Organic silicon heat-resistant finish paint and preparation method thereof

A silicone, heat-resistant technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of poor mechanical strength, adhesion and corrosion resistance, poor drying, small use range and application, etc., to enhance adhesion and resistance. High temperature performance, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

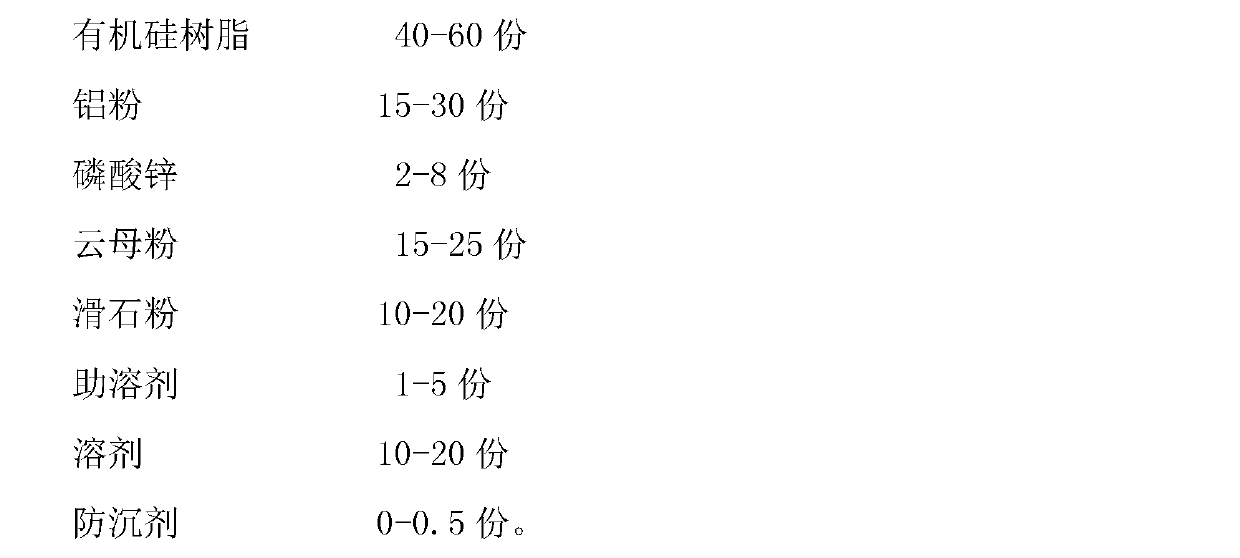

[0022] Silicone heat-resistant topcoat consists of the following raw materials in parts by weight:

[0023]

[0024] The specific preparation method is as follows:

[0025] (1) Mix silicone resin, aluminum powder, mica powder, talcum powder, zinc phosphate, anti-sedimentation agent and some solvents according to the proportion and stir them into a paste;

[0026] (2) Put the uniformly mixed material in (1) into a sand mill for grinding for 20 minutes, so that the particle size of the material is not greater than 30 μm;

[0027] (3) Add a co-solvent and the remaining solvent to the material in (2) to disperse, and filter to obtain a silicone heat-resistant topcoat.

