Free-spraying polyamide resin with metal effect, and preparation method thereof

A polyamide resin and metal effect technology, which is used in the field of polyamide resin with metal effect without spraying and its preparation, can solve the problem of poor compatibility between metal pigments and polyamide resin, uneven dispersion of metal pigments, flow marks of injection products, etc. problems, to improve compatibility and dispersion, reduce processing costs and ecological environment pollution, reduce flow marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

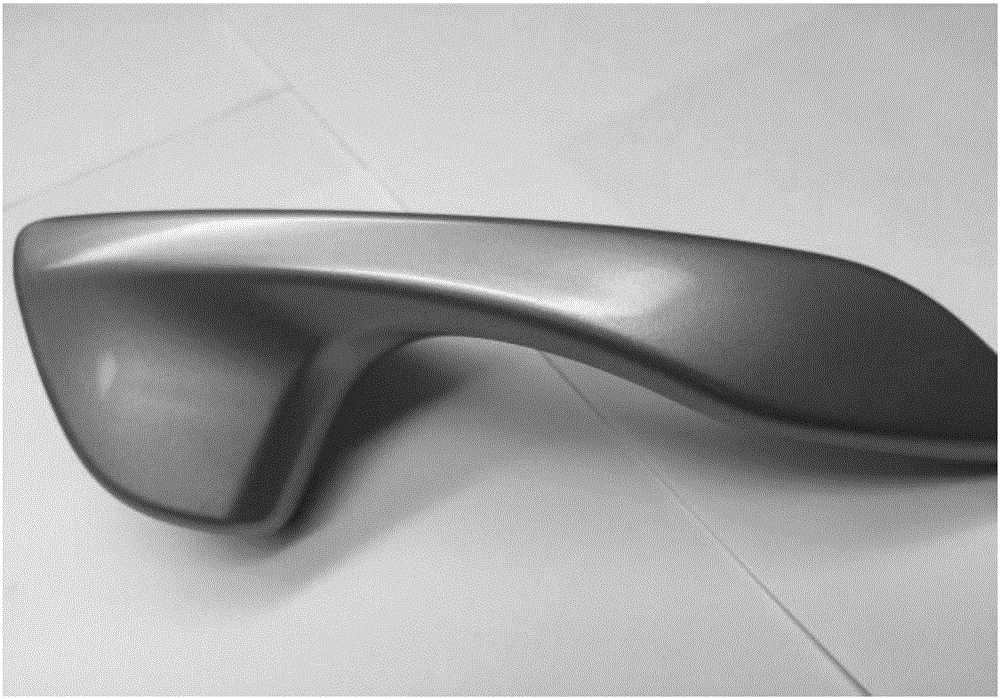

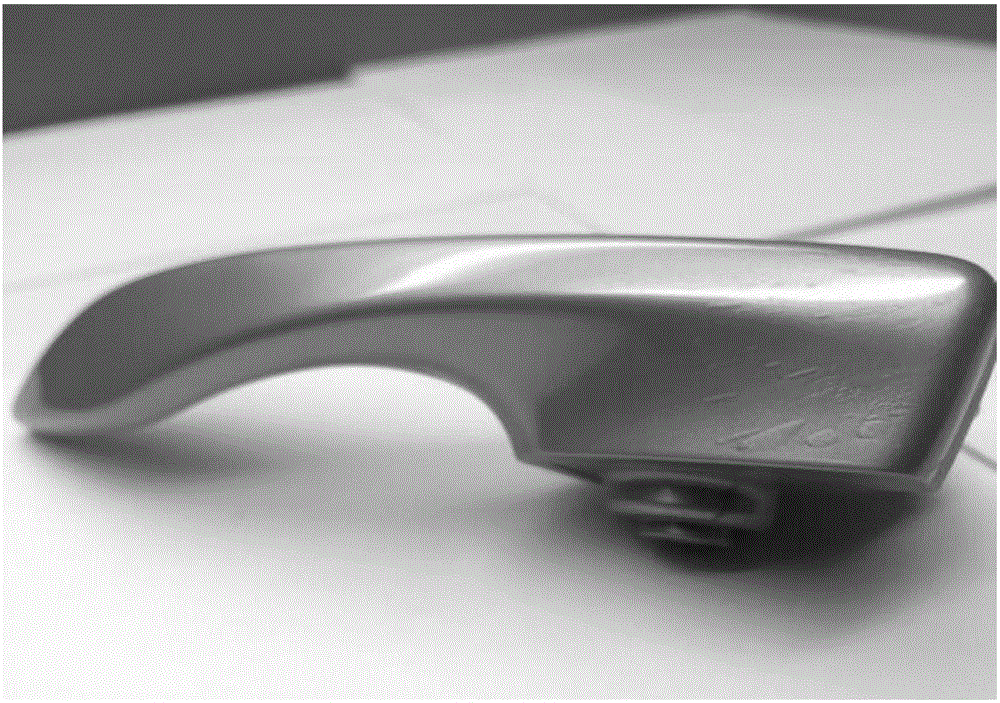

Image

Examples

Embodiment 1

[0083] A polyamide resin, which is compounded according to the following raw material ratio:

[0084]

[0085]

[0086] Among them, the metallic color pigment is copper powder, the lubricant is polyethylene wax, the coupling agent is silane coupling agent KH550, the antioxidant is 0.2 part of antioxidant 168 and 0.2 part of antioxidant 1010.

[0087] Prepare as follows:

[0088] Mix the metallic color pigment, coupling agent and zinc stearate in a high-speed mixer, and blend for 3 minutes at a speed of 220r / min to obtain the first mixture; mix polyamide, lubricant and antioxidant at high speed In the mixer, blend for 2 minutes at a speed of 320r / min to obtain the second mixture; add the first mixture and the second mixture into the twin-screw extruder, and then pass through nine hot zones for melt blending , Set the speed of the twin-screw extruder to 400r / min, the temperature of the first hot zone is 210°C, the temperature of the second hot zone is 225°C, the temperature of the thi...

Embodiment 2

[0091] A polyamide resin, which is compounded according to the following raw material ratio:

[0092]

[0093]

