Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Improve salt water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

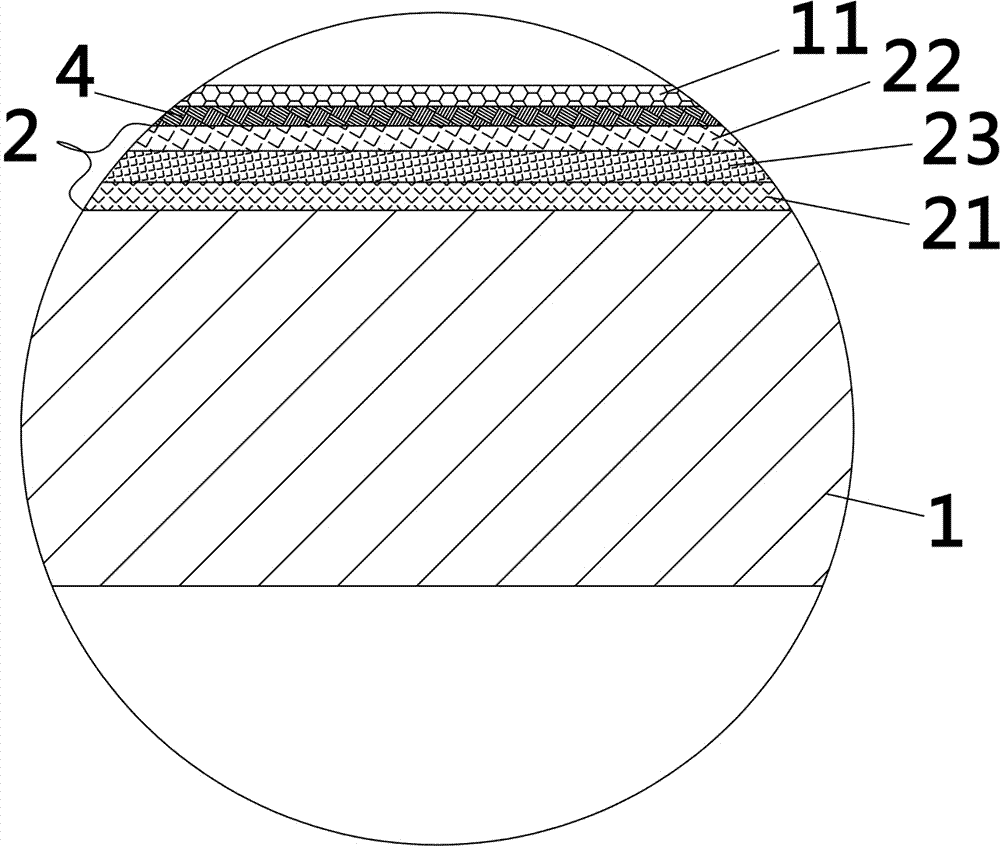

Plasma non-stick pan and fabrication method thereof

ActiveCN104757863AGood decontamination effectGood neutralization effectCooking-vessel materialsMolten spray coatingHardnessToughness

The invention discloses a plasma non-stick pan and a fabrication method thereof. The plasma non-stick pan comprises a pan body and a non-stick coating, and the pan body is coated with the non-stick coating. A plasma layer is arranged between the non-stick coating and the pan body and comprises a MCrALY layer and a mixture layer coated on the outside of the MCrALY layer. The mixture layer is formed by MCrALY particles and metallic oxide particles. The MCrALY layer is good in toughness, high in bonding force, capable of being easily bonded with a substrate, high in bonded firmness and capable of providing a buffer effect well and laying a foundation for subsequent mixture layer coating. The MCrALY particles and the metallic oxide particles are blended in the mixture layer, so that high rigidity and brittleness are provide, and the pan body surface rigidity and anti-abrasion performances are improved greatly; by the buffering effect of the MCrALY layer, the mixture layer and the MCrALY layer are bonded firmly, reliably and enduringly in the condition that the high rigidity and brittleness of the mixture layer is guaranteed.

Owner:ZHEJIANG SANHO KITCHENWARE

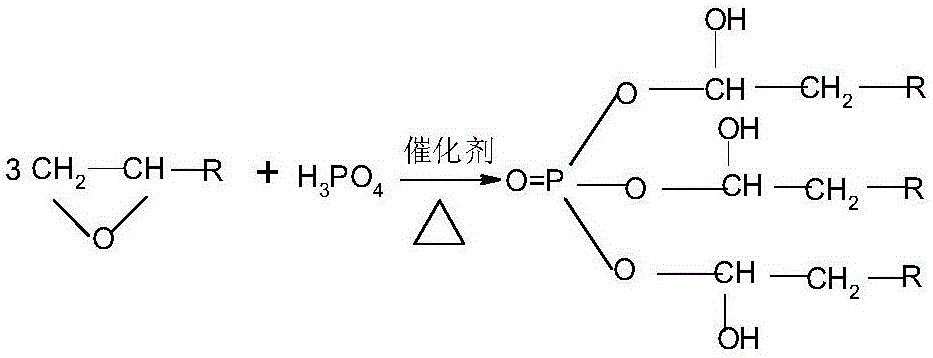

Hydroxy acrylic ester emulsion containing phosphoester group

InactiveCN101412781AImprove adhesionImprove corrosion resistanceAnti-corrosive paintsMetallic material coating processesEmulsionPhosphate

The invention relates to a hydroxyl acrylic emulsion containing phosphate ester groups, which is an emulsion formed by neutralization, salifying, watering and emulsifying of an acrylate copolymer which is formed by copolymerization of acrylate monomers in the presence of an initiator and a hydrophilic solvent. The percentage of the acrylate monomers in the gross weight portion of monomers is as follows: acrylate monomers with hydroxyl account for 5 to 20 percent; acrylate monomers without hydroxyl account for 60 to 90 percent; and acrylate monomers containing the phosphate ester groups account for 1 to 20 percent. The amount of the initiator and the amount of a neutralizing agent account for 0.2 to 1 percent and 1 to 5 percent of the gross weight portion of the acrylate monomers respectively; the ratio of the amount of the hydrophilic solvent to the total amount of the acrylate monomers is 1.0 to 1.5; and the amount of deionized water is at least 80 percent of the amount of the hydrophilic solvent. The emulsion can be taken as aqueous bicomponent anticorrosive coating, and both the anticorrosive property and the adhesive force of the coating are superior to those of coating prepared by the prior acrylic emulsion.

Owner:CHINA NAT OFFSHORE OIL CORP +2

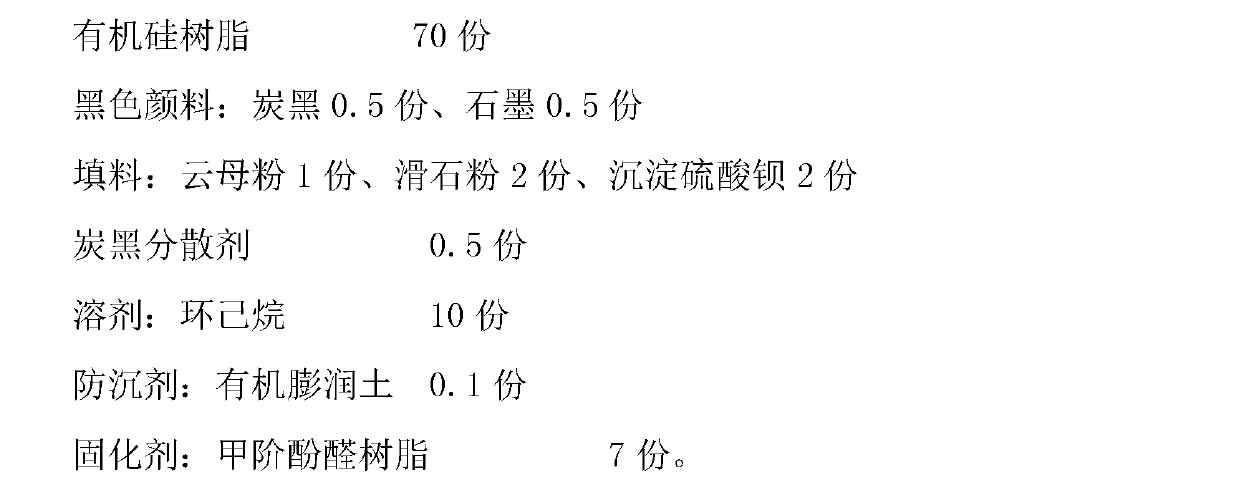

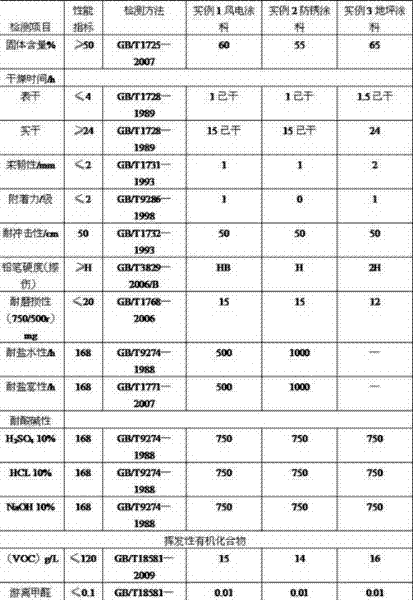

Black organic silicon heat resisting paint and preparation method thereof

The invention provides black organic silicon heat resisting paint and a preparation method thereof. The black organic silicon heat resisting paint is prepared from organic silicon resin, black paints, filler, a carbon black dispersant, a solvent, an anti-settling agent and a curing agent in parts by weight. Two black paints are combined in use and the carbon black dispersant is soaked and dispersed in advance, so that the heat resistance and relative blackness of the paint are improved, and the coarseness return condition of the paint is further avoided, and meanwhile, the paint film has a certain blackness and good appearance. The black organic silicon heat resisting paint prepared by the invention has luster and maintains the luster at temperatures above 300 DEG C, and has higher heat resistance. The hardness of the paint film can reach above 0.5, and the hardness of the paint film is improved.

