Special waterborne fiber paint for heat transfer printing and preparation method thereof

A thermal transfer printing and fiber technology, applied in cellulose coatings, anti-fouling/underwater coatings, polyester coatings, etc., can solve the problems of inability to meet the individual artistic needs of interior decoration, single artistic expression forms, etc., and achieve practical Excellent comprehensive performance of sex and decoration, bright colors, and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

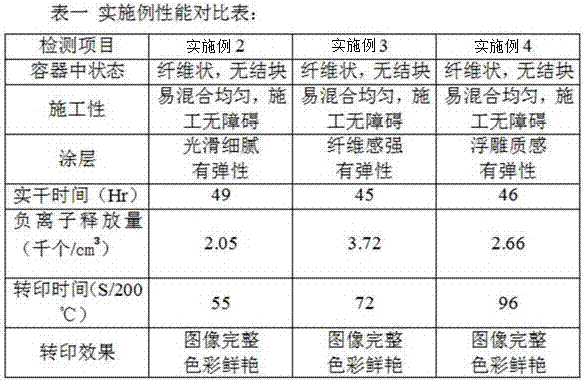

Examples

Embodiment 1

[0032] A special water-based fiber coating for thermal transfer described in this embodiment, the fiber coating includes the following mass ratio components:

[0033] (Raw material) (Amount wt)

[0034] Fiber 60-85%;

[0035] Glitter powder 0.5-3%;

[0036] Gold and silver wire 0.5-3%;

[0037] Mica flakes 1-5%;

[0038] Negative ion powder 1-5%;

[0039] Powder defoamer 0.2-0.5%;

[0040] Powder fiber softener 0.2-0.5%;

[0041] Powder antifungal agent 0.2-0.5%;

[0042] Redispersible latex powder 5-15%;

[0043] Hydroxypropyl methylcellulose 2-10%;

[0044] Polyvinyl alcohol 2-10%.

[0045] in:

[0046] The fiber is one or more of cotton fiber, bamboo fiber, wood fiber, viscose fiber, polyester fiber, polyamide fiber, polyacrylonitrile fiber, polyurethane fiber, polyvinyl chloride fiber, polyvinyl formal fiber A mixture of polyester fibers is the best;

[0047] The length of the fiber is 1-6mm, wherein the shorter the length, the better and finer the coating flat...

Embodiment 2

[0058] A special water-based fiber coating for thermal transfer described in this embodiment, the fiber coating includes the following mass ratio components:

[0059] Raw material dosage (wt)

[0060] Fiber 74%;

[0061] Glitter powder 1%;

[0062] Filigree 1%;

[0063] Mica flakes 2%;

[0064] Negative ion powder 2%;

[0065] Powder defoamer 0.5%;

[0066] Powder fiber softener 0.2%;

[0067] Powder antifungal agent 0.3%;

[0068] Redispersible latex powder 5%;

[0069]Hydroxypropyl methylcellulose 6%;

[0070] Polyvinyl alcohol 8%.

[0071] Wherein the special water-based fiber paint preparation method for thermal transfer printing in Example 2 differs from the preparation method in Example 1 only in that the proportioning of the formula contained in Step 1 in Example 1 is replaced by the formula in Example 2 Matching.

Embodiment 3

[0073] A special water-based fiber coating for thermal transfer described in this embodiment, the fiber coating includes the following mass ratio components:

[0074] Raw material dosage (wt)

[0075] Fiber 66%;

[0076] Glitter powder 2%;

[0077] Gold and silver wire 0.5%;

[0078] Mica flakes 3%;

[0079] Negative ion powder 5%;

[0080] Powder defoamer 0.5%;

[0081] Powder fiber softener 0.5%;

[0082] Powder antifungal agent 0.5%;

[0083] Redispersible latex powder 8%;

[0084] Hydroxypropyl methylcellulose 4%;

[0085] Polyvinyl alcohol 10%.

[0086] Wherein the special water-based fiber paint preparation method for thermal transfer printing in Example 3 differs from the preparation method in Example 1 only in that the proportioning of the formula contained in Step 1 in Example 1 is replaced by the formula in Example 3 Matching.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com