Water-based polymer antibacterial material with good water resistance and preparation method thereof

A technology of water-based polymers and antibacterial materials, which is applied in the field of coatings and can solve problems such as poor functionality and insufficient processing and adaptation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

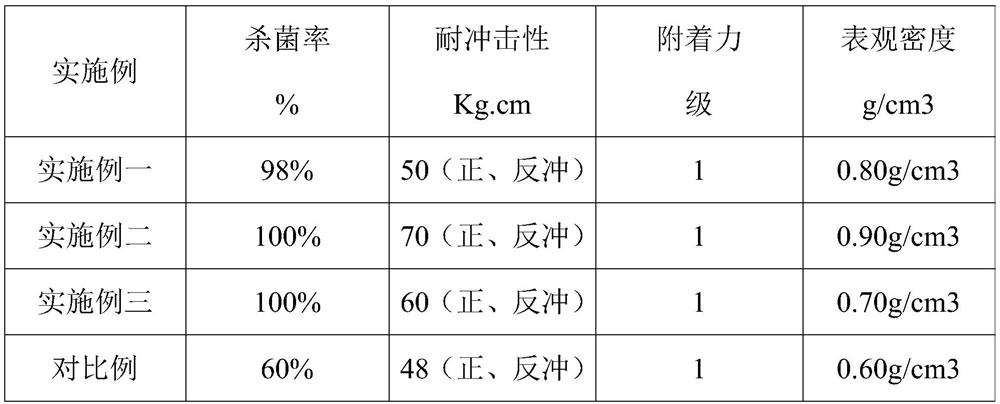

Examples

Embodiment 1

[0046] First prepare modified starch, modified water-based polyurethane and reactive emulsifier in sequence:

[0047] Step S1: cornstarch is used as raw material for modified starch, sodium periodate is used as oxidant, and hydrochloric acid is used as acidolysis agent. The acidolysis agent and oxidant are first added to deionized water for mixing, and then cornstarch is added and stirred to prepare starch milk;

[0048] Step S2: Next, transfer the prepared starch milk to a chemical reaction kettle for one-step acidolysis and oxidation reaction;

[0049] Step S3: After the acidolysis oxidation reaction is completed, the obtained material is washed until the material is neutral, then dried and ground in sequence, and finally the powdered material is filtered to obtain powdered dialdehyde starch;

[0050] Step S4: using a Fourier transform infrared spectrometer to detect the prepared powdery dialdehyde starch, and verify whether it is qualified according to the characterization; ...

Embodiment 2

[0066] First prepare modified starch, modified water-based polyurethane and reactive emulsifier in sequence:

[0067] Step S1: cornstarch is used as raw material for modified starch, sodium periodate is used as oxidant, and hydrochloric acid is used as acidolysis agent. The acidolysis agent and oxidant are first added to deionized water for mixing, and then cornstarch is added and stirred to prepare starch milk;

[0068] Step S2: Next, transfer the prepared starch milk to a chemical reaction kettle for one-step acidolysis and oxidation reaction;

[0069] Step S3: After the acidolysis oxidation reaction is completed, the obtained material is washed until the material is neutral, then dried and ground in sequence, and finally the powdered material is filtered to obtain powdered dialdehyde starch;

[0070] Step S4: using a Fourier transform infrared spectrometer to detect the prepared powdery dialdehyde starch, and verify whether it is qualified according to the characterization;...

Embodiment 3

[0086] First prepare modified starch, modified water-based polyurethane and reactive emulsifier in sequence:

[0087] Step S1: cornstarch is used as raw material for modified starch, sodium periodate is used as oxidant, and hydrochloric acid is used as acidolysis agent. The acidolysis agent and oxidant are first added to deionized water for mixing, and then cornstarch is added and stirred to prepare starch milk;

[0088] Step S2: Next, transfer the prepared starch milk to a chemical reaction kettle for one-step acidolysis and oxidation reaction;

[0089] Step S3: After the acidolysis oxidation reaction is completed, the obtained material is washed until the material is neutral, then dried and ground in sequence, and finally the powdered material is filtered to obtain powdered dialdehyde starch;

[0090] Step S4: using a Fourier transform infrared spectrometer to detect the prepared powdery dialdehyde starch, and verify whether it is qualified according to the characterization;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com