Resin molded body and method of manufacturing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

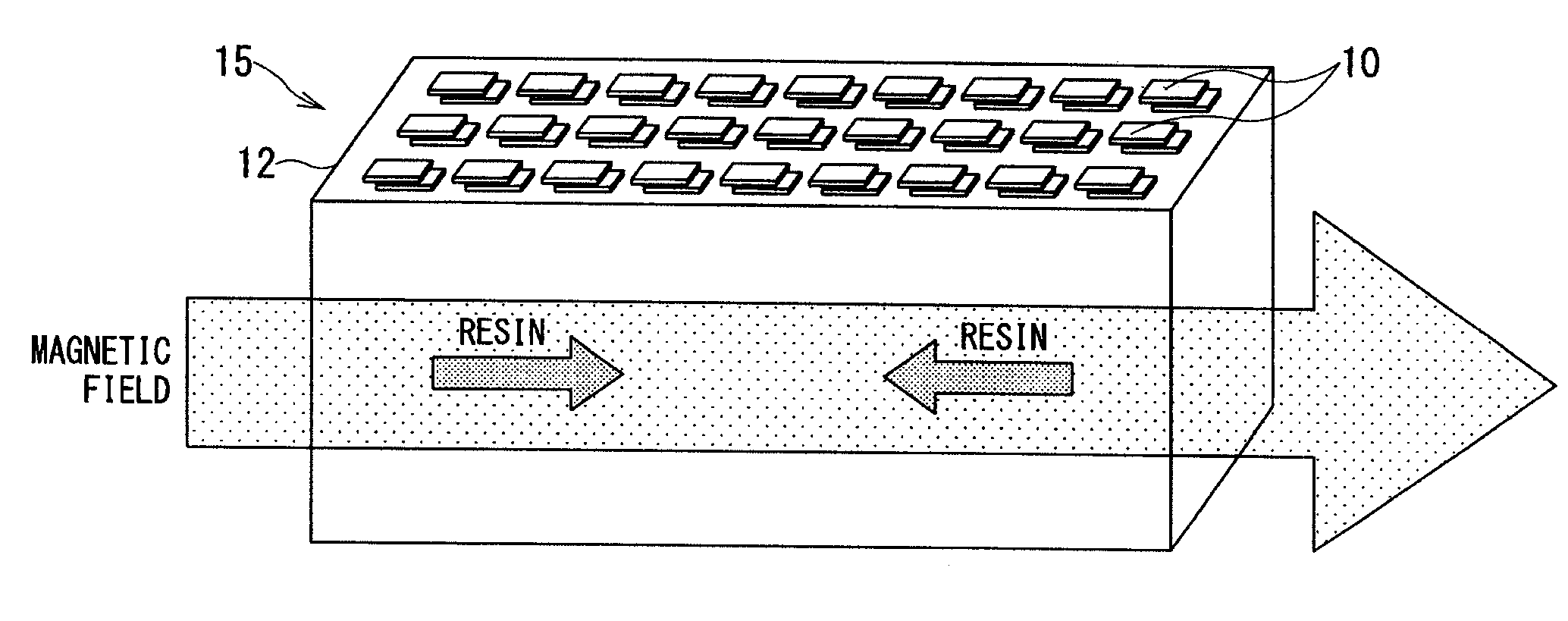

Method used

Image

Examples

example 1

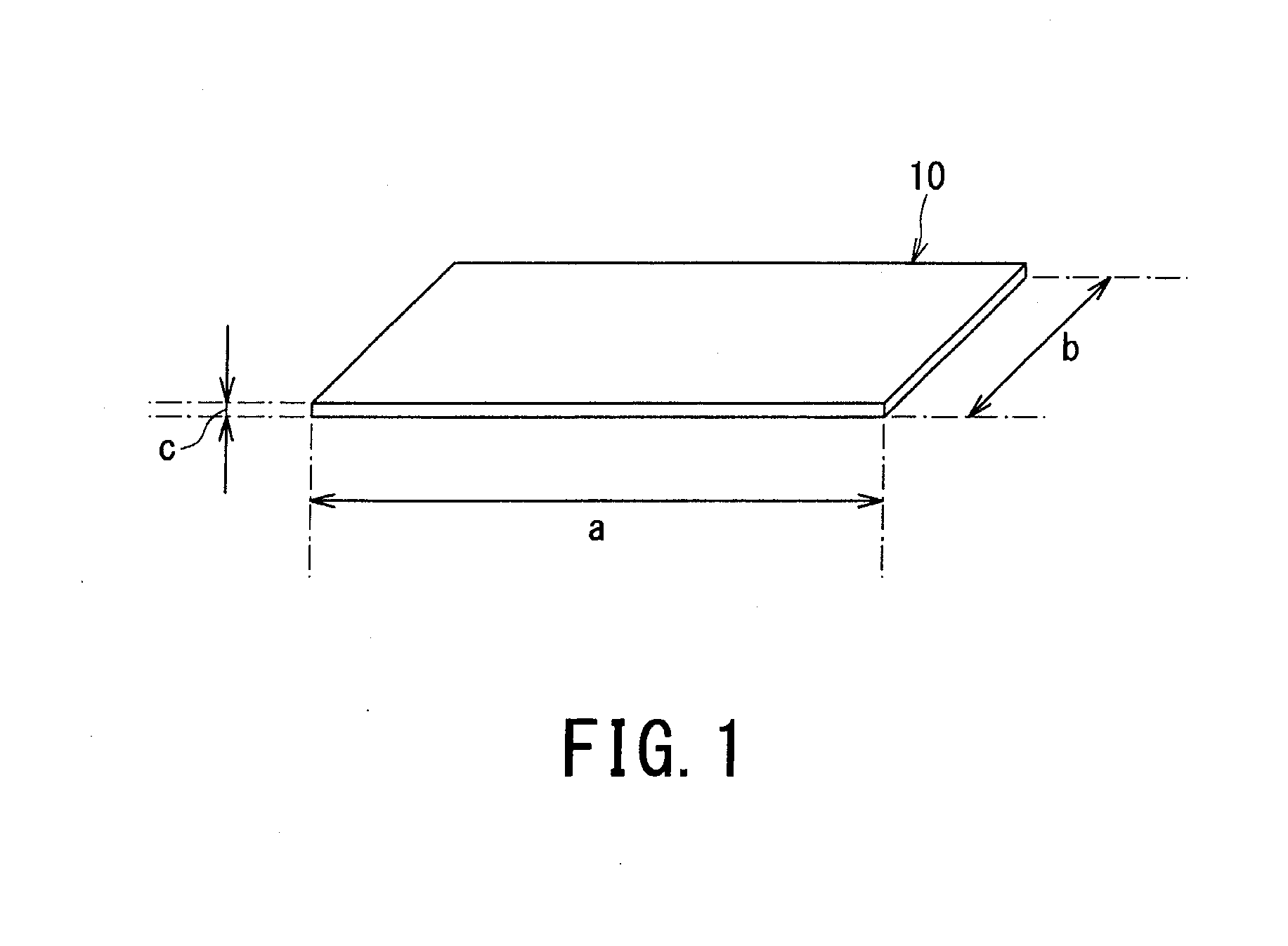

[0139]A room-temperature curing-type liquid silicone rubber having a viscosity of 100 Pa·s was prepared for the resin material as the sample 26. Scale-like PC permalloy flakes having an average particle diameter of 24 μm and an aspect ratio of 40 were prepared for the ferromagnetic glittering agent 10. Then, the prepared ferromagnetic glittering agent 10 was added and uniformly dispersed into the prepared sample 26 to thereby obtain a slurry. The addition rate of the ferromagnetic glittering agent 10 was as low as 10 wt % or less, for example, 2 wt %. The slurry thus obtained was poured into the non-magnetic glass container 25 (mold cavity) having a diameter of 20 mm and a thickness of 2 mm, and the container 25 was set on the rotating table 20 of the rotating magnetic field apparatus 15 illustrated in FIGS. 8A and 8B. In this state, an experiment was carried out.

[0140]Then, in the rotating magnetic field apparatus 15 illustrated in FIGS. 8A and 8B, a rotating magnetic field was app...

