present invention is prepared by reaction injection molding from 100 parts by weight of lactam, 6 parts by weight of catalyst and 20 parts by weight of block prepolymer.

[0026] In this embodiment, the lactam is specifically caprolactam, and the catalyst is specifically caprolactam magnesium bromide. The block prepolymer is prepared by polymerizing polytetramethylene glycol and toluene diisocyanate, wherein the ratio of the hydroxyl group contained in polytetramethylene glycol to the NCO group contained in toluene diisocyanate is 1:1. The number average molecular weight of the block prepolymer was 8,000.

[0027] A method for preparing the quincunx-shaped elastic element of the above-mentioned present embodiment, comprising the following steps:

[0028] (1) take caprolactam, caprolactam magnesium bromide and block prepolymer by above-mentioned parts by weight;

[0029] (2) Put 6 parts of catalyst and 50 parts of caprolactam in...

Embodiment 2

[0033] A quincunx-shaped elastic element of the present invention, the quincunx-shaped elastic element is injected by reaction by 100 parts by weight of lactam (90 parts of caprolactam and 10 parts of laurolactam), 8 parts by weight of catalyst and 30 parts by weight of block prepolymer The molding method is prepared.

[0034] In this example, the lactam is specifically a mixture of caprolactam and laurolactam, the catalyst is specifically sodium caprolactam, and the block prepolymer is prepared by polymerization of polyglycerol and triphenylmethane triisocyanate, wherein polyglycerol The ratio of the amount of the hydroxyl group contained in the alcohol to the NCO group contained in the triphenylmethane triisocyanate is 1:0.8. The number average molecular weight of this block prepolymer was 15,000.

[0035] A method for preparing the quincunx-shaped elastic element of the above-mentioned present embodiment, comprising the following steps:

[0036] (1) Take caprolactam, laur...

Embodiment 3

[0040] A quincunx-shaped elastic element of the present invention is prepared by reaction injection molding from 100 parts by weight of lactam, 10 parts by weight of catalyst and 35 parts by weight of block prepolymer.

[0041] In this example, the lactam is specifically caprolactam, the catalyst is specifically caprolactam magnesium bromide, and the block prepolymer is prepared by polymerization of pentaerythritol and isophthalyl caprolactam, wherein the hydroxyl group contained in pentaerythritol and isophthaloyl The ratio of the amount of imide group contained in formyl caprolactam to substance is 1:1.3. The number average molecular weight of the block prepolymer was 25,000.

[0042] A method for preparing the quincunx-shaped elastic element of the above-mentioned present embodiment, comprising the following steps:

[0043] (1) take caprolactam, caprolactam magnesium bromide and block prepolymer by above-mentioned parts by weight;

[0044] (2) Put 10 parts of catalyst and 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com