Owner:TIANCHANG JULONG TRAVEL PAINT

High-performance silicone-acrylate-modified water-based epoxy emulsion and production method thereof

InactiveCN102336874AImprove adhesionExcellent closed shielding performanceAnti-corrosive paintsFilling pastesWater basedChemical industry

The invention discloses a high-performance silicone-acrylate-modified water-based epoxy emulsion and a production method thereof, relating to the technical field of production of coatings used in the chemical industry field. The emulsion is prepared with a core-shell mechanism process; in a core layer, a grafted polymer consists of low molecular bisphenol A epoxy resin, epoxy group siloxane and acrylic ester; a shell body consists of hydroxyl-containing siloxane and acrylic ester; and the shell body and the core layer are subjected to interpenetration graft polymerization. In the invention, epoxy resin is modified with an organic silicon acrylic acid monomer, so that a dense crosslinked netlike structure with a special interpenetration network and excellent enclosed shielding performance is obtained. Multiple series of anti-corrosive paints can be prepared on the basis of the high-performance silicone-acrylate-modified water-based epoxy emulsion provided by the invention by taking mixed modified amine as a curing agent. The emulsion has the advantages of easy and convenient production process, saving in energy, environmental friendliness, easiness for coating construction, low sensitivity to water vapor and temperature, extremely high substrate adhesion, high corrosion resistance, high chemical stability and wide formula adjusting range.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

Process for preparing low temperature baking silver mirror back lacquer

InactiveCN1900189ALow baking temperatureShort baking timeInstrumentsPolyester coatingsOrganic solventLacquer

The lower temperature baked silver mirror back lacquer consists of priming lacquer and finishing paint. The priming lacquer consists of inorganic cross-linking agent, talc powder, barium sulfate, modified alkyd resin, coloring pigment, antiskimming agent, drying agent, and organic solvent in certain weight proportion. The finishing paint consists of inorganic cross-linking agent, talc powder, barium sulfate, modified alkyd resin, coloring pigment, antiskimming agent, drying agent, leveling agent and organic solvent in certain weight proportion. The present invention has silver mirror back lacquer with baking temperature lowered to 100 deg.c, raised adhesion, high wet head resistance, high temperature change tolerance, high salt fog resistance, high salt water resistance, high corrosion resistance and good post finishing property.

Owner:SHANGHAI JIAO TONG UNIV

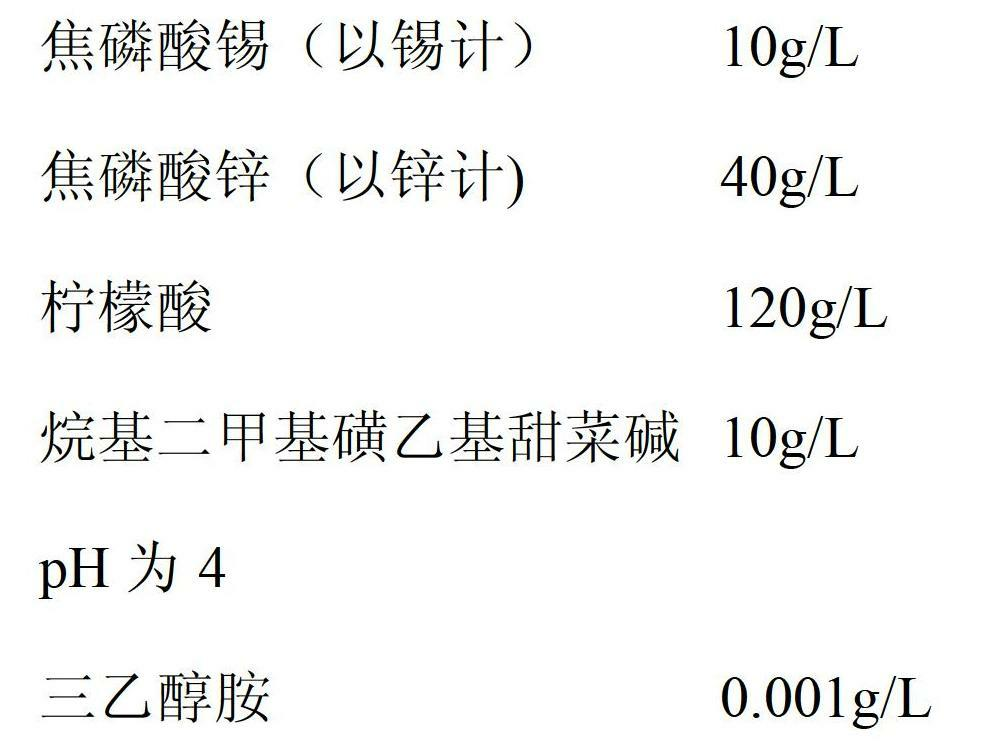

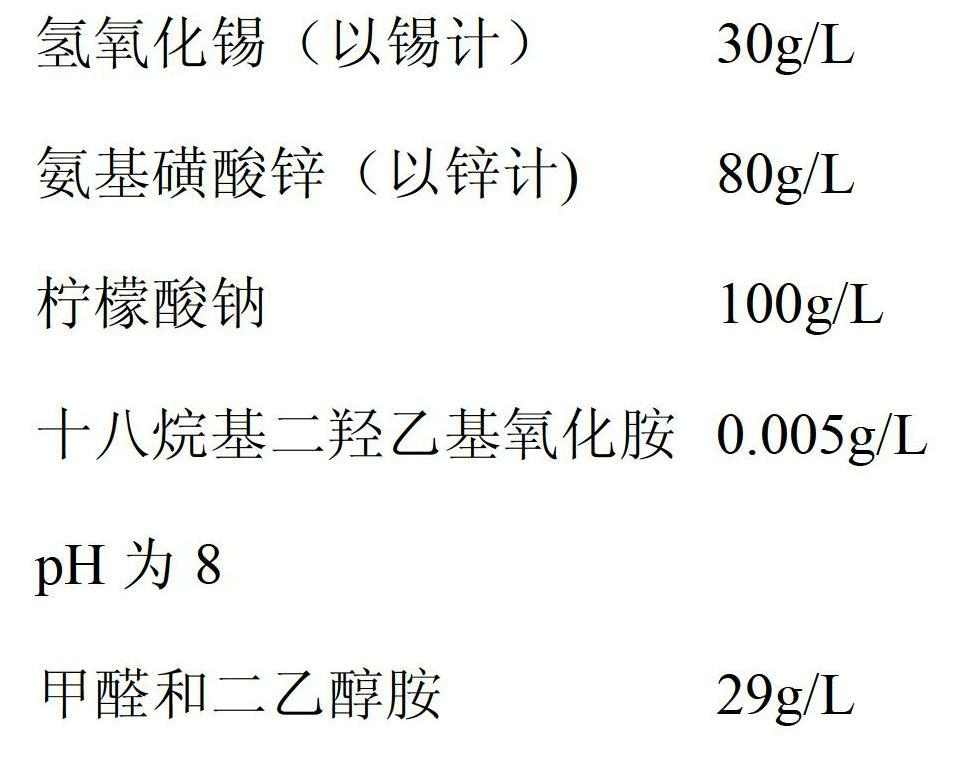

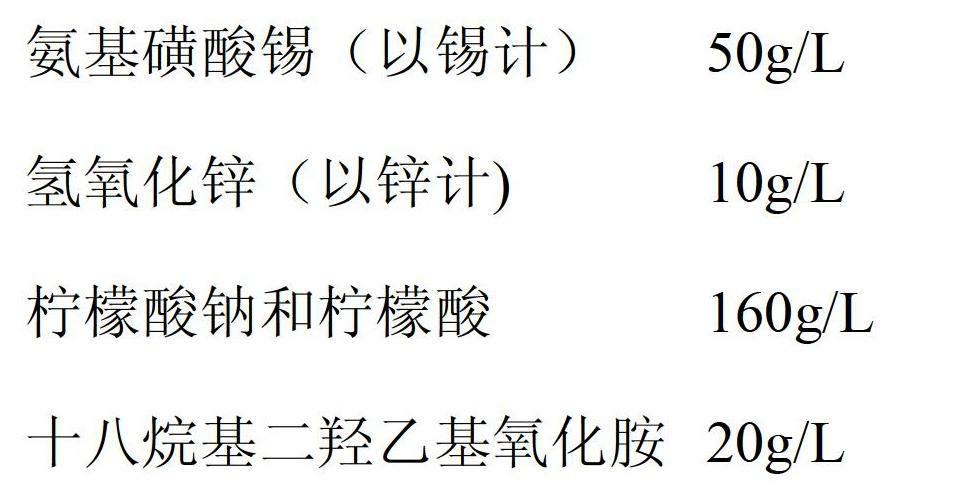

Tin-zinc alloy electroplating method

The invention aims to provide a tin-zinc alloy electroplating method. The method is performed under the following conditions: plating bath temperature: 15-25 DEG C; plating solution stirring speed: 50-200m / min; and cathodic current density: 5-100A / dm2. The tin-zinc alloy electroplating method is obtained by selection of a plating bath temperature, a cathode current density and the like and the use of a specific tin-zinc alloy plating bath, and the tin-zinc alloy plating obtained using the method has strong corrosion resistance and reduced pollution, and is an ideal substitute for cadmium plating.

Owner:东莞市闻誉实业有限公司

Preparation method of aqueous fluorine-modified phosphorus-containing acrylate emulsion

InactiveCN103833888AWith fine grainFlash corrosion resistantFibre treatmentCoatingsEnvironmental resistanceFunctional monomer

The invention discloses a preparation method of an aqueous fluorine-modified phosphorus-containing acrylate emulsion. The preparation method comprises the steps of firstly preparing a pre-emulsion, then preparing a seed emulsion, and carrying out emulsion polymerization, so as to obtain the milky-white and slightly-blue aqueous fluorine-modified phosphorus-containing acrylate emulsion. According to the preparation method, a phosphate emulsifier is taken as an anionic emulsifier, meanwhile, phosphate is added as a functional monomer, phosphate groups are intruded into the emulsion, so that the emulsion has the characteristics of fine granularity and flash rusting resistance, and a coating has high adhesive force and certain salt water resistance; by adding a fluorine-containing modified monomer having good effects in the reduction of surface free energy and the improvement of surface dewatering and oleophobic performance, the water resistance of the coating of the emulsion is enhanced, and the pollution resistance of the coating of the emulsion is improved; meanwhile, the utilized fluorine-containing modified monomer is a fluorine-containing acrylic monomer, so that the problems of environment friendliness and biological harm of a long-fluorocarbon-chain compound are avoided, and the prepared emulsion is environmental friendly; the utilized nonionic emulsifier does not contain APEO (alkylphenol ethoxylate) and is environmental friendly.

