Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "High transfer rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

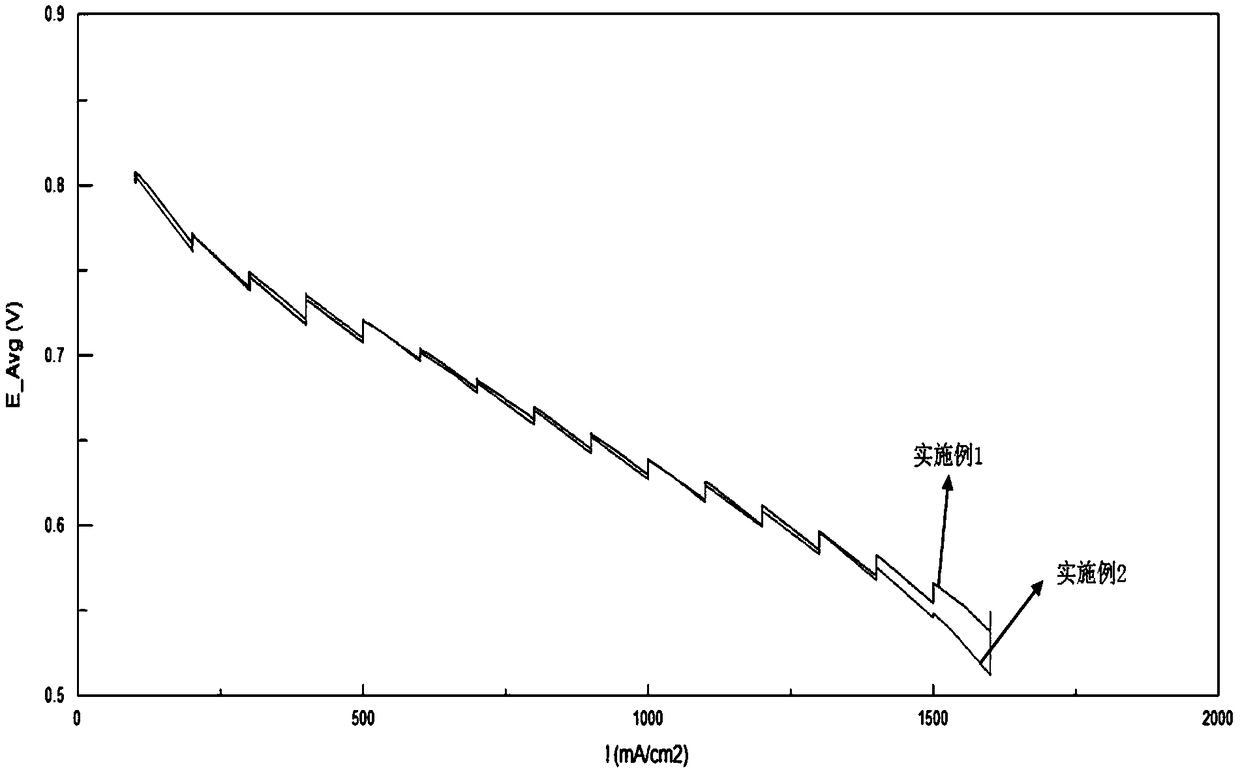

Proton exchange membrane fuel cell ccm membrane electrode and preparation method thereof

InactiveCN109088073AImprove yieldIncrease productivityCell electrodesFinal product manufactureHot pressCoating

The invention relates to a preparation method of a ccm membrane electrode of a proton exchange membrane fuel cell and a product thereof. The preparation method comprises the following steps: providinga catalyst slurry, a two-release membrane and a proton exchange membrane; A release film is placed on a coating machine, and a catalyst slurry is coated on the release film by a coating tool to obtain a cathode transfer medium; placing another release film on a coating machine, coating catalyst slurry on the release film by using a coating tool, and obtaining an anode transfer medium; drying a cathode transfer medium and an anode transfer medium to obtain a dried cathode transfer medium and an anode transfer medium; placing the dried cathode transfer medium and the anode transfer medium on both sides of the proton exchange membrane respectively, and then hot-pressed to transfer, and then the release membranes in the cathode transfer medium and the anode transfer medium are stripped off respectively to obtain the ccm membrane electrodes of the proton exchange membrane fuel cell. By using the release film as the transfer medium, the catalyst transfer efficiency is high and the production efficiency is improved.

Owner:东莞众创新能源科技有限公司

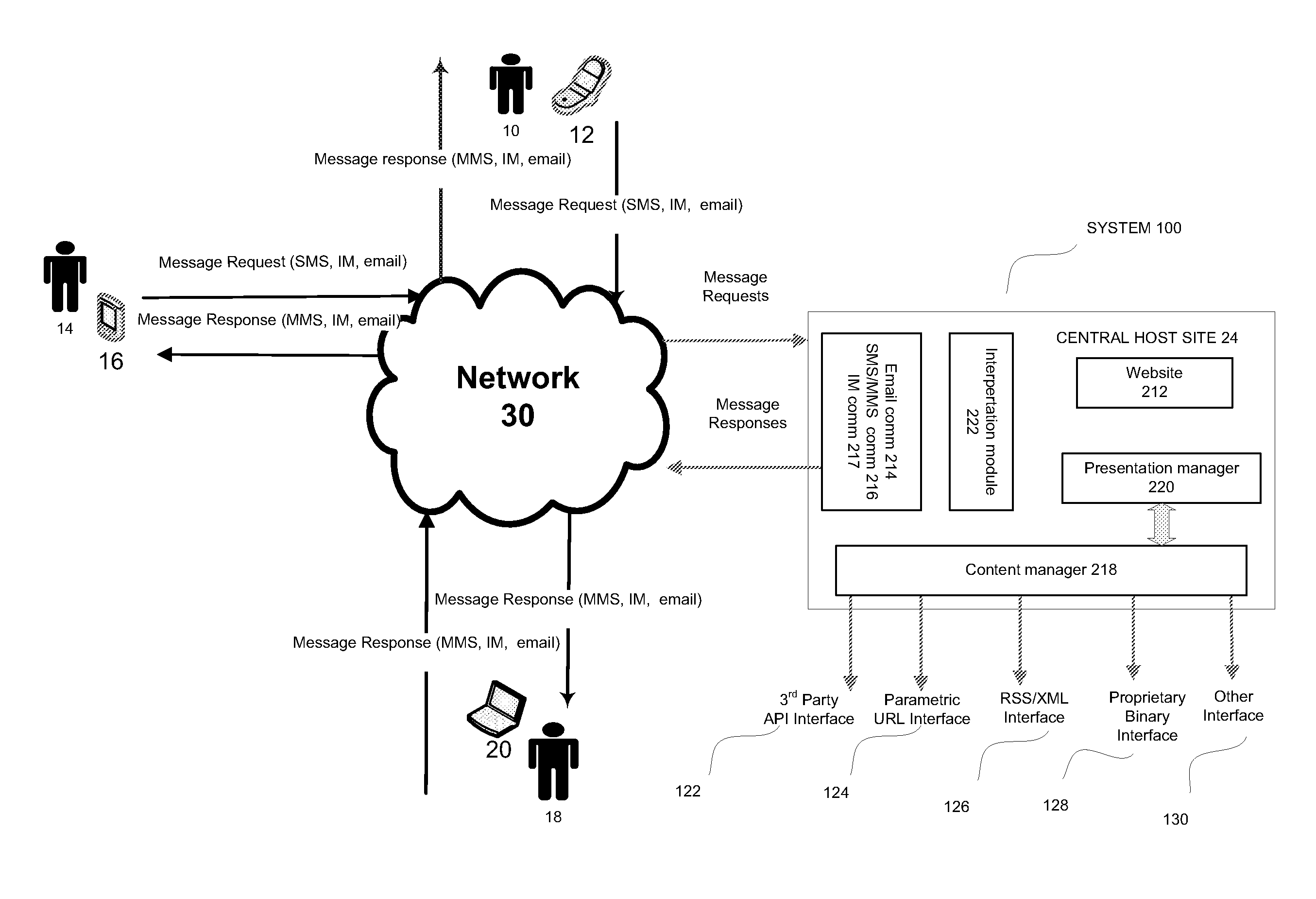

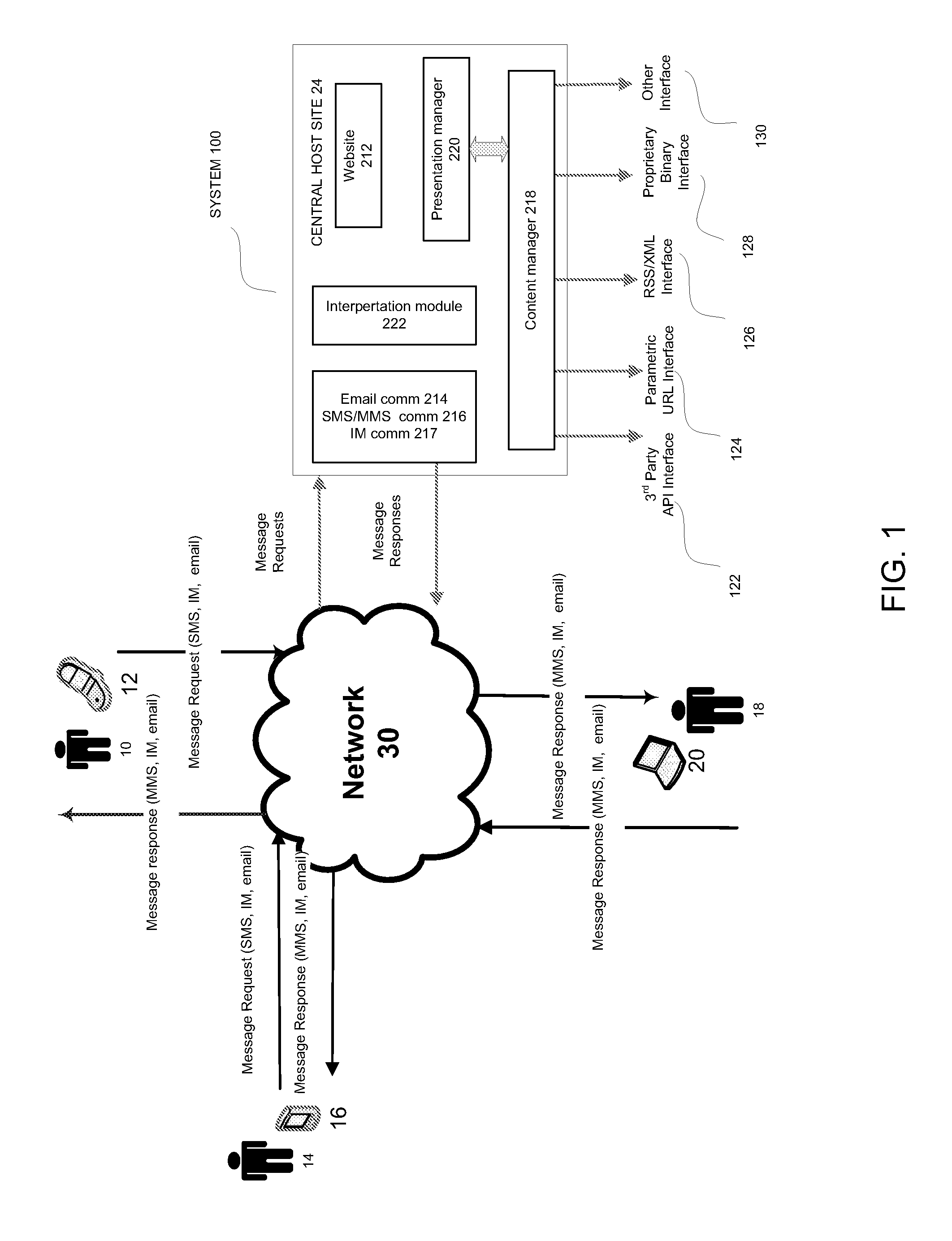

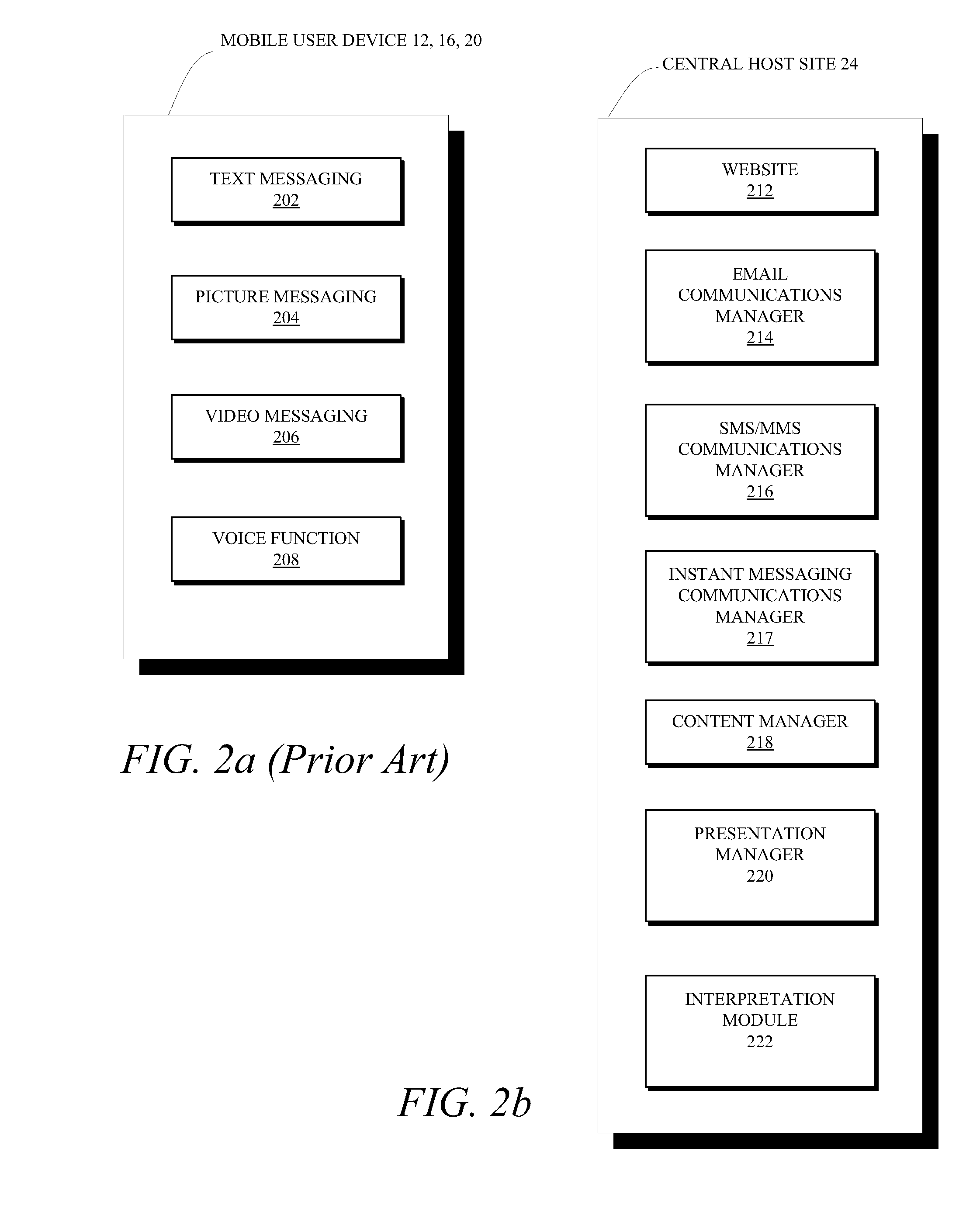

System and method for responding to information requests from users of personal communication devices

InactiveUS20080293387A1Reduce usageEasily and naturally viewedTelevision system detailsColor television detailsDisplay deviceEngineering

There are provided methods and systems for responding to information requests from users of personal communication devices, such as mobile telephones and more particularly cellular telephones. In one embodiment, information requests issued from a plurality of user's cellular telephones are received and processed at a central host site. Processing comprises parsing the user requests to determine the content and category type of the request and retrieving relevant content configured as a sequence of images (frames), referred to as a “video strip”. When a user plays back a video strip on his or her personal communication device, the sequence of images appear on the user's display as a sequence of still images, played back at a slow rate, unlike conventional movie playback frame rates. When viewing a video strip, a viewer may stop, start, and pause the video strip. Pausing playback of a video strip enables the user to easily peruse the contents of each video strip frame.

