Production method for toner

A manufacturing method and toner technology, which can be applied in the fields of developer, electrography, optics, etc., can solve the problems of uneven distribution of particle charge amount, pollution of machines and environment, poor fluidity of toner, etc., to avoid unpleasant charging. The effect of uniformity, reducing waste toner and improving print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 100.0 parts by weight of styrene-acrylic resin

[0036] Carbon black 8.0 parts by weight

[0037] Charge modifier 2.0 parts by weight

[0038] 2.0 parts by weight of polypropylene wax

[0039] Put the above raw materials into the Henschel mixer for mixing, melt and mix them through a twin-screw extruder, cool and coarsely pulverize them, and then pulverize and classify them through a jet mill, so that the median diameter of the particles is 7.2 microns, the sphericity is 0.915, and 0.4% of the particle size is added Silica with a median diameter of 15 nanometers is mixed evenly, and heat treatment for spheroidization is carried out by using a hot air flow as a heating medium. The temperature of the hot air flow is 280°C, and the heat treatment time is 1 to 10 seconds. The diameter is 7.1 microns, the sphericity is 0.960, and the yield is 97%. Add 0.8% silicon dioxide and 0.2% titanium dioxide to obtain a black toner. After printing 2000 pages on the HP2600 printer, t...

Embodiment 2

[0041] 100.0 parts by weight of polyester resin

[0042] Pigment C.I. Pigment Blue 15-3 4.0 parts by weight

[0043] Charge regulator (CCA) E-84 2.0 parts by weight

[0044] 1.0 parts by weight of polypropylene wax

[0045] Put the above raw materials into a Henschel mixer for mixing, melt and mix through a twin-screw extruder, cool and coarsely pulverize, and pulverize and classify through a jet mill, so that the particle size is 7.0 microns in diameter, sphericity is 0.910, and 5% of the particle size is added Silica with a median diameter of 10 nanometers is mixed evenly, and heat treatment is carried out by using hot air as the heating medium for spheroidization. The temperature of the hot air is 250°C, and the heat treatment time is 1 to 10 seconds. The blue toner basic particles obtained are medium in size. The diameter is 6.8 microns, the sphericity is 0.960, and the yield is 96%, and 0.8% silicon dioxide is added to obtain a blue toner. Print 2000 pages on the HP260...

Embodiment 3

[0047] 100.0 parts by weight of polyester resin

[0048] Pigment C.I. Pigment yellow 17 4.0 parts by weight

[0049] Charge modifier E-84 2.0 parts by weight

[0050]Palm wax (Carnauba Wax) 1.0 parts by weight

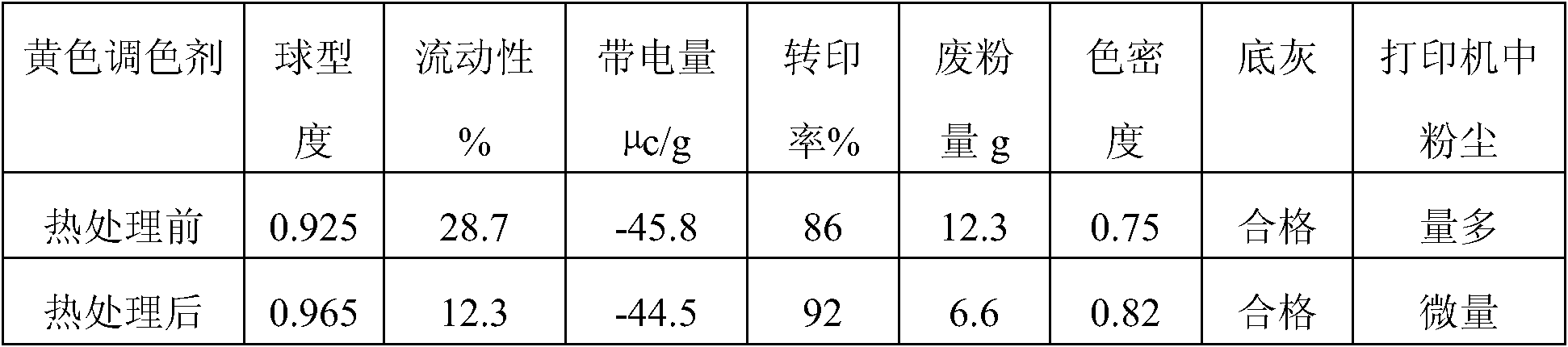

[0051] Put the above raw materials into the Henschel mixer for mixing, melt and mix them through a twin-screw extruder, cool and coarsely pulverize, and pulverize and classify through a jet mill, so that the median diameter of the particles is 7.5 microns, the sphericity is 0.925, and 0.1% of the particle size is added Silica with a median diameter of 30 nanometers is mixed evenly, and hot water is used as the heating medium for spheroidization heat treatment. The temperature of the hot water is 80°C, and the spheroidization heat treatment time is 1 to 10 minutes. The yellow toner basic particles obtained are The median diameter of the particle size is 7.2 microns, the sphericity is 0.965, and the yield is 97%. Add 0.8% silicon dioxide and 0.2% titanium dioxide to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com