Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "High bending strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Target of intermetallic compound with B2-ordered lattice structure, production method thereof and magnetic recording medium having B2-structured underlayer

InactiveUS6159625AHigh bending strengthSmall grain sizeCellsBase layers for recording layersSputter depositionCrystallite

A target for sputter-depositing a B2-structured thin film for an underlayer of a magnetic recording medium. Since the target is made of a sintered body of an intermetallic compound being substantially a B2-ordered lattice structure, the target has a uniform small grain size and a high bending strength. The target produces a thin film with a small grain size and a minimized particle deposition.

Owner:HITACHI METALS LTD

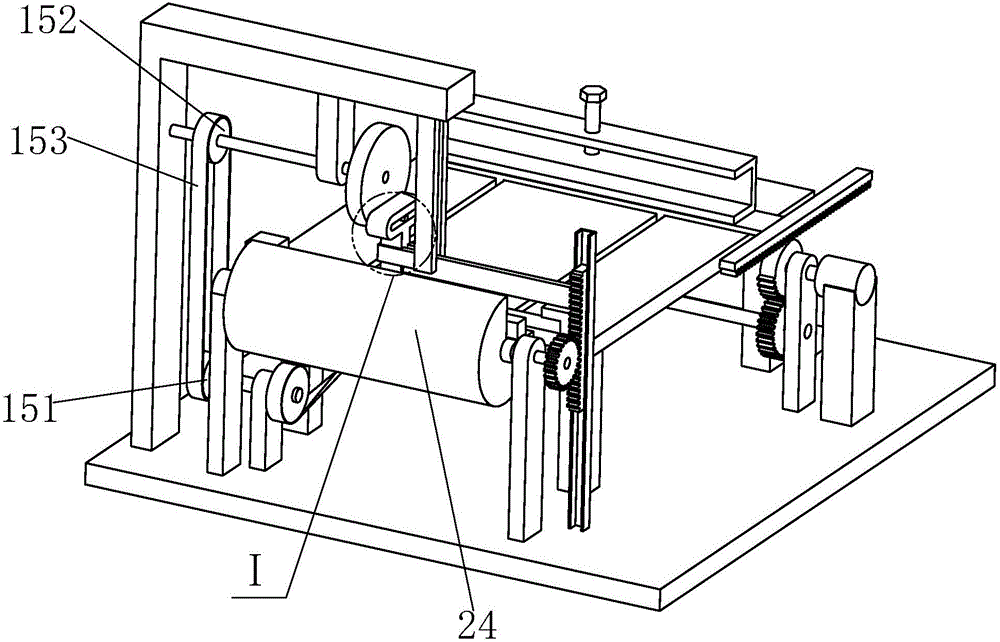

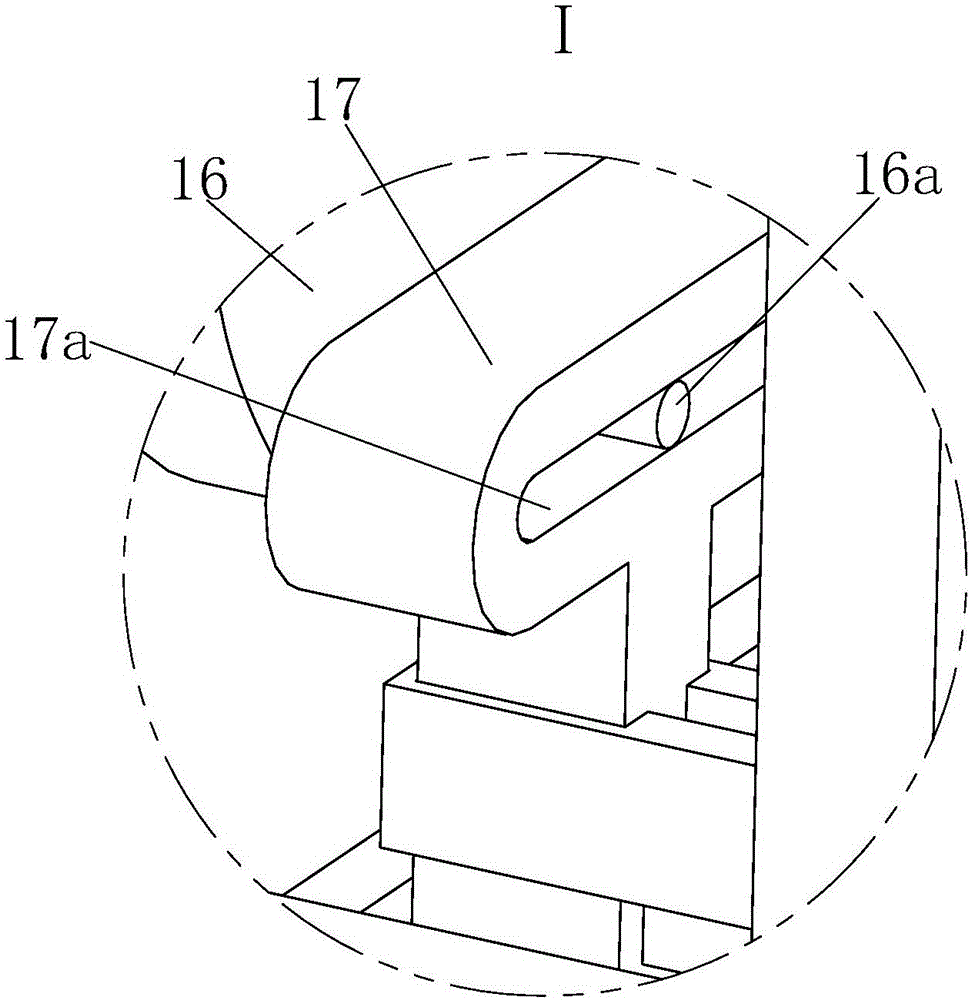

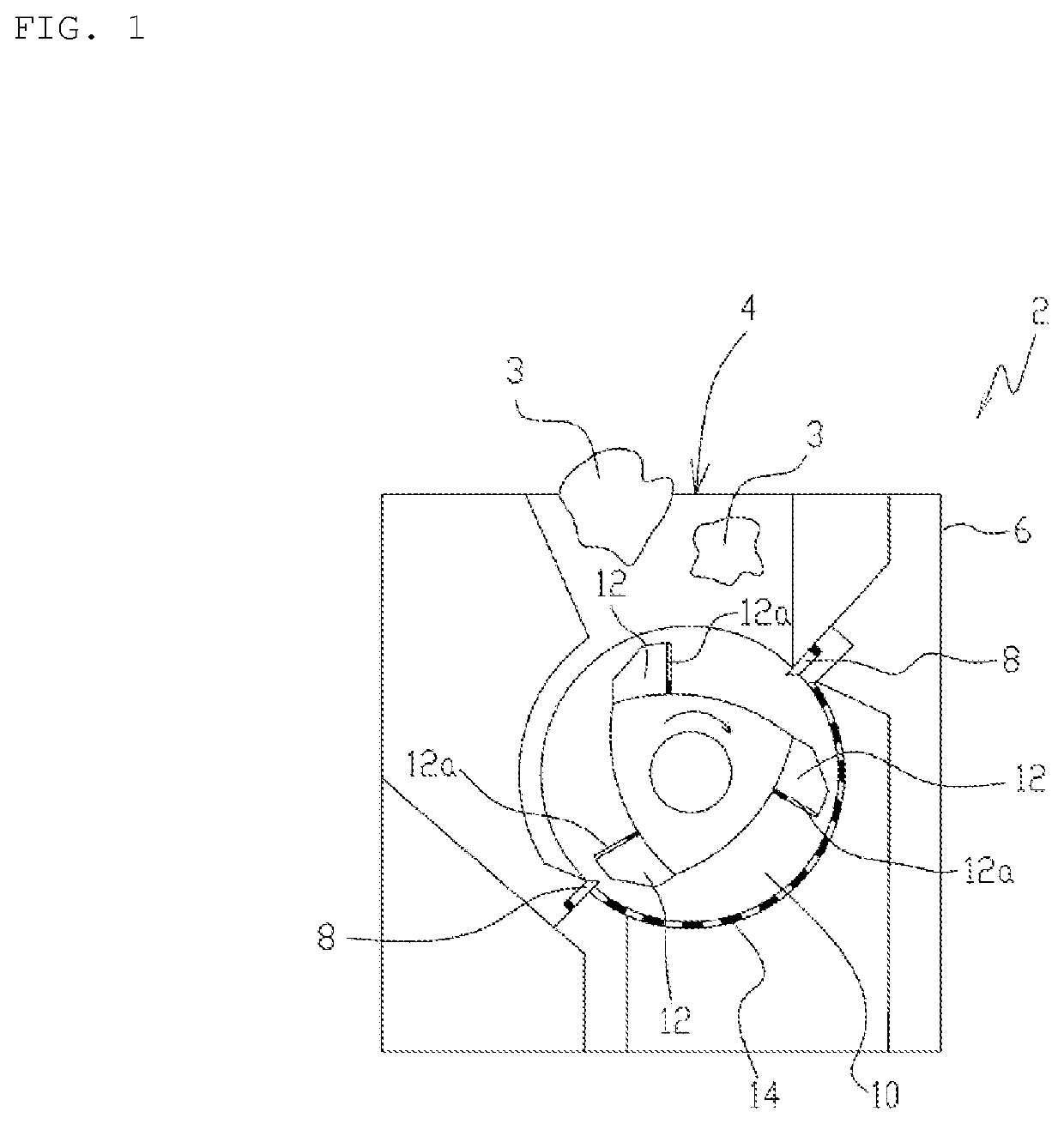

Sheet metal part bending machine

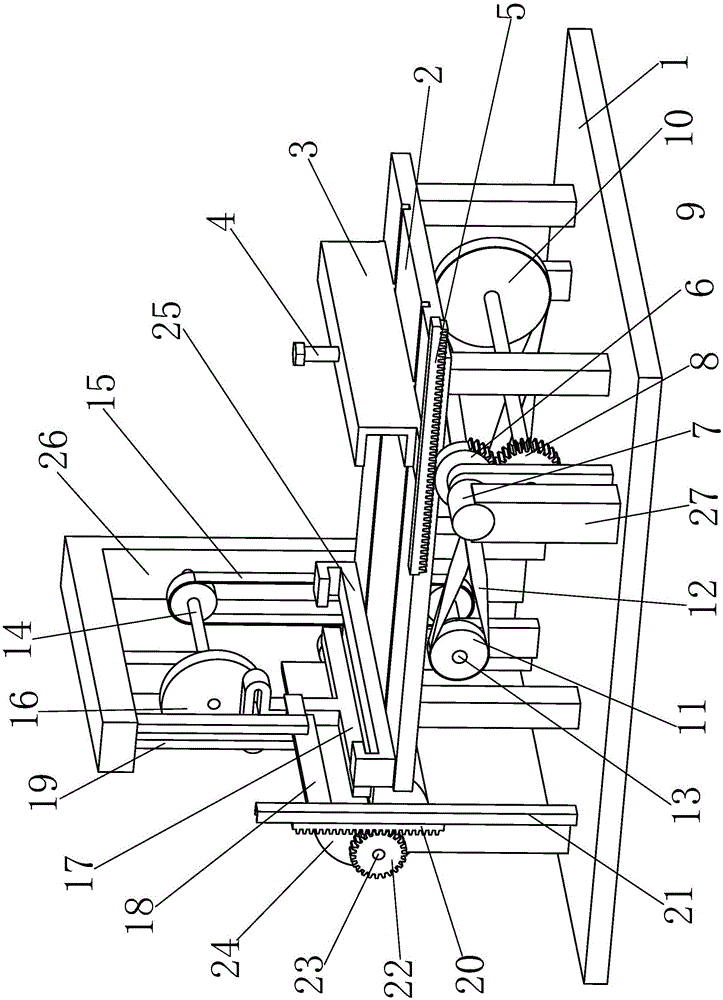

ActiveCN106799413AHigh bending strengthFast bending speedMetal-working feeding devicesPositioning devicesEngineeringRack and pinion

The invention relates to a sheet metal part bending machine which comprises a bottom plate and a workbench. A clamp opening frame is mounted on the workbench in a sliding manner and provided with a fastening bolt. A first gear rack is welded to the clamp opening frame. An incomplete gear is arranged at the lower end of the first gear rack and connected with a motor. A transmission gear is arranged below the incomplete gear and connected with a transmission shaft. The transmission shaft is connected with a right belt wheel. A left belt wheel is arranged right at the left portion of the right belt wheel. A flat rope belt is arranged between the left belt wheel and the