example 2

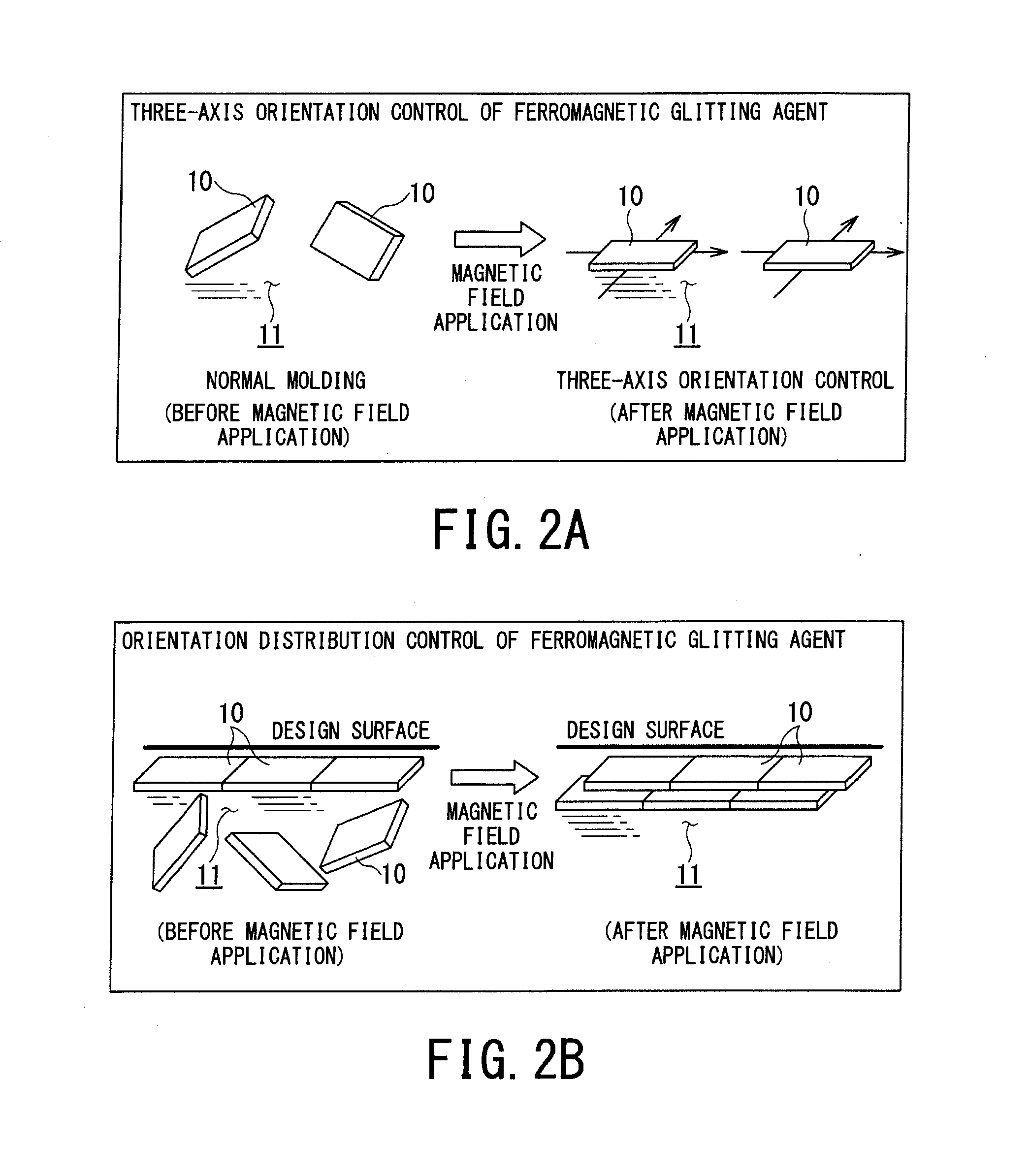

[0152]With regard to the three-axis orientation control on the ferromagnetic glittering agent, an experiment was carried out using the rotating magnetic field apparatus 16 illustrated in FIGS. 9A and 9B, in order to prove that the ab surfaces of all the particles of the ferromagnetic glittering agent 10 added to the resin material as the sample 26 faced the upper surface of the sample 26 (three-axis orientation control state). In the rotating magnetic field apparatus 16, the sample 26 was set in the area between the magnetic poles 17 and 18, the area having a uniform magnetic field without a magnetic field gradient. The experiment was carried out using the rotating magnetic field apparatus 16 under the condition that only the three-axis orientation control was performed on the permalloy flakes as the ferromagnetic glittering agent 10 added to the molten resin 11.

[0153]The scale-like PC permalloy flakes (ferromagnetic glittering agent 10) having an average particle diameter of 24 μm ...

example 3

[0155]With regard to the orientation distribution control on the ferromagnetic glittering agent, a corroborative experiment concerning shift movement was carried out using the PC permalloy flakes as the ferromagnetic glittering agent 10 of Example 1, in order to prove that the orientation (alignment) distribution of the ferromagnetic glittering agent 10 is controlled inside of the molten resin 11 of the sample 26.

[0156]In Example 3, the scale-like PC permalloy flakes (ferromagnetic glittering agent 10) having an average particle diameter of 24 μm and an aspect ratio of 40 were added and uniformly dispersed into a room-temperature curing liquid silicone rubber (resin material) having a viscosity of 100 Pa·s, thus obtaining a slurry.

[0157]The addition rate of the ferromagnetic glittering agent 10 was low, for example, 2 wt %. Further, an additive-free room-temperature curing liquid silicone rubber was set on the slurry thus obtained. Under this condition, the same experiment as that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Angular velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com