Spraying-free material and preparation method thereof

A spray-free and resin-free technology, applied in the field of spray-free materials and their preparation, can solve problems such as flow marks, mechanical property decline, weld marks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

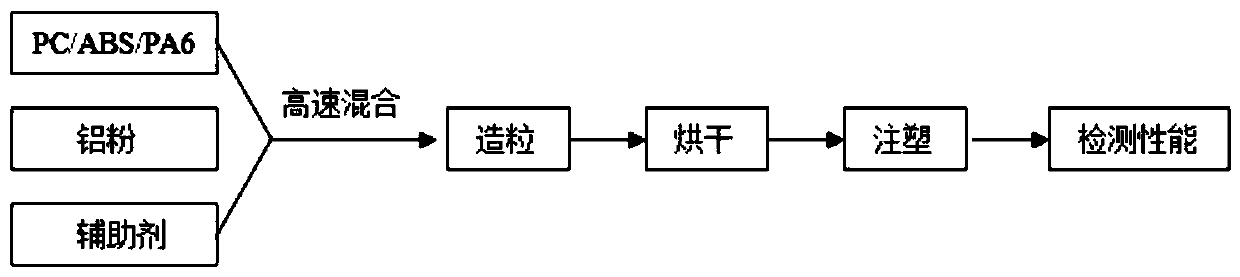

[0043] The present invention also relates to the preparation method of spray-free material, its flow chart is as follows figure 1 As shown, including the above-mentioned components, namely PC resin, ABS resin, PA6 resin, compatibilizer, antioxidant and melt index improver, adding aluminum silver powder according to the situation, mixing evenly, granulating, and drying to obtain The spray-free material of the present invention.

[0044] In one embodiment of the present invention, the mixing is performed by a high-speed mixer, and the mixing time is 1-2 minutes. High-speed mixers generally refer to high-speed mixers in the plastics industry, which are suitable for mixing powders, granules, additives, toners, masterbatches, plastics and other materials. The barrel adopts an arc-shaped structure, and the special blade structure is mainly used to make the material form a vortex-like high-speed stirring, and can be modified by heating.

[0045] In one embodiment of the present inv...

experiment example

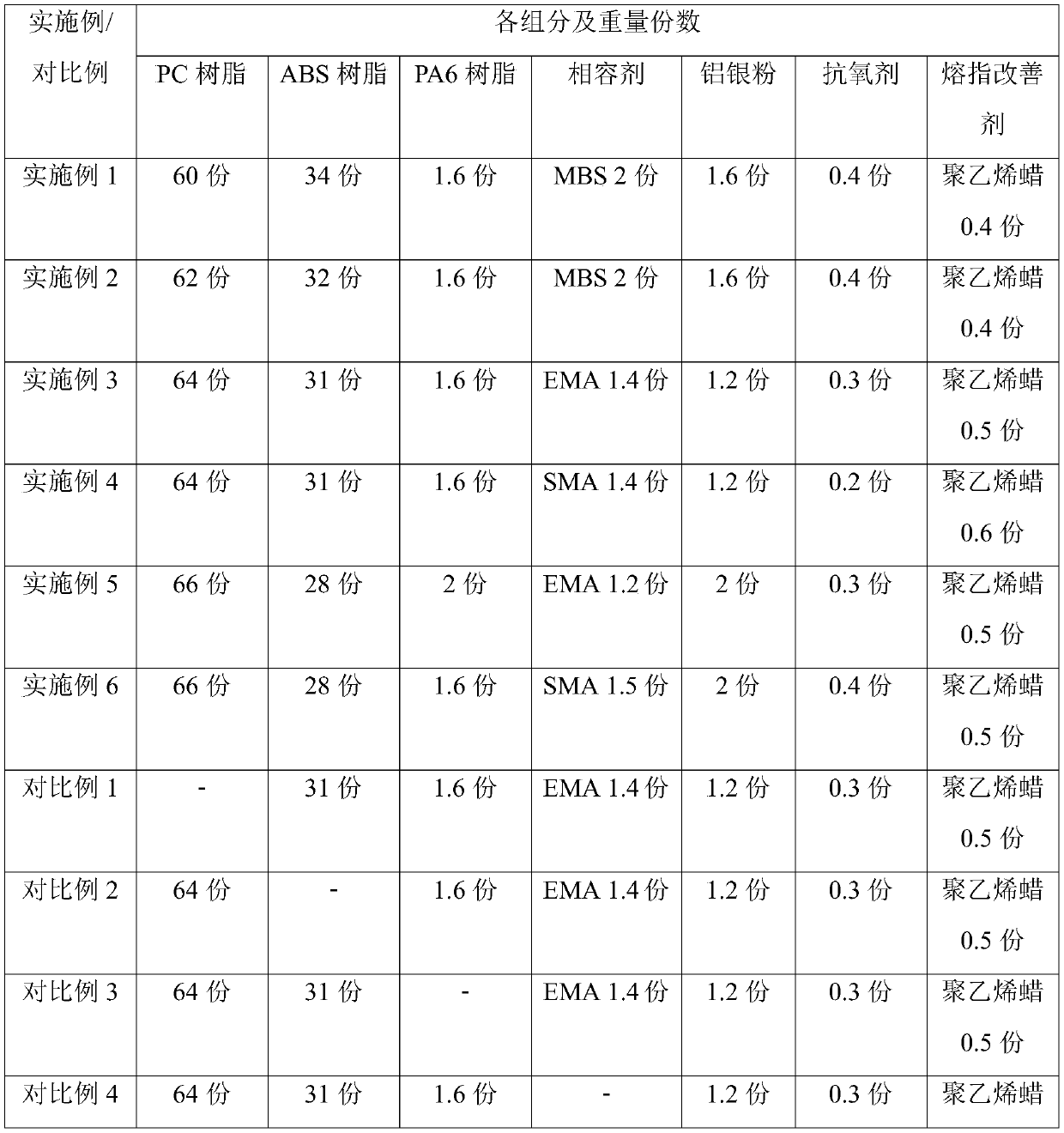

[0047] Pour the resin and other auxiliary materials into a high-speed mixer and mix for 1-2 minutes, then granulate through a twin-screw extruder, and the extrusion processing temperature is 210-235°C. See Table 1 for the proportions of each component of Examples 1-5 and Comparative Examples 1-3.

[0048] Table 1

[0049]

[0050]

[0051] "-" in Table 1 means no addition. Examples 1-6 and Comparative Examples 1-4 use compound antioxidants, and the mass ratio of antioxidant 1010 to antioxidant 168 is 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com