Owner:西安佳龙油漆新技术发展有限公司

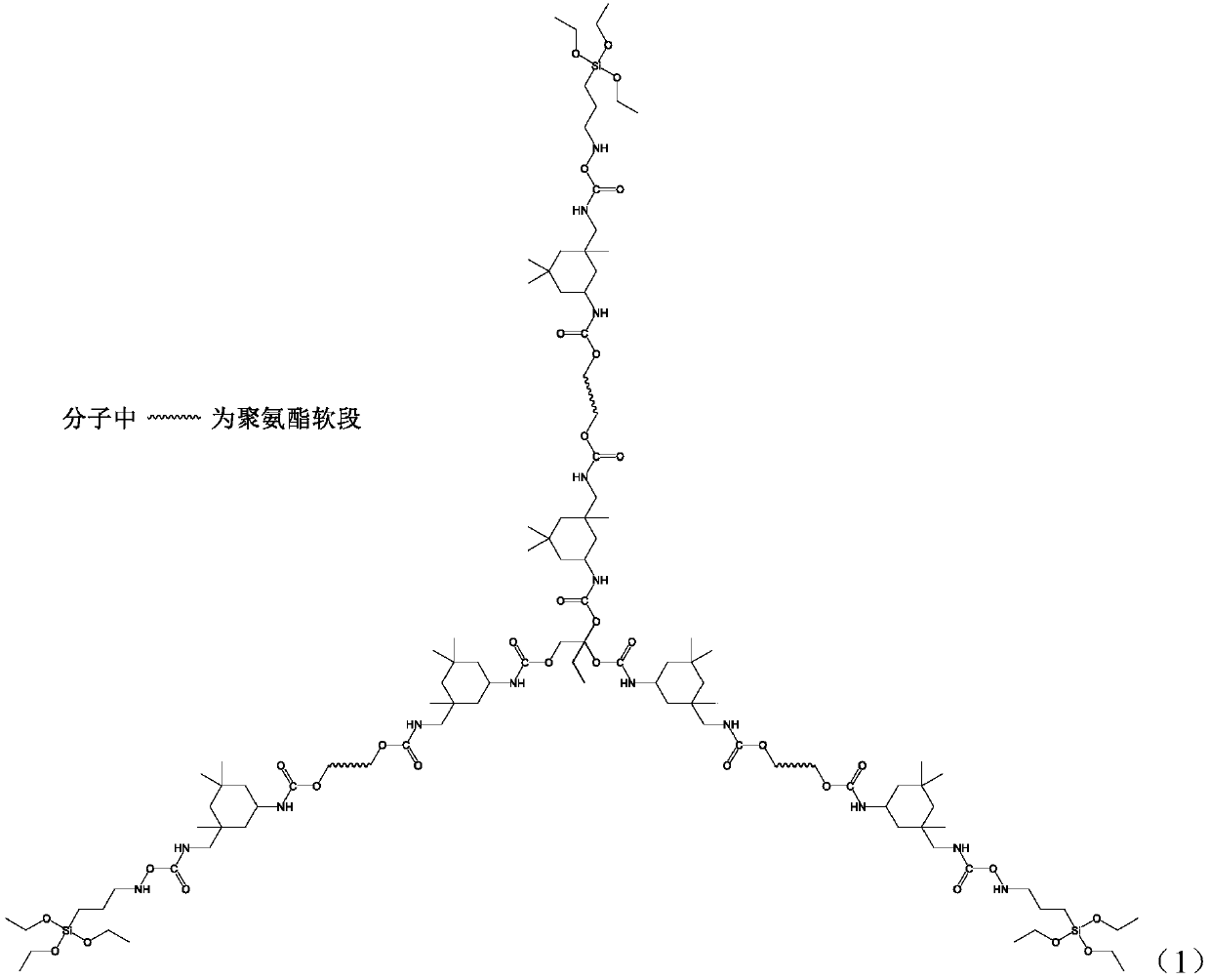

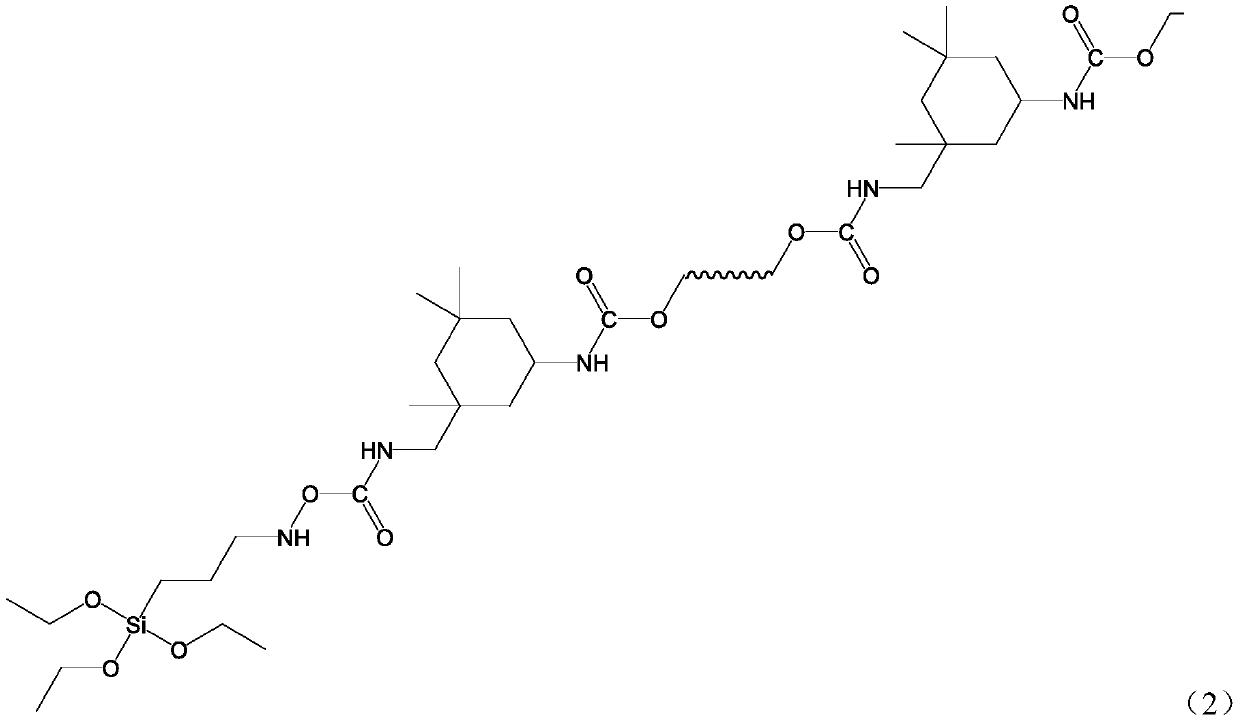

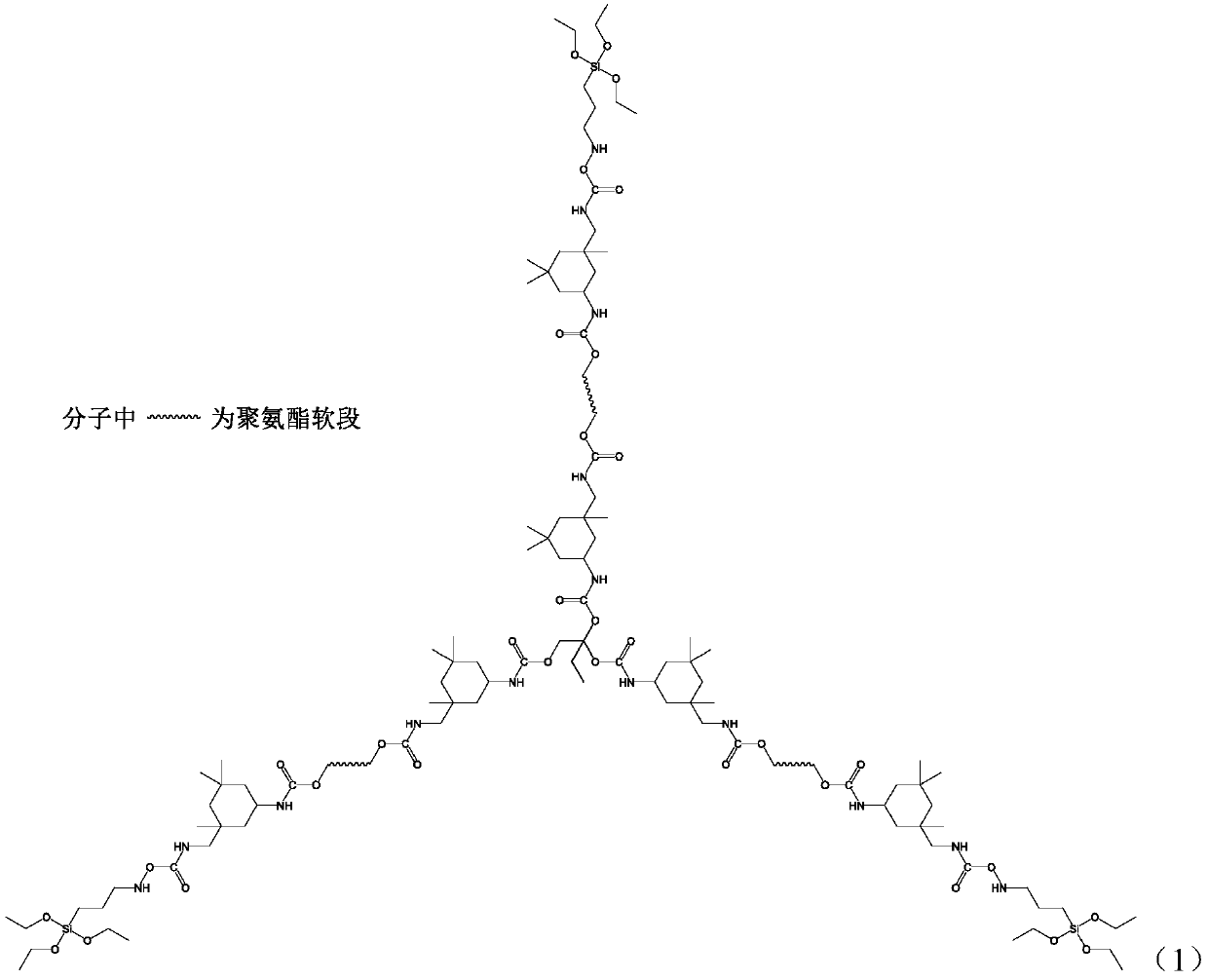

Hyperbranched silane modified polyurethane composite polysiloxane antifouling paint and preparation method thereof

ActiveCN111138974AOvercoming the problem of poor adhesionImprove adhesionAntifouling/underwater paintsPaints with biocidesXylylenePolymer science

The invention relates to a marine antifouling coating technology, and aims to provide a hyperbranched silane modified polyurethane composite polysiloxane antifouling coating and a preparation method thereof. The coating is a three-liquid type product, wherein the main paint is formed by mixing organopolysiloxane containing at least two condensation reactive groups, filler and a xylene solvent; thecross-linking curing agent is formed by mixing hyperbranched silane modified polyurethane, organosilane (which can be subjected to condensation reaction with condensation reactive groups of main paint resin), partial hydrolysate of the organosilane, and a xylene solvent; wherein the curing accelerator is formed by mixing a silane coupling agent, an organic tin catalyst and a xylene solvent. According to the present invention, the adhesion of the polysiloxane low surface energy antifouling finishing coat coating to the epoxy primer can be enhanced, and the low surface energy antifouling finishing coat has advantages of excellent fresh water resistance, salt and alkali corrosion resistance, long-term stable existence at the room temperature, environmental protection requirement meeting, andlow application cost; good rheological performance and film forming performance are achieved, and then good construction performance is achieved; the synthesis method is relatively simple and convenient for industrial production.