[0094] The metallic pigment is aluminum powder, the lubricant is ethylene bisstearic acid amide, the coupling agent is silane coupling agent Z-601, and the antioxidant is 0.2 part of antioxidant 168 and 0.1 part of antioxidant 1010.

[0095] Prepare as follows:

[0096] Mix the metallic pigment, coupling agent and zinc stearate in a high-speed mixer, and blend for 4 minutes at a speed of 250r / min to obtain the first mixture; mix polyamide, lubricant and antioxidant at high speed In the mixer, blend for 6 minutes at a speed of 350r / min to obtain a second mixture; add the first mixture and the second mixture into the twin-screw extruder, and then pass through nine hot zones for melt blending , Set the speed of the twin-screw extruder to 450r / min, the temperature of the first hot zone is 220°C, the temperature of the second hot zone is 230°C, the temperature of the third hot...

Embodiment 3

[0099] A polyamide resin, which is compounded according to the following raw material ratio:

[0100]

[0101]

[0102] The metallic pigment is pearl powder, the lubricant is stearic acid monoglyceride, the coupling agent is silane coupling agent Z-6020, and the antioxidant is 0.1 part of antioxidant 1076.

[0103] Prepare as follows:

[0104] Mix the metallic pigment, coupling agent and zinc stearate in a high-speed mixer, and blend for 5 minutes at a speed of 260r / min to obtain the first mixture; mix polyamide, lubricant and antioxidant at high speed In the mixer, blend for 10 minutes at a speed of 380r / min to obtain the second mixture; add the first mixture and the second mixture to the twin-screw extruder, and then pass through nine hot zones for melt blending , Set the speed of the twin-screw extruder to 500r / min, the temperature of the first hot zone is 225°C, the temperature of the second hot zone is 235°C, the temperature of the third hot zone is 245°C, and the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com