Preparation method of benzoxazine resin

A technology of benzoxazine and resin, which is applied in the field of preparation of benzoxazine resin, can solve the problems of large amount of waste water, wide molecular weight distribution of benzoxazine resin, time-consuming and labor-intensive problems, and achieve the goal of improving adsorption rate and adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

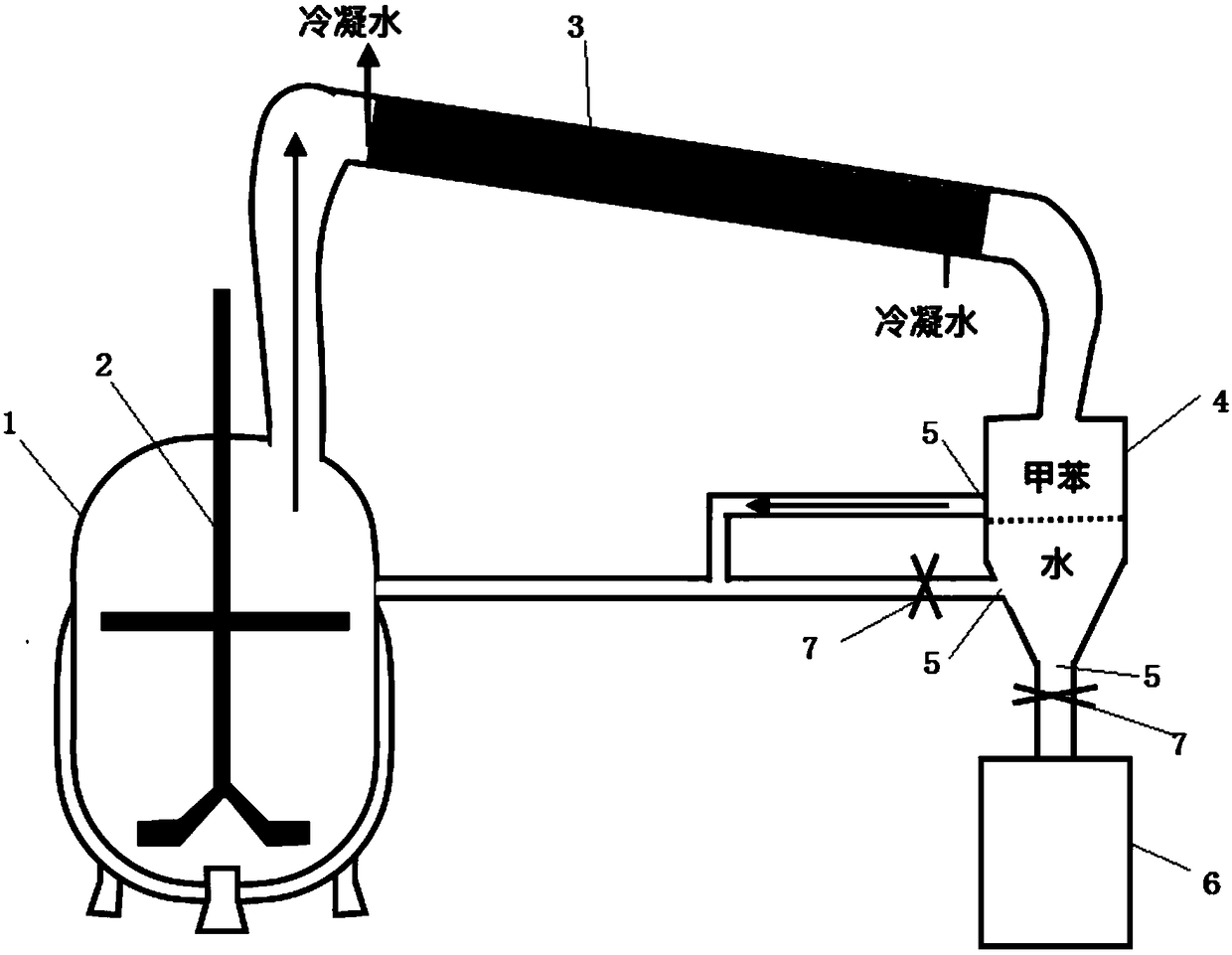

Image

Examples

Embodiment 1

[0029] Step S1, the preparation of the activated carbon catalyst specifically includes steps S11 and S12.

[0030] S11. First, process the solid benzoxazine resin into a spherical shape; then raise the temperature to 300°C at 0.2°C / min in the air atmosphere, and keep the temperature constant for 2h, and carry out oxidation treatment; after oxidation, under the protection of high-purity nitrogen, after oxidation The temperature of the resin balls was raised to 800°C at 5°C / min, and kept at a constant temperature for 30 minutes for carbonization treatment, and finally activated with water vapor for 40 minutes to obtain nitrogen-containing spherical activated carbon.

[0031] S12. Add nitrogen-containing spherical activated carbon particles into a sodium hydroxide solution with a mass concentration of 50% and soak for 24 hours, filter with suction, dry the filter residue at 150°C for 2 hours, put it into a desiccator to cool, and obtain a sodium hydroxide with a mass content of 30...

Embodiment 2

[0037] Step S1, the preparation of the activated carbon catalyst specifically includes steps S11 and S12.

[0038] S11. First, process the solid benzoxazine resin into a spherical shape; then raise the temperature to 300°C at 0.2°C / min in the air atmosphere, and keep the temperature constant for 2h, and carry out oxidation treatment; after oxidation, under the protection of high-purity nitrogen, after oxidation The temperature of the resin balls was raised to 800°C at 5°C / min, and kept at a constant temperature for 30 minutes for carbonization treatment, and finally activated with water vapor for 40 minutes to obtain nitrogen-containing spherical activated carbon.

[0039] S12. Add nitrogen-containing spherical activated carbon particles into a calcium hydroxide solution with a mass concentration of 50% and soak for 24 hours, filter with suction, dry the filter residue at 150° C. for 2 hours, put it into a desiccator to cool, and obtain a calcium hydroxide with a mass content o...

Embodiment 3

[0045] Step S1, preparation of activated carbon catalyst: add the purchased activated carbon particles into a magnesium hydroxide solution with a mass concentration of 50% and soak for 24 hours, filter with suction, dry the filter residue at 150°C for 2 hours, put it into a desiccator to cool, and obtain hydrogen oxide An activated carbon catalyst with a magnesium mass content of 30%.

[0046] Step S2, add the solvent toluene, phenol, paraformaldehyde, and diaminodiphenylmethane to the reaction kettle in sequence, keep the reaction kettle at 40°C, start stirring, and add the activated carbon catalyst prepared in step S1, wherein the amount of toluene added accounts for 10% of the reaction kettle 30% of the total mass of all reaction materials in the mixture, the molar ratio of phenol:paraformaldehyde:diaminodiphenylmethane is 2:4:1, and the catalyst dosage is 5% of the mass of phenol.

[0047] Step S3: After adding the catalyst, start to raise the temperature, and stop heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com