Owner:QUZHOU RES INST OF ZHEJIANG UNIV

Water-based anticorrosive paint

InactiveCN104987831AImprove anti-corrosion performancePerfect anti-corrosion mechanismFireproof paintsAnti-corrosive paintsWater basedPhosphoric acid

The invention provides water-based anticorrosive paint. The water-based anticorrosive paint comprises, by weight, 82-95 parts of phenyl glycidyl ether modified polyaniline, 60-80 parts of epoxy resin, 30-60 parts of alkyd resin, 20-40 parts of modified polyurethane, 10-15 parts of modified nanometer titania, 5-12 parts of zinc phosphate, 6-18 parts of aluminum phosphate, 5-12 parts of imvite, 3-8 parts of mica powder, 2-9 parts of talcum powder, 4-14 parts of quartz powder, 8-18 parts of pigment, 2-8 parts of defoaming agents, 3-6 parts of dispersing agent, 1-5 parts of flatting agents, 4-9 parts of coalescing agents and 60-83 parts of water. The water-based anticorrosive paint is good in antiseptic property, excellent in waterproofness, long in service life and low in cost.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

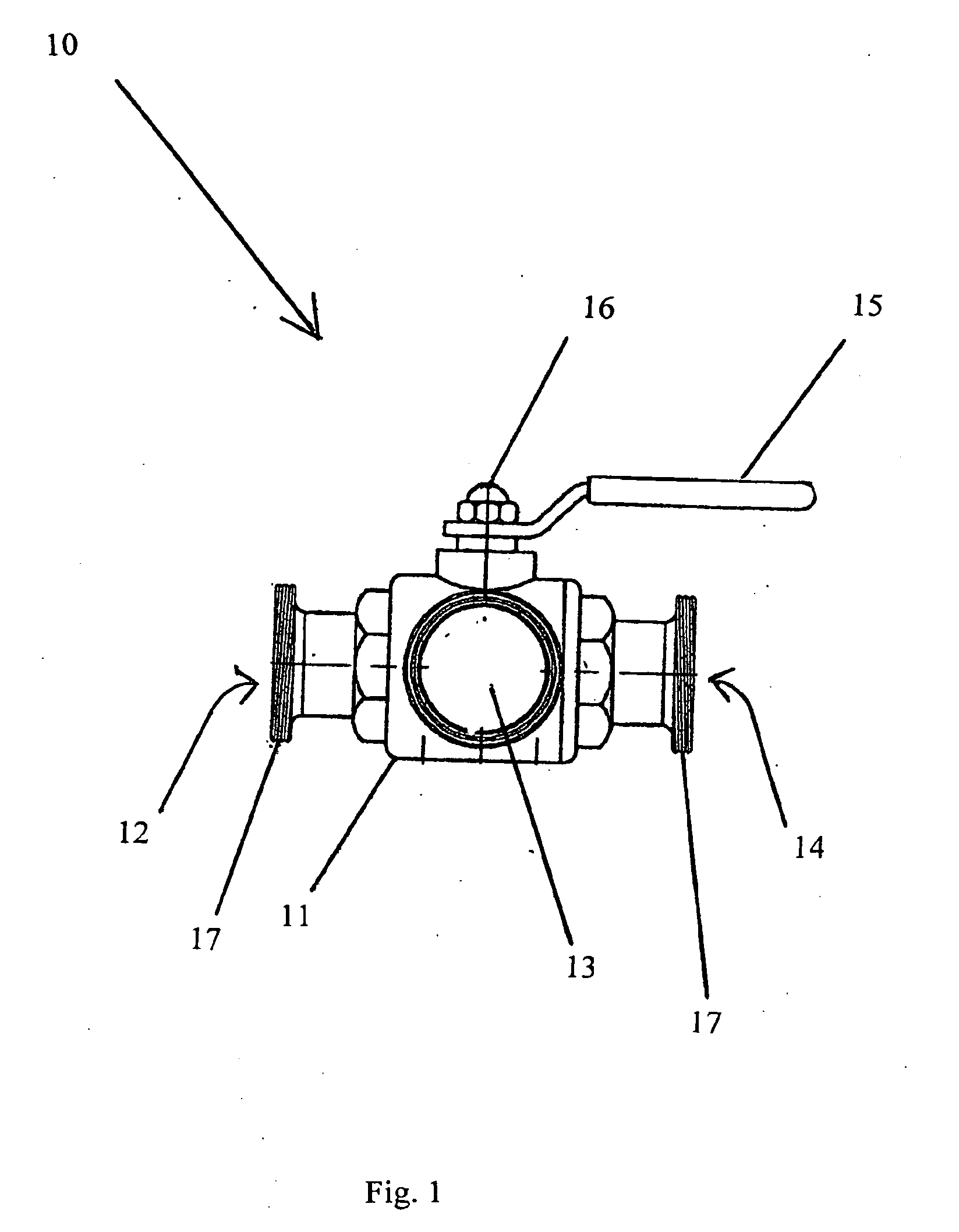

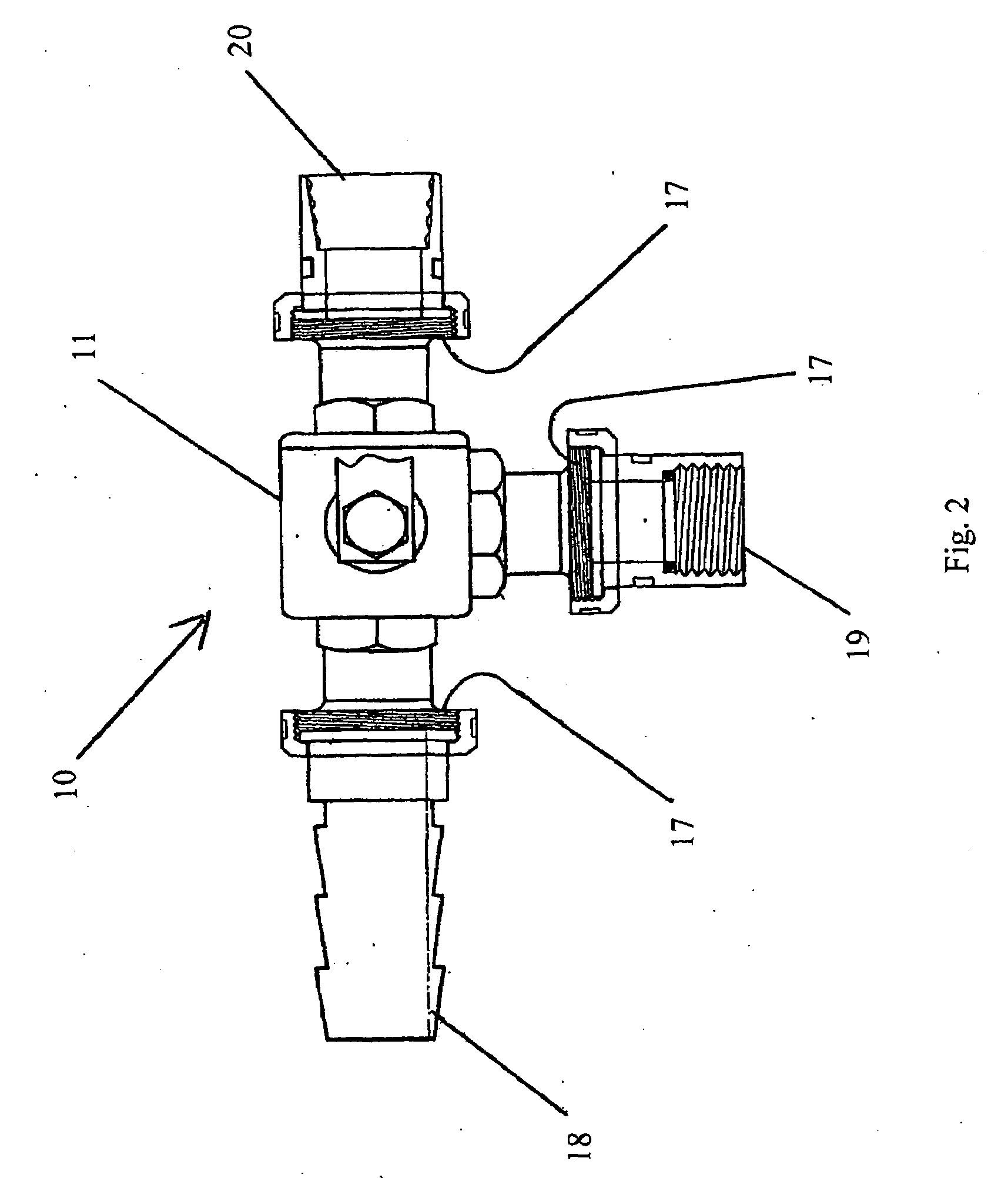

Fresh water flushing system for boat engines

InactiveUS20090029609A1Easy to installImprove integrityPower plants using condensersLiquid coolingEngineeringFresh water

The present invention is a system and method for flushing marine engines with fresh water comprising a three way valve configured to receive three hose connections, a fresh water inlet; hoses to connect said valve to a marine engine; and union rings at the junction of each hose connection.