Owner:GLOTO

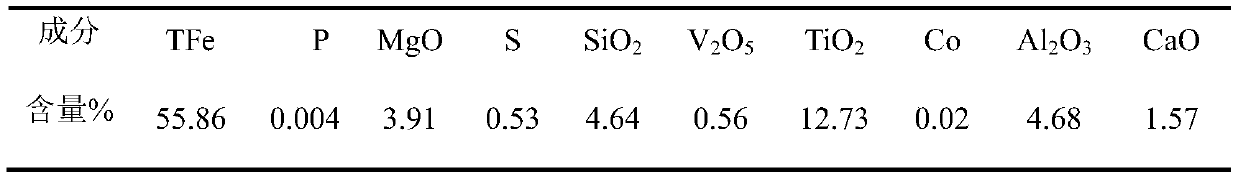

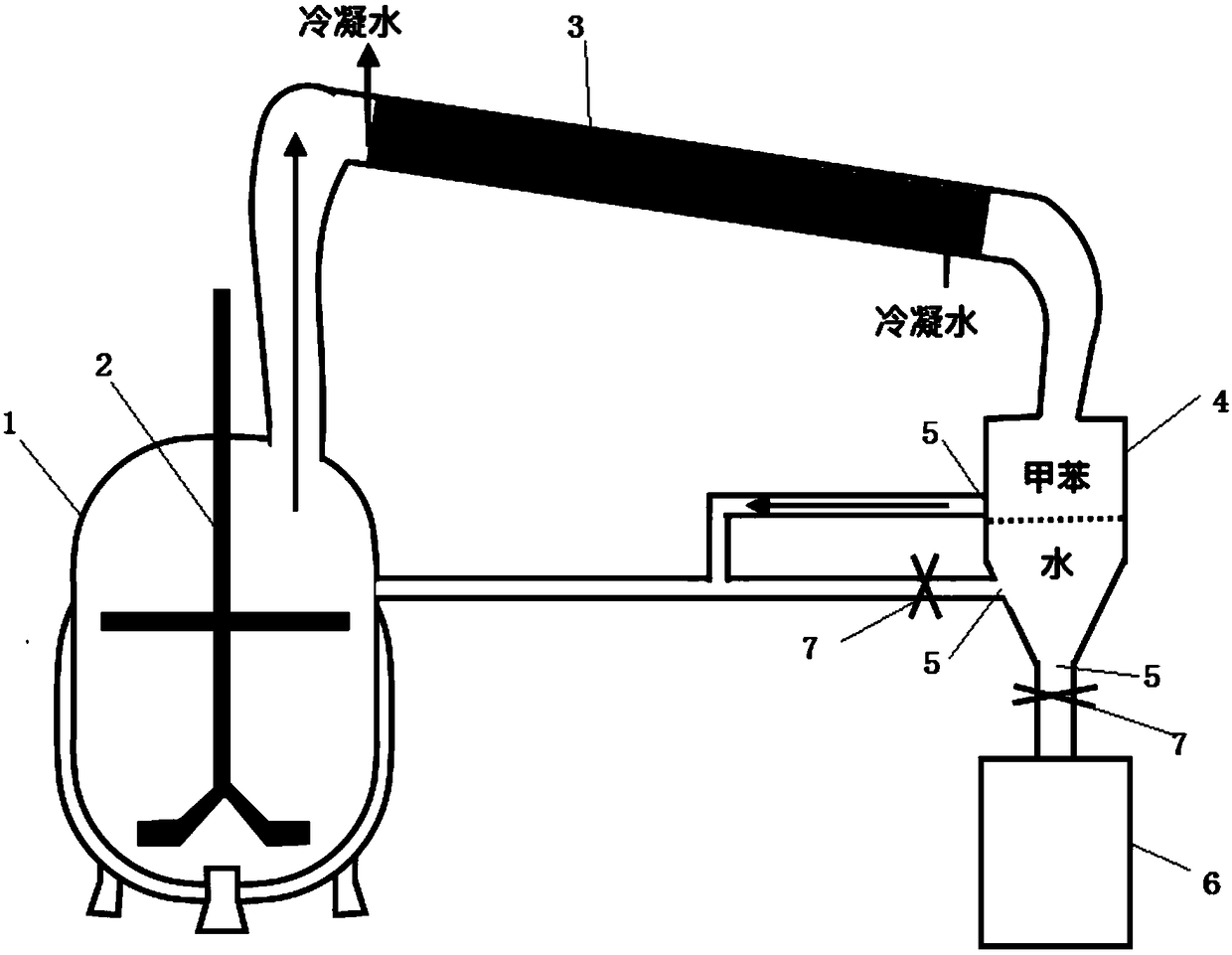

Method for extracting vanadic anhydride from stone coal vanadium ore

InactiveCN101182596AReduced drying processFew ingredientsVanadium oxidesProcess efficiency improvementCelsius DegreeDesorption

The invention relates to a method for extracting vanadic oxide from bone coal vanadium mine; the method comprises the following steps that the bone coal vanadium mine is selected to be delivered into a kiln for baking and the kiln temperature is controlled between 750 to 1100 Celsius degrees and the discharge temperature of the baked material is 750 to 1000 Celsius degrees; and then the materials are delivered into a heat-preservation warehouse to be kept still for 24 to 120 hours; and then the material is extracted and the pH value of the obtained extraction liquid is adjusted to be 2.5; the liquid is absorbed and desorbed to obtain the desorption liquid and then the desorption liquid is purified and the silicon and phosphor in the desorption liquid is removed; ammonium chloride is added to precipitate vanadium and obtain ammonium meta-vanadate; the ammonium meta-vanadate is implemented with the process of pyrolysis to obtain the vanadic oxide. The beneficial effect of the invention is that the bone coal vanadium mine is directly baked which reduces the working procedures of baking, proportioning, ball grinding and balling; the invention adopts the heat-preserving warehouse for preserving heat and the extraction rate can reach more than 90 percent if the temperature is kept between 750 to 1100 Celsius degrees for more than 72 hours; the extraction rate is higher if the heat-preserving time is longer; moreover, the mechanization degree is high and no dust pollution exists.

Owner:杨秋良

Ultra wideband radio transmitter, ultra wideband radio receiver, and ultra wideband radio communication method

InactiveUS20060234761A1Improve communication qualityHigh transfer rateSubstation equipmentSecret communicationUltra-widebandCommunication quality

Disclosed are ultra wideband radio transmitter, ultra wideband radio receiver, and ultra wideband radio communication method capable of securing higher transfer rate and communication quality than conventional ones while avoiding a band where communication signals are concentrated, and capable of miniaturizing an antenna. In a transmitter, a delay time controller (12) outputs a periodic pulse to matched filters 11-1 and 11-2 when transmission data is 1, and outputs the periodic pulse to matched filters 11-1 and 11-3 when the transmission data is 0. The matched filter 11-1 outputs reference signal, the matched filter 11-2 outputs first data signal ahead of the reference signal, and the matched filter 11-3 outputs second data signal behind the reference signal. An adder (13) adds up these, a mixer (21) frequency-converts output of the adder using a local signal received from a local oscillator (23), and an antenna (6) radiates output of the mixer (21).

Owner:SAMSUNG ELECTRONICS CO LTD

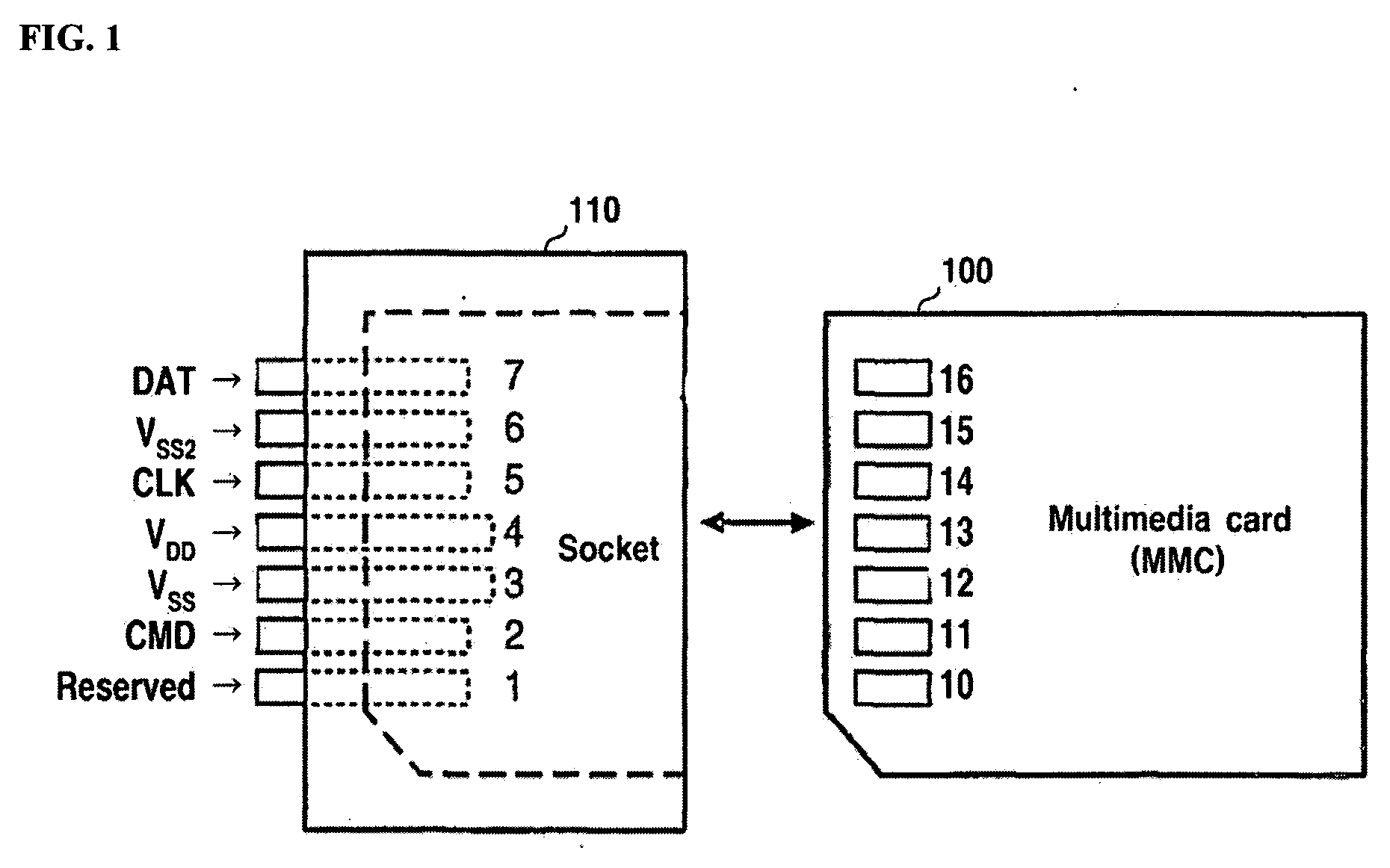

Method for enhancing transfer rate of multimedia card using differential signal

InactiveUS20050045722A1High transfer rateImprove transfer rateBaseband system detailsCo-operative working arrangementsData transmissionData channel

Provided is a method and apparatus for enhancing a data transfer rate by adding a new data transfer channel using a differential signal to a conventional MMC. The method includes steps of determining whether a host controller is a host controller for a high-speed multimedia card; determining whether a multimedia card is a high-speed multimedia card; transferring data using a VDAT channel if the host controller is a host controller for a high-speed multimedia card and the multimedia card is a high-speed multimedia card; and transferring the data using a DAT channel in the other cases. A host controller for controlling a multimedia card configures a VDAT channel capable of transferring a differential signal using a reserved terminal of a conventional multimedia card and a newly added terminal, and includes a data channel selection unit for using the configured channel.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for directly extracting vanadium from high-calcium vanadium slag by roasting-alkali leaching

The invention provides a method for directly extracting vanadium from high-calcium vanadium slag by roasting-alkali leaching, which comprises the following steps: 1) crushing and screening high-calcium vanadium slag in which the CaO / V2O5 mole ratio is 3-5; 2) carrying out oxidizing roasting on the screened high-calcium vanadium slag at 600-950 DEG C for 1.5-2.5 hours; 3) crushing and screening the vanadium slag clinker subjected to oxidizing roasting; 4) leaching the screened vanadium slag clinker in an Na2CO3 solution at 65-95 DEG C for 10-180 minutes to extract the vanadium; 5) carrying out solid-liquid separation on the leaching solution, and washing the vanadium slag with a 5-7 wt% Na2CO3 solution 2-3 times while filtering so as to obtain vanadium slag and a vanadium-containing filtrate which are used for subsequent vanadium settling treatment. The method is simple and easy to operate and low in cost; when the method is used for extracting vanadium, the leaching rate of vanadium can be up to 94%, and the leaching rate of the impurity element phosphorus can be down to 11%, thereby enhancing the purity of the vanadium product.

