A method for strengthening the surface of metal materials by using a laser machine

A metal material and surface strengthening technology, applied in metal material coating technology, laser welding equipment, metal processing equipment, etc., can solve the problems of high brittleness, inconvenient production and use, and insufficient strength of tungsten-cobalt cemented carbide. Effects of Corrosive Advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

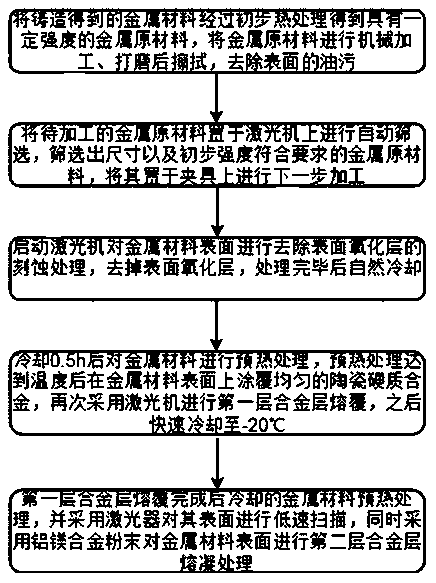

[0022] Such as figure 1 as shown, figure 1 It is a flow chart of Embodiment 1 of using a laser machine to strengthen the surface of a metal material in the present invention, a method for using a laser machine to strengthen the surface of a metal material, and the specific production method is as follows:

[0023] Step 1: Preliminarily heat-treat the cast metal material to obtain a metal raw material with a certain strength, machine the metal raw material, polish it, and then wipe it to remove oil stains on the surface;

[0024] Step 2, put the metal raw materials to be processed on the laser machine for automatic screening, screen out the metal raw materials whose size and preliminary strength meet the requirements, and place them on the fixture for the next step of processing;

[0025] Step 3, start the laser machine to etch the surface of the metal material to remove the surface oxide layer, remove the surface oxide layer, and cool naturally after the treatment;

[0026] ...

Embodiment 2

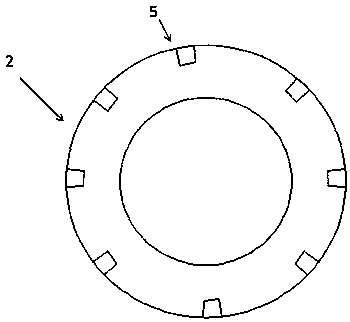

[0032] Figure 2-3 It is a schematic diagram of the core structure of Embodiment 2 of the present invention, the core of the mold can be processed by the laser machine in the above embodiment 1 to strengthen the surface of the metal material, such as figure 2 As shown, the core after machining and molding also includes stress grooves 5. Since the boss 2 is matched with the molded parts, the deformation of thermal expansion and contraction generated after the molded parts are formed and cooled will be concentrated on the bosses. 2 and the junction of the cylinder 1 may cause damage such as bending of the cylinder 1 or cracks caused by stress fracture at the junction of the cylinder 1 in severe cases. It can prevent damage caused by stress concentration on the surface of the joint. A plurality of stress grooves 5 are uniformly arranged along the circumference of the boss 2 . In order to prevent the core body from being damaged by stress during mechanical cutting when opening ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com