Owner:TSUNAMI MARINE

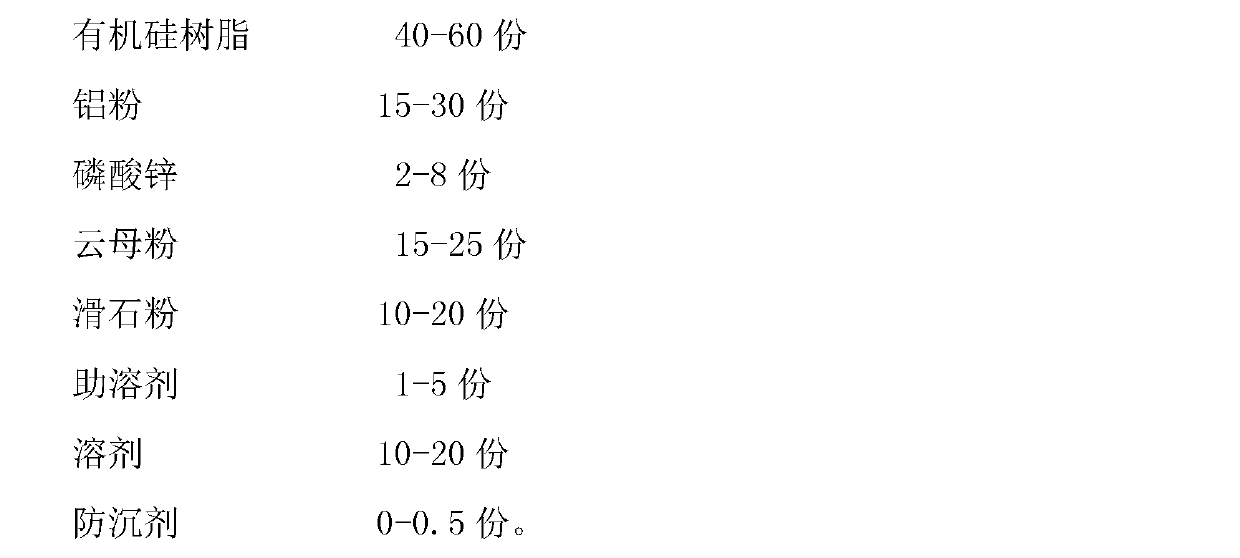

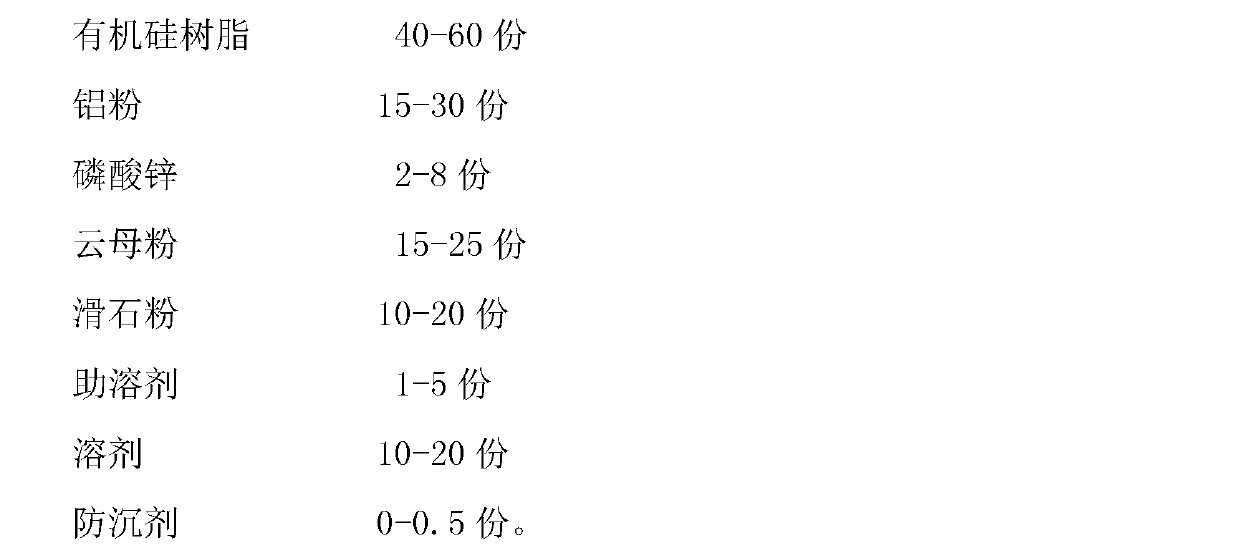

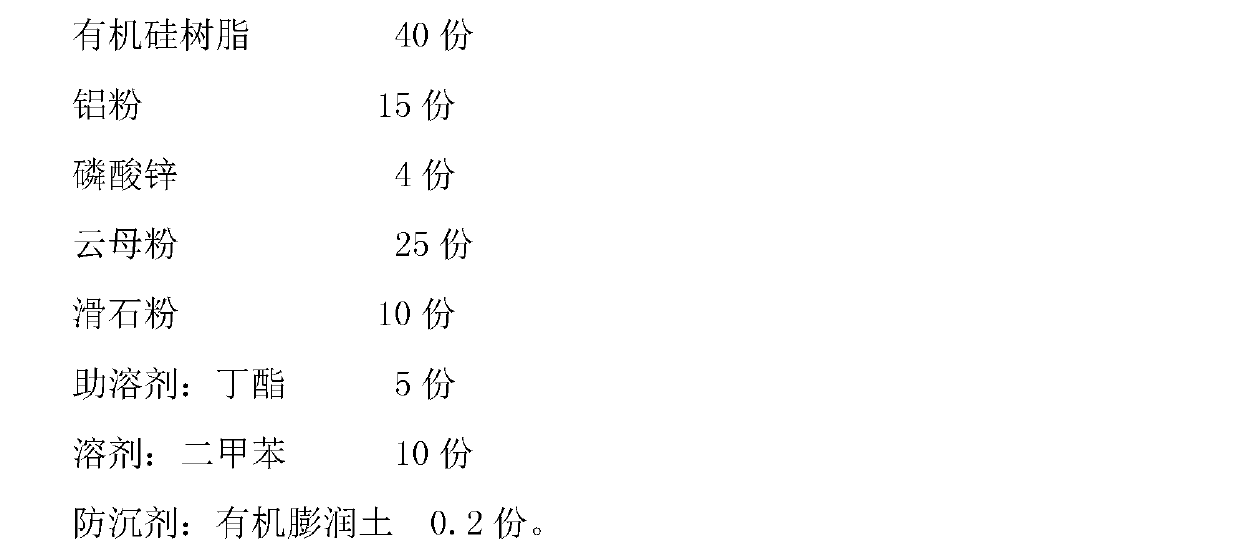

Organic silicon heat-resistant finish paint and preparation method thereof

InactiveCN103342959AImprove adhesionImprove high temperature resistanceAnti-corrosive paintsAdhesion forceSolvent

The invention provides organic silicon heat-resistant finish paint and a preparation method thereof. The organic silicon heat-resistant finish paint consists of an organic silicon resin, aluminum powder, mica powder, talcum powder, an anti-settling agent, a solvent and the like. The organic silicon heat-resistant finish paint has good high-temperature performance and high drying property, is subjected to surface drying within an hour and is subjected to hard drying within four hours; the adhesion force and corrosion resistance of the organic silicon heat-resistant finish paint are obviously improved.

Owner:TIANCHANG JULONG TRAVEL PAINT

Water-based silicone-acrylic mica iron oxide anti-corrosion coating

InactiveCN103865348AGood chemical stabilityImproved liquid resistanceAntifouling/underwater paintsPaints with biocidesEmulsionBrown iron oxide

The invention discloses a water-based silicone-acrylic mica iron oxide anti-corrosion coating. The anti-corrosion coating is prepared from the following raw materials in parts by weight: 30-50 parts of silicone-acrylic base material, 20-41 parts of pigment, 1-10 parts of auxiliary pigment, 4-15 parts of filler, 5-20 parts of water and 1-20 parts of assistant, wherein the pigment is micaceous iron oxide gray; the auxiliary pigment is at least one of rutile titanium dioxide, nano-titanium dioxide, phthalocyanine pigment, compound pigment and iron oxide pigment; the weight ratio of the auxiliary pigment to the pigment is (1-10):(20-41); the silicone-acrylic base material is water-based silicone-acrylic emulsion, a mixture of water-based silicone-acrylic emulsion and water-based pure silicone-acrylic emulsion or a mixture of water-based silicone-acrylic emulsion and water-based styrene-acrylic emulsion. By adopting the coating, not only is the water, acid and saline resistance increased, but also the corrosion resistance is excellent.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Wear-resistant nonskid polyurethane deck paint, and manufacture method thereof

InactiveCN102190954AGood chemical stabilityImprove acid and alkali corrosion resistancePolyurea/polyurethane coatingsGas phaseWear resistant

The invention relates to a wear-resistant nonskid polyurethane deck paint, and a manufacture method thereof. The manufacture method comprises the following steps of: adding a hydroxyl acrylic resin, polyether polyol, hydroxyl-containing fluorocarbon acrylic resin, a polyacrylate copolymer solution, poly(methyl alkyl siloxane) solution and [b-[3-(2-H-benzotriazol-2-yl)-5-(1,1-dimethylethyl)-4-hydroxyphenyl]-1-oxopropyl]-hydroxypoly(oxo-1,2-ethanediyl) to a mixed solvent of xylene, n-butyl acetate, methyl isobutyl ketone and butanone for high-speed stirring; adding rutile titanium white powder, talcum powder, aluminum oxide ceramic powder, sericite powder, silicon micropowder, carbon black and gas-phased silicon dioxide; milling with a sand mill while controlling fineness of a mixture not higher than 60 mu m to obtain a liquid A; and forming a liquid B by a mixed solution of 1,6-hexamethylene diisocyanate tripolymer, anhydrous xylene and n-butyl acetate, and mixing 1 weight part of the liquid A with 0.2-1.0 weight part of the liquid B for use. The obtained wear-resistant nonskid polyurethane deck paint can be used for the corrosion protection of the steel surfaces of deck and ocean facilities.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

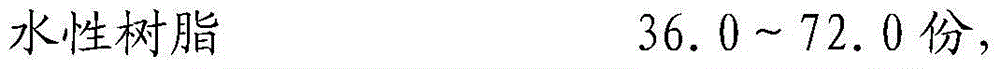

Water-based antirust paint and preparation method thereof

ActiveCN103555109AImprove rust resistanceIncreased durabilityAnti-corrosive paintsRed Ferric OxideWater based

