Method for extracting vanadium by using vanadium slag mixed alkali roasting

A technology of mixing alkali and roasting, which is applied in the field of vanadium chemical industry and metallurgy. It can solve the problems of high roasting temperature, pollute the environment, reduce the roasting holding time, etc., and achieve the effects of reducing the degree of sintering, increasing the conversion rate, and increasing the rate of leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

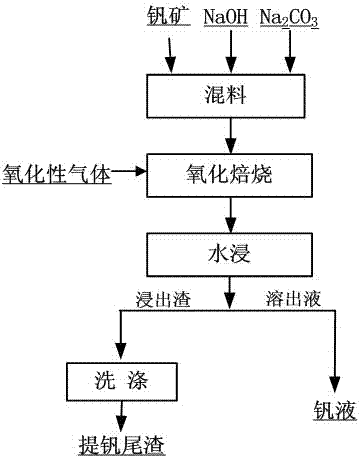

[0018] Example 1: figure 1 Shown, the processing step of the method for the vanadium extraction method of this vanadium slag mixed alkali roasting is as follows:

[0019] (1) Ingredients: mix 1kg of vanadium slag with 50g of Na 2 CO 3 , 50g of NaOH and stir evenly, the vanadium slag contains V 2 o 5 10wt%;

[0020] (2) Roasting: The mixture enters the rotary kiln and is heated to 800°C for 2 hours, the O in the rotary kiln 2 Volume content is 11%, obtains roasted clinker;

[0021] (3) Leaching: leaching the roasted clinker obtained in step (2) in water at 80°C, the pH value of the leach solution is 11; and then filtering to obtain vanadium extraction tailings and vanadium-containing eluate.

[0022] After detection and calculation, the conversion rate of vanadium in the present embodiment is 98%.

Embodiment 2

[0023] Embodiment 2: the processing steps of the method for the vanadium extraction method of this vanadium slag mixed alkali roasting are as follows:

[0024] (1) Ingredients: mix 1kg of vanadium slag with 20g of Na 2 CO 3 , 180g of NaOH and stir evenly, the vanadium slag contains V 2 o 5 20wt%;

[0025] (2) Roasting: The mixture enters the rotary kiln and is heated to 600°C for 3 hours, the O in the rotary kiln 2 Volume content is 5%, obtains roasted clinker;

[0026] (3) Leaching: leaching the roasted clinker obtained in step (2) in water at 90°C, the pH value of the leachate is 9; and then filtering to obtain vanadium extraction tailings and vanadium-containing eluate.

[0027] After detection and calculation, the conversion rate of vanadium in this embodiment is 99%.

Embodiment 3

[0028] Embodiment 3: the processing step of the method for the vanadium extraction method of this vanadium slag mixed alkali roasting is as follows:

[0029] (1) Ingredients: mix 1kg of vanadium slag with 20g of Na 2 CO 3 , 30g of NaOH and stir evenly, the vanadium slag contains V 2 o 5 11wt%;

[0030] (2) Roasting: The mixture enters the rotary kiln and is heated to 750°C for 4 hours, the O in the rotary kiln 2 Volume content is 15%, obtains roasted clinker;

[0031] (3) Leaching: leaching the roasted clinker obtained in step (2) in water at 60° C., the pH value of the leachate is 14; and then filtering to obtain vanadium extraction tailings and vanadium-containing eluate.

[0032] After detection and calculation, the conversion rate of vanadium in this embodiment is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com