Environment-friendly anticorrosive paint

An anti-corrosion coating, an environmentally friendly technology, applied in the direction of anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems that water-soluble coatings are prone to biological damage, cannot effectively protect equipment, and the elasticity of the coating film is easy to age. , to achieve the effect of inhibiting the generation of mold, short drying time of film formation and good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

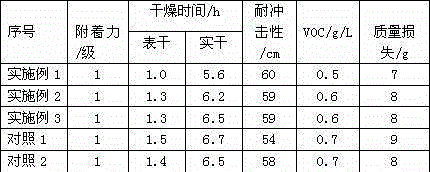

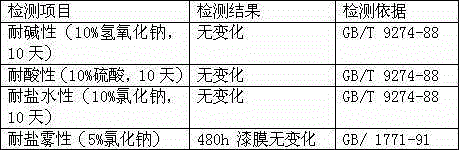

Examples

Embodiment 1

[0012] An environment-friendly anti-corrosion coating, which is composed of the following components in parts by weight: 27 parts of phenolic epoxy resin, 10 parts of calcium carbonate, 6 parts of kaolin, 5 parts of titanium dioxide, 18 parts of high-chlorinated polyethylene resin, and 2 parts of zinc borate , 5 parts of antimony oxide, 4 parts of plasticizer, 3 parts of dispersant, 3 parts of defoamer, 4 parts of preservative. Wherein, the preservative is a mixture of sorbic acid and potassium sorbate, and the weight ratio of the two is sorbic acid: potassium sorbate=1:2.

Embodiment 2

[0014] An environment-friendly anti-corrosion coating, which is composed of the following components in parts by weight: 18 parts of phenolic epoxy resin, 15 parts of calcium carbonate, 4 parts of kaolin, 9 parts of titanium dioxide, 12 parts of high-chlorinated polyethylene resin, and 3 parts of zinc borate , 2 parts of antimony oxide, 6 parts of plasticizer, 2 parts of dispersant, 5 parts of defoamer, 2 parts of preservative. Wherein, the preservative is a mixture of sorbic acid and potassium sorbate, and the weight ratio of the two is sorbic acid: potassium sorbate=1:2.

Embodiment 3

[0016] An environment-friendly anti-corrosion coating, which is composed of the following components by weight: 35 parts of phenolic epoxy resin, 7 parts of calcium carbonate, 7 parts of kaolin, 3 parts of titanium dioxide, 20 parts of high-chlorinated polyethylene resin, and 2 parts of zinc borate , 6 parts of antimony oxide, 3 parts of plasticizer, 3 parts of dispersant, 2 parts of defoamer, 4 parts of preservative. Wherein, the preservative is a mixture of sorbic acid and potassium sorbate, and the weight ratio of the two is sorbic acid: potassium sorbate=1:2.

[0017] Control 1

[0018] An environment-friendly anti-corrosion coating, which is composed of the following components in parts by weight: 27 parts of phenolic epoxy resin, 10 parts of calcium carbonate, 6 parts of kaolin, 5 parts of titanium dioxide, 18 parts of high-chlorinated polyethylene resin, and 2 parts of zinc borate , 5 parts of antimony oxide, 4 parts of plasticizer, 3 parts of dispersant, 3 parts of de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com