Light diffusion plate and light guide plate having micro structure

A light diffusing plate and microstructure technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of incomplete molding of the second convex part, difficult to fully squeeze in, and weaken the brightness effect, so as to reduce the cost and increase the turnover. The effect of write rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of three preferred embodiments with reference to the drawings.

[0028] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

[0029]

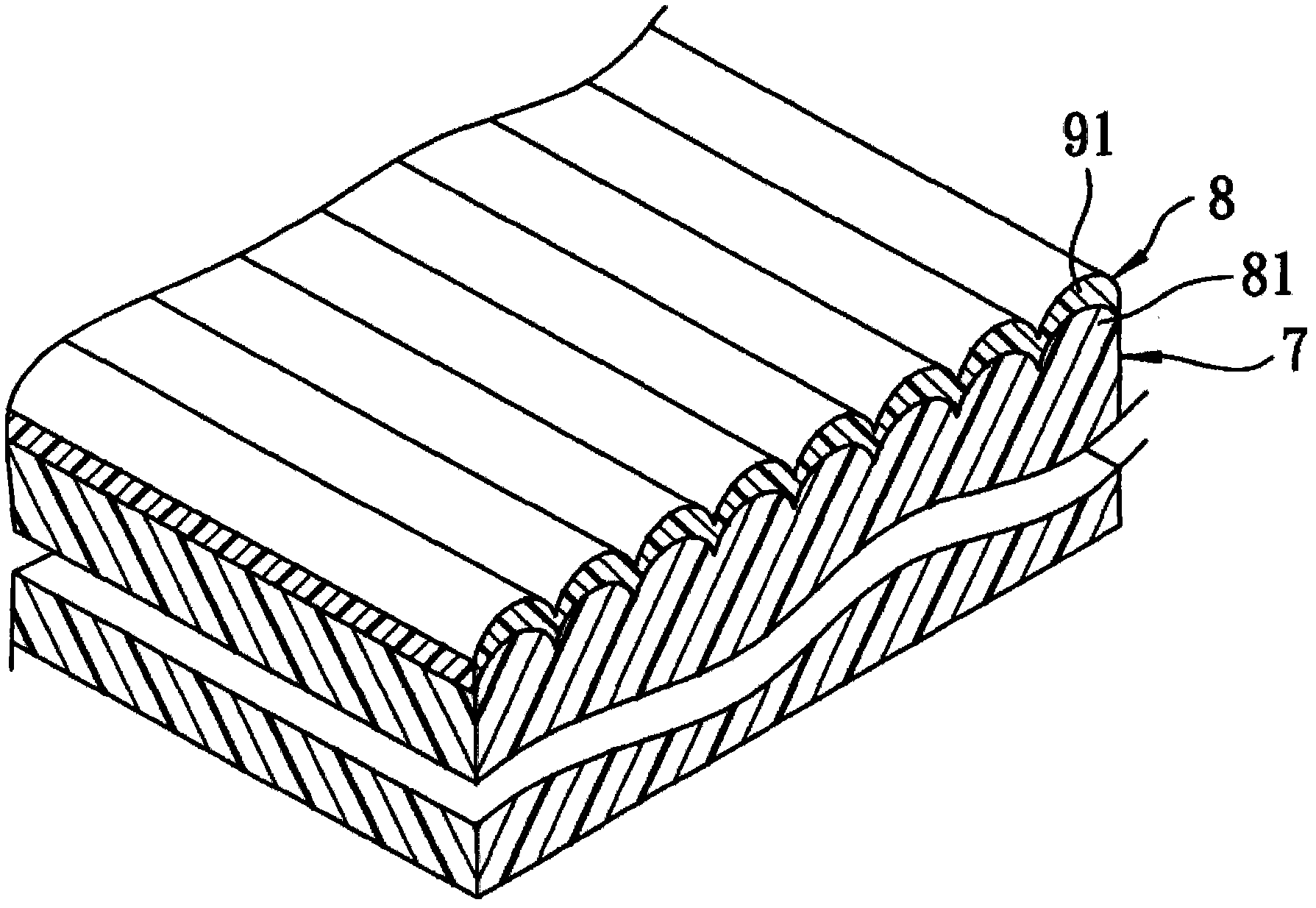

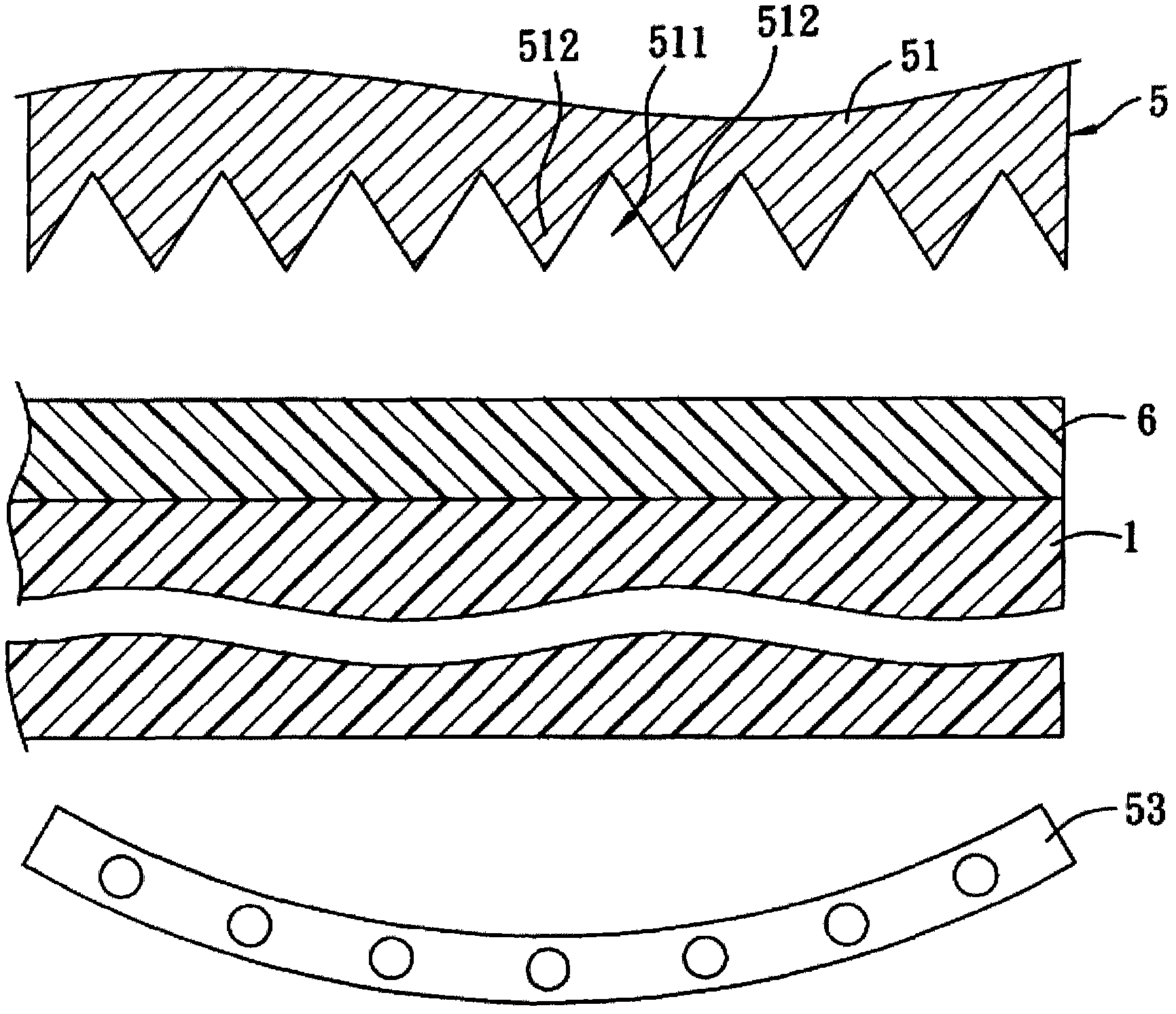

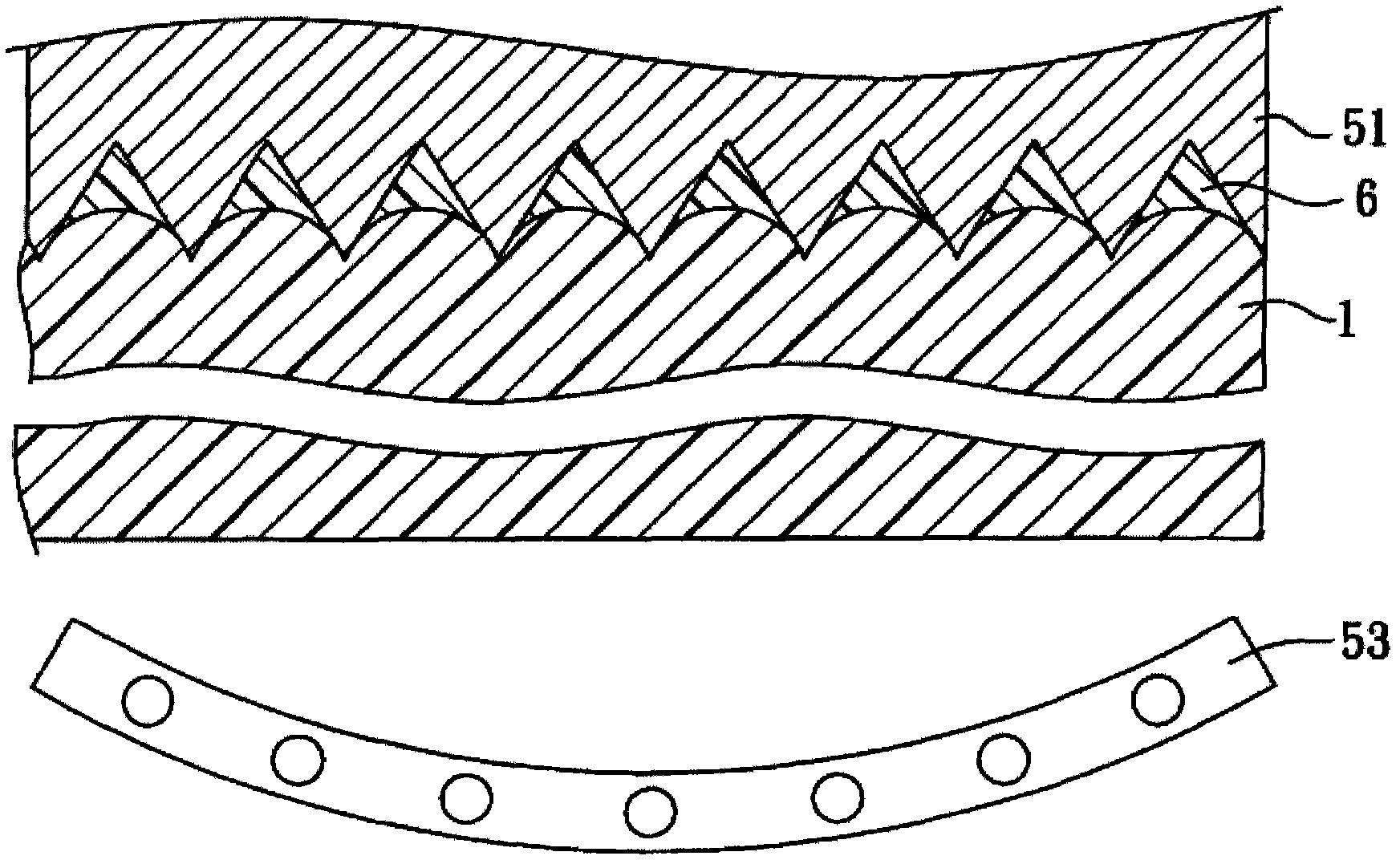

[0030] refer to figure 2 and image 3 , the first preferred embodiment of the present invention is to use a molding device 5 to produce a light diffusion plate with microstructures, the molding device 5 includes a molding die 51 and a lighting unit 53 . The stamper mold 51 has a plurality of transfer microstructures 512 arranged side by side, and the transfer microstructures 512 jointly define a mold cavity 511 . In addition, a substrate 1 with a thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com