Ceramic tile chamfering grinding piece and production method thereof

A grinding and chamfering technology, applied in abrasives, grinding devices, grinding/polishing equipment, etc., can solve the problems of low cost performance, environmental pollution, short service life, etc., to achieve environmental protection, good wear resistance, sharp good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

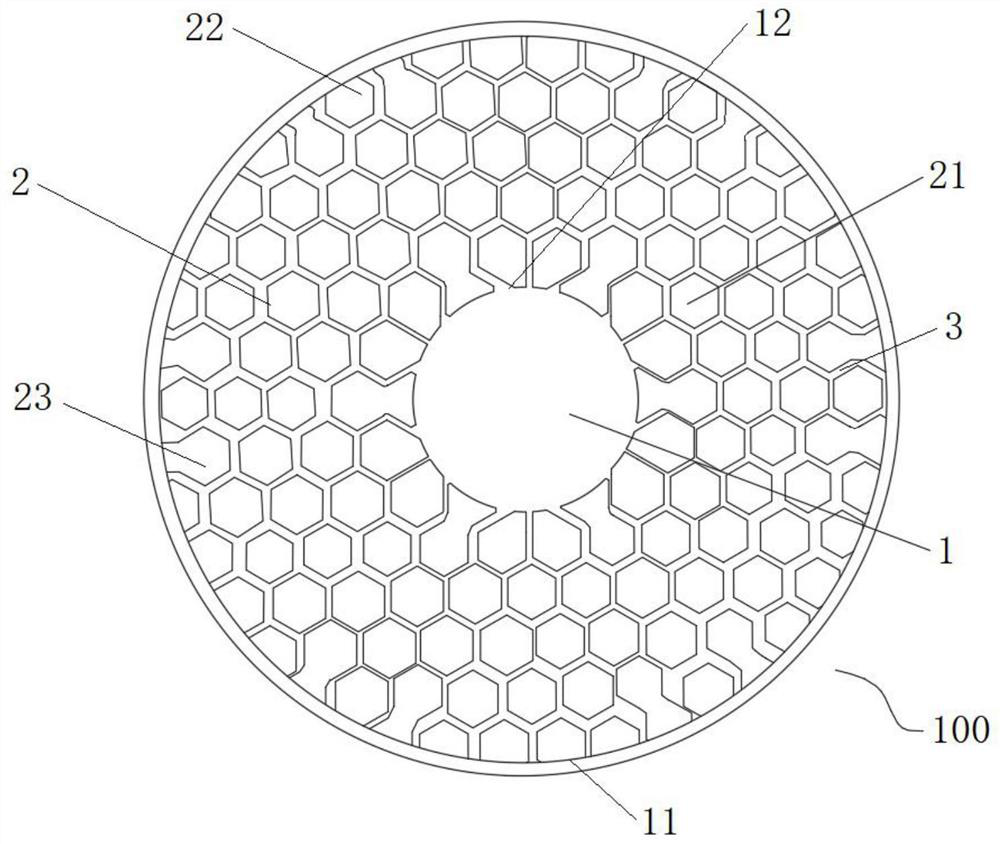

[0044] As a preferred embodiment, the grinding plate includes the following components by weight percentage: 50-60% of bonding agent, 10-15% of diamond abrasive and 20-30% of filler.

[0045] As a preferred embodiment, the filler includes 10% to 15% of cerium oxide, 20% to 30% of cryolite and 10% to 15% of titanium dioxide by weight percentage. Cerium oxide can significantly improve the smoothness after chamfering; cryolite is good for heat dissipation during grinding; titanium dioxide bleaches the color of the product, and avoids staining when chamfering tiles.

[0046] As a preferred embodiment, the filler also includes one component or two or more components of aluminum oxide, zinc oxide and calcium carbonate in parts by weight, which is mainly to increase the service life and reduce the cost.

[0047] As a preferred embodiment, the filler further includes 30%-40% aluminum oxide and 10%-15% calcium carbonate by weight.

[0048] As a preferred embodiment, the filler further i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com