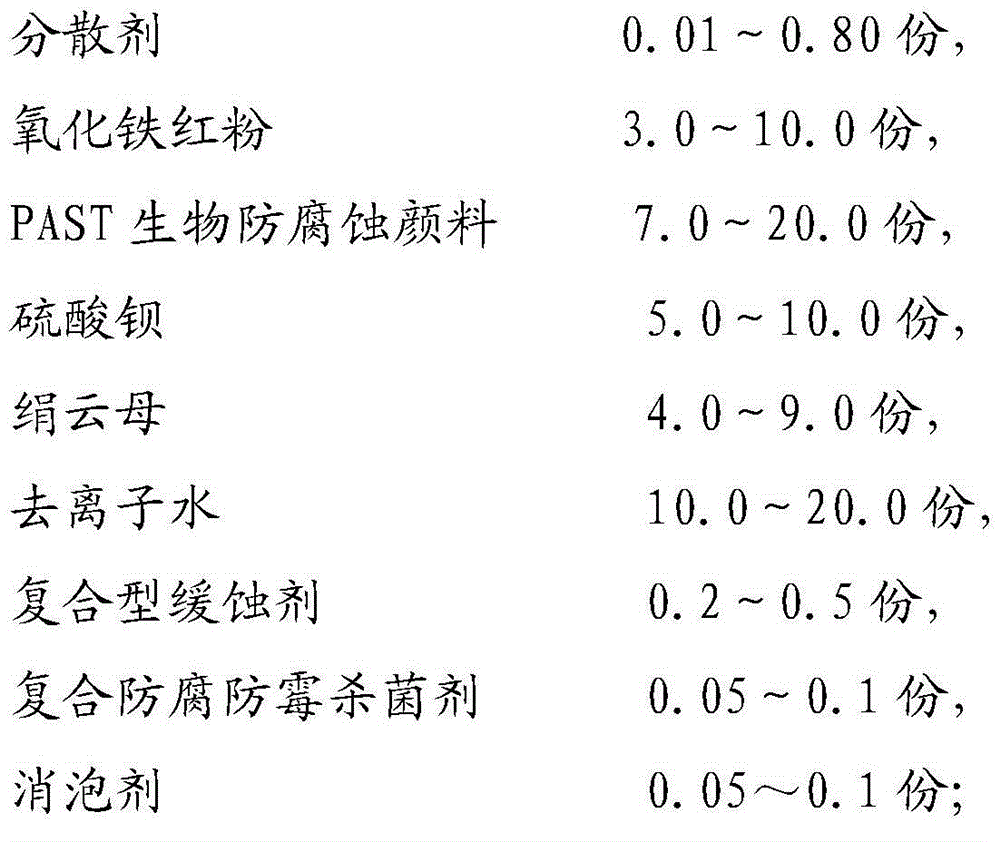

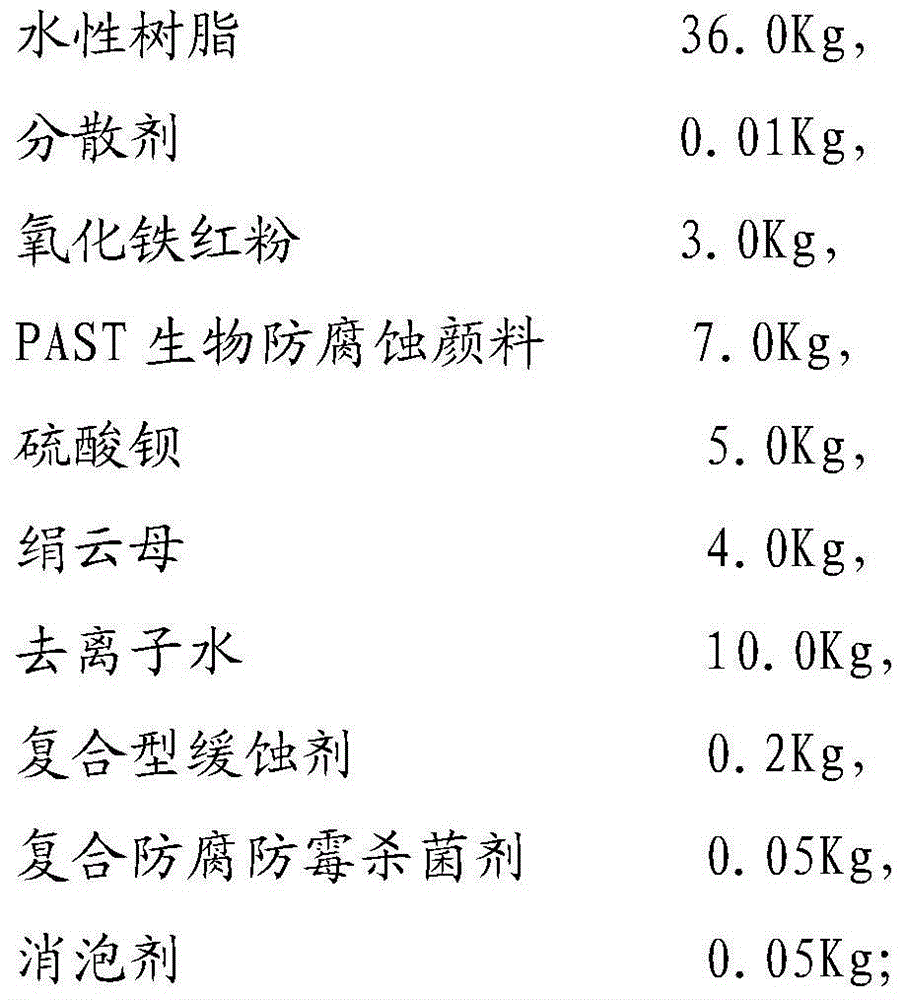

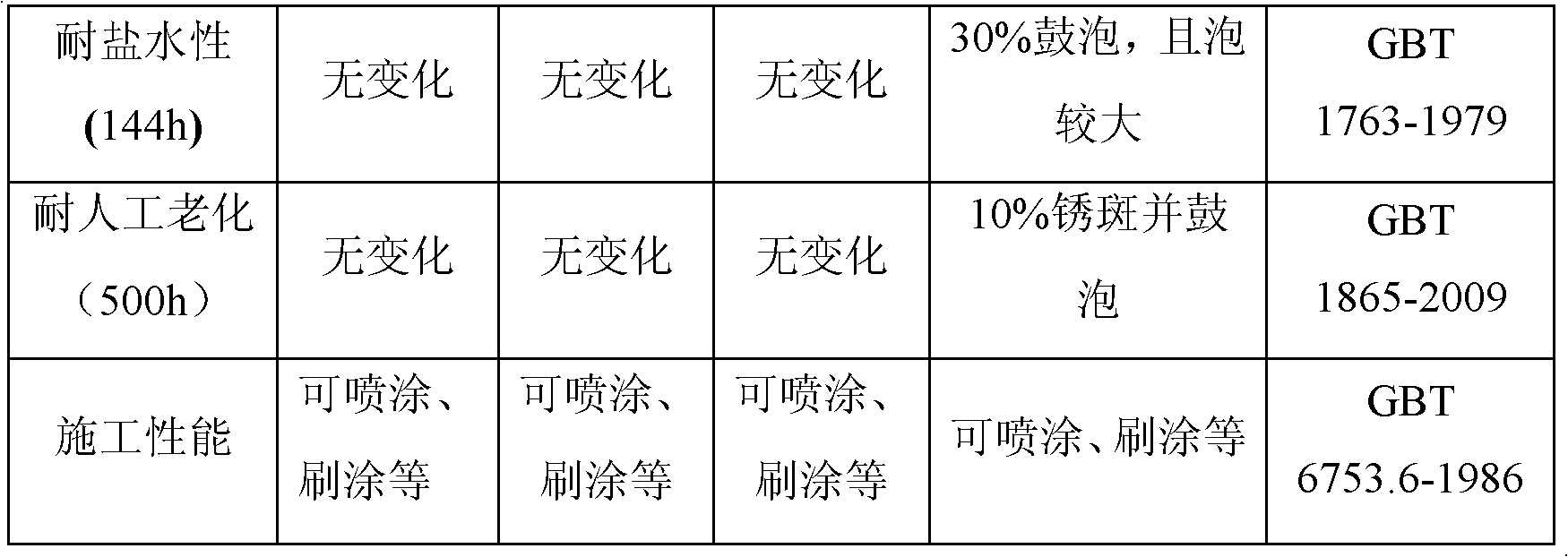

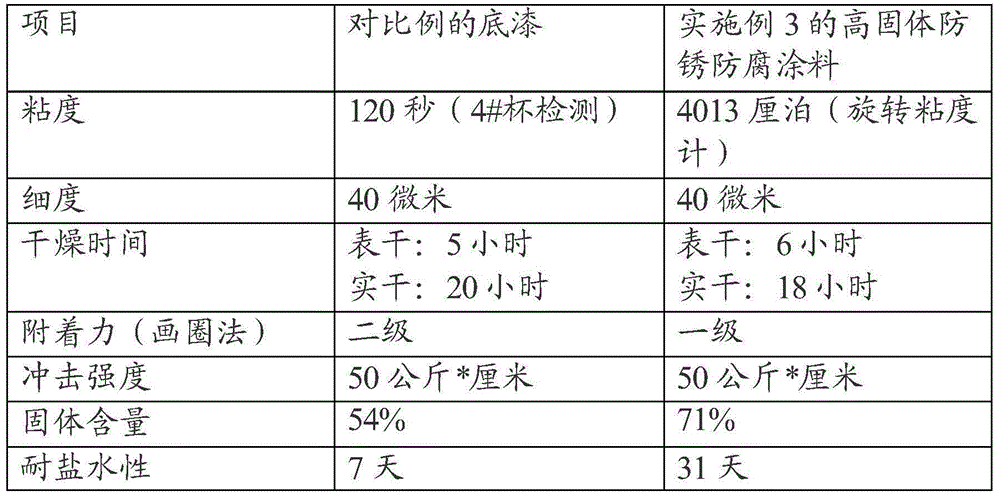

The invention discloses a water-based antirust paint and a preparation method thereof. The water-based antirust paint comprises the following active ingredients in parts by weight: 36.0-72.0 parts of water-based resin, 0.01-0.80 part of a dispersing agent, 3.0-10.0 parts of red ferric oxide powder, 7.0-20.0 parts of PAST-2 biological anti-corrosion pigment, 5.0-10.0 parts of barium sulfate, 4.0-9.0 parts of sericite, 10.0-20.0 parts of deionized water, 0.2-0.5 part of a composite type corrosion inhibitor, 0.05-0.1 part of composite anti-corrosion mould-proof bactericide, and 0.05-0.1 part of a defoaming agent. The preparation method comprises the following steps of adding the dispersing agent, composite anti-corrosion mould-proof bactericide, composite type corrosion inhibitor and the defoaming agent into the deionized water, stirring and dissolving, then adding red ferric oxide powder, PAST-2 biological anti-corrosion pigment, barium sulfate and sericite, and stirring at high speed and dispersing to obtain color paste; carrying out ball milling on the color paste, then adding the water-based resin, and evenly dispersing to obtain the water-based antirust paint.