right belt wheel. The left belt wheel is connected with a countershaft. An upper shaft is arranged over the countershaft. A parallel belt transmission mechanism is arranged between the countershaft and the upper shaft. According to the sheet metal part bending machine, by means of alternate meshing of the incomplete gear, the gear rack and the transmission gear, sheet metal parts can be slid leftwards at equal distance, a lifting bending frame and a drive rotating disc cooperate to alternately bend the sheet metal parts by 90 degrees, and then the sheet metal parts can be automatically and fast bent by 90 degrees many times; and the beneficial effects of large bending strength and high bending speed are achieved.

Owner:ANHUI PULUN INTELLIGENT EQUIP CO LTD

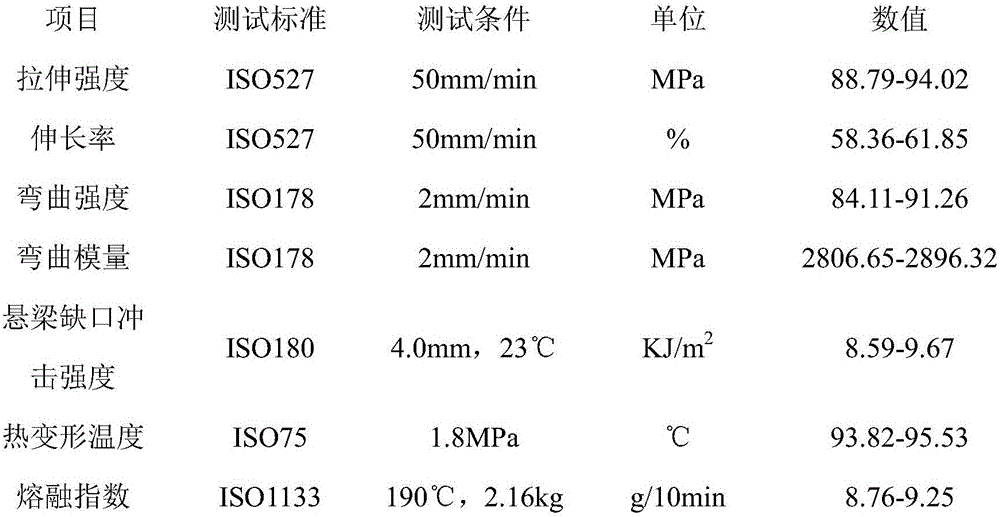

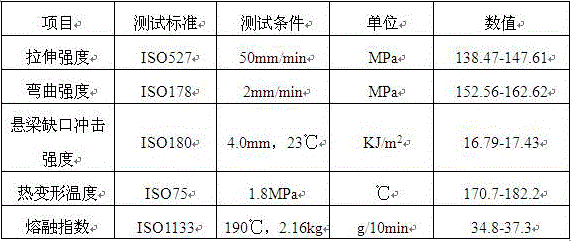

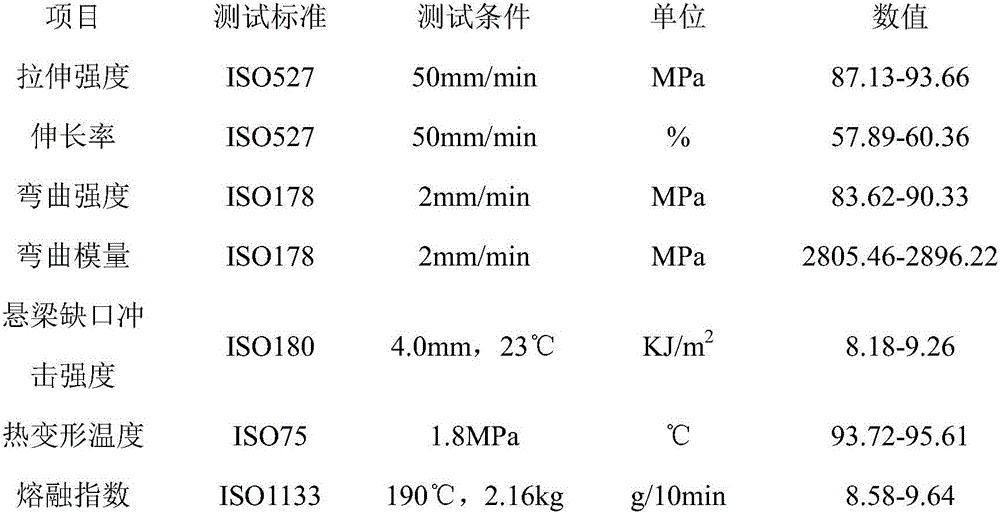

Graphene printing material

InactiveCN106589864AHigh tensile strengthHigh heat distortion temperatureAdditive manufacturing apparatusHeat deflection temperaturePolymer science

The invention discloses a graphene printing material and belongs to the technical field of 3D printing materials. The graphene printing material comprises, by weight, 5.5-7.6 parts of graphene, 24.6-30.4 parts of waste plastic, 34.2-38.2 parts of polylactic acid, 11.6-22.7 parts of potassium tripolyphosphate, 18.3-24.5 parts of adipate, 9.2-17.3 parts of a special synthetic agent, and 5.2-9.5 parts of a starch synthetic agent. The graphene printing material has high tensile strength, high bending strength and high notch impact strength and is high in thermal deformation temperature and melt index. A product produced through 3D printing technology is high in quality, has high anti-impact property and is high in strength. The material has wide market prospect.