Owner:CHONGQING UNIV

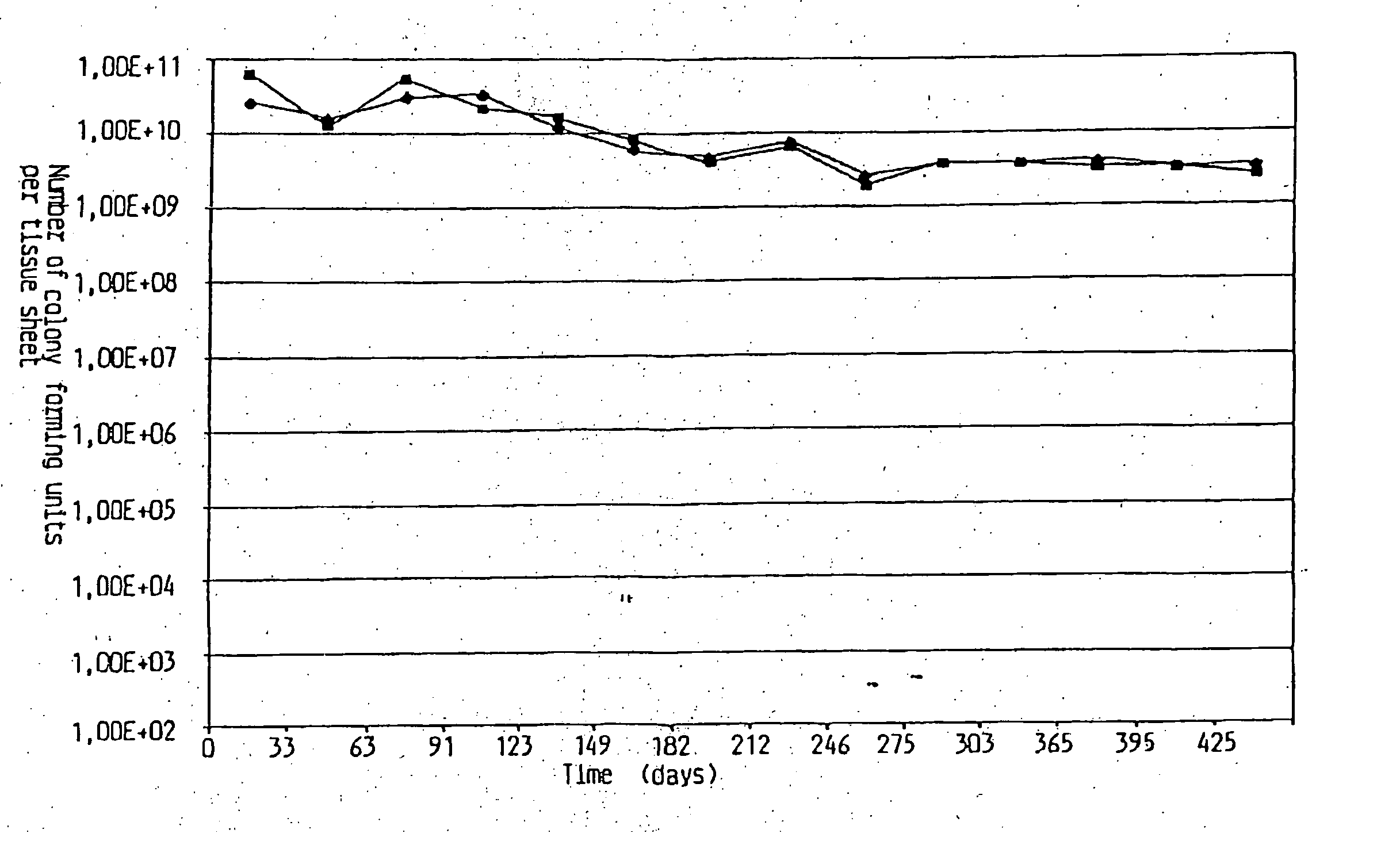

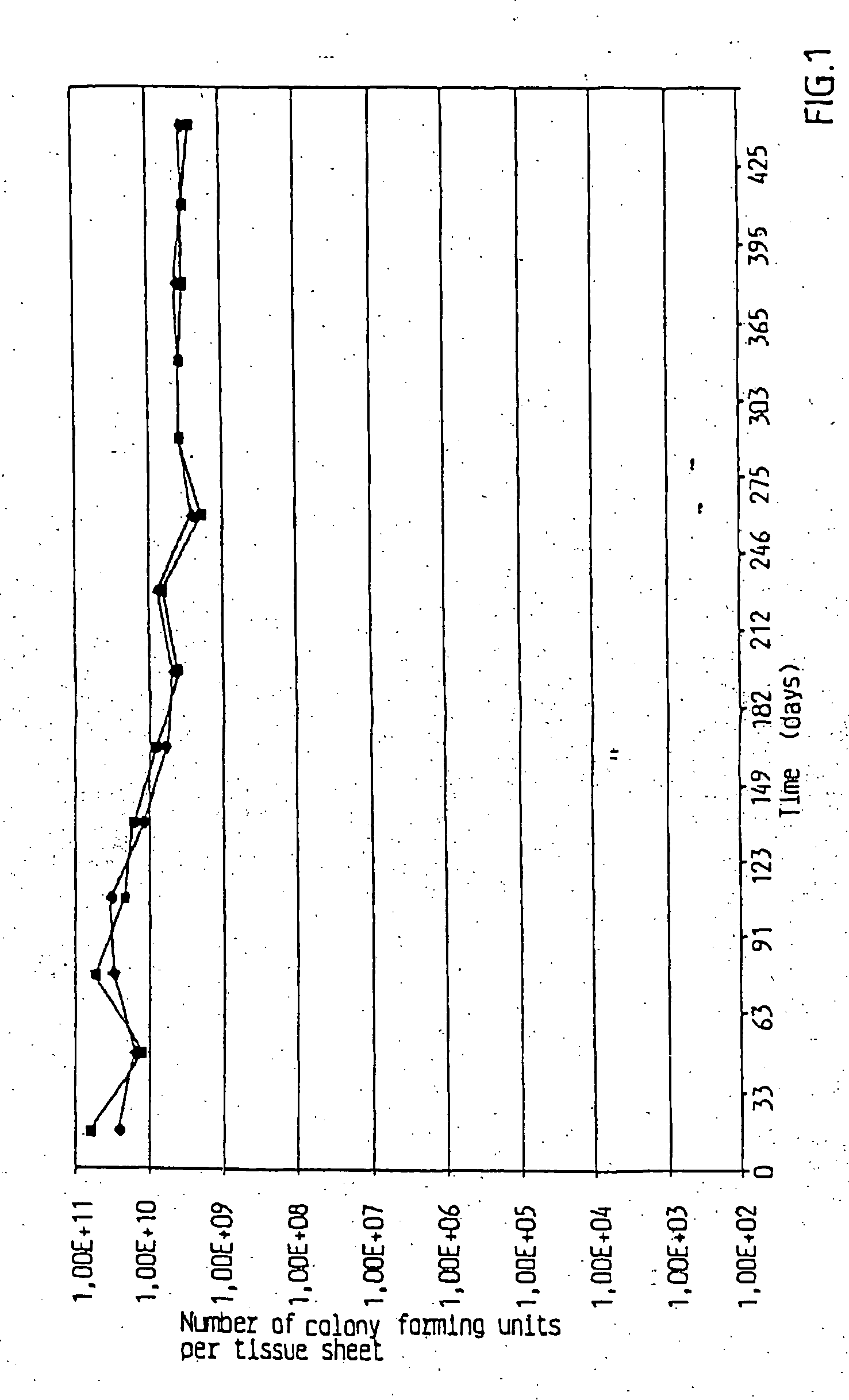

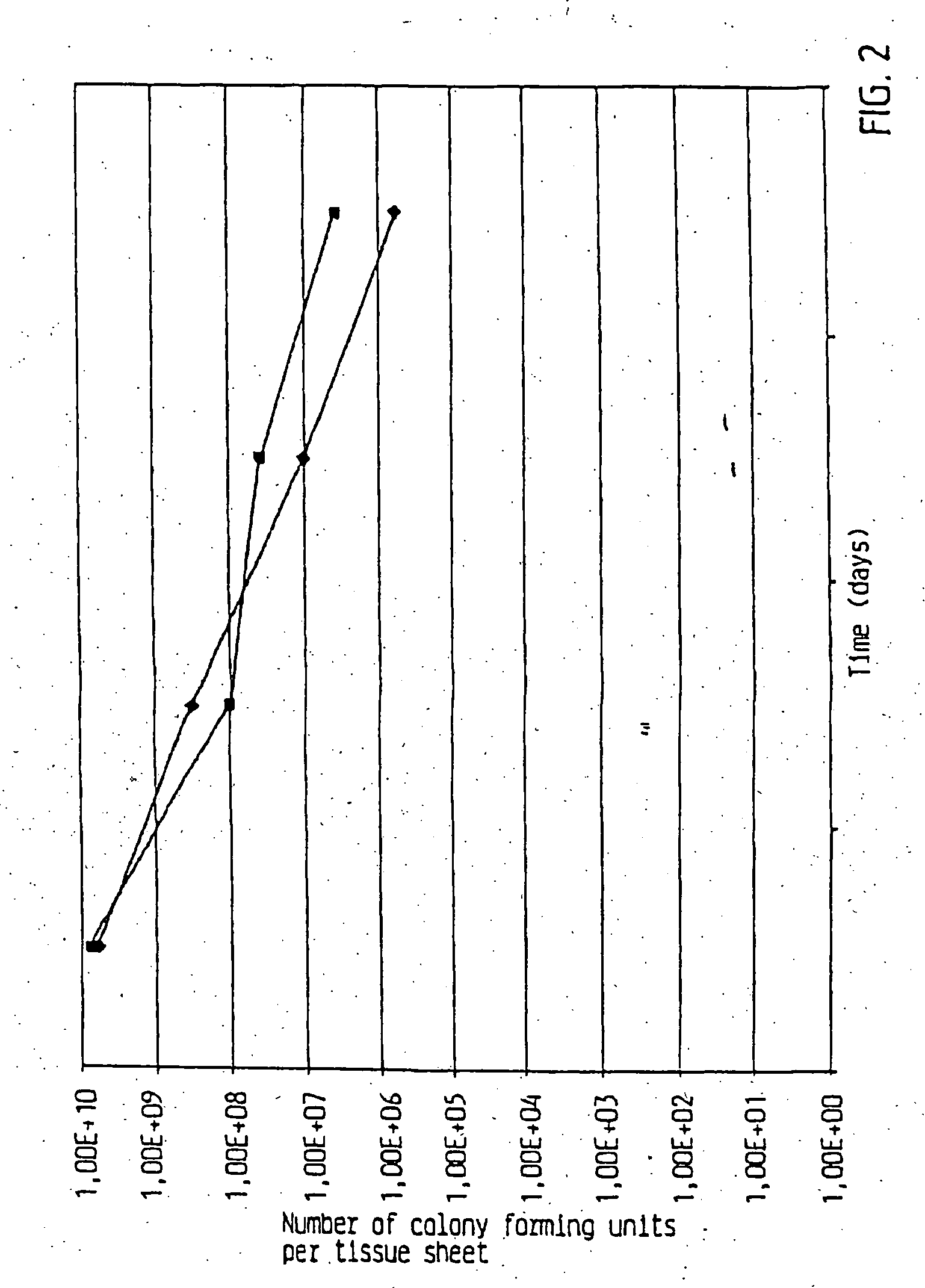

Hygiene tissue with lactic acid producing bacterial strains

InactiveUS20040142832A1Enhance longevityHigh transfer ratePowder deliveryCosmetic preparationsLactic acid producing bacteriaMoisture

A hygiene tissue is used for both cleaning and transferring lactic acid producing bacteria to the skin and urogenital area. The hygiene tissue contains, on separate parts of the tissue, cleaning liquid and a bacterial composition. Bacterial viability and transfer ability is maintained by suspending the bacteria in a lipid which protects the bacteria from moisture. The lipid also enhances transfer of the bacteria from the tissue to the skin or urogenital area. Different designs of the hygiene tissue prevent the mixing of the cleaning liquid and the bacterial composition.

Owner:SCA HYGIENE PROD AB

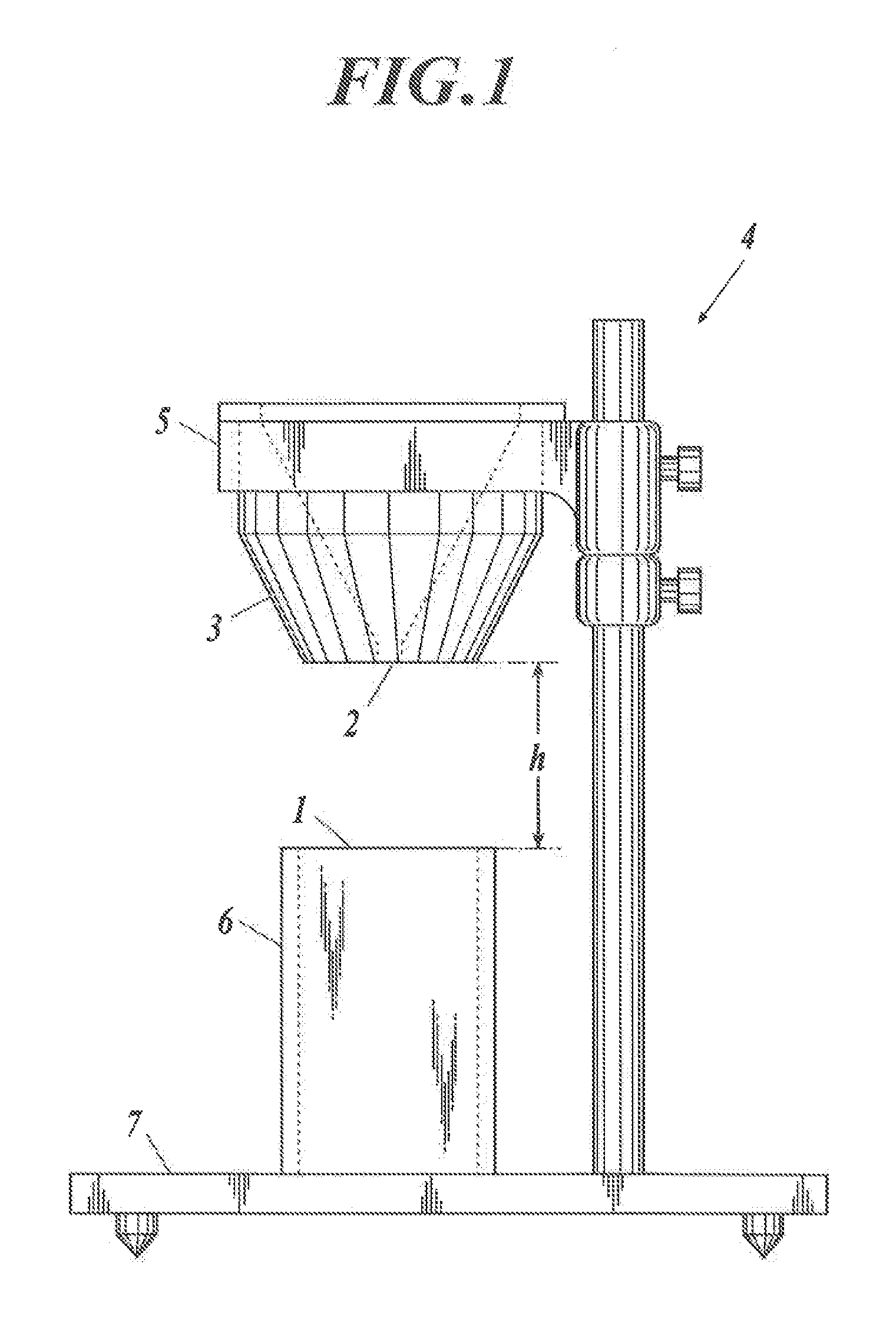

Torrefaction additive for extracting vanadium pentoxide from vanadium-containing bone coal and method of use thereof

The invention relates to a roasted additive for extracting vanadic oxide in vanadium-containing stone coal and application method thereof. The additive comprises barium compounds, barium powder or barium solvent accounting for 0.5% to 2% of additive mine of vanadium-containing stone coal. The method comprises steps of mixing the barium compounds, or barium powder or barium solvent and vanadium-containing stone coal in an oven to roast, controlling temperature at 700 DEG C to 1050 DEG C, roasting for 6h to 72h, and leaching the obtained roasted dregs to recycle vanadium. Beneficial effect of the invention lies in that 1) the existing device is unnecessary to be changed or altered; 2) sulfur can be effectively fixed, and roasting smoke is less than national discharge standard; 3) furnace temperature range is wide and the furnace temperature is easy to control; 4) leaching ratio is high; 5) concentration of sulfuric acid for acid leaching is only 1% to 2%; 6) roasting dregs of the invention use dilute sulphuric acid to leach, thus acid consumption is low; 7) the cost of water leaching and acid leaching in the invention is low.