Owner:山东乐化漆业股份有限公司

Organic silicon polyurethane composite modified alkyd resin coating composition and preparation method thereof

ActiveCN102134441AAvoid separationImprove stabilityPolyurea/polyurethane coatingsComposition BResin coating

The invention discloses an organic silicon polyurethane composite modified alkyd resin coating composition and a preparation method thereof. The double-component coating composition contains the components in parts by weight: 0.3 to 1.2 parts of A and 6 parts of B, wherein the component A is modified active polysiloxane; the component B comprises alkyd resin, solvent, pigment and filler, wetting dispersant, leveling agent and anti-skinning agent; and when in use, the component A and the component B are mixed uniformly according to the proportion. The composition B is prepared by the following steps of: 1) uniformly mixing, abrading and dispersing the raw materials; and 2) adding the leveling agent and the anti-skinning agent to the abrasive. The coating composition disclosed by the invention has excellent comprehensive properties including good adhesion, salt spray resistance, salt water resistance, ageing resistance and the like, and is suitable for heavy-duty coating protection of a steel structure.

Owner:CHINA ELECTRIC POWER RES INST +1

High-solid anti-rust and anti-corrosion coating

InactiveCN104449248AImprove thixotropyImprove salt water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySilicon dioxide

The invention discloses a high-solid anti-rust and anti-corrosion coating. The coating comprises a component A and a component B in the weight ratio of 5: 1, wherein the component A comprises the following components in parts by weight: 18-22 parts of first epoxy resin, 18-24 parts of second epoxy resin, 10-15 parts of magnet powder, 2-10 parts of iron oxide red, 3-6 parts of zinc phosphate, 1-6 parts of zinc powder, 0.1-0.2 part of a dispersant, 0.5-0.7 part of modified bentonite, 0.2-0.4 part of nano-silicon dioxide, 0.2-0.3 part of an assistant and 12-15 parts of a diluent; and the component B comprises the following components in parts by weight: 56-62 parts of a first amine curing agent, 12-18 parts of a second amine curing agent and 20-30 parts of ethanol. The high-solid anti-rust and anti-corrosion coating adopts two different types of epoxy resin and curing agents to form a film by crosslinking and curing. The film-forming mechanism is that active H<+> is contained in the amine curing agents and can react with epoxy groups in epoxy resin at normal temperature and form a reticular structure by crosslinking; and the reticular structure is dense and hard, good in anti-corrosion performance, strong in adhesion and outstanding in chemical resistance.

Owner:湖南中汉高分子材料科技有限公司

Composite modified mortar for air-entrained bricks

The invention discloses composite modified mortar for air-entrained bricks. The mortar is prepared from the following ingredients (by weight): 58% of quartz sand, 11% of fly ash, 4% of glass fiber, 2% of diatomite, 3% of bentonite, 4.5% of quicklime, 9% of cement, 2% of aluminium powder, 4.5% of redispersible latex powder, 1% of a water reducer and 1% of an additive. The production technology is simple, and cost is low. The prepared mortar has good strength, low thermal conductivity and good crack resistance, is energy-saving and environmentally friendly, satisfies needs of constructional engineering and accords with requirements of environmental protection. By adding expansive soil into cement for calcination modification, adhesion of cement in the mortar is enhanced. By adding diatomite obtained after technological modification, performance of the mortar is improved, and the mortar has little shrinkage deformation. By using 1 wt% of cellulose ether as an additive, bondability of the ingredients is raised so as to further enhance strength of an air-entrained brick.

Owner:ANHUI KUNLONG BUILDING MATERIALS CO LTD

Stable permeation composite type rust coating and preparation method thereof

ActiveCN105885631AHigh hardnessStrong adhesionAnti-corrosive paintsMetallic material coating processesEpoxyPhosphate ion

The invention discloses stable permeation composite type rust coating and a preparation method thereof. The stable permeation composite type rust coating is formed by mixing epoxy resin E-44, xylene, absolute ethyl alcohol, aluminum triphosphate, zinc phosphate, iron oxide red, zinc molybdate, penetrant epoxy phosphate, a dispersing agent, a defoaming agent and a curing agent. Antirust agents are aluminum triphosphate, zinc phosphate and zinc molybdate. Triphosphate radical ions can have a stronger chelating ability with various metal ions, and a passive film is formed on the surface of a coated object; zinc phosphate and ferric ions have a higher condensation ability, phosphate anions react with iron anodes, a firm protection film with ion phosphate as a main body can be formed, and the compact purification film is insoluble in water, high in hardness and excellent in adhesive force; zinc molybdate can release molybdic acid ions, a composite insoluble substance formed on the surface of steel has an anti-rust effect; in this way, the anti-corrosion performance of the coating is excellent through the synergistic effect of the components.

Owner:SHANDONG UNIV OF SCI & TECH

Coupling method for waterborne epoxy coating and graphene oxide composite coating interfacial hyperbranched polyamide

The invention discloses a coupling method for a waterborne epoxy coating and graphene oxide composite coating interfacial hyperbranched polyamide. The method is characterized in that graphene oxide grafted with hyperbranched polyamide in situ is obtained on the basis of a polycondensation reaction of carboxy group on the surface of the graphene oxide and the hyperbranched polyamide; furthermore, abundant amino groups at the ends of hyperbranched polyamide molecules participate in curing of the waterborne epoxy coating to realize the coupling of the waterborne epoxy coating and the graphene oxide. According to the graphene oxide interfacial hyperbranched polyamide, on the one hand, the dispersity of the graphene oxide is improved; on the other hand, interfacial chemical reaction is improved. The method has the advantages that the action of water, saline water, acid and alkali is remarkably isolated from that of hydrophilic groups and base materials in the coating, and the properties such as water resistance, saline water resistance, acid and alkali resistance and the like in the coating are improved.

Owner:NANJING FORESTRY UNIV +1

Salt-water-resistant waterborne acrylic coating

The invention discloses a salt-water-resistant waterborne acrylic coating. The salt-water-resistant waterborne acrylic coating comprises the following raw materials in parts by weight: 140-180 parts of waterborne epoxy-modified acrylic emulsion, 20-30 parts of fumed silica, 14-20 parts of heavy calcium carbonate, 6-10 parts of precipitated barium sulfate, 10-16 parts of coal gangue powder, 2-4 parts of tetrabutyl titanate, 4-8 parts of water-based defoamer, 3-6 parts of coalescing agent, 2.5-4.5 parts of antifreeze, 2.5-4.5 parts of water-based wetting and leveling agent, 2.5-4.5 parts of water-based preservative, 2.5-4.5 parts of water-based thickener, and 100-140 parts of water. According to the salt-water-resistant waterborne acrylic coating, the obtained coating has excellent curing performance, has a large coating film density, has excellent adhesion, and has extremely high salt water resistant performance, and meanwhile, the phenomenon of coating film sagging is overcome, and thecoating has a long service life.

Owner:合肥林邦门业有限公司

Technological method of preparation of self-emulsified waterborne epoxy coating

InactiveCN106634400AEliminate wear processShort manufacturing cycleEpoxy resin coatingsEpoxyWeather resistance

The invention discloses a technological method of preparation of a self-emulsified waterborne epoxy coating, and the technological method comprises the following steps: A, epoxy resin is ground, an emulsifier is added to the ground epoxy resin, and stirring is conducted, so that an epoxy resin dispersion is obtained; B, the nanoscale epoxy resin obtained in the step A is added to an aqueous solution of an amidated polyamine emulsifier, and heating is conducted to obtain an epoxy resin aqueous dispersion system; C, by using the waterborne epoxy resin obtained through the step A and step B as a base material, the epoxy coating is prepared; D, a mixed emulsion obtained in the step C is heated at 100 to 105 DEG C for 15 to 30 minutes, so that a flaky semi-finished product is obtained; and E, the flaky semi-finished product obtained in the step D is ground, and testing and packing are conducted. The coating disclosed by the invention reduces the coating times and the cost of applying the coating to the steel structure products, extends the service life of the steel structure products and improves the weather resistance and salt-solution resistance.

Owner:丹阳市海信涂料化工厂

Anti-rust modified coating

InactiveCN107298903AImprove rust resistanceWell mixedAnti-corrosive paintsMetallic material coating processesDiethylene glycol monobutyl etherChlorinated paraffins

The invention discloses an anti-rust modified coating, which is prepared from the following raw materials: modified styrene-acrylic emulsion, modified hydroxyl calcium phosphate, a modified rust inhibitor, modified borate, high chlorinated polyethylene resin, xylene resin, diethylene glycol monobutyl ether, aluminum tripolyphosphate, modified zinc phosphate, composite iron-titanium powder, mica powder, triphenyl phosphite, graphite, sodium nitrite, sodium molybdate, chlorinated paraffin, a dispersing agent, a defoaming agent and an anti-flash-rust agent. The anti-rust modified coating has excellent anti-rust performance.

Owner:TIANCHANG JULONG TRAVEL PAINT

Waterborne acrylic acid modified alkyd pre-coating primer for railway vehicle and preparation method of pre-coating primer

InactiveCN109554061ABig performance impactInconvenient to paintAnti-corrosive paintsWater basedSoftened water

The invention belongs to the technical fields of pre-coating primers and preparation methods thereof. The invention discloses a waterborne acrylic acid modified alkyd pre-coating primer for a railwayvehicle and a preparation method of the pre-coating primer. The main technical characteristics of the pre-coating primer are that the waterborne acrylic acid modified alkyd pre-coating primer for therailway vehicle comprises water-based resin, wherein the water-based resin is prepared from the following components in parts by weight: 2-4 parts of plant oil, 1.29-1.47 parts of a polyhydric alcohol, 20-40 parts of saturated binary acid, 20-40 parts of unsaturated binary acid, 10-20 parts of acrylic acid, 10-20 parts of methacrylic acid, 1.5-2.0 parts of butyl acrylate, 20-40 parts of styrene, 20-40 parts of a cosolvent, 15-30 parts of a neutralizer, 10-20 parts of xylene, 0.01-0.03 part of an initiator, and 29-32.5 parts of softened water with conductivity of less than or equal to 10 [mu]S / cm. The resin is used for preparing the pre-coating primer which is a polymer taking lipophilic alkyd as a core and taking a hydrophilic acrylate copolymer as a shell. The particle size is small, compactness of the obtained paint film is high, the adhesive force is strong, and corrosion resistance is good.

