Method for extracting vanadium by sodium salt roasting from vanadium-bearing iron concentrate

A technology of sodium roasting and concentrated ore, which is applied in the field of vanadium extraction by sodium roasting, can solve the problems of low transfer leaching rate and large pollution, and achieve the effect of increasing transfer rate, low equipment requirements and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

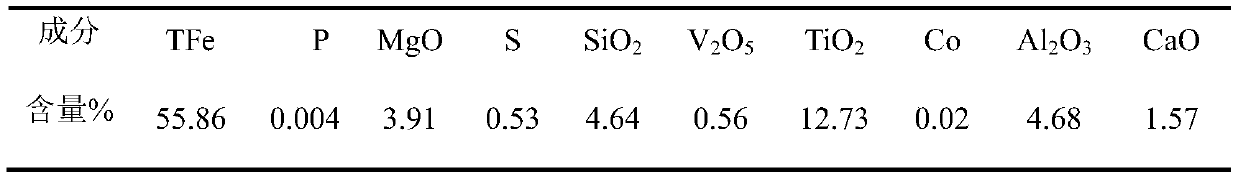

Embodiment 1

[0045] Take 100g of the iron ore concentrate in Table 1 that has passed through a 200 sieve, mix it with 5g of NaF for 10min, and use a lubricating mill to lubricate the mixture for 30min. The mixture is placed in a disc pelletizer and sprayed with 10% sodium hydroxide solution to prepare wet pellets. After the wet pellets are dried, the moisture content is less than 1%. The dried pellets were placed in a muffle furnace for high-temperature calcination at a temperature of 850°C for 60 minutes, and the pellets were taken out at 600°C. Place the taken out pellet clinker in water at 60°C, leaching for 2 hours, and filter and separate to obtain V in the leaching residue. 2 o 5 The content is 0.15%.

Embodiment 2

[0047] Take 100g of the iron ore concentrate in Table 1 that has been passed through a 200 sieve, mix it with 10g of NaF for 30min, and use a lubricating mill to lubricate the mixture for 60min. The mixture is placed in a disc pelletizer and sprayed with 5% sodium hydroxide solution to prepare wet pellets. After the wet pellets are dried, the moisture content is less than 1%. The dried pellets were placed in a muffle furnace for high-temperature calcination at a temperature of 1050°C for 120 minutes, and the pellets were taken out at 700°C. Put the taken-out pellet clinker in water at 80°C, leaching for 24 hours, and filter and separate to obtain V in the leaching residue. 2 o 5 The content is 0.10%.

Embodiment 3

[0049] Take 100g of the iron ore concentrate in Table 1 that has passed through a 200 sieve, mix it with 15g of NaF for 100min, and use a lubricating mill to lubricate the mixture for 120min. The mixture is placed in a disc pelletizer and sprayed with 10% sodium hydroxide solution to prepare wet pellets. After the wet pellets are dried, the moisture content is less than 1%. The dried pellets were placed in a muffle furnace for high-temperature calcination at a temperature of 1200°C for a calcination time of 180 minutes, and the pellets were taken out at 650°C. Place the taken-out pellet clinker in water at 80°C, leaching for 48 hours, and filter and separate to obtain V in the leaching residue. 2 o 5 The content is 0.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com