Owner:淅川县玉典钒业有限责任公司

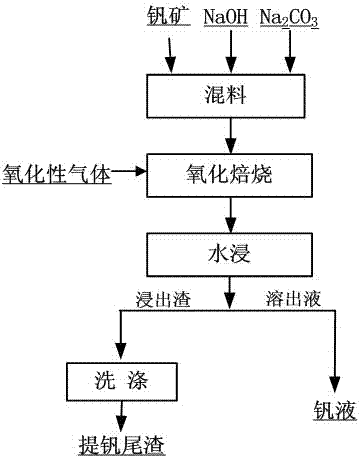

Method for extracting vanadium by using vanadium slag mixed alkali roasting

InactiveCN104498735ALow recovery rateIncrease contactProcess efficiency improvementSlagChloride sodium

The invention discloses a method for extracting vanadium by using vanadium slag mixed alkali roasting. The method comprises the following process steps: (1) uniformly mixing vanadium slag, Na2CO3 and NaOH mixed alkali, performing oxidizing roasting in a calcining kiln, thereby obtaining the roasted clinker; (2) leaching the roasted clinker by using water, controlling the pH value of the leaching solution to be 9-14, performing solid-liquid separation, thereby obtaining the leaching slag and the vanadium liquid. According to the method for extracting vanadium by virtue of mixed alkali roasting and water leaching, due to the absence of addition of sodium chloride and sodium sulfate salts, toxic and harmful gases are not produced; the mixed alkali roasting is adopted, and the immersion ratio of vanadium is higher than 95 percent; and moreover, the mixed alkali roasting temperature is reduced by 50-150 DEG C compared with pure alkali roasting, a sintering phenomenon is avoided in the roasting process, the energy consumption increased by ball-milling and roasting of the clinker at the later stage is eliminated, and the method is a clean and high-efficiency vanadium extraction method.

Owner:HEBEI IRON AND STEEL

Connecting material for cold transfer printing paper and preparation

ActiveUS20080280758A1Increase print qualityHigh transfer ratePattern printingAblative recordingEngineeringAcrylic coating

A connecting material for cold transfer printing paper is provided and includes an acrylic coating agent composition as an isolating layer and an acrylic coating agent composition as an ink-receiving layer. Also provided is a method for preparing the connecting material for cold transfer printing paper, a cold transfer printing paper and a method for printing a pattern or letter on a fabric by using the cold transfer printing paper.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

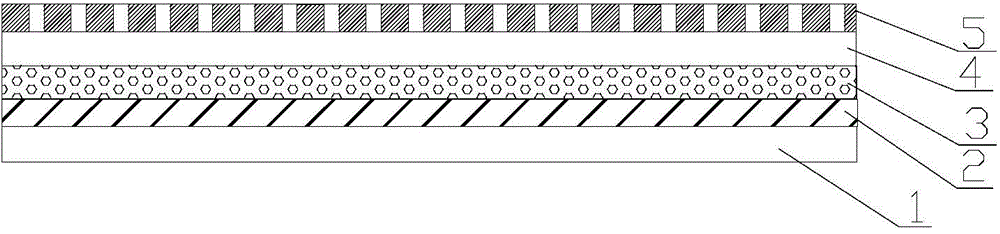

Self-adhesive quick-drying thermal sublimation transfer printing digital cloth

ActiveCN104553431AWith stretchable strengthSolve the technical problem of low recycling rateThermographyPolyvinyl alcoholPrinting ink

The invention relates to the technical field of thermal sublimation transfer printing, and discloses a piece of self-adhesive quick-drying thermal sublimation transfer printing digital cloth. The digital cloth sequentially comprises a piece of digital substrate cloth, an adhesive water-pervious layer, a water-absorbing layer, an ink-absorbing layer and a mesh-shaped surface layer from bottom to top, wherein the water-absorbing layer comprises mesopores and is an acrylic acid-2-acrylamide-2-sodium methacrylate copolymer; the mesh-shaped surface layer comprises a polyvinyl alcohol-vinyl acetate copolymer and sodium carboxymethyl cellulose; the digital substrate cloth has better strength than a paper substrate material, can be repeatedly used, the production cost is saved, and meanwhile, the production efficiency is improved; holes are formed in the hydrophilic end of the water-absorbing layer, so that moisture in ink is adsorbed into the holes, and the ink transferred to a dielectric material is quickly dried. The structure of the mesh-shaped surface layer facilitates quick absorbing of the ink in the printing process; in the transfer printing process, maximum adhesion of the mesh-shaped surface layer and the dielectric material can be realized, and the technical problem of double pattern imaging caused by the fact that the printing ink is prone to moving during absorption and transfer printing is solved.

Owner:杭州华大海天科技股份有限公司

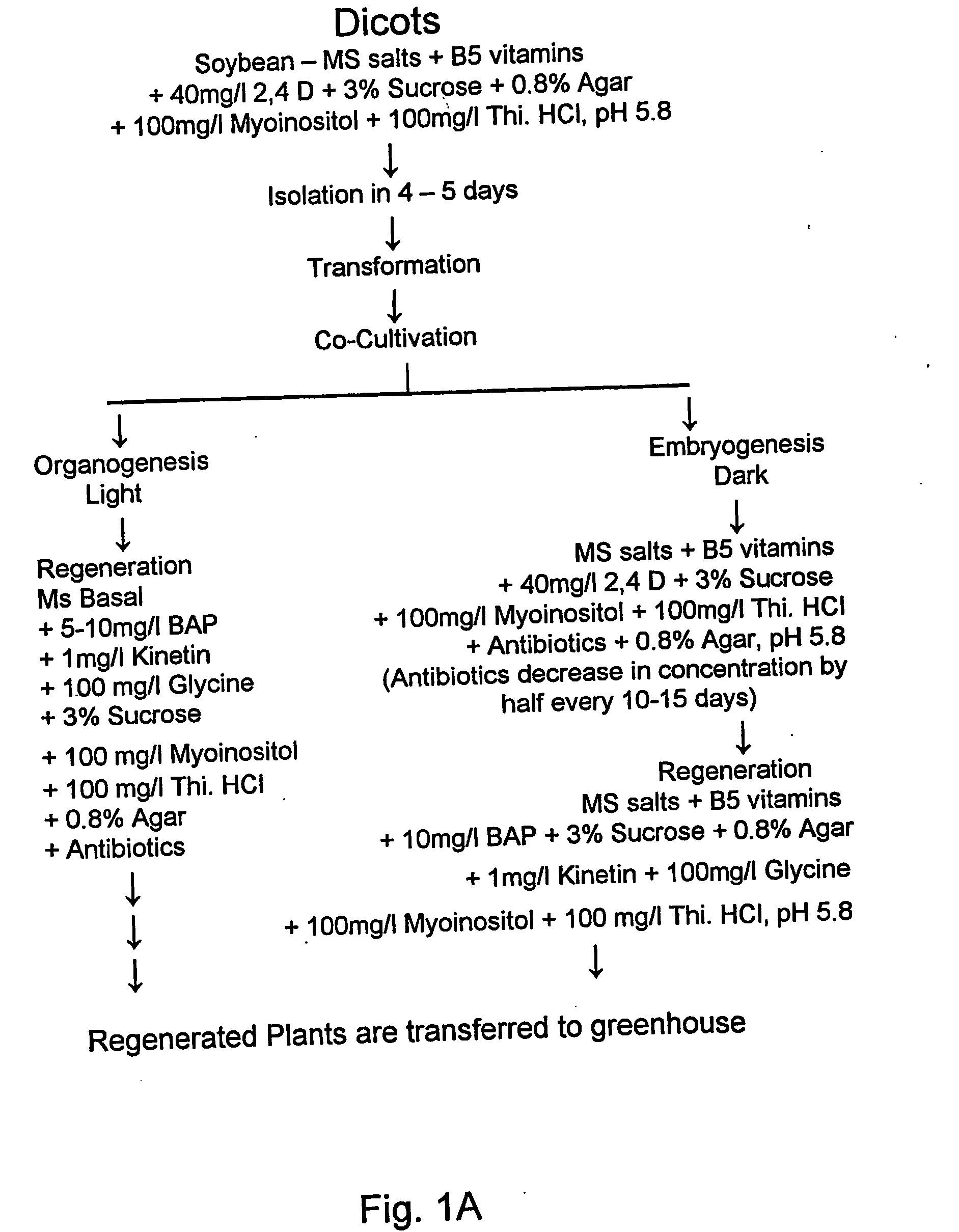

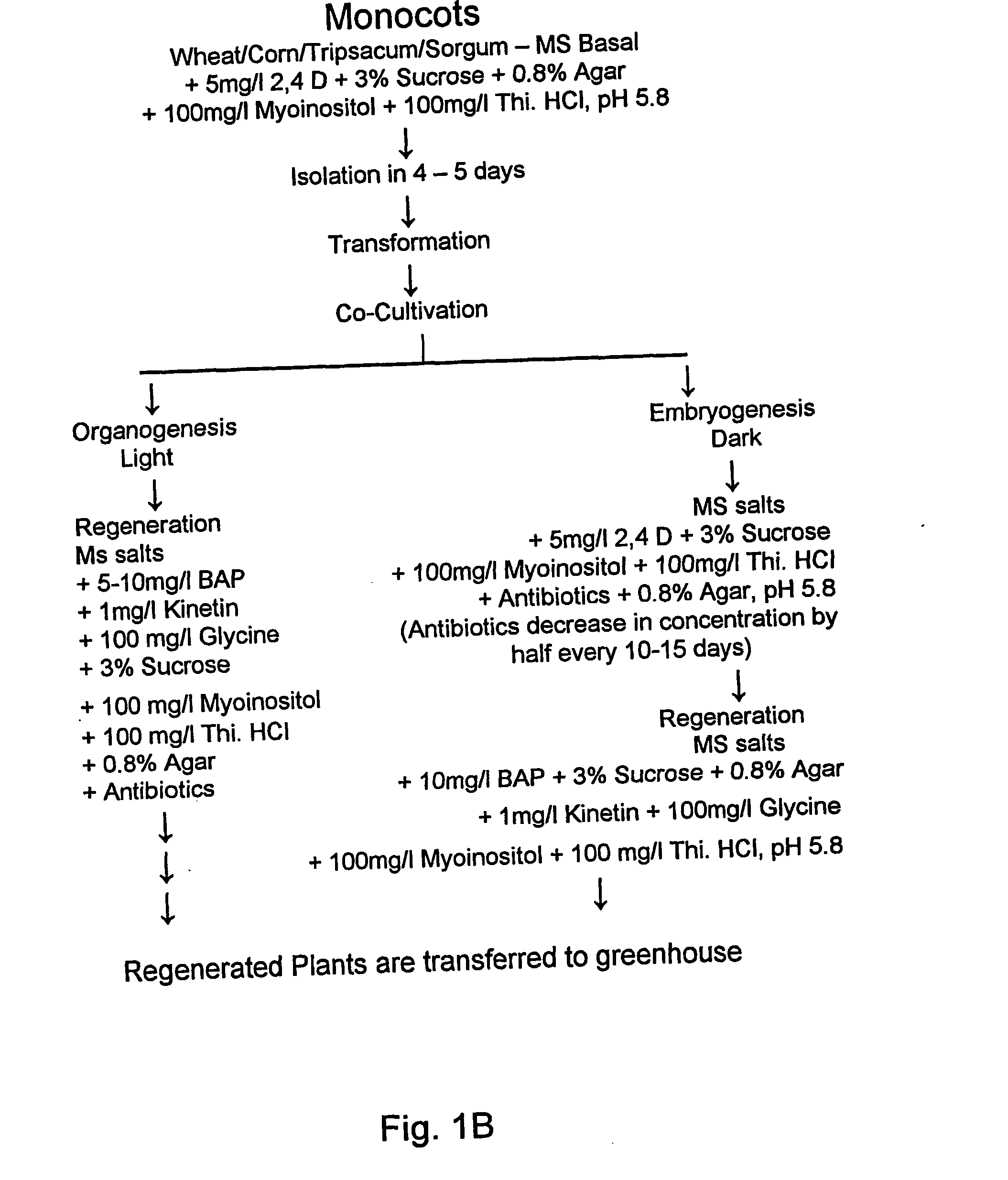

Method for transformation of mono-and di-cotyledonous plants using meristematic tissue and nodal callus from dicotyledonous plants

InactiveUS20040237133A1Efficient productionIncrease productionOther foreign material introduction processesFermentationBiotechnologyNODAL

This invention relates to a method for the introduction of genes encoding desirable traits into both monocotyledonous and dicotyledonous plants and to plants and parts thereof produced by growing plants using this method. The time required for the production of transgenic plants is significantly decreased, while the number of transgenic plants is significantly increased. These increases are not dependent upon the use of super-virulent Agrobacterium strains. The invention also relates to an improved technique for in vitro regeneration of mono- and di-cotyledonous plants in a suitable medium containing a novel growth regulator regime that promotes cell elongation in the production of numerous somatic embryos that are regenerable into fertile plants.

Owner:TOLEDO UNIV OF

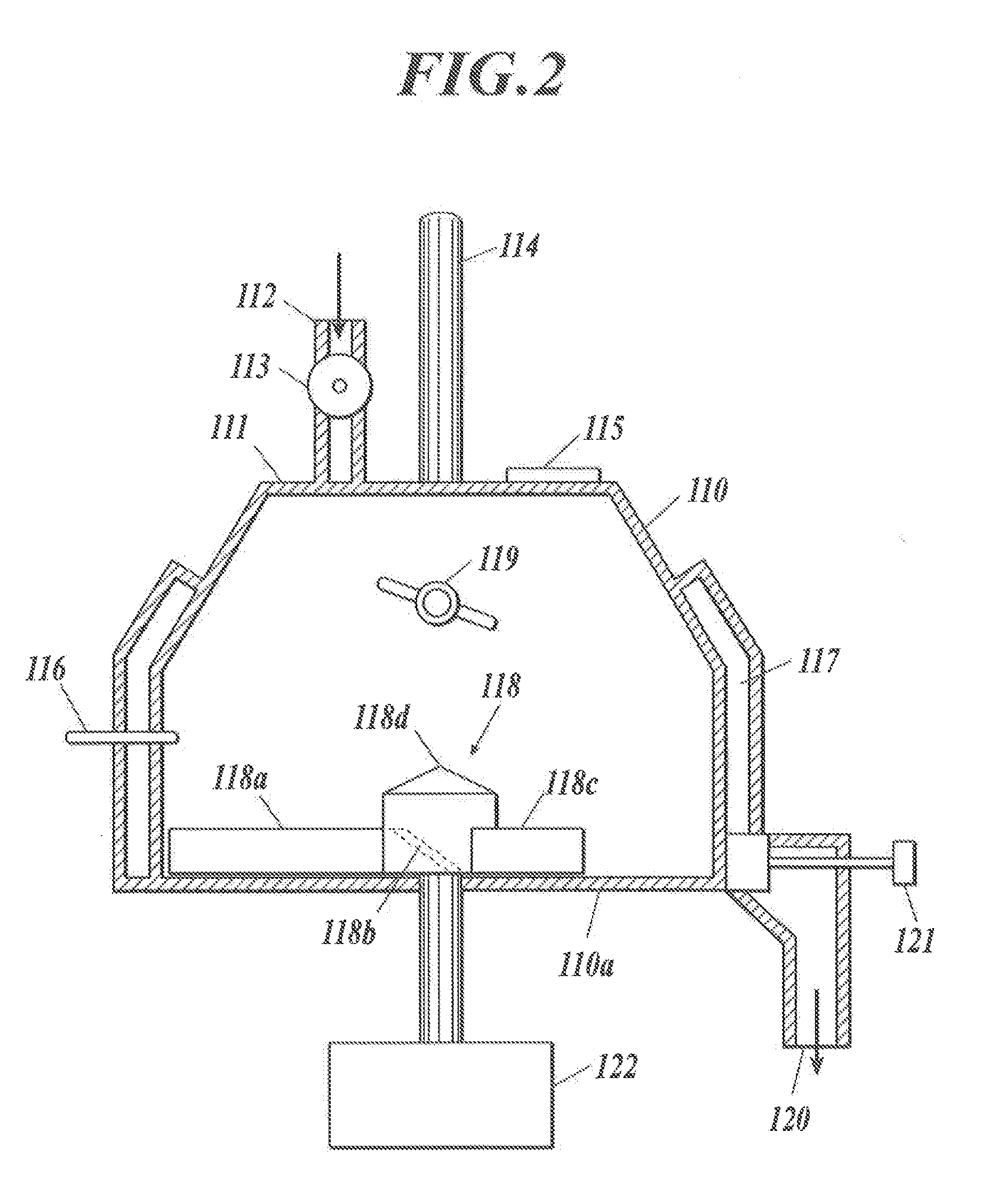

Method for roasting vanadium pentoxide extracted by scherbinaite coal contained primary ore