Owner:GUANGXI ZHUMENG SANTI TECH CO LTD

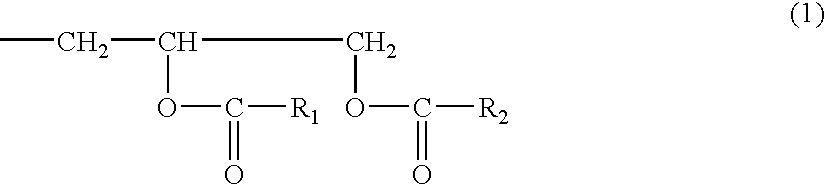

Epoxy resin-forming liquid preparation containing inorganic particle

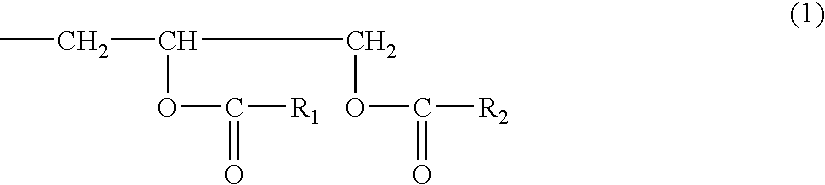

InactiveUS20100137475A1Advantageous handling propertyHigh bending strengthSemiconductor/solid-state device detailsSolid-state devicesChemistryFlexural strength

There is provided a liquid preparation for forming an epoxy resin having curing properties combining high transparency and high bending strength while maintaining advantageous handling properties as in a liquid state. A liquid preparation for forming an epoxy resin comprising: an A agent; and a B agent; wherein the A agent contains a modified epoxy resin (I) formed from at least one type of compound (i) having in a molecule thereof, at least one functional group of Formula (1):(where R1 and R2 individually represent an alkyl group, an alkenyl group, an alkynyl group, an aryl group, an aralkyl group, a heterocyclic group or a halogenated, aminated or nitrated derivative of any of the groups) and a compound (ii) having a glycidyl group in a molecule thereof, and an inorganic particle (II); and the B agent contains a curing agent (III). A liquid preparation for forming an epoxy resin comprising: an A′ agent; and a B′ agent; wherein the A′ agent contains the modified epoxy resin (I); and the B′ agent contains the inorganic particle (II) and the curing agent (III).

Owner:NISSAN CHEM IND LTD

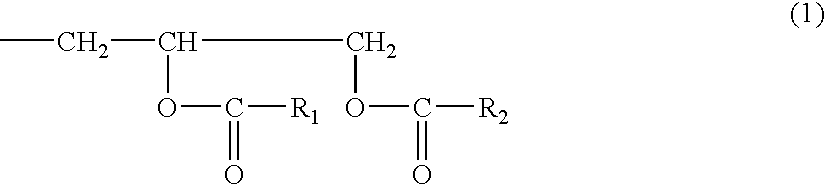

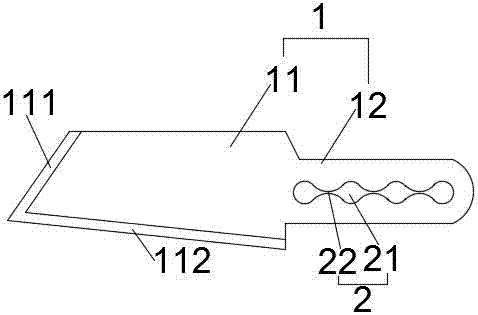

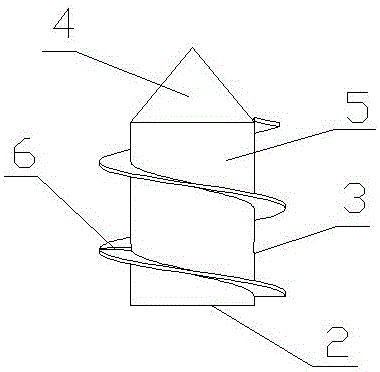

Aluminum-plastic composite panel with high rigidity and high bending strength and preparation method of aluminum-plastic composite panel

ActiveCN103709479AEasy to produceRigidSynthetic resin layered productsMetal layered productsPolymer adhesiveFlexural strength

The invention relates to an aluminum-plastic composite panel, and in particular relates to an aluminum-plastic composite panel with high rigidity and high bending strength and a preparation method of the aluminum-plastic composite panel. According to the aluminum-plastic composite panel and the preparation method thereof, firstly a PE / PP (Polyethylene / Polypropylene) core layer is reinforced by adopting coupling agent modified nanometer calcium carbonate, meanwhile the PE / PP core layer is modified by using dicumyl peroxide and triallyl isocyanurate; finally the needed panel is prepared according to a production process of the aluminum-plastic composite panel. The aluminum-plastic composite panel sequentially comprises a coating aluminum plate (1), a first type of polymer adhesive film (2), the PE / PP core layer (3), a second type of polymer adhesive film (4) and a coating aluminum plate (5) from top to bottom. The aluminum-plastic composite panel produced by the preparation method is convenient to produce, the rigidity and bending strength of an aluminum-plastic composite material produced by utilizing the modified PE / PP core layer are higher than those of a conventional aluminum-plastic composite material, and the aluminum-plastic composite panel can be widely used in transportation, decoration materials, municipal gardens and the like.

Owner:JIANGSU PIVOT NEW DECORATIVE MATERIALS

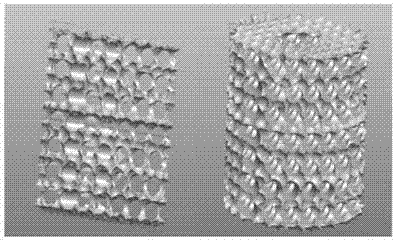

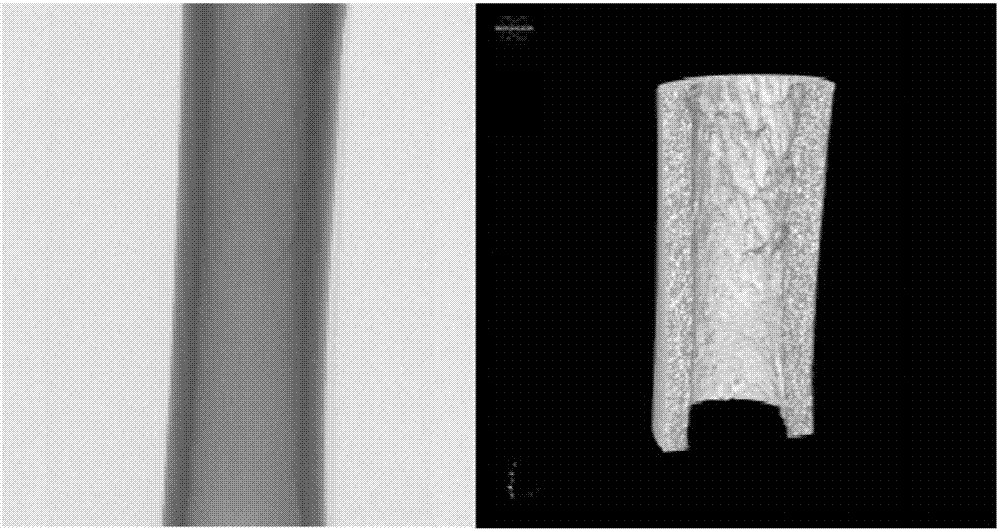

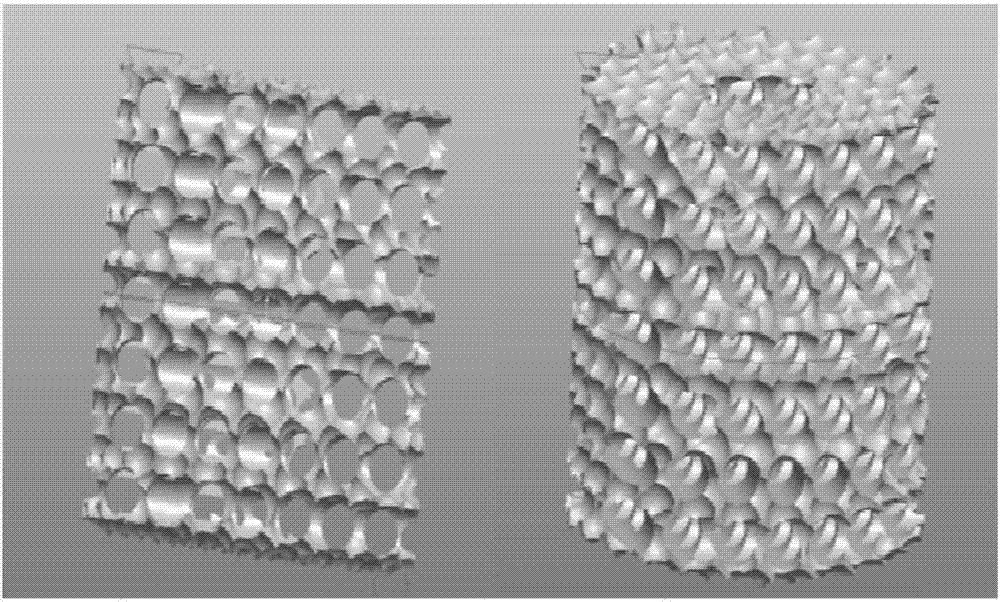

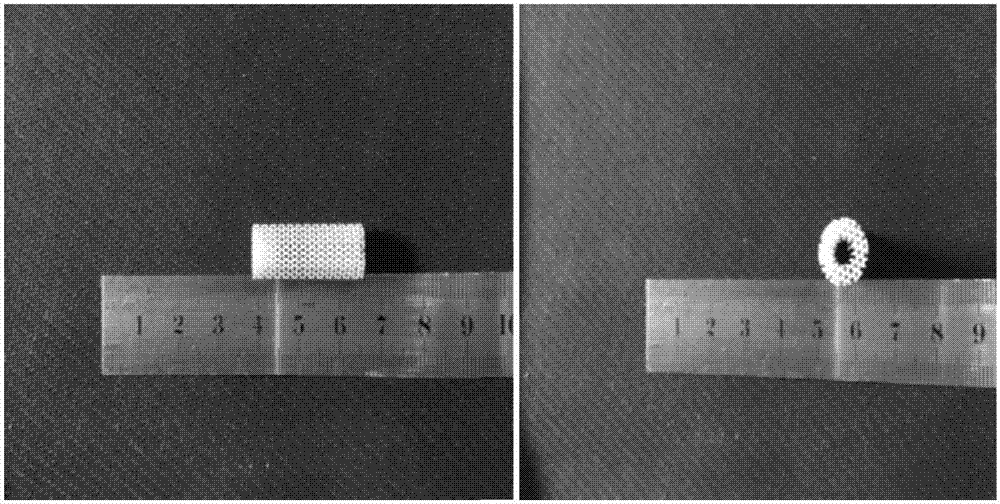

Zirconium dioxide porous biologic bone repair scaffold customized in individualized way based on light curing three-dimensional (3D) printing technology, and preparation method of zirconium dioxide porous biologic bone repair scaffold

