Spray-free polypropylene material for automotive exterior decorations and preparation technology thereof

A polypropylene material and preparation process technology, applied in the field of polypropylene materials, can solve the problems of restricting the application of spray-free polypropylene composite materials, unqualified appearance of products, etc., achieve good gloss and metallic texture, improve surface quality, and simplify the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

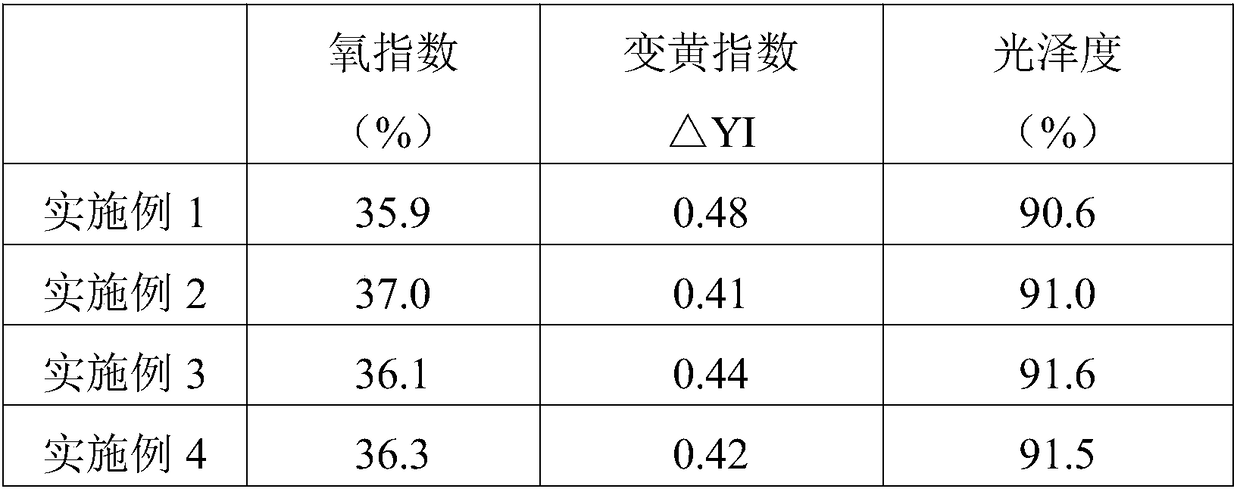

Embodiment 1

[0041] Spray-free polypropylene material for automotive exteriors, prepared from the following mass percentages of raw materials: 2.3% silver powder, 1.2% pearl powder, 3% ethylene-ethyl acrylate, 9% talc, 0.25% triethylene glycol ether -Bis(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate, 0.3% N,N'-ethylene bisstearamide, 6% polymer type phosphorus flame retardant, 0.2 %1-bromo-5,5-dimethylhydantoin, 0.25% 5-chloro-2-(((dimethylamino)methylene)amino)benzophenone, the balance is polypropylene.

[0042] The preparation process of the above-mentioned spray-free polypropylene material for automobile exteriors includes the following steps:

[0043] (1) Add the raw materials to the mixer and stir and mix for 8 minutes at a speed of 1000r / min to obtain a mixture;

[0044] (2) Put the mixture into a twin-screw extruder, melt and extrude the strips, cool with water, blow off the water on the surface of the strips, and cut into cylindrical pellets with a diameter of 3mm×3mm to obtain automo...

Embodiment 2

[0046] Spray-free polypropylene material for automotive exteriors, prepared from the following mass percentages of raw materials: 2.3% silver powder, 1.2% pearl powder, 3% ethylene-ethyl acrylate, 9% modified talc, 0.25% triethylene Alcohol ether-bis(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate, 0.3% N,N'-ethylene bisstearamide, 6% polymer type phosphorus-containing flame retardant , 0.2% 1-bromo-5,5-dimethyl hydantoin, 0.25% 5-chloro-2-(((dimethylamino)methylene)amino)benzophenone, the balance is polypropylene.

[0047] The modified talc powder was prepared by the following method: 100g talc powder was added to 1000g deionized water, and then 25.2g ammonium carbonate and 4.7g cerium nitrate were added at a rotational speed of 300r / min for 10min, and then 0.06mol / L hydrochloric acid Adjust the pH to 4, continue stirring at a temperature of 90°C at 300r / min for 60 minutes, centrifuge at a speed of 6000r / min for 20 minutes, and roast the precipitate in 100% steam at a temperat...

Embodiment 3

[0052] Spray-free polypropylene material for automotive exteriors, prepared from the following mass percentages of raw materials: 2.3% silver powder, 1.2% pearl powder, 3% ethylene-ethyl acrylate, 9% modified talc, 0.25% triethylene Alcohol ether-bis(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate, 0.3% N,N'-ethylene bisstearamide, 6% polymer type phosphorus-containing flame retardant , 0.2% 1-bromo-5,5-dimethyl hydantoin, 0.25% 5-chloro-2-(((dimethylamino)methylene)amino)benzophenone, the balance is polypropylene.

[0053] The modified talc powder was prepared by the following method: 100g talc powder was added to 1000g deionized water, and then 25.2g ammonium carbonate and 4.7g cerium nitrate were added at a rotational speed of 300r / min for 10min, and then 0.06mol / L hydrochloric acid Adjust the pH to 4, continue stirring at a temperature of 90°C at 300r / min for 60 minutes, centrifuge at a speed of 6000r / min for 20 minutes, and roast the precipitate in 100% steam at a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com