The invention relates to a method for roasting vanadium pentoxide extracted by scherbinaite coal contained primary ore. After being smashed to certain mesh degree, scherbinaite coal contained primary ore is sent into the main bed and the secondary bed of a fluidzed bed furnace; different blasting intensities when the main bed and the secondary bed roast are controlled, twice fluidization roasting is carried out to completely decarburize; after the decarburization material of the main bed and the secondary bed is added with barium salt, the mixture is roasted in a rotary kiln. The invention has the beneficial effects of short process flow, simple and easy operation, high yield and low production cost and can realize production automation control; vanadium has high immersion ratio which can be above 80%; and sulfuric acid consumption amount is low, only about 50 kg of sulfuric acid is consumed for each ton of cinder. The invention is the optimum path for comprehensively utilizing scherbinaite coal contained primary ore and can realize 'one ore three factories', i.e. a stone coal mine, a power station, a vanadium plant and a cement plant. The scherbinaite coal contained primary ore is in fluidized bed roasting to generate electricity; electricity is generated for the cinder to extract vanadium; the vanadium extracting tailings are high-quality filler of the cement plant to realize comprehensive utilization of resources, thus creating great economic benefit and social benefit.

Owner:淅川县玉典钒业有限责任公司

Resin paint

Disclosed is a resin coating,aiming at supplying a resin coating with good adhesive force,resistance to scrape,boiling,adhereing, and high printing-passing efficiency. It is comprised of the following components: polyamide resin 10-15%, modified abietic resin 6-9%, polyethylene 3-7%,filler 7-23%,color 9-11% and dispersant 0.1-0.5% polyamide resin is thermoplasticity, in 50% alcohol solution, its softening point is 80-180deg.C, viscosity 25deg.C, value of amine not larger than softening point. The modified abietic resin has softening point between 100-150deg.c and acid value smaller than 20.

Owner:葛祥利

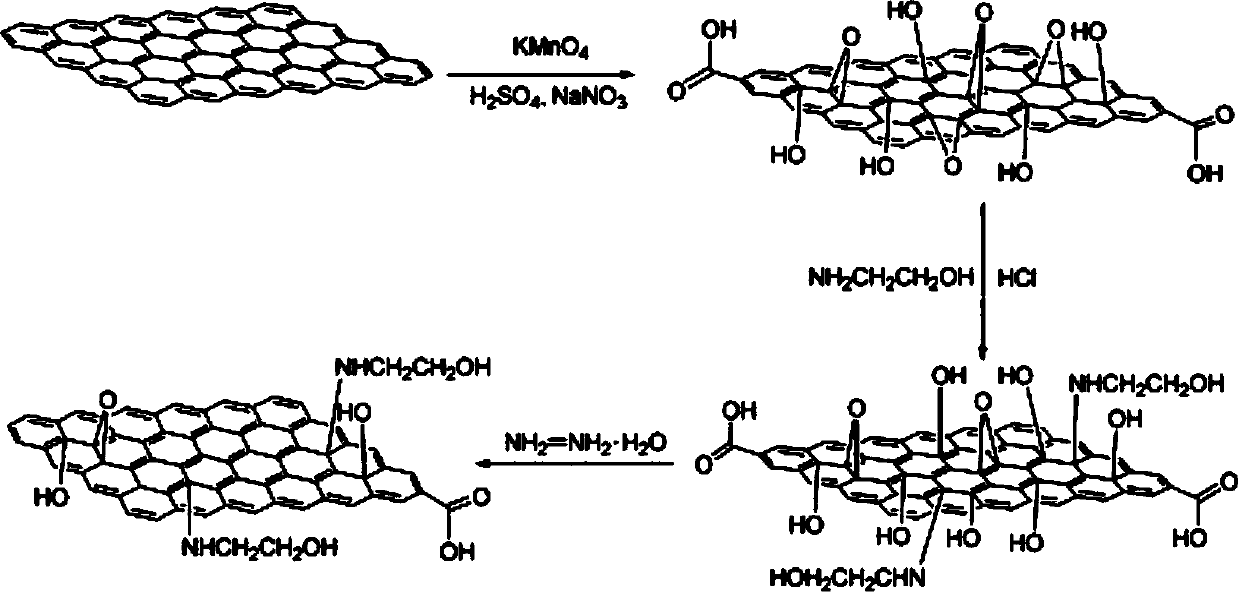

Gradient gel and preparation method thereof

InactiveCN103575792AHigh transfer rateImprove transfer qualityMaterial analysis by electric/magnetic meansElectrophoresisProtein transfer

The invention discloses a gradient gel and a preparation method thereof. The preparation method is characterized by comprising the following steps: respectively blending water, acrylamide separation gel stock solution, separation gel buffer solution, SDS (sodium dodecyl sulfate) and ammonium persulfate into two or more separation gels with concentration of 8-15% according to a certain proportion, quickly pouring the blended two or more separation gels in different concentrations into a glass plate crack in vertical slab electrophoresis from high to low concentration in order, adding water, adding spacer gel after the separation gel is solidified, and waiting the solidification of the spacer gel. According to the method, the electrophoresis speed is increased, the penetrability of protein molecules is enhanced, and the protein transfer rate and the protein transfer quality are improved.

Owner:GUANGZHOU WONDFO BIOTECH

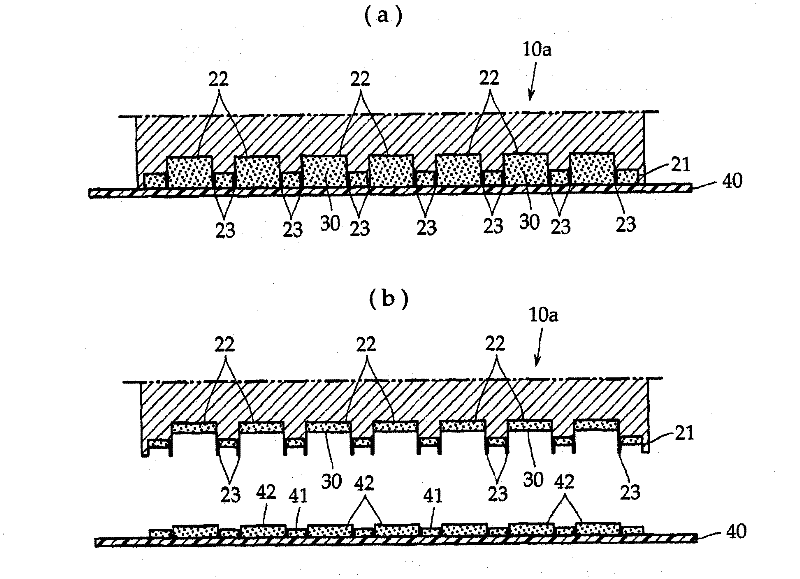

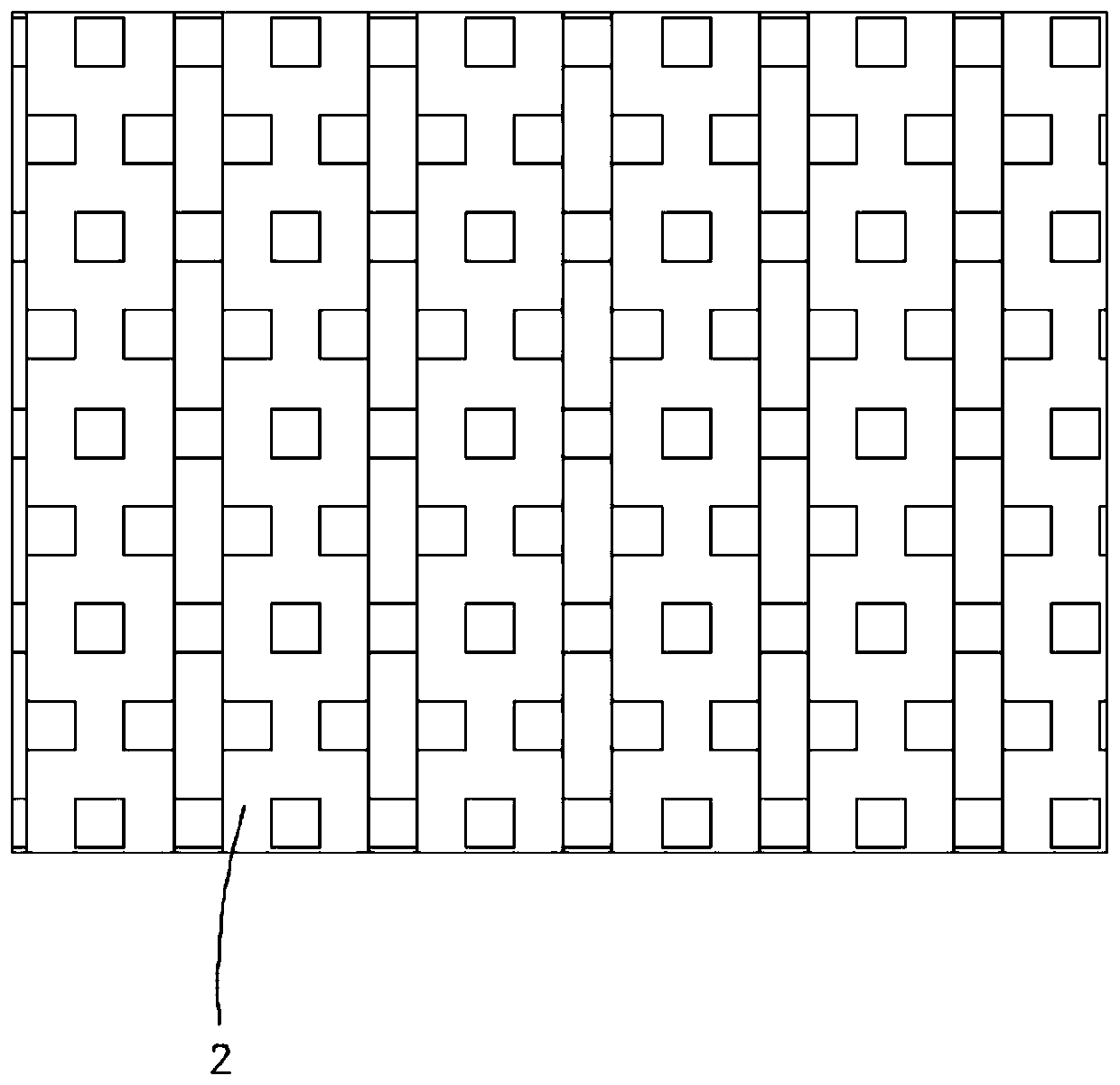

Gravure roll for application of pressure-sensitive adhesive and process for producing pressure-sensitive adhesive tape

ActiveCN102186602AHigh transfer rateGood reproducibilityLiquid surface applicatorsPlate printingManufacturing technologyEngineering

A technique for producing a pressure-sensitive adhesive tape is provided which attains satisfactory coating pattern reproducibility when a pressure-sensitive adhesive is applied with a gravure roll. Partitions (23) which separate cells (21, 22) formed in the surface of a gravure roll (10a or 10b) are disposed at the boundaries between the cells (21, 22), and fine irregularities (24) are further formed in the surface of the partitions (23) in order to improve coating pattern reproducibility.

Owner:NITOMS INC

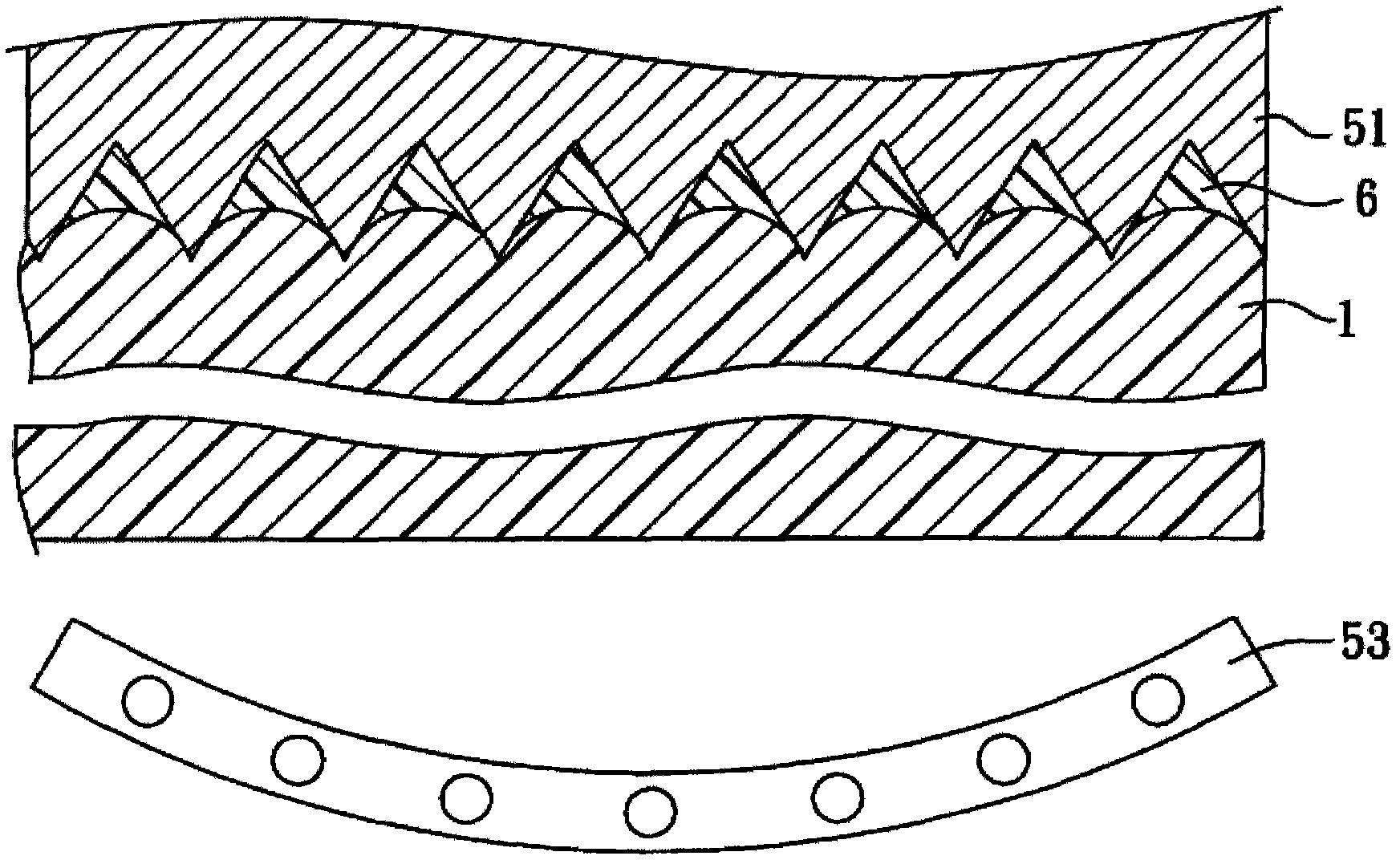

Transfer process and membrane electrode

The invention relates to the technical field of fuel cells, and provides a transfer process and a membrane electrode. The transfer process comprises the following steps: isopropyl alcohol and water are mixed as a solvent, perfluorosulfonic acid resin is added and then the mixture is uniformly mixed to prepare a perfluorosulfonic acid resin solution; the perfluorosulfonic acid resin solution is sprayed on aproton exchange membrane; the base material sprayed with the catalyst is placed on the two sides of the proton exchange membrane and hot pressing is performed; and the base material is stripped and thus the membrane electrode is obtained. Good adhesion is formed between the perfluorosulfonic acid resin and the original proton exchange membrane and the catalytic layer, and the proton exchange membrane and the catalytic layer are bonded by the perfluorosulfonic acid resin so that temperature and pressure required for transferring are greatly reduced while the high transfer rate is ensured, and the proton exchange membrane is protected from being damaged at high temperature and high pressure.

