Aqueous gold powder gloss oil and preparation method thereof

A technology of gold powder and varnish, applied in the field of coatings, can solve problems such as the adverse impact of production and use environments, adverse effects on human health, and influence on metallic luster, and achieve chemical properties that are not easy to burn, improve the characteristics of easy oxidation and blackening, and improve flammability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

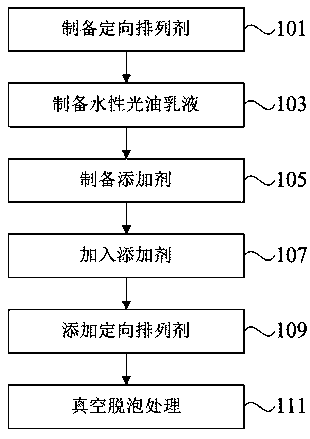

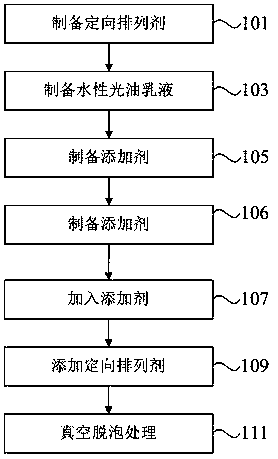

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0025] A water-based gold powder varnish, comprising the following components in parts by mass: 50 to 70 parts of acrylic emulsion, 0.3 to 0.7 parts of a foam suppressor, 0.4 to 0.8 parts of copper gold powder antioxidant, and 0.2 to 0.6 parts of a wetting agent 0.3 to 0.7 parts of alignment agent and 35 to 40 parts of solvent. In other embodiments, the water-based gold powder varnish includes the following components by mass: 55 to 65 parts of acrylic emulsion, 0.4 to 0.6 parts of antifoaming agent, 0.5 to 0.7 parts of copper and gold powder antioxidant, moisturizing 0.3 to 0.5 parts of wet agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com