Embodiment 2

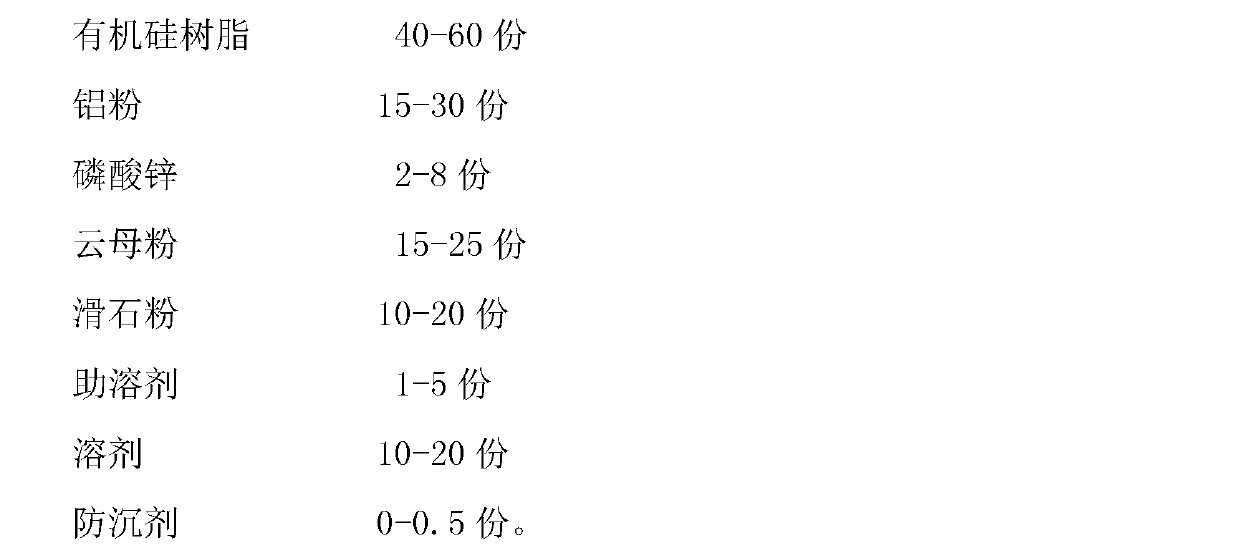

[0029] Silicone heat-resistant topcoat consists of the following raw materials in parts by weight:

[0030]

[0031] The specific preparation method is as follows:

[0032] (1) Mix silicone resin, aluminum powder, mica powder, talcum powder, zinc phosphate, anti-sedimentation agent and some solvents according to the proportion and stir them into a paste;

[0033] (2) Put the uniformly mixed material in (1) into a sand mill for grinding for 25 minutes, so that the particle size of the material is not greater than 30 μm;

[0034] (3) Add a co-solvent and the remaining solvent to the material in (2) to disperse, and filter to obtain a silicone heat-resistant topcoat.

Embodiment 3

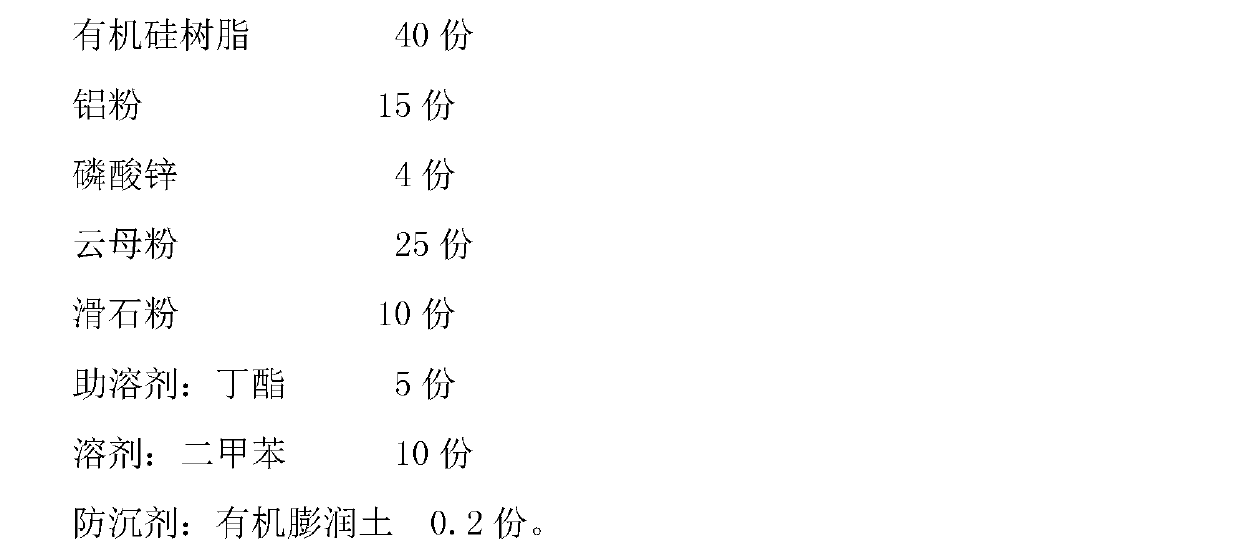

[0036] Silicone heat-resistant topcoat consists of the following raw materials in parts by weight:

[0037]

[0038] The specific preparation method is as follows:

[0039] (1) Mix silicone resin, aluminum powder, mica powder, talcum powder, zinc phosphate, anti-sedimentation agent and some solvents according to the proportion and stir them into a paste;

[0040] (2) Put the uniformly mixed material in (1) into a sand mill for grinding for 30 minutes, so that the particle size of the material is not greater than 30 μm;

[0041] (3) Add a co-solvent and the remaining solvent to the material in (2) to disperse, and filter to obtain a silicone heat-resistant topcoat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com