Owner:SHENZHEN SOUTHERNTECH FUEL CELL CO LTD

Formula of Pleurotus citrinopileatus stock compost and preparation method of compost

The invention relates to a Pleurotus citrinopileatus stock compost which is characterized in that corn kernels are used as main raw materials, and cottonseed hulls and fine wood dust are used as auxiliary materials, wherein the water content of the corn kernels is 45-48%, and the water content of the wood dust is 62-63%. The invention also includes a preparation method of the compost. Compared with a wood dust compost, the compost provided by the invention has the following advantages: 1, the corn kernels are abundant in nutrition, hyphae can quickly grow, and the bottle filling time is shortened; 2, the corn kernel stock is uniform in granularity, the transplant rate (cultivated species) is high, and the strains germinate quickly and grow vigorously after transplant; and 3, the coarse and fine auxiliary materials are reasonably blended, so that the air permeability and water retention property of the compost are enhanced, thus preventing the corn kernels from age hardening and prolonging the storage life of the strains.

Owner:邬金飞

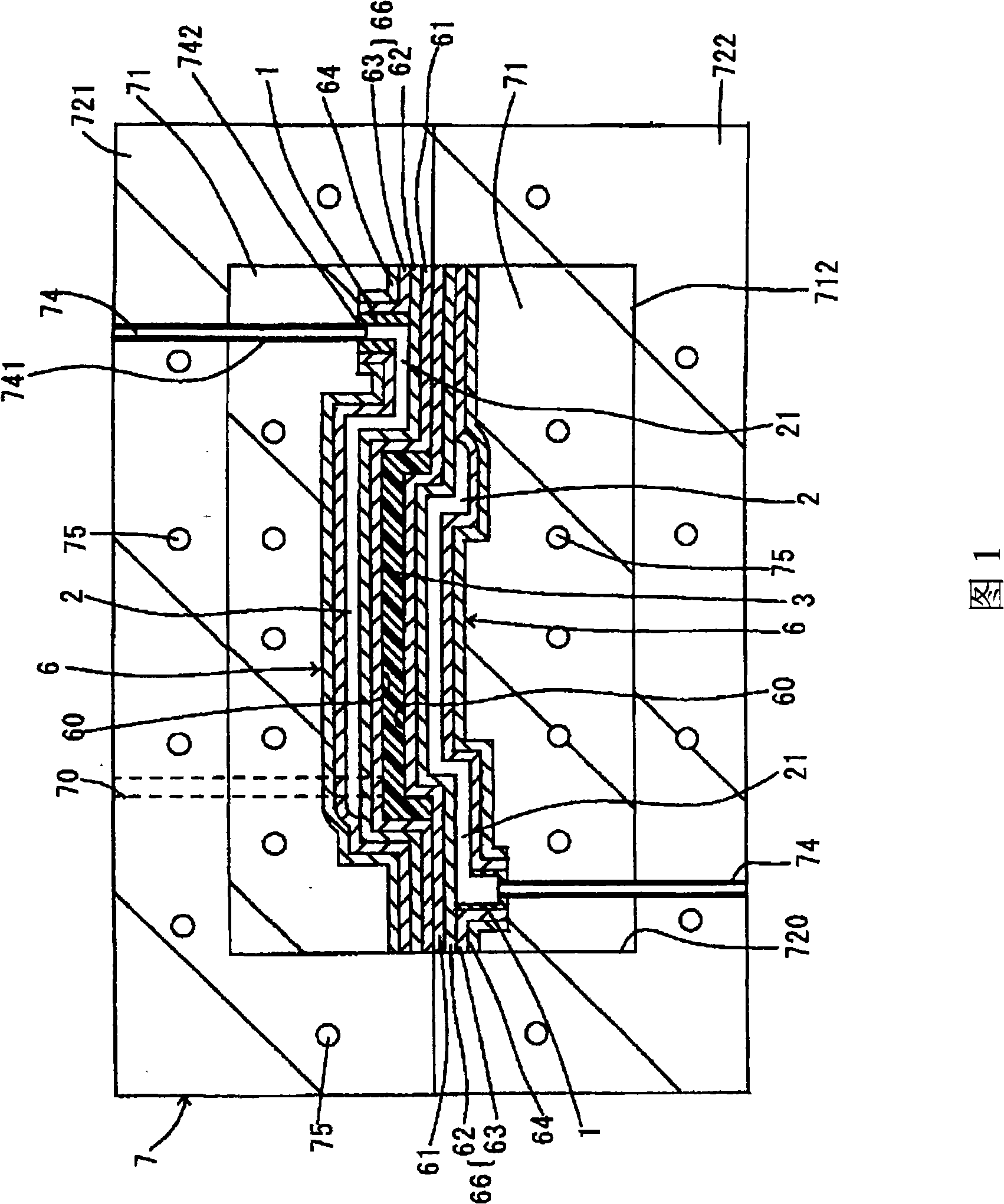

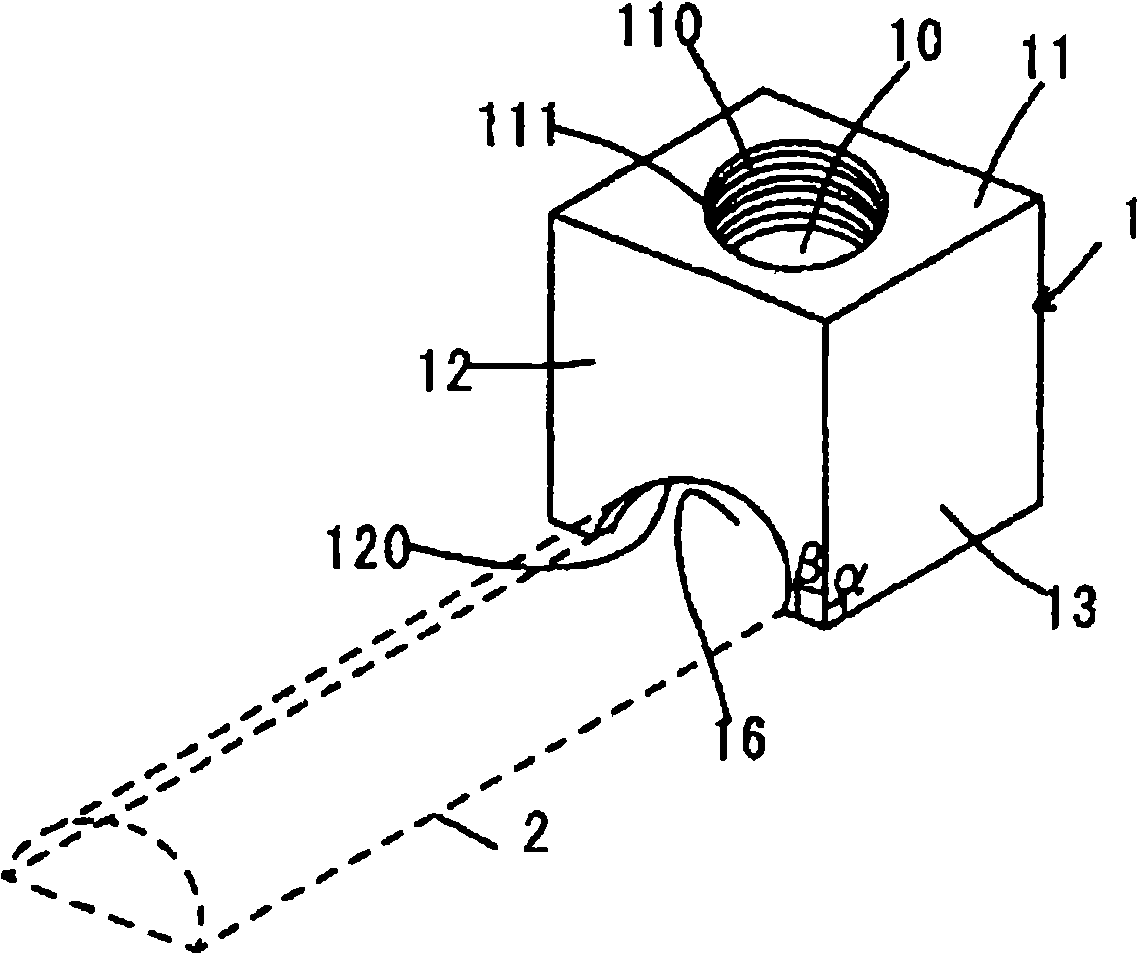

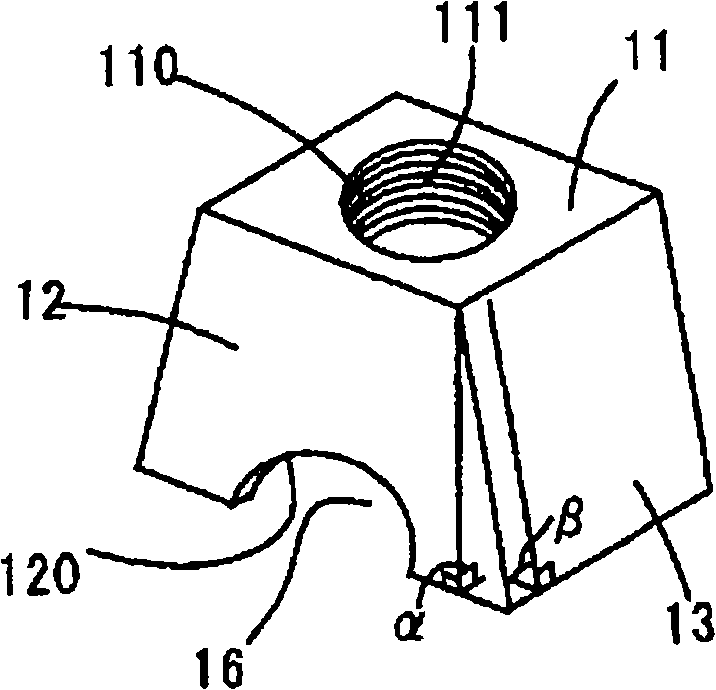

Electroformed mold and manufacturing method therefor

The invention discloses an electroformed mold, comprising an electroformed shell (6) having a forming surface (60) formed by electroform; a medium flowing passage (2) for cycling a heat medium so as to adjust temperature on the forming surface (60) formed in the electroformed shell (6); a back lining piece (71) adding lining for the electroformed shell (6); and a medium transport passage (74) respectively arranged on an upriver end (21) and a downriver end (22) for the heat medium flowing into or out of the medium flowing passage (2). A connection clamp (1) for connecting the medium flowing passage (2) and the medium transport passage (74) is embedded in the electroformed shell (6). The connection clamp (1) comprises a cavity formed inside, an opening hole, a section shape of which is basically identical to a radial section of the medium flowing passage (2) and a connection hole, a section shape of which is basically identical to an external radial section of a pipe piece of the medium transport passage (74). The opening hole is connected with the connection hole by the cavity.

Owner:TOYODA GOSEI CO LTD

Method for extracting vanadium by sodium salt roasting from vanadium-bearing iron concentrate

InactiveCN109797297AHigh transfer rateSimple processProcess efficiency improvementChemical industryFiltration

The invention relates to a method for extracting vanadium by sodium salt roasting from a vanadium-bearing iron concentrate, and belongs to the technical field of vanadium extraction chemical industry.The method solves the technical problems of low conversion leaching rate and high pollution during existing vanadium-titanium magnetite extraction by sodium salt roasting. The method for extracting vanadium by sodium salt roasting from the vanadium-bearing iron concentrate comprises the steps that a, the vanadium-bearing iron concentrate is crushed and then mixed uniformly with sodium fluoride toobtain a mixture, and then a pellet is obtained by pelletizing, sieving and drying; b, the pellet obtained in the step a is roasted in a high temperature environment to obtain vanadium-containing iron concentrate roasted clinker; and c, the roasted clinker obtained in the step b is placed in a leaching agent for leaching, and vanadium-containing leachate is obtained through separation by filtration. The method can obviously improve the conversion leaching rate of vanadium in the iron concentrate, has the advantages such as simple and easy process, low equipment requirements, convenient operation and low cost, and has good social and economic benefits.

Owner:四川大裂谷钒业有限公司

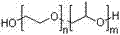

Surfactant for uncoated thermal transfer ink, uncoated thermal transfer ink and preparation method of surfactant

The invention discloses and provides a surfactant for an uncoated thermal transfer ink, the uncoated thermal transfer ink and a preparation method of the surfactant. The surfactant for the uncoated thermal transfer ink is capable of reducing the cost of thermal transfer paper, reducing the usage amount of ink, and improving the heat transfer rate and the color concentration of the ink. The uncoated thermal transfer ink is prepared from the following raw materials in parts by weight: 20-40 parts of non-azo disperse dyes, 5-40 parts of an organic solvent, 1-10 parts of a surfactant, 0.05-1 part of a pH modifier, 0.05-1 part of a buffering agent, 0.01-0.3 part of a preservative, 0.1-1 part of an emulsifier, 0.05-1 part of a chelating agent and 20-50 parts of water; the surfactant is a polyoxyethylene polyoxypropylene copolymer; the preparation method of the uncoated thermal transfer ink comprises the following steps: firstly, stirring an organic solvent mixed with water; adding the surfactant, stirring for 30 minutes to be full and uniform; adding the pH modifier, the buffer agent, the preservative, the emulsifier and the chelating agent, stirring for 30 minutes to be full and uniform; adding the non-azo disperse dyes, stirring for 2 hours to be full and uniform; and filtering with 1.0micron of filter membrane, thus obtaining the thermal transfer ink.