ActiveCN107007888AShort preparation timeAccurate porosityAdditive manufacturing apparatusPharmaceutical delivery mechanismPorosityIndividualized treatment

The invention relates to a preparation method of a biological ceramic scaffold material, in particular to a preparation method of a zirconium dioxide porous biologic bone repair scaffold customized in an individualized way based on a light curing three-dimensional (3D) printing technology. The method comprises the following steps: (1) establishing a health status chart of a bone, which is not damaged, by using a two-dimensional or three-dimensional imaging technology of computed tomography (CT), and separating out a form figure of a bone needing to be implanted in combination of a status chart of the damaged bone waiting for implanting; (2) using special data software to convert CT data into 3D print data; (3) preparing the zirconium dioxide porous biologic bone repair scaffold in the individualized way by using the light curing 3D printing technology. The bone repair biological ceramic material prepared by the method is in accordance with the individualized treatment principle; the method is short in manufacturing process time and high in efficiency; the prepared material is more accurate in porosity, small in error, high in compressive strength and bending strength and good in biocompatibility.

Owner:HANGZHOU CITY XIAOSHAN DISTRICT TRADITIONAL CHINESE MEDICAL HOSPITAL

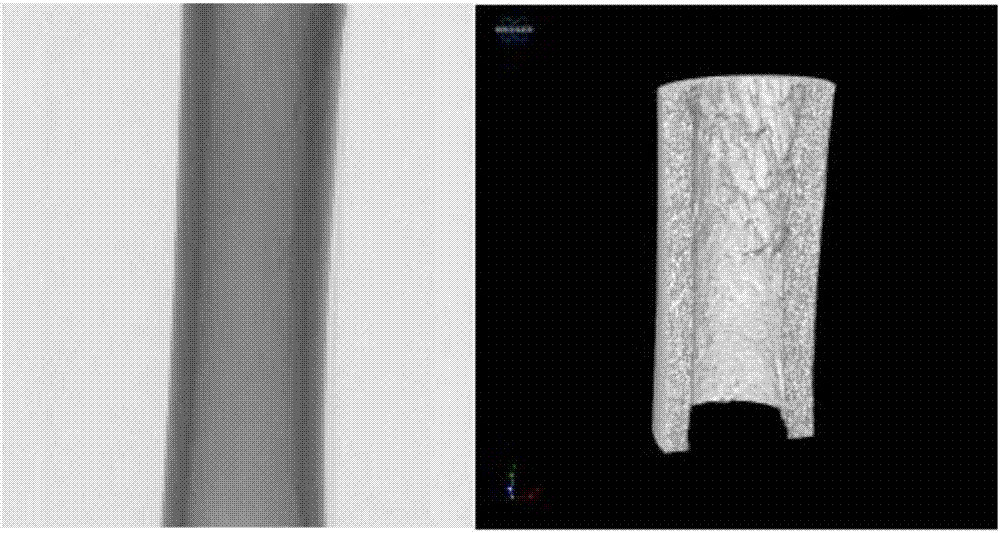

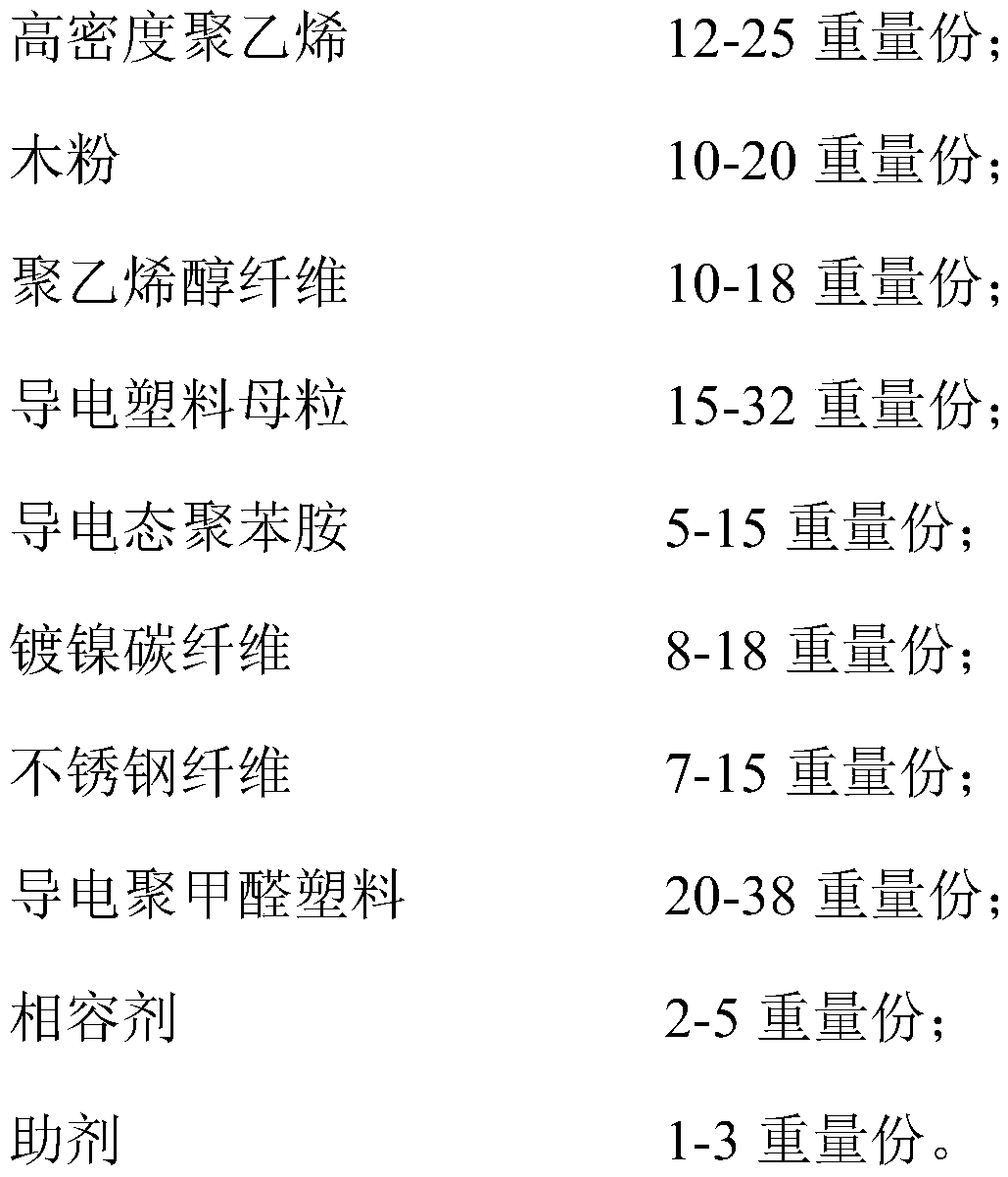

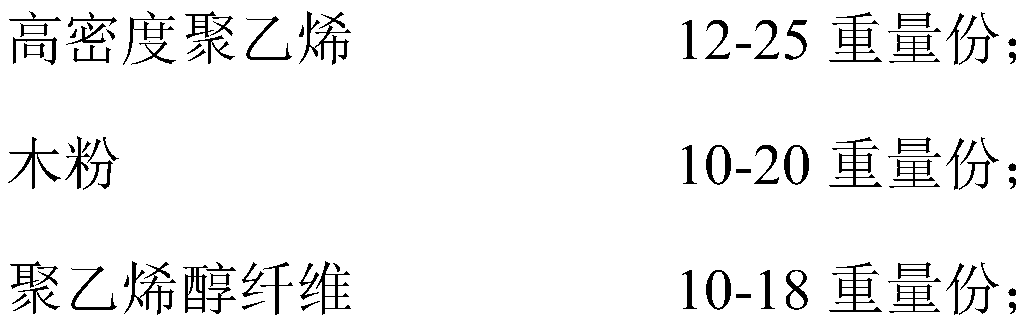

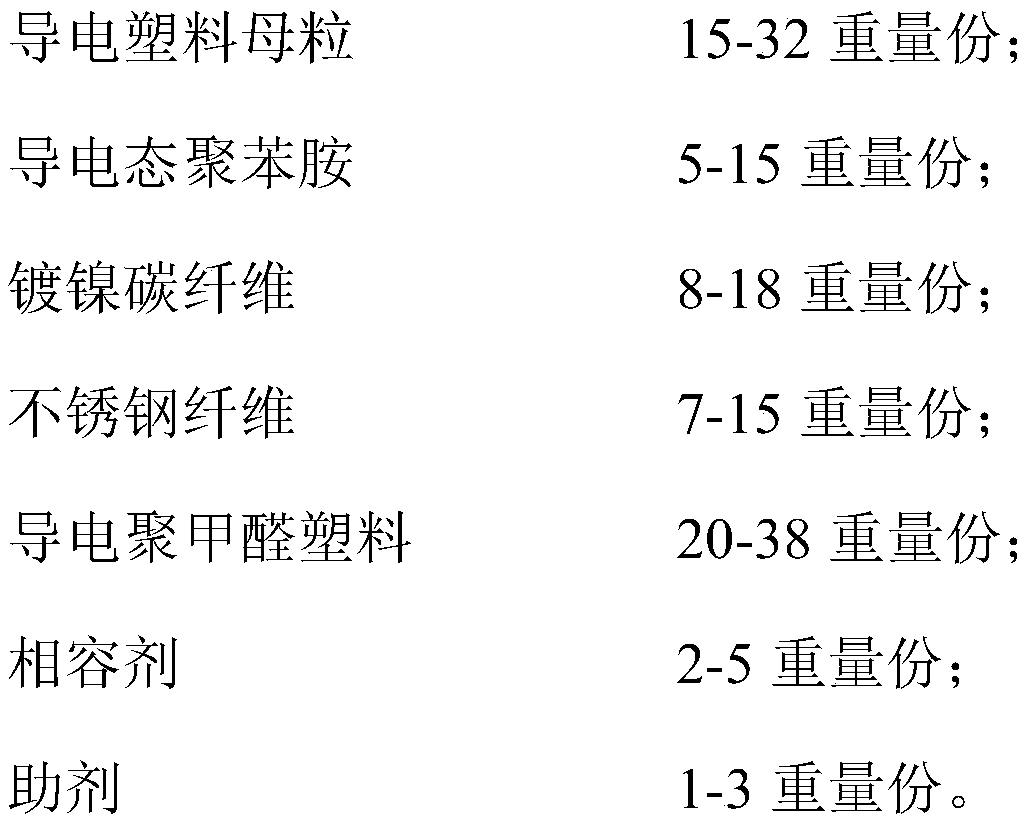

Anti-bending, anti-slip and anti-static type plastic-wood composite material and preparation method thereof

InactiveCN110283420AHigh mechanical strengthImprove antistatic performanceCarbon fibersPolyvinyl alcohol

The invention belongs to the technical field of functional plastic-wood materials, specifically relates to an anti-bending, anti-slip and anti-static type plastic-wood composite material, and further discloses a preparation method thereof. According to the anti-bending, anti-slip and anti-static type plastic-wood composite material disclosed by the invention, high-density polyethylene, wood powder, high-strength and high-modulus polyvinyl alcohol fibers, conductive plastic masterbatches, conductive-state polyaniline, nickel coated carbon fibers, 304 stainless steel fibers, conductive polyformaldehyde plastic, a compatibilizer, and auxiliaries such as a coupling agent, a lubricant, and an ultraviolet absorbent are taken as raw materials, and a product is obtained through extrusion pelleting, molding, and surface brush grinding and coarsen treatment through a wire brush. The plastic-wood composite material provided by the invention integrates outstanding anti-bending, surface anti-slip and anti-static properties, and has significant application value.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD

Bone repair biological ceramic scaffold material formed through individualized customization based on photocuring 3D printing technology and preparation method of bone repair biological ceramic scaffold material

InactiveCN107050518AShort preparation timeAccurate porosityAdditive manufacturing apparatusTissue regenerationPorosityIndividualized treatment

The invention relates to a preparation method of a biological ceramic scaffold material. The preparation method of the bone repair biological ceramic scaffold material formed through individualized customization based on photocuring 3D printing technology comprises the following steps: (1) establishing a health state diagram when the skeleton is not damaged by adopting the CT two-dimensional and three-dimensional imaging technologies, and by combining with the to-be-implanted defect skeleton state diagram, separating out the to-be-implanted skeleton state diagram; (2) converting CT data into 3D printing data by adopting special data software; and (3) preparing the bone defect biological ceramic repairing material in an individualized manner by adopting the photocuring 3D printing technology. The bone repair biological ceramic material prepared by adopting the method provided by the invention conforms to the individualized treatment principle, the preparation process is short is time and high in efficiency, and the prepared material has the accurate porosity, small errors, large compression-resisting strength and bending-resisting strength, and good biocompatibility.

Owner:HANGZHOU CITY XIAOSHAN DISTRICT TRADITIONAL CHINESE MEDICAL HOSPITAL

Cermet cutter material, cutter and manufacture method

ActiveCN107587022AHigh hardnessStrong toughnessMilling cuttersTurning toolsHardnessOxidation resistant

A cermet cutter material comprises, by mass percentage, 70-90% of TiNC, 4-10% of Cr2C3, 1-2% of MoC2, 4-20% of Ni, and 0.4-1% of Y. A cermet cutter is made from the cermet cutter material. A manufacture method of the cermet cutter comprises: S1, preparing raw materials according to the formula of the cermet cutter material; S2, grinding the raw materials into powder, and drying the powder; S3, adding a forming agent to powder and performing granulation; S4, performing compression moulding to granules to obtain a cutter blank; S5, sintering the blank; and S6, performing coarse grinding, fine grinding and polishing to the sintered product to obtain the cermet cutter. The cutter made from the cermet cutter material is high in hardness, large in fracture toughness and flexure strength, and good in oxidation resistance and durability.

