Ultraviolet-curing gradient color electroplating intermediate paint

A gradient color, ultraviolet light technology, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of deep paint curing, film performance decline, incomplete paint deep curing, etc., to avoid oxygen inhibition. , Improve curing conditions, good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

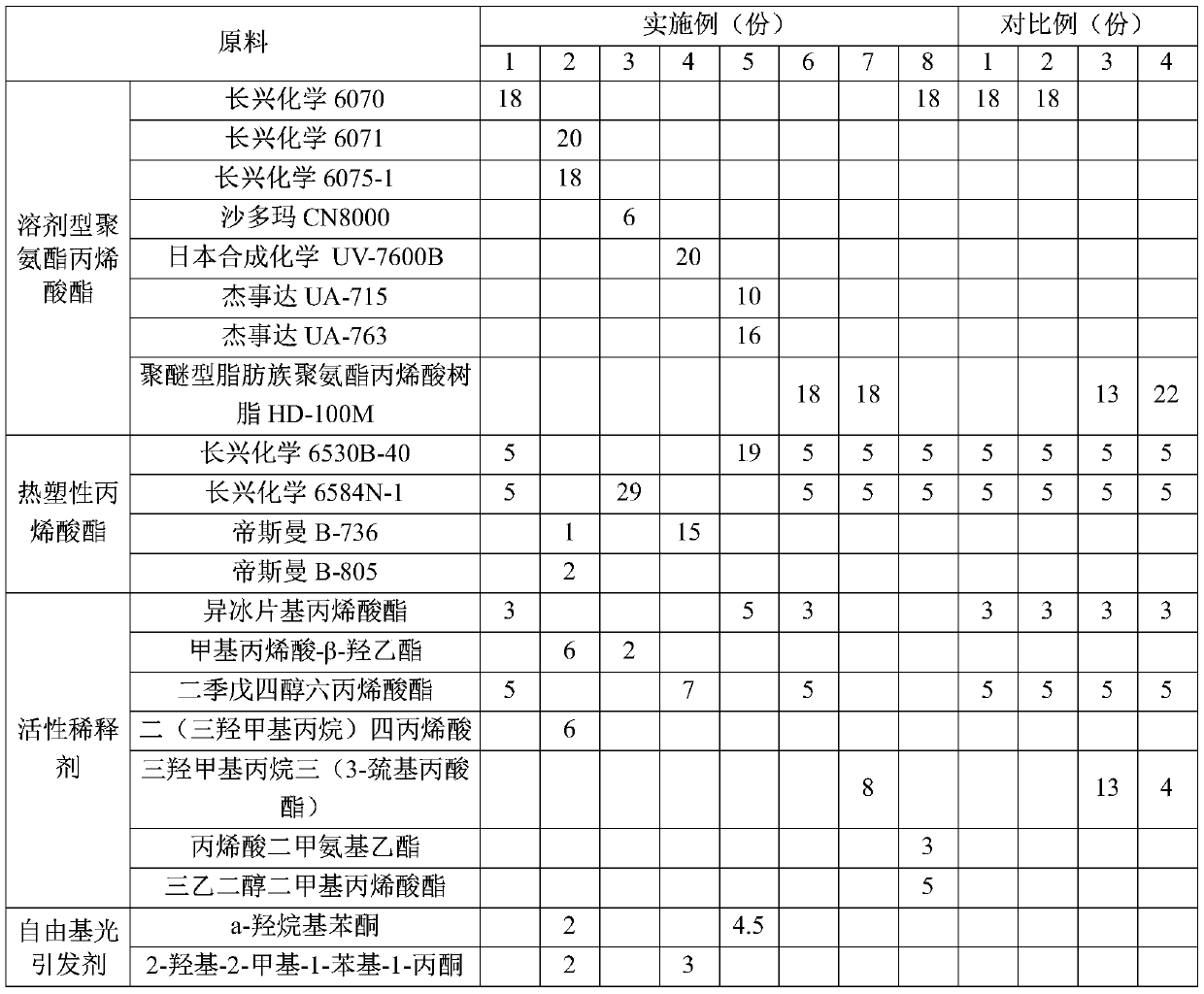

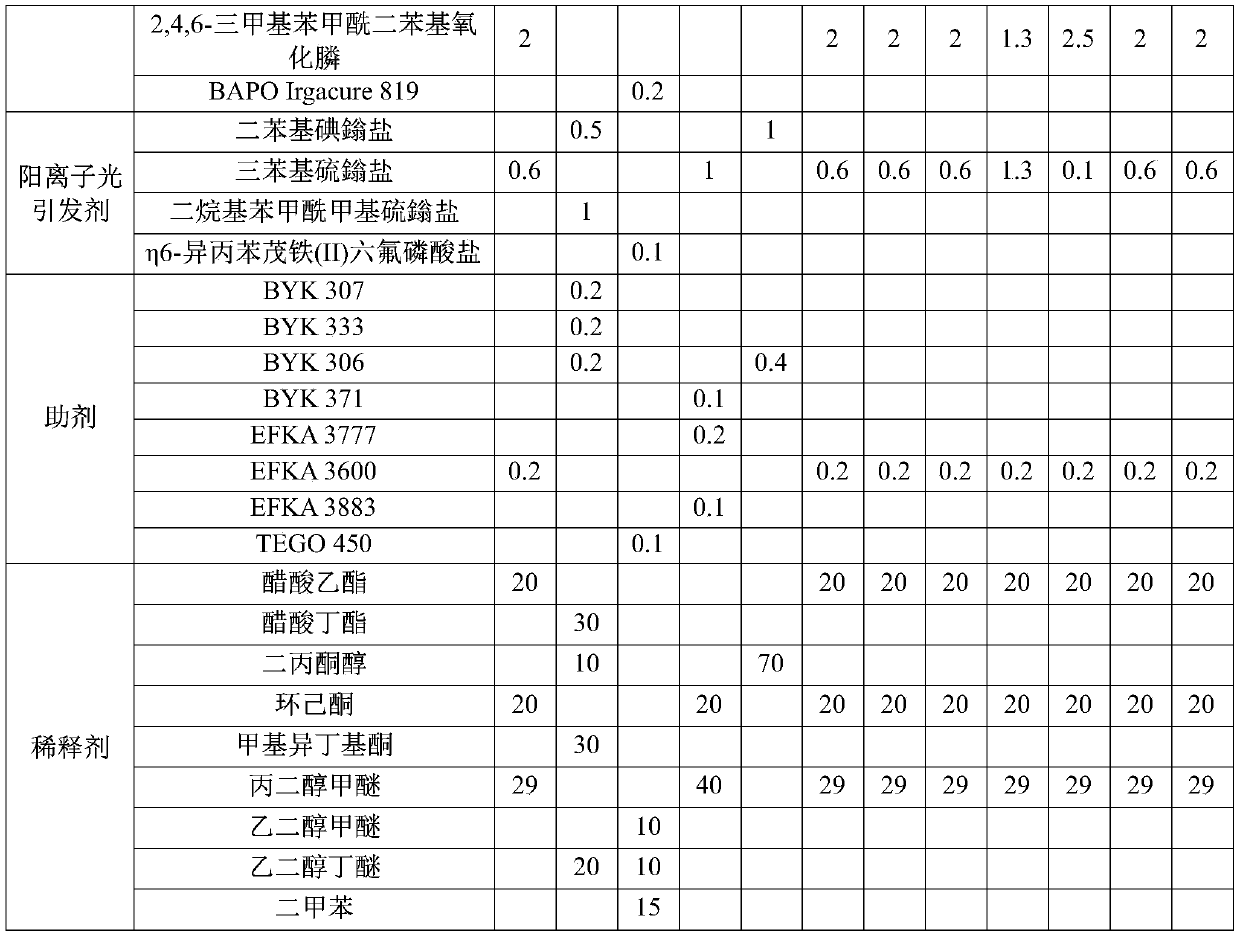

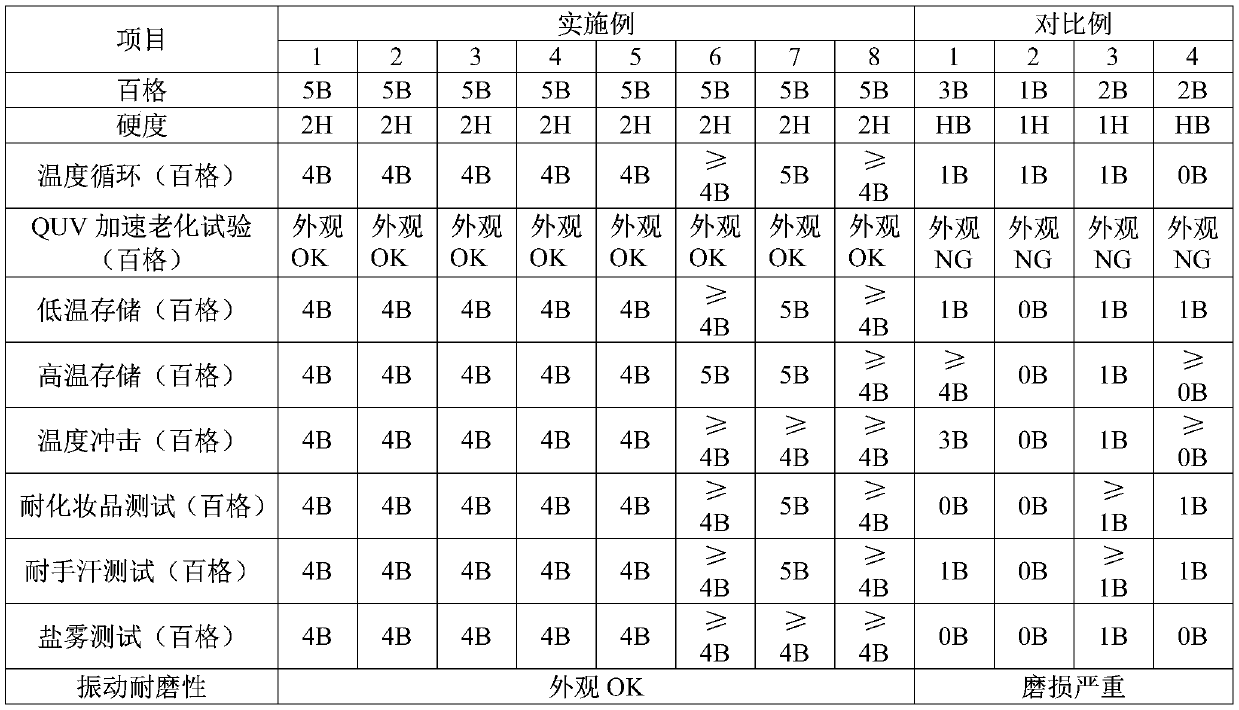

[0035] The present invention is described in further detail now in conjunction with embodiment.

[0036] The thiol acrylate is trimethylolpropane tris(3-mercaptopropionate) from Hubei Xinmingtai Chemical Co., Ltd., and the amine acrylate is dimethylaminoethyl acrylate from Hubei Xinmingtai Chemical Co., Ltd. The acrylic ester is triethylene glycol dimethacrylate from Hubei Xinmingtai Chemical Co., Ltd. The polyether type polyurethane acrylate is selected from Changzhou Houding Chemical Co., Ltd. polyether type aliphatic polyurethane acrylic resin HD-100M. The nano-color paste is selected from Shanghai Xiyan Chemical Nano-color Paste or Korea Yisan Chemical Nano-color Paste.

[0037] The following is the preparation method of each example gradient color electroplating middle paint:

[0038] Step 1: Add the diluent into the stirring container and stir evenly, then add the photoinitiator, mix evenly, the stirring temperature is 30-50°C, the stirring speed is 400-600r / min, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com