Owner:珠海欣威科技有限公司

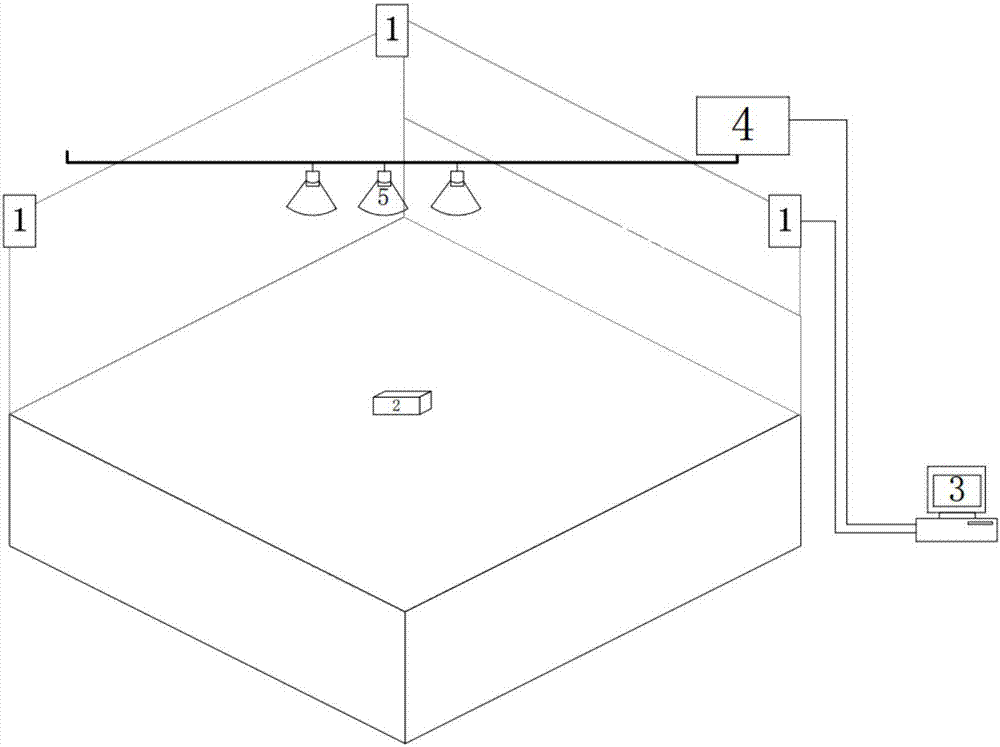

Stage light positioning tracking system based on UWB

PendingCN107135587ARealize automatic tracking functionImprove the level of intelligenceElectric light circuit arrangementWireless commuication servicesComputer control systemExecution control

The invention discloses a stage light positioning tracking system based on UWB. In a UWB positioning system, a label is bound with a target, and is in communication connection with a substrate. A base station is connected with a positioning subsystem, and the positioning subsystem comprises a calibration module for calibrating the base station, and a positioning module which indirectly obtains the position parameters of the target according to the label position information collected by the base station and uploads the position parameters to an upper computer system. The upper computer system comprises a positioning control module which is used for solving the position parameters and converting the position parameters into the control parameters of a spotlight, and a positioning transmission module which is used for transmitting the control parameters to a spotlight circuit control system. A spotlight drive circuit control system comprises a control parameter conversion module which is used for receiving the control parameters transmitted by an upper computer control system and converting the control parameters into a pulse instruction, and a drive circuit which executes the control according to the pulse instruction so as to achieve the rotation and pitching control of the spotlight. The system is lower in cost, is small in workload, is higher in safety, and is simple in wiring network.

Owner:义乌敦仁智能科技有限公司

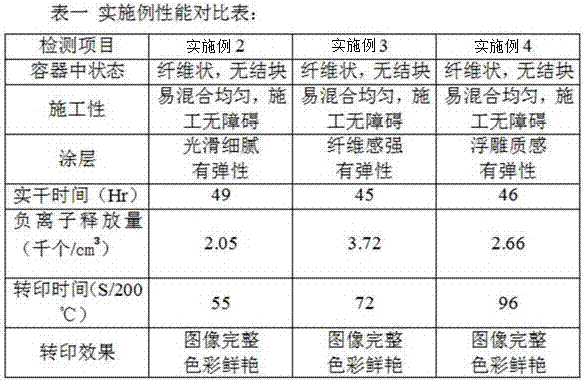

Special waterborne fiber paint for heat transfer printing and preparation method thereof

ActiveCN107083118AHigh transfer rateColorfulAntifouling/underwater paintsCellulose coatingsYarnFiber

The invention specifically relates to a special waterborne fiber paint for heat transfer printing and a preparation method thereof, belonging to the technical field of architectural paints. The fiber paint comprises fibers, glitter powder, metallic yarns, mica sheets, negative ion powder, a powdery antifoaming agent, a powdery fiber softener, a powdery mildew inhibitor, a redispersible latex powder, hydroxypropyl methyl cellulose and polyvinyl alcohol. A coating prepared from the fiber paint realizes transfer printing of digital patterns on its surface through heat transfer printing; transfer printing of the coating is simple and rapid; a transfer printing rate is high; the coating with a transferred pattern has a gorgeous color and is long-lasting and durable; and no matter the size and shape of a wall, the coating with a transferred pattern can be applied and no joint is left. The coating also has excellent crack resistance, mildew resistance, flexibility, air permeability and heat insulation performance, can realize negative oxygen ions and is an interior decoration wall material with excellent functionality, practicality, decorative performance and other comprehensive properties.

Owner:FUZHOU BIMITER ENVIRONMENT FRIENDLY PROD

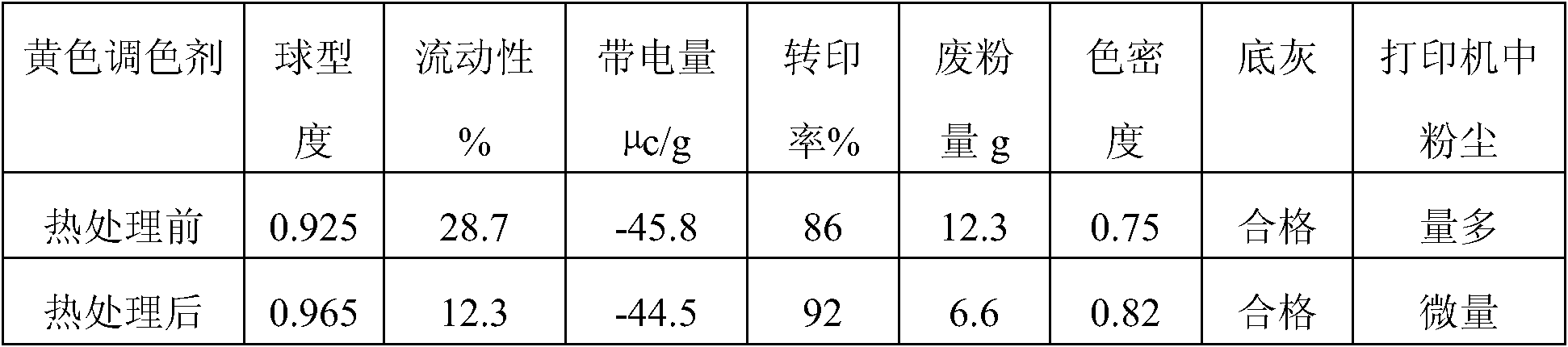

Production method for toner

The invention discloses a production method for toners. The method comprises the following steps: obtaining micron-class toner powder, adding nanometer-class silicon dioxide in the micron-class toner powders; carrying out sphericized heat treatment on the toner powder added with silicon dioxide, adding and mixing additive in the sphericized toner powder after sphericized heat treatment, and screening and obtaining the toner. The toner produced by adopting the method has more uniformly distributed electric quantity, the flowing characteristic of the toner in the developing process can be improved, the waste powder quantity is reduced, the transfer printing rate is improved, the printing quality is obviously improved, and pollution can not be generated to machines and environment.

Owner:ICMI CHINA

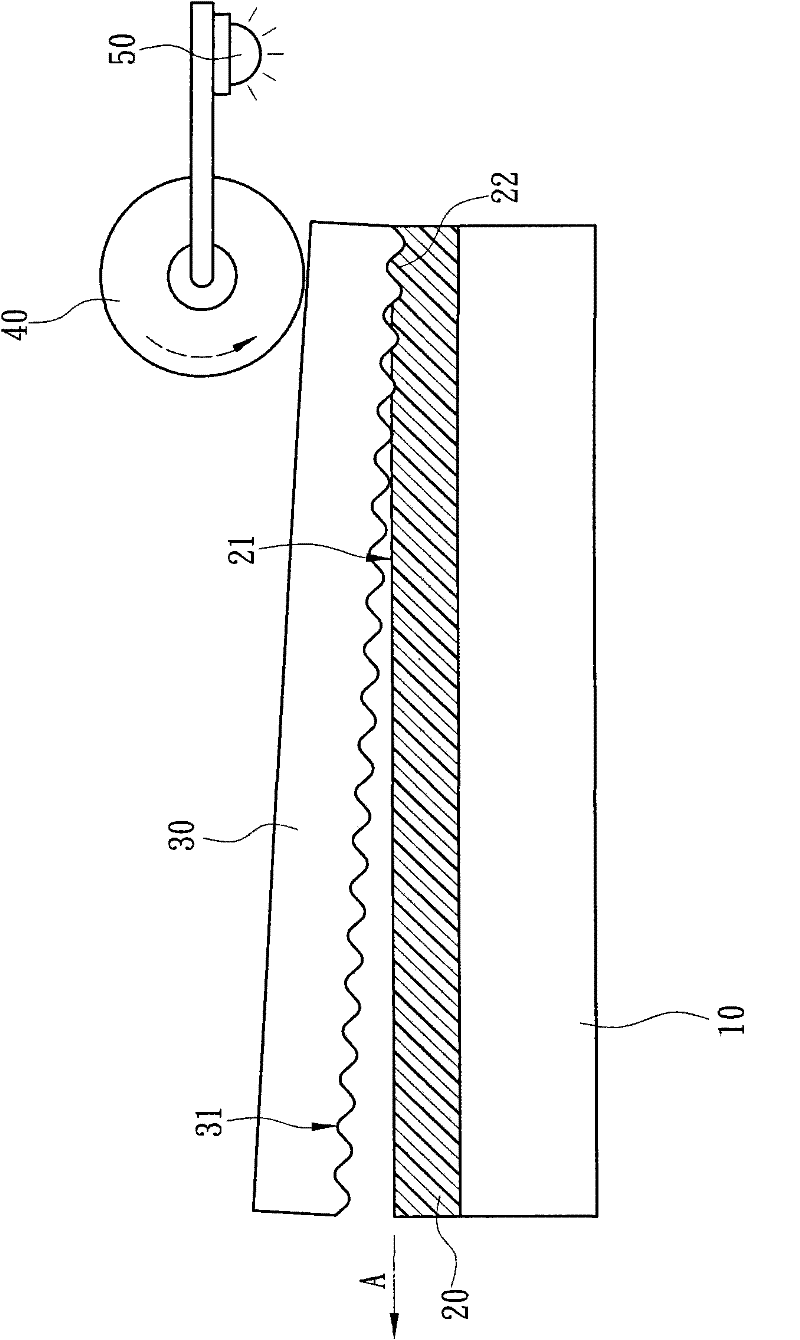

Light guide plate manufacturing method

InactiveCN102455460AGood brightness performanceReduce the number of bubblesOptical light guidesLight guideOptoelectronics

The light guide plate manufacturing method comprises the following steps of: using a rolling depression device comprising an imprinter, wherein the surface of the imprinter comprises a first structure; rolling a resin layer arranged on a substrate by the imprinter, or forming the resin layer on the imprinter to roll the substrate, enabling the resin layer to continuously form a second structure complementary to the first structure, and attaching the second structure on the substrate. The rolling depression area formed by the rolling depression mode is smaller, so the uniformity of pressure application is easy to control, the light guide plate can have high transcription rate, and defects are reduced.