Owner:DONGGUAN HUAJING POWDER METALLURGY

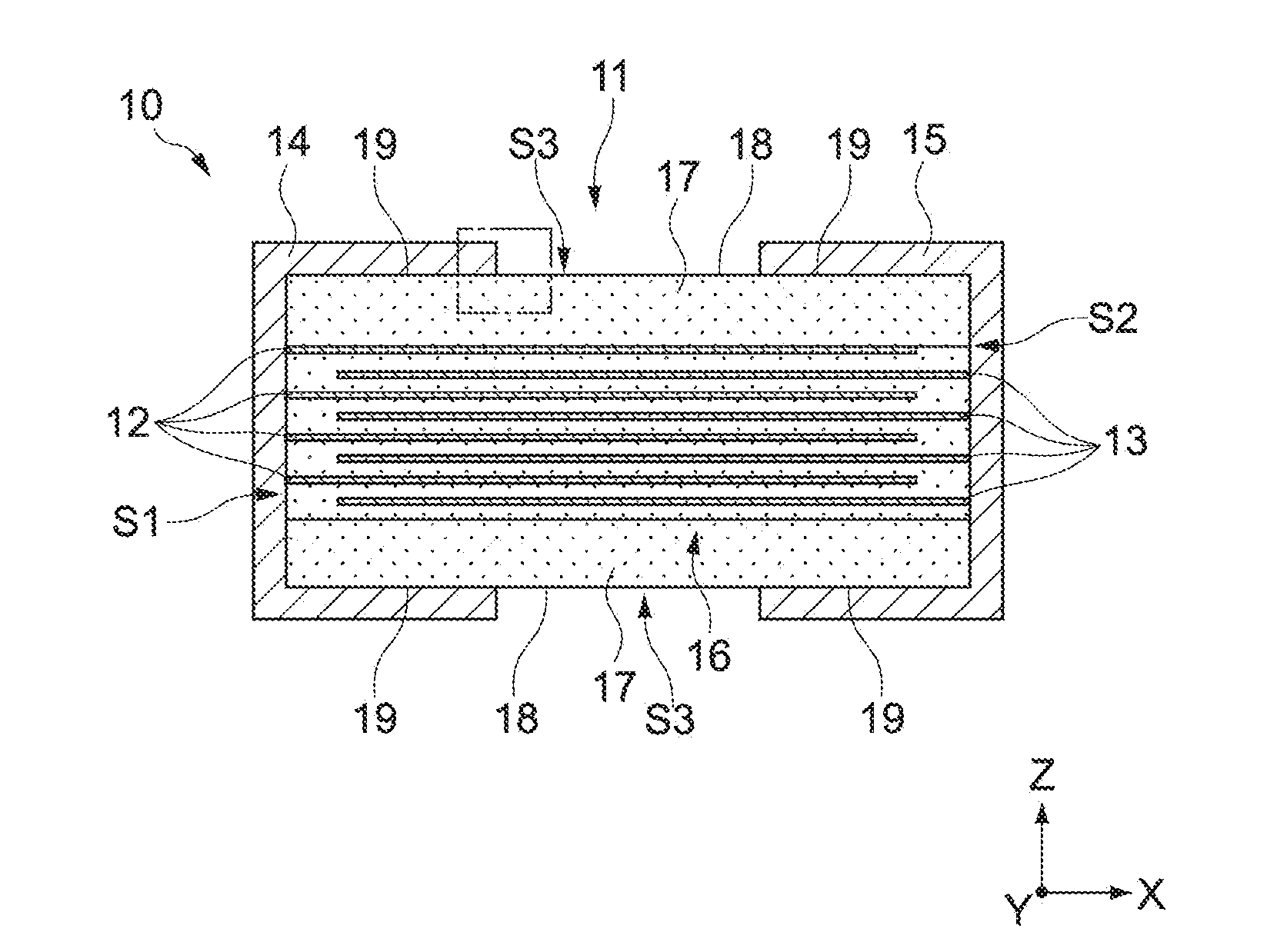

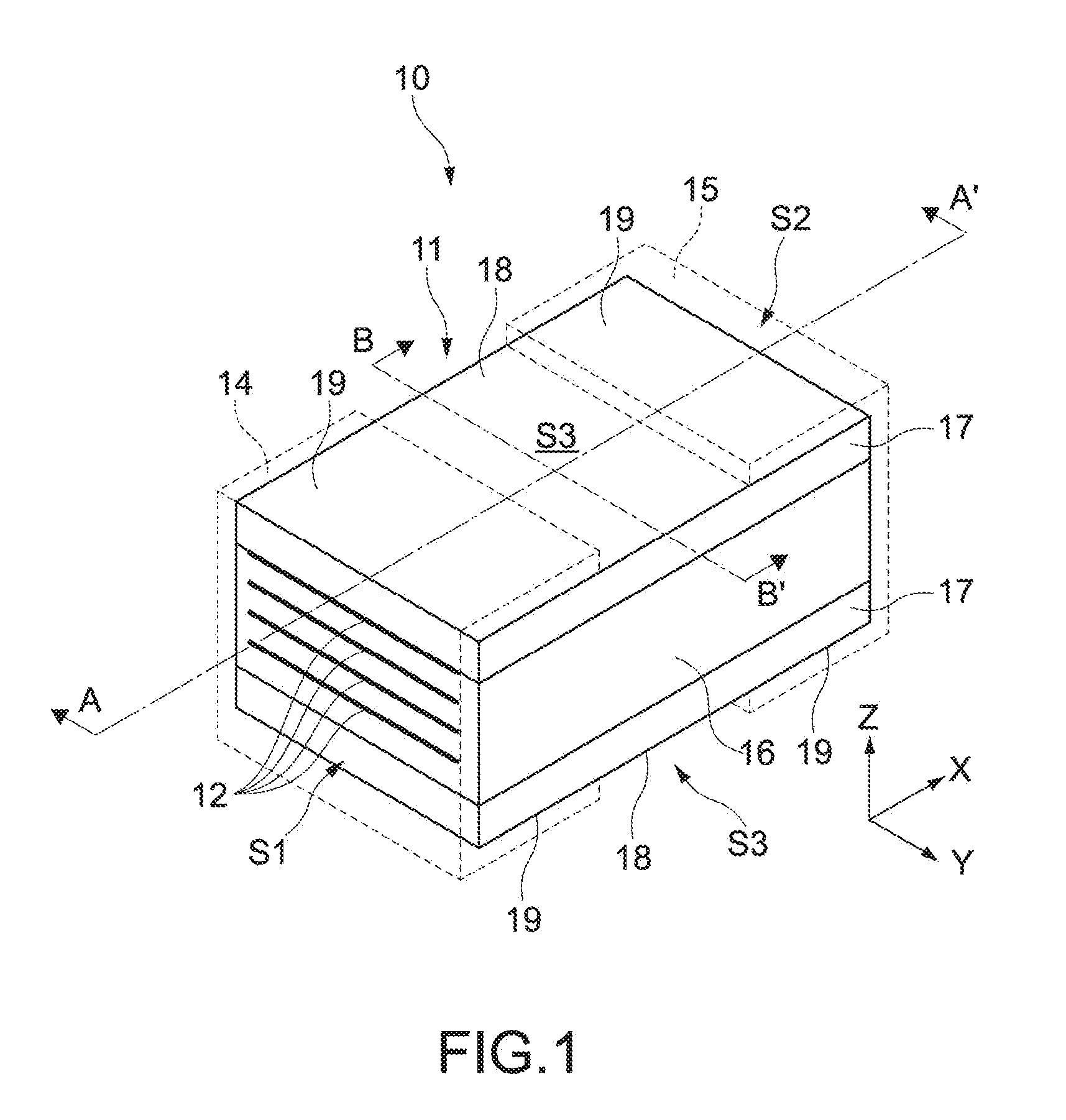

Ceramic Electronic Component and Method of Producing the Same

ActiveUS20170047163A1High bending strengthImprove bending strengthFixed capacitor electrodesFixed capacitor dielectricMaterials scienceHigh energy beam

There is provided a ceramic electronic component including: a ceramic chip having a first surface, a second surface facing the first surface, and a third surface connecting the first surface to the second surface; a first electrode unit disposed on the first surface; a second electrode unit disposed on the second surface apart from the first electrode unit; and a modified zone disposed on the third surface, and modified by irradiation of a high energy beam.

Owner:TAIYO YUDEN KK

Carbon/ceramic heat-resistant composite material and preparation process thereof

InactiveCN1793037AObvious advantagesObvious positive effectCeramic shaping apparatusRoom temperatureFree cooling

The invention relates to a carbon / ceramic heat proof compounding material and the manufacturing method. The wt% of the material is C squama 25-65, ceramic powder SiC+B4C 30-60, of which SiC: SiC+B4C=5:1, TiO2 5-13, adopting acetone phenolic resin as binding agent. Mixing the constituents, molding at the pressure of 30-50MPa, keeping the temperature and cooling to room temperature, the material would be gained. The invention has the feature of light, high intensity, high toughness, antifriction, high temperature poof, and anti-oxidation.

Owner:NORTHEASTERN UNIV

Composite building decorative material

The invention discloses a composite building decorative material. The material is composed of 20% of brucite, 8% of aluminum hydroxide, 12% of ammonium polyphosphate, 28% of magnesium aluminosilicate, 15% of a flame retardant and 13% of ammonium phosphomolybdate (molybdotungstophosphate). For usage, the above raw materials are mixed, ground and stirred according to routine to obtain a finished product. The product provided by the invention has the technical characteristics of no toxicity, no harm and no fading; the film effectively integrates with the substrate to realize the effects of fire prevention, water prevention, no deformation, smoke resistance, easy cleaning, acid and alkali resistance, no breaking at low temperature, radiation resistance, light weight, high compressive strength, high flexural strength, safety and no toxicity; in addition, the technological operation is simple.

Owner:HARBIN LONGDI BUILDING MATERIAL

Folding-type airport emergency repair and construction composite combination way panel and manufacturing method thereof

ActiveCN109235177AHigh molecular weightHigh molecular weight polyethylene fiber, which has tensile breaking strengthHelicopter landing platformSynthetic resin layered productsFiberEpoxy

The invention provides a folding-type airport emergency repair and construction composite combination way panel and a manufacturing method thereof. The composite combination way panel is composed of asingle board and a connecting cloth. The veneer is a rectangular plate, which is laid side by side on the upper and lower surfaces of the connecting cloth, and the veneers on the upper and lower surfaces are symmetrically arranged; The veneer and the connecting cloth are bonded together by epoxy resin; Each veneer is made of composite fiber material, glass fiber cloth, ultra-high molecular weightpolyethylene fiber cloth and carbon fiber cloth. The composite pavement slab is light in material, the density is only 1.15-1.17, and the density is less than one sixth of ordinary steel plate. The bending strength of the panel is higher than 280MPa and the impact toughness is higher than 240K j / m2. The strength of the panel can satisfy the bearing capacity of the third generation fighter and allkinds of armed helicopters. The panel has the advantages of high bending strength, strong impact toughness, light material quality, large area, good anti-aging durability, simple and convenient repair pavement, time-saving and high efficiency of emergency repair, and can be used repeatedly.