Owner:ANPING JINLONG VEHICLE EQUIP

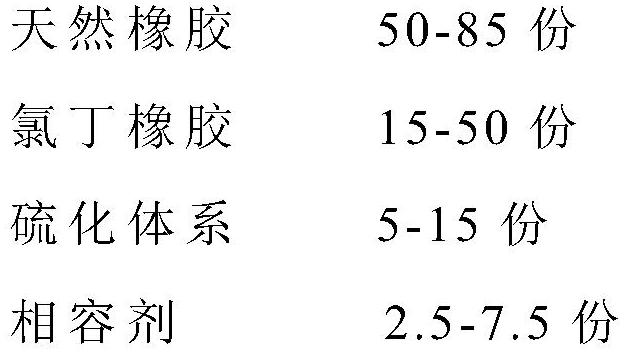

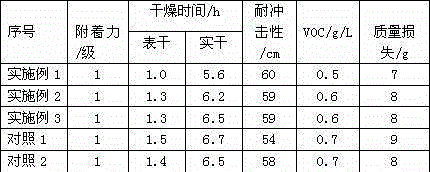

Natural rubber chloroprene rubber composition for seawater-resistant rubber support as well as preparation method and application of natural rubber chloroprene rubber composition

Owner:SUZHOU HAIDER NEW MATERIAL TECH CO LTD

Construction method of water-based heavy-duty anti-corrosion fluorocarbon coating

InactiveCN112122086AHigh degree of bindingImprove adhesionPretreated surfacesAnti-corrosive paintsWeather resistanceCorrosion resistant

The invention discloses a construction method of a water-based heavy-duty anti-corrosion fluorocarbon coating. The construction method comprises the following steps of removing oil stains on the surface of steel by using an alkaline degreasing agent, and washing with water after cleaning; removing rust scale by using acid pickling, removing the rust scale on the surface of the steel, and then conducting water washing; adding a phosphating agent for phosphating to form a phosphating film; adopting water-based heavy-duty anti-corrosion fluorocarbon paint as primer paint to be sprayed, being thespraying thickness 10-20 microns, and forming a primer coating through maintenance; using the water-based heavy-duty anti-corrosion fluorocarbon coating as a finish paint coating to be sprayed, beingthe spraying thickness 10-30 microns, and forming a finish paint protective coating through maintenance. According to the construction method of the water-based heavy-duty anti-corrosion fluorocarboncoating, the combination degree of the primer, the finish paint and the surface of the steel is high, the adhesive force of the coating is improved, the wear resistance, salt water resistance, weatherresistance and other properties of the coating are enhanced, the corrosion resistance of the steel is improved, meanwhile, the obtained coating is flat and uniform, the coating is lighter and thinner, the less paint can be used, cost is reduced, and construction is convenient.

Owner:葫芦岛渤船工贸通和防腐有限公司

Environment-friendly anticorrosive paint

InactiveCN105017939AHigh hardnessShorten drying timeAntifouling/underwater paintsPaints with biocidesEpoxyDrying time

The invention discloses an environment-friendly anticorrosive paint. The environment-friendly anticorrosive paint is prepared from following ingredients, by weight, 18 to 40 parts of novolac epoxy, 5 to 15 parts of calcium carbonate, 4 to 8 parts of kaolin, 2 to 9 parts of titanium dioxide, 12 to 24 parts of high chlorinated polyethylene resin, 1 to 3 parts of zinc borate, 2 to 6 parts of antimony oxide, 3 to 6 parts of a plasticizer, 2 to 4 parts of a dispersant, 1 to 5 parts of an antifoaming agent, and 2 to 4 parts of an antiseptic. Synergistic effects of the ingredients are excellent; film formation drying time is short; hardness is high; application of a mildew inhibitor is capable of inhibiting generation of mildew; application of the antiseptic is capable of improving salt water resistance, weatherability, and antiseptic property of the environment-friendly anticorrosive paint; and cooperation of the mildew inhibitor and the antiseptic is capable of prolonging lasting time of antimould effects.

Owner:湖州大周高分子材料有限公司

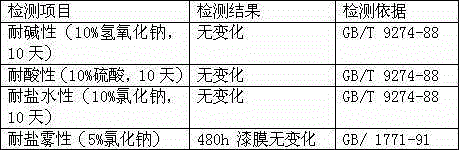

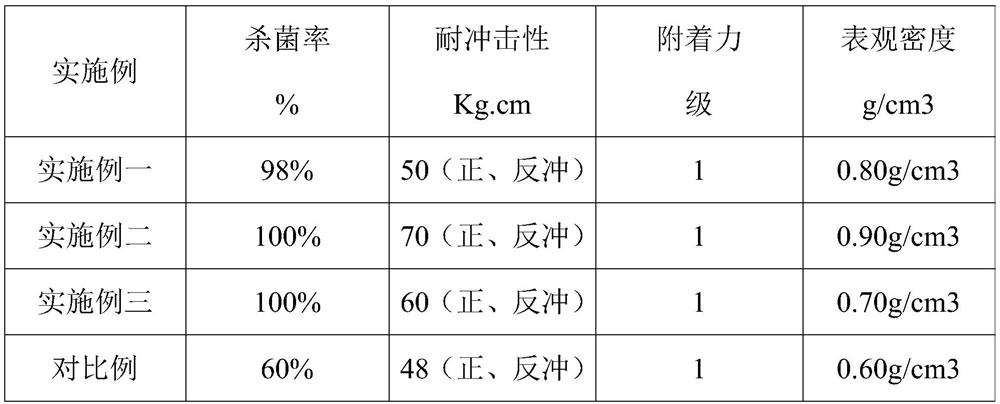

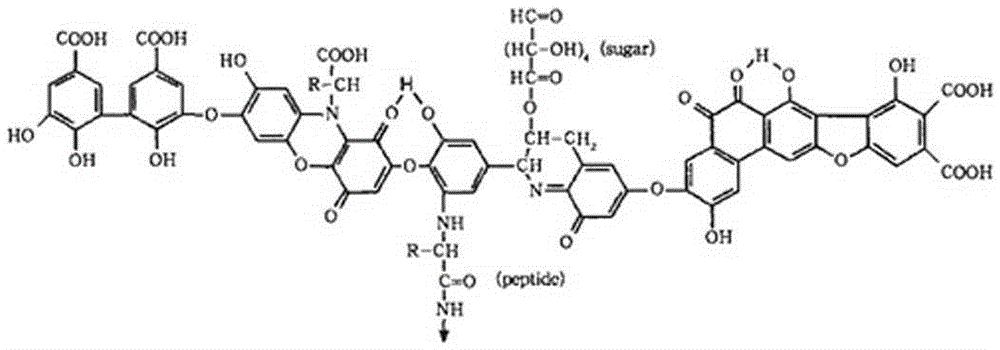

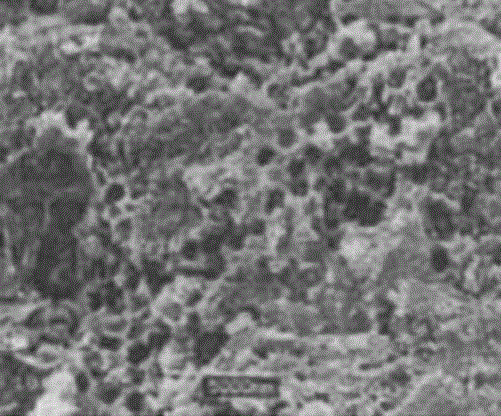

Water-based polymer antibacterial material with good water resistance and preparation method thereof

InactiveCN113372766AImprove water resistanceImprove salt water resistanceStarch dervative coatingsAntifouling/underwater paintsPhenolic antioxidantSalt water

The invention discloses a water-based polymer antibacterial material with good water resistance and a preparation method thereof. The water-based polymer antibacterial material is prepared from the following components in parts by weight: 50-70 parts of modified starch, 20-30 parts of modified water-based polyurethane, 40-50 parts of a reactive emulsifier, 10-15 parts of a nano-silver dispersant, 5-10 parts of negative ion crystals and 10-20 parts of a phenolic antioxidant. The problem that a coating film formed by waterborne polyurethane is low in initial viscosity and poor in water resistance is solved. The water resistance, salt water resistance, corrosion resistance and other physical and mechanical properties of the coating can be effectively improved by adding the reactive emulsifier, and the negative ion crystals are used, so that the waterborne polymer coating can release a large number of negative ions, the content of formaldehyde, voc and dust in indoor air is effectively reduced, and the effects of killing bacteria and removing peculiar smell are achieved.

Owner:SHENZHEN DECHENGDA PHOTOELECTRIC MATERIAL CO LTD

Oxidized peat fulvic acid composite water retaining agent and preparation method thereof

InactiveCN105384882AReduce energy consumptionImprove responseAgriculture tools and machinesBuilding constructionsMeth-Ethyl group

An oxidized peat fulvic acid composite water retaining agent is prepared from, by mass, 50-60 parts of oxidized peat fulvic acid, 15-25 parts of cationic compound monomers, 8-15 parts of anionic compound monomers, 0.1-0.8 part of a cross-linking agent and 0.4-3.8 parts of initiator. The oxidized peat fulvic acid is prepared from, by mass, 1 part of oxidized peat, 0.05-0.20 part of an oxidizing agent and 2.95-8 parts of industrial pure water. The cationic compound monomer is one of (3-methacrylamidipropyl) trimethyl ammonium chloride, methyl acrylyl ethyl trimethyl ammonium iodide, (3-acrylamidopropyl)trimethyl ammonium chloride, dimethylaminoethyl methacrylate, N,N-dimethylaminoethyl acrylate and 2-diethylaminoethyl methacrylate. The cross-linking agent is composed of, by mass, 5-8 parts of N,N-methylene bisacrylamide and 0.5-3 parts of glycerine or ethylene glycol diglycidyl ether or dimethylol urea. The initiator is prepared from, by mass, 5 parts of ammonium persulfate and 1-4 parts of potassium sulfite.

Owner:SHANXI AGRI UNIV

Mining nitro mixed paint

InactiveCN106280725AImprove water resistanceImprove salt water resistancePolyester coatingsSalt resistanceSalt water

The invention belongs to the technical field of mining paint and relates to mining nitro mixed paint designed for a mine environment. The technical scheme includes that the mining nitro mixed paint is prepared from nitro base materials, modified alkyd resin, a resin cross-linking agent, ultrafine calcium, precipitated barium sulfate, a combined solvent, a drier, a passivator, a waterproof cover agent and pigments. The mining nitro mixed paint is long in service life, excellent in water resistance and salt water resistance and widely applicable to mines.

Owner:大同煤矿矿山铁路实业公司中富涂料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com