Owner:WIN OPTICAL

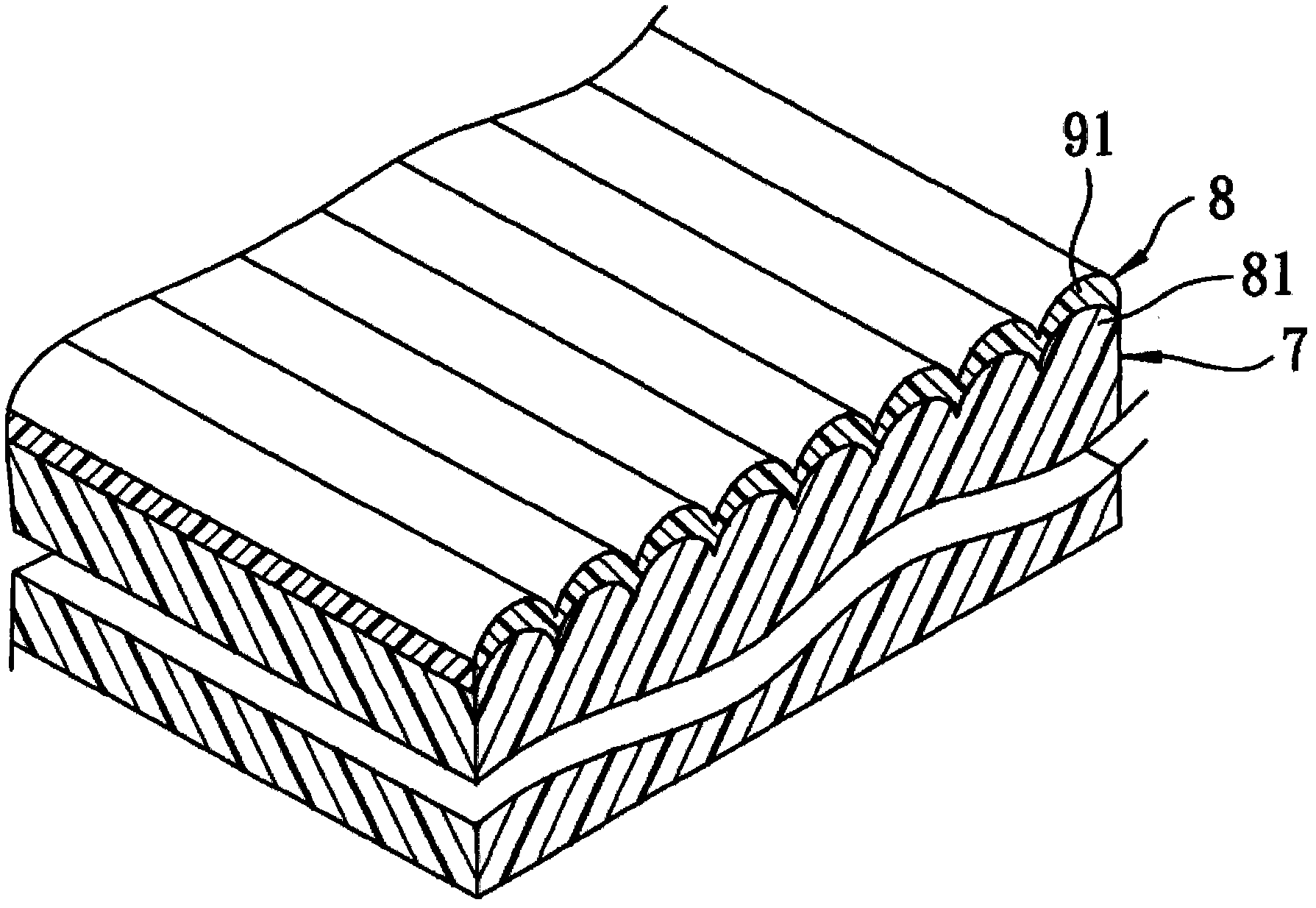

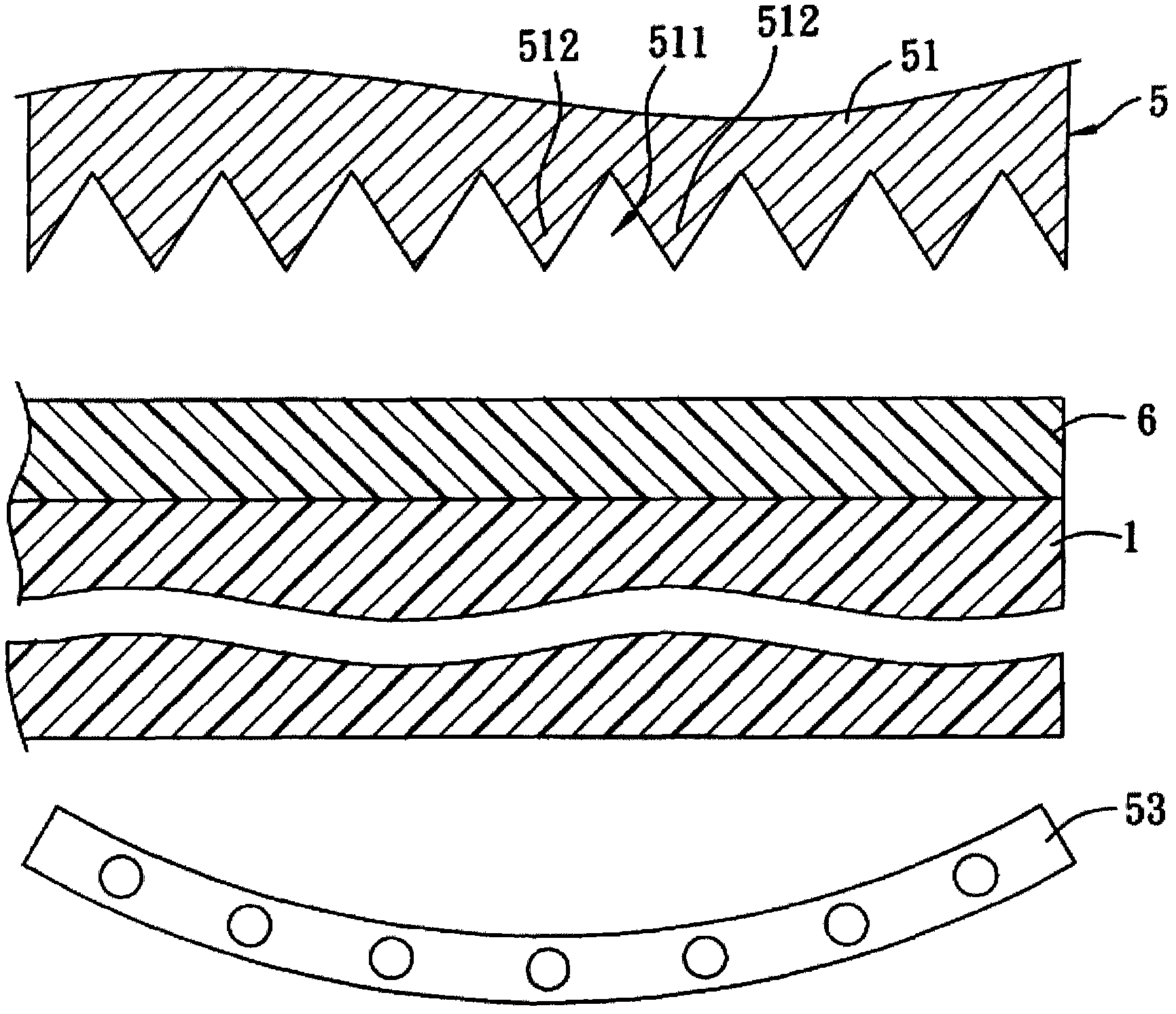

Light diffusion plate and light guide plate having micro structure

InactiveCN102466830ALow costHigh transfer rateDiffusing elementsOptical light guidesMicro structureLight guide

The invention provides a light diffusion plate and a light guide plate having micro structure. The light diffusion plate and the light guide plate include substrates and a plurality of micro structures disposed on the substrate. Each of the micro structures includes a first projection and a second projection connecting with the first projection in a direction departing from the substrates. The substrate and the first projection are all formed by heat plasticity resin material. The first projection is provided with a projection interface projection from the substrate and connecting with the second projection. The second projection is made of photosensitive resin material and is provided with an outer surface separated with the projection interface of the first projection. Through controlling that the minimum vertical distance between the outer surface of the second projection and the projection interface of the first projection is less than 5 micro meters and the firt projection and the second projection adopt resin raw material having different liquidity, not only the high transferring rate can be realized, but also the costs of manufacturing the light diffusion plate and the light guide plate are reduced.

Owner:CHI MEI CORP

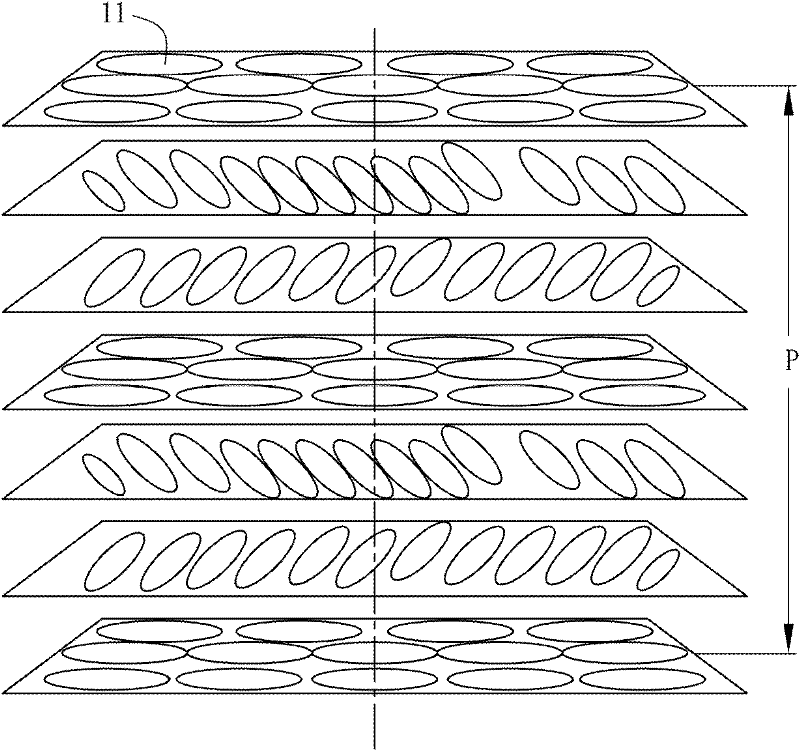

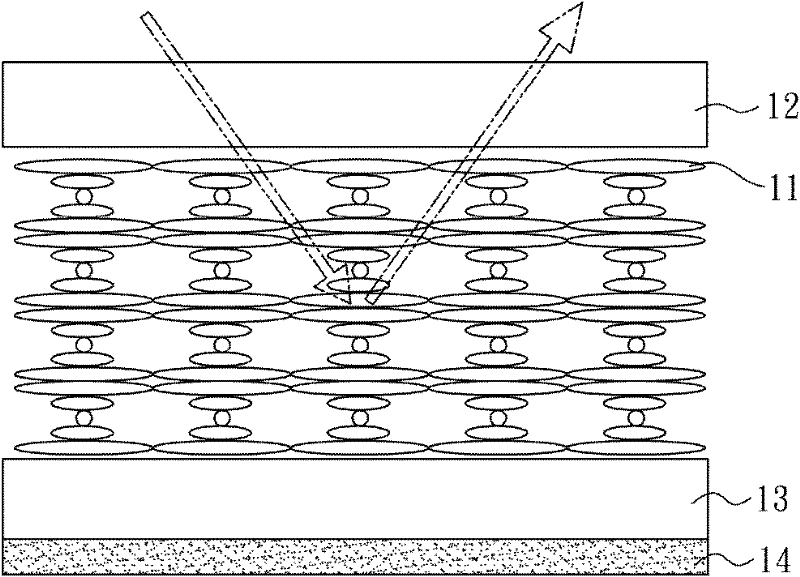

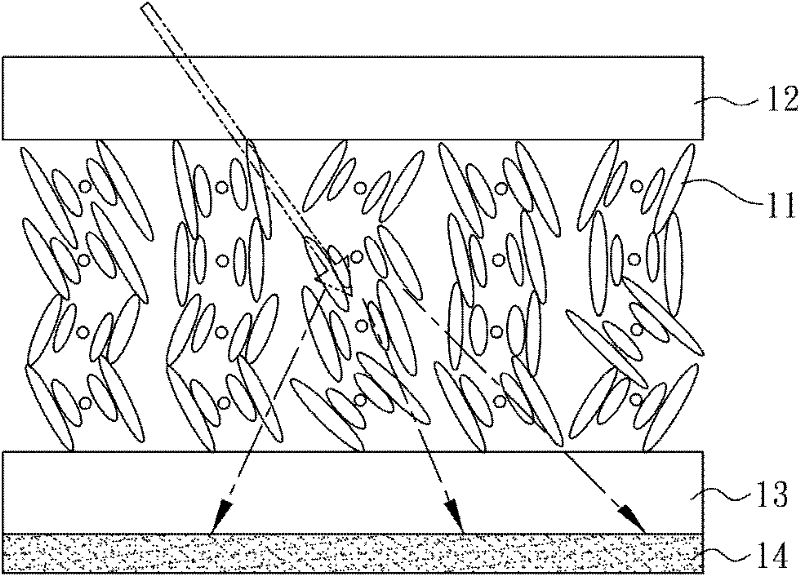

Method for manufacturing polymeric membrane with photonic crystal structure

InactiveCN102532567AIncrease polymerization rateHigh transfer rateOptically active additivePhotonic crystal structure

The invention discloses a method for manufacturing a polymeric membrane with a photonic crystal structure. The method comprises a mixing step, at least one irradiation step, at least one dispersion step and a liquid crystal removal step, wherein in the mixing step, a nonchiral liquid crystal, an optical active additive, a monomer and a photo initiator are at least mixed to form a liquid crystal monomer mixture; in at least one irradiation step, the liquid crystal monomer mixture is irradiated through a photomask; in at least one dispersion step, monomers at the periphery of one of irradiated areas of the liquid crystal monomer mixture are dispersed to the irradiated area; and in the liquid crystal removal step, the nonchiral liquid crystal is removed so as to form the polymeric membrane. Through the dispersion step after the irradiation step, the polymerization rate of the monomer can be improved, so a ratio of polymer in the polymeric membrane is improved and a chirality transfer rate is improved; and therefore, the polymeric membrane can display the photonic crystal structure and Bragg reflection characteristics under the condition of not requiring any fluid.

Owner:NAT CHENG KUNG UNIV

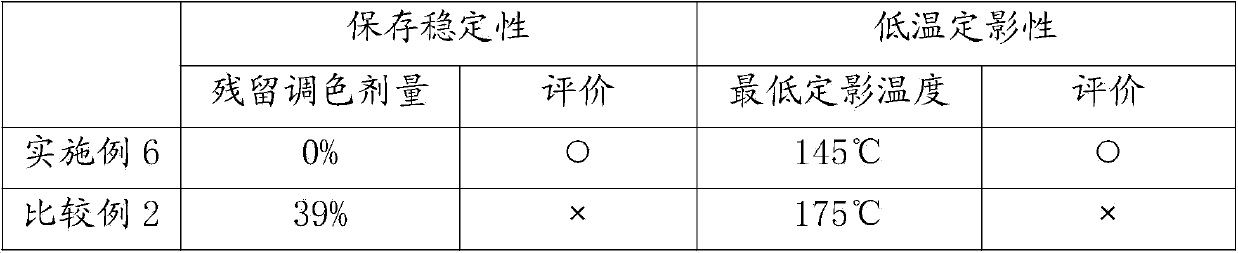

Adhesive resin of color matching agent and color matching agent

InactiveCN103728854AExcellent low temperature fixabilityExcellent thermal storage stabilityDevelopersVitrificationCharge control

The invention provide a color matching agent which comprises a color matching agent master batch and an external additive, wherein the color matching agent master batch comprises a coloring agent, adhesive resin, a charge control agent and a mold release agent, and the glass-transition temperature of the adhesive resin ranges from 50 DEG C to 80 DEG C. The color matching agent provided by the invention has excellent low-temperature photographic fixing performance, heat-resisting storage stability and liquidity simultaneously, so that the charge quantity of the color matching agent is uniformly distributed, the waste powder quantity is reduced, the transfer ratio is increased, the printing quality is improved, further, pollution to the machine and the environment is avoided, and high-quality images are obtained.

Owner:中山市永南彩印有限公司

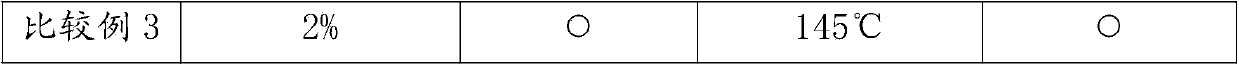

Developing device and image forming apparatus

InactiveUS20140205327A1High transfer ratePrevent adhesionElectrographic process apparatusDevelopersEngineeringImaging equipment

A developing device includes a developer container, a developing unit, a developer outlet and a replenishment developer inlet. The developer container contains a developer composed of a toner and a first carrier. The developing unit develops an electrostatic latent image on an image carrier using the developer. The developer outlet discharges the developer. The replenishment developer inlet supplies a replenishment developer to the developer container. The replenishment developer includes a second carrier. A ratio of a poured bulk density of the second carrier to a poured bulk density of the first carrier ranges from 0.60 to 0.95.

Owner:KONICA MINOLTA INC

Preparation method of benzoxazine resin

ActiveCN108559042AWell-developed pore structureIncrease the adsorption rateCarbon compoundsEnergy inputActivated carbonDistillation

The invention discloses a preparation method of benzoxazine resin. The preparation method comprises the following steps: S1, adding activated carbon particles into an alkali solution for soaking to obtain an activated carbon catalyst adsorbing alkali; S2, adding a solvent toluene, phenolic compounds, aldehyde and amine compounds into a reaction still in sequence, keeping the temperature of the reaction still at 40 DEG C, stirring and adding the activated carbon catalyst; S3, raising the temperature to 70 DEG C and then stopping heating; continuously raising the temperature of reaction liquid by waste heat; when the temperature reaches 85 DEG C, carrying out reflux reaction on the reaction liquid for 2 to 6 hours; S4, replacing the reaction still with an atmospheric distillation device, raising the temperature to 110 DEG C for distilling, returning the toluene in distillate to the inner part of the reaction still, distilling until no water is drained from the reaction still, cooling anddischarging; S5, filtering the discharged material, and obtaining filtrate, namely a toluene solution containing benzoxazine; washing and drying filter residues and recycling the activated carbon catalyst. According to the preparation method of the benzoxazine resin, disclosed by the invention, the catalyst alkali is immobilized in activated carbon, so that the catalyst can be recycled and a washing operation step in an existing preparation method is omitted.

Owner:成都科宜高分子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com