Owner:NINGBO DACHENG ADVANCED MATERIAL +1

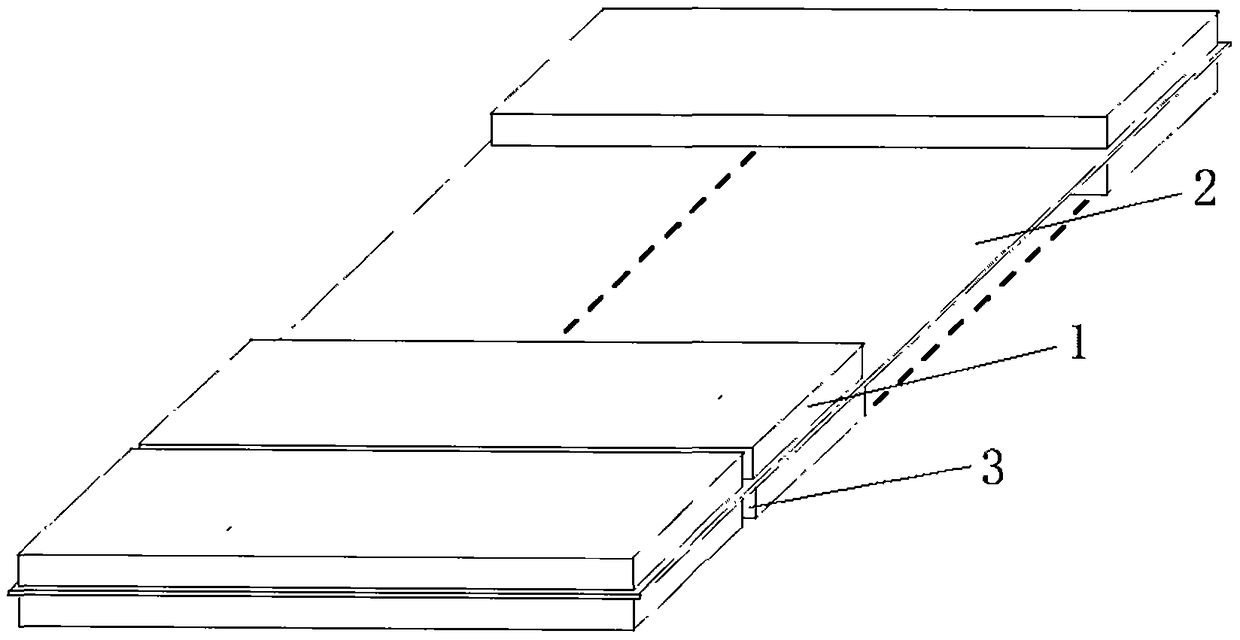

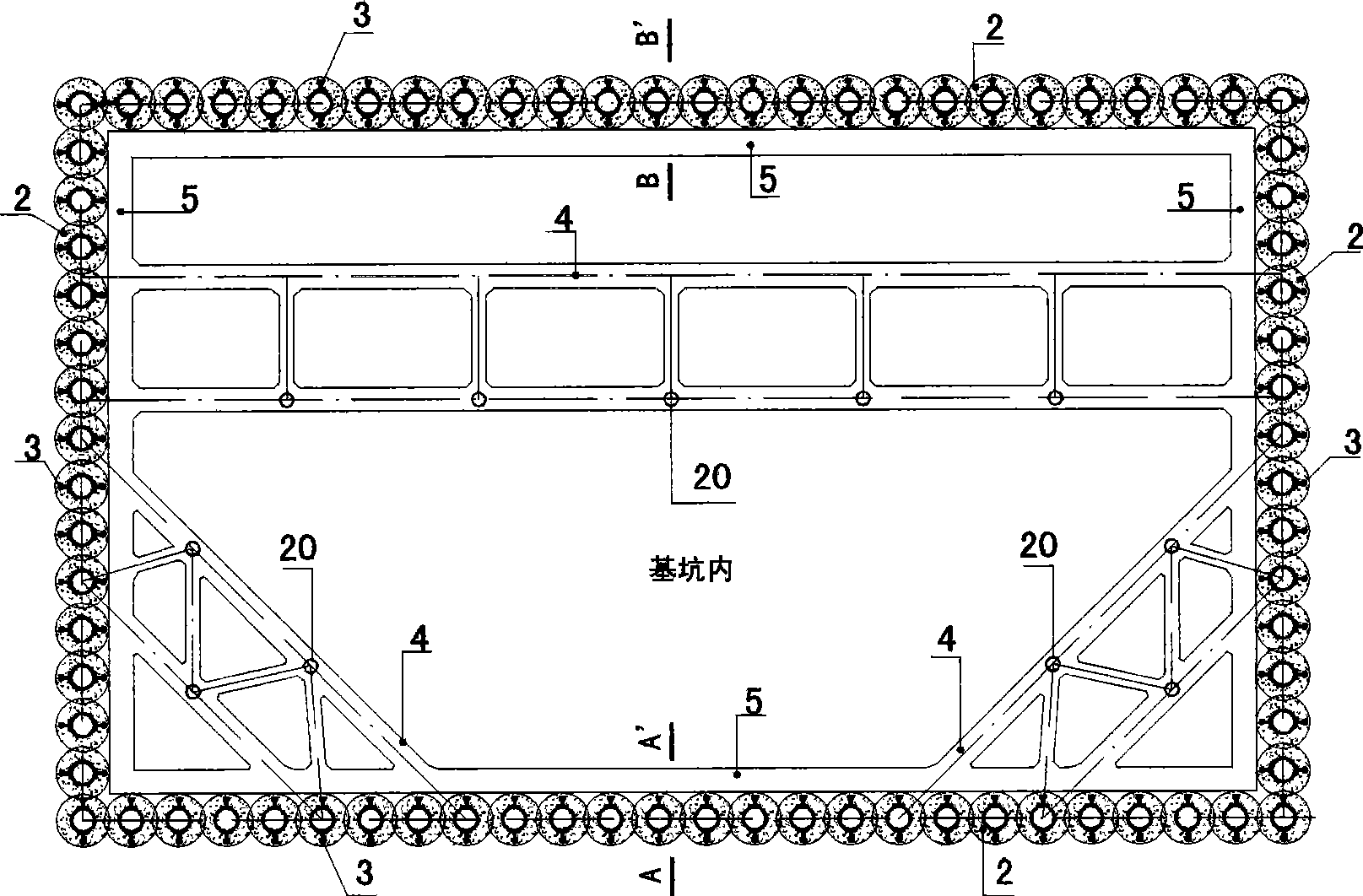

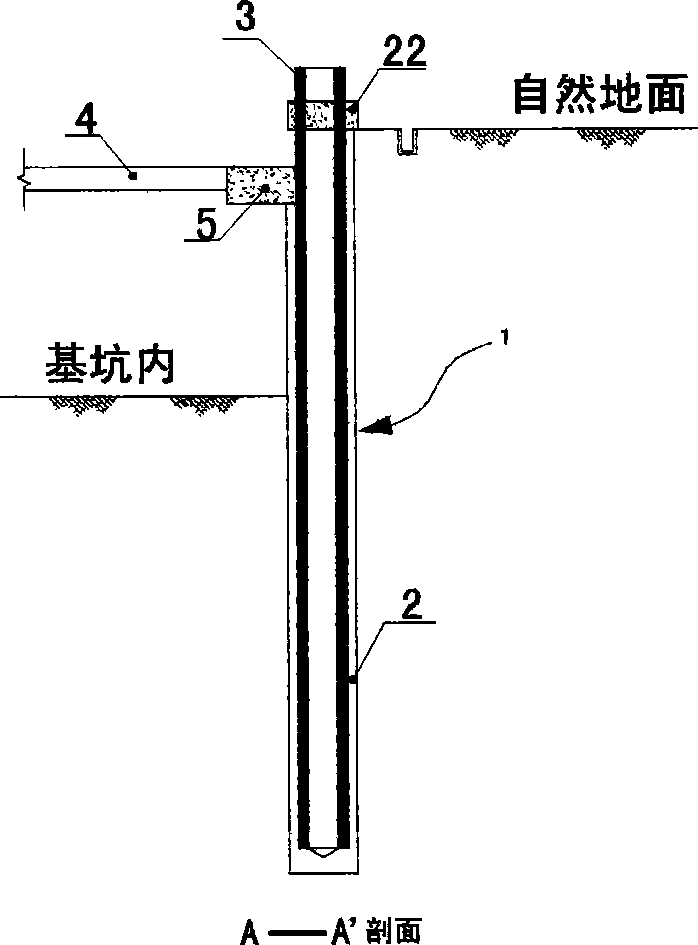

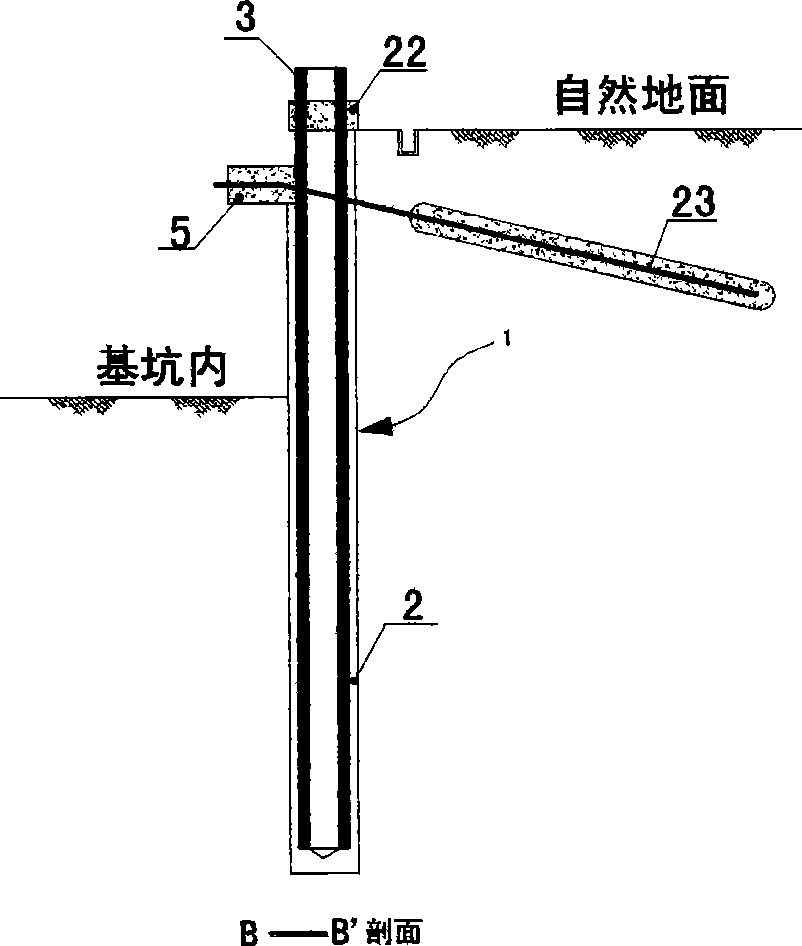

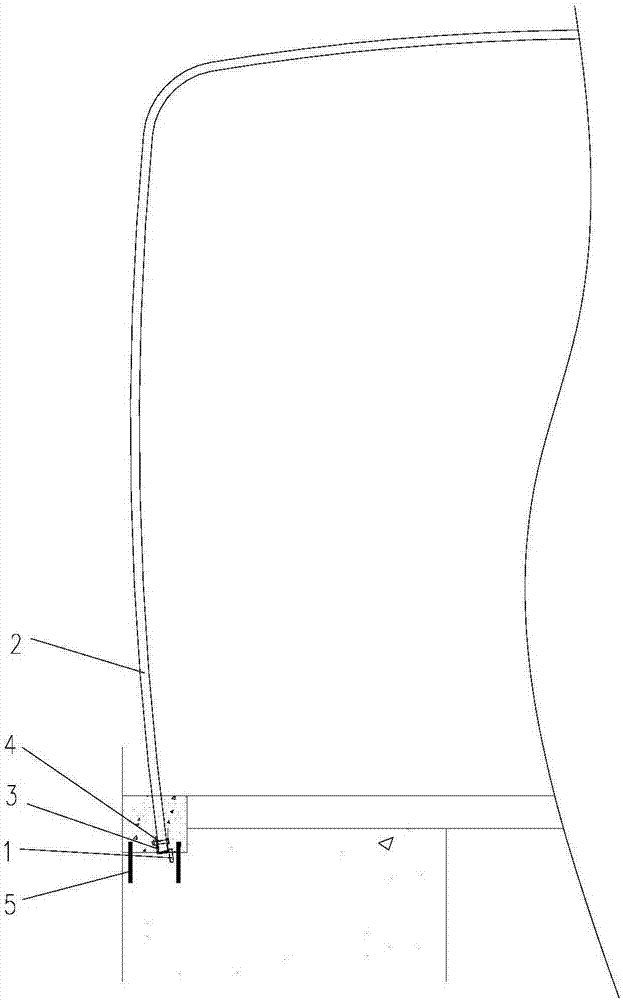

Retaining structure of cement-soil pile-wall for rail beam and construction method

InactiveCN101363225APullout stress reductionEasy to removeExcavationsBulkheads/pilesSlurry wallSoil cement

The invention provides a support structure for a rail beam cement-soil pile-wall to form an underground continuous wall for the support of foundation pits and side slopes. The support structure is composed of rail beam cement-soil pile support components in a continuously occluded arrangement form and support components in the foundation pits or pit wall anchor components. The rail beam is composed of a rail, a rail supporting component for supporting rails between rails, a connection flange in beam end bolts, a heat circulating reflux component attached to the inside of the beam and release agent paint to rail beam surfaces. The pile wall support components have the advantages of large buckling strength and stiffness, small wall deformation, flexible soil-cement pile material ratio, even mixing, convenient, flexible and fast construction, easy recovery of rail beams, low cost, no pollution, etc. The invention can be widely used in foundation pit and side slop support and protection works.

Owner:袁建标

Reinforcing method for railway culvert

ActiveCN107100099AImprove carrying capacityImprove seismic performanceGround-workEngineeringCompressive strength

The invention provides a reinforcing method for a railway culvert. The reinforcing method includes: a first step, digging a foundation pit along a lateral wall edge of an inner side surface of a culvert, and implanting a pre-buried member in a bottom surface of the foundation pit; a second step: arranging a corrugated plate assembly matching the shape of the culvert in the culvert, wherein two sides of the corrugated plate assembly are fixedly connected to the pre-buried member; a third step, pouring concrete into the foundation pit so as to form a foundation; and a fourth step, filling a gap between the corrugated plate assembly and the inner side surface of the culvert. In the method, the corrugated plate assembly is used to maintain the existing culvert; the flexure strength and the compressive strength of a corrugated plate are excellent, and then the corrugated plate assembly has high bearing capability, is excellent in resistance to earthquake, and can adapt to large sedimentation and deformation.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

High-impact glass fiber composite for 3D printing

InactiveCN106634000AHigh heat distortion temperatureHigh melt indexAdditive manufacturing apparatusFlexural strengthStearic acid

The invention discloses a high-impact glass fiber composite for 3D printing and belongs to the technical field of preparation of materials for 3D printing. The high-impact glass fiber composite for 3D printing is prepared from the following raw materials in parts by weight: 85-123 parts of glass fibers, 24-33 parts of waste plastic, 11-15 parts of acetylglutamine, 4-7 parts of metaldehyde, 7-11 parts of polyurethane, 8-10 parts of alkyd resin, 6-12 parts of zinc acrylate resin, 5-9 parts of high chlorinated polyethylene resin, 9-16 parts of stearic acid, 4-7 parts of polyacrylamide, 12-20 parts of a specific synthetic agent and 8-12 parts of a flame retardant. The high-impact glass fiber composite for 3D printing has the characteristics of high tensile strength, bending strength and notch impact strength, high heat deformation temperature, high melt index and the like, and a product printed with a 3D printing technology has high quality, high impact resistance and high strength, and has broad market prospect.

Owner:蒙宇

Graphene 3D printing material with high melt index

InactiveCN106566217AImprove melt indexHigh tensile strengthAdditive manufacturing apparatusPolymer scienceFlexural strength

The invention discloses a graphene 3D printing material with a high melt index and belongs to the technical field of preparation of materials for 3D printing. The graphene 3D printing material with the high melt index contains the following raw materials in parts by weight: 5.4-7.7 parts of graphene, 25-31 parts of waste plastics, 35-40 parts of polylactic acid, 12-23 parts of sodium hexapolyphosphate, 18-24 parts of propylene glycol methyl ether acetate, 9-18 parts of specific synthesizer and 5-9 parts of starch synthesizer. The graphene 3D printing material disclosed by the invention has the characteristics of high tensile strength, flexural strength and notch impact strength, high thermal deformation temperature and melt index, and the like; and products printed through a 3D printing technology are high in quality, high in impact resistance and high in strength, thereby having a broad market prospect.

Owner:GUANGXI ZHUMENG SANTI TECH CO LTD

Dissecting blade high in strength and hardness and used in ceramic surgical department and production process thereof

InactiveCN107296643AHigh hardnessImprove flexural strengthIncision instrumentsClaywaresBiocompatibility TestingPerformance index

The invention belongs to the technical field of medical apparatuses and instruments and particularly relates to a dissecting blade high in strength and hardness and used in the ceramic surgical department and a production process thereof. The dissecting blade high in strength and hardness and used in the ceramic surgical department is high in hardness and bending strength, strong in toughness, good in abrasion resistance and long in service life, and blade and scalpel handle connection is firmer and the overall length of a scalpel can be also conveniently adjusted by arranging a connecting hole structure. The cost is low, the dissecting blade has good biocompatibility with the human body tissues, and all the performance index requirements for the dissecting blade of the standards of the medical apparatus and instrument industry are met. The production process is simple, low in cost, green and environmentally friendly and does not cause environmental pollution.

Owner:TAICANG DONGNENG ENVIRONMENTAL PROTECTION EQUIP

Glass fiber reinforced concrete material and preparation method thereof

InactiveCN111925166AReduce pollutionLow requirements for preparation conditionsMicrosphereCyclodextrin

The invention discloses a glass fiber reinforced concrete material. The glass fiber reinforced concrete material is characterized by being prepared from the following raw materials in parts by weight:30-40 parts of cement, 2-5 parts of zircon sand, 10-15 parts of surface-grafted beta-cyclodextrin glass fibers, 3-6 parts of waste gypsum, 10-20 parts of volcanic ash, 20-30 parts of gravels, 60-80 parts of fine river sand, 4-8 parts of sulfate-containing organic silicon microspheres, 3-6 parts of additives and 15-20 parts of water. The glass fiber reinforced concrete material also comprises thefollowing preparation raw materials: 3-6 parts of rare earth fluoride nanofibers and 1-3 parts of zinc oxide mesoporous nanofibers. The invention also provides a preparation method of the glass fiberreinforced concrete material. The glass fiber reinforced concrete material disclosed by the invention is good in interface bonding effect and compatibility among the components, good in comprehensiveperformance, high in toughness and bending strength, and excellent in durability and impermeability.

Owner:曹均云

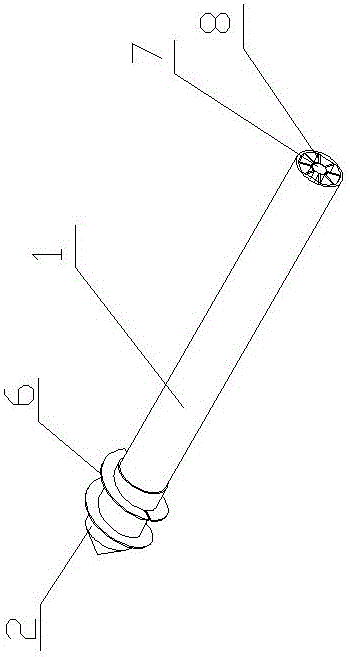

Insert rod for sea area aquaculture

InactiveCN105724233AOverall light weightOptimize layoutCultivating equipmentsSeaweed cultivationPulp and paper industryUltimate tensile strength

An insert rod for sea area aquaculture comprises a tubular plastic rod body, a drill bit is connected at the lower end of the rod body and comprises a screw-in portion and an inverted-cone-shaped pointed end portion, the screw-in portion comprises a column, the outer surface of the column is provided with projections in thread-shaped distribution, the column is connected with the lower end of the rod body, and the bottom surface of the pointed end portion is connected with the column. The insert rod for sea area aquaculture, made of plastics, is lightweight, high in bending strength and corrosion resistance, long in service life, cheap, reusable, free of pollution, convenient and labor saving to mount and arrange and saving in labor, time and expense.

Owner:林后准

