High-solid anti-rust and anti-corrosion coating

A rust and anti-corrosion, high-solid technology, applied in the field of coatings, can solve problems such as environmental hazards, unsatisfactory anti-corrosion performance, and inability to satisfy customers, and achieve good thixotropic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

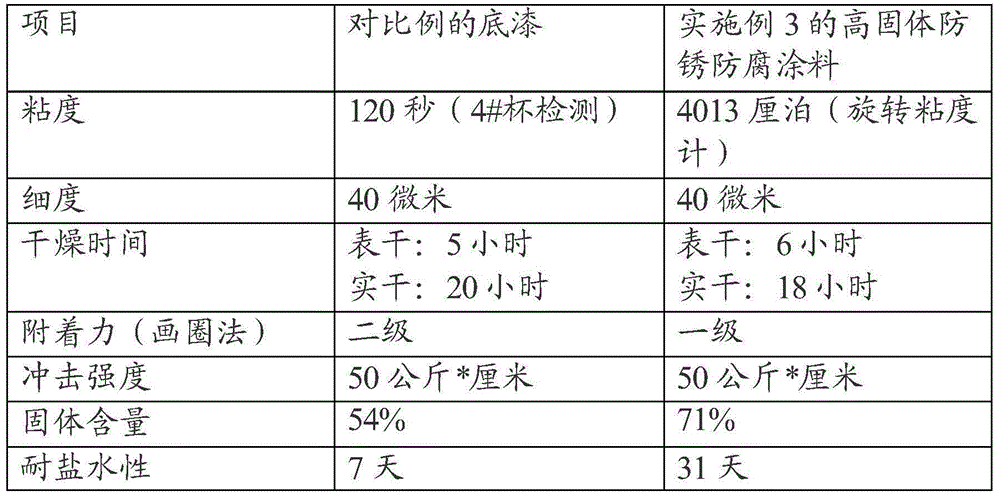

Examples

preparation example Construction

[0061] The preparation method of above-mentioned high solid antirust anticorrosion paint, comprises the following steps:

[0062] In parts by weight, 18-22 parts of the first epoxy resin, 10-15 parts of magnet powder, 2-10 parts of iron oxide red, 3-6 parts of zinc phosphate, 1-6 parts of zinc powder and 0.1-0.2 parts of dispersed agent, stirred until the fineness reaches 35 microns, and discharged to obtain a mixture;

[0063] Weigh xylene, and under constant stirring, add 0.5-0.7 parts of modified bentonite, stir evenly, add ethanol, and carry out ball milling with the mixture, and pour into the mixing tank after the ball milling is completed;

[0064] Add 18-24 parts of the second epoxy resin into the diluent, then add 0.2-0.4 parts of nano-silica under stirring, pour into the mixing tank after stirring; when the powder reaches a rotational viscosity of 4000 centipoise , discharging, to obtain component A;

[0065] Weigh 56-62 parts of the first amine curing agent, add 20...

Embodiment 1

[0069] A kind of high-solid antirust anticorrosion paint, comprising A component and B component that the weight ratio is 5:1, by weight, A component comprises:

[0070] 18 parts of E44 resin (first epoxy resin), 18 parts of E20 resin (second epoxy resin) with a mass fraction of 60%, 10 parts of magnet powder, 2 parts of iron oxide red, 3 parts of zinc phosphate, and 1 part of zinc powder , 0.1 parts of dispersant, 0.2 parts of R972 (nano silica), 0.5 parts of 881-B (modified bentonite), 0.2 parts of additives and 12 parts of diluent;

[0071] Component B includes:

[0072] Hexamethylenediamine (first amine curing agent) 56 parts, 651 polyamide (second amine curing agent) 12 parts, ethanol 20 parts.

[0073] The preparation method of above-mentioned high solid antirust anticorrosion paint, comprises the following steps:

[0074] Stir E44 resin, magnet powder, iron oxide red, zinc phosphate, zinc powder, and dispersant until the fineness reaches 35 microns, and discharge to o...

Embodiment 2

[0080] A kind of high-solid antirust anticorrosion paint, comprising A component and B component that the weight ratio is 5:1, by weight, A component comprises:

[0081] 22 parts of E44 resin (first epoxy resin), 24 parts of E20 resin (second epoxy resin), 15 parts of magnet powder, 10 parts of iron oxide red, 6 parts of zinc phosphate, 6 parts of zinc powder, 0.2 parts of dispersant, 0.4 parts of R972 (nano silica), 0.7 parts of 881-B (modified bentonite), 0.3 parts of additives and 15 parts of diluent;

[0082] Component B includes:

[0083] Hexamethylenediamine (first amine curing agent) 62 parts, 651 polyamide (second amine curing agent) 18 parts, ethanol 30 parts.

[0084] The preparation method of above-mentioned high solid antirust anticorrosion paint, comprises the following steps:

[0085] Stir E44 resin, magnet powder, iron oxide red, zinc phosphate, zinc powder, and dispersant until the fineness reaches 35 microns, and discharge to obtain a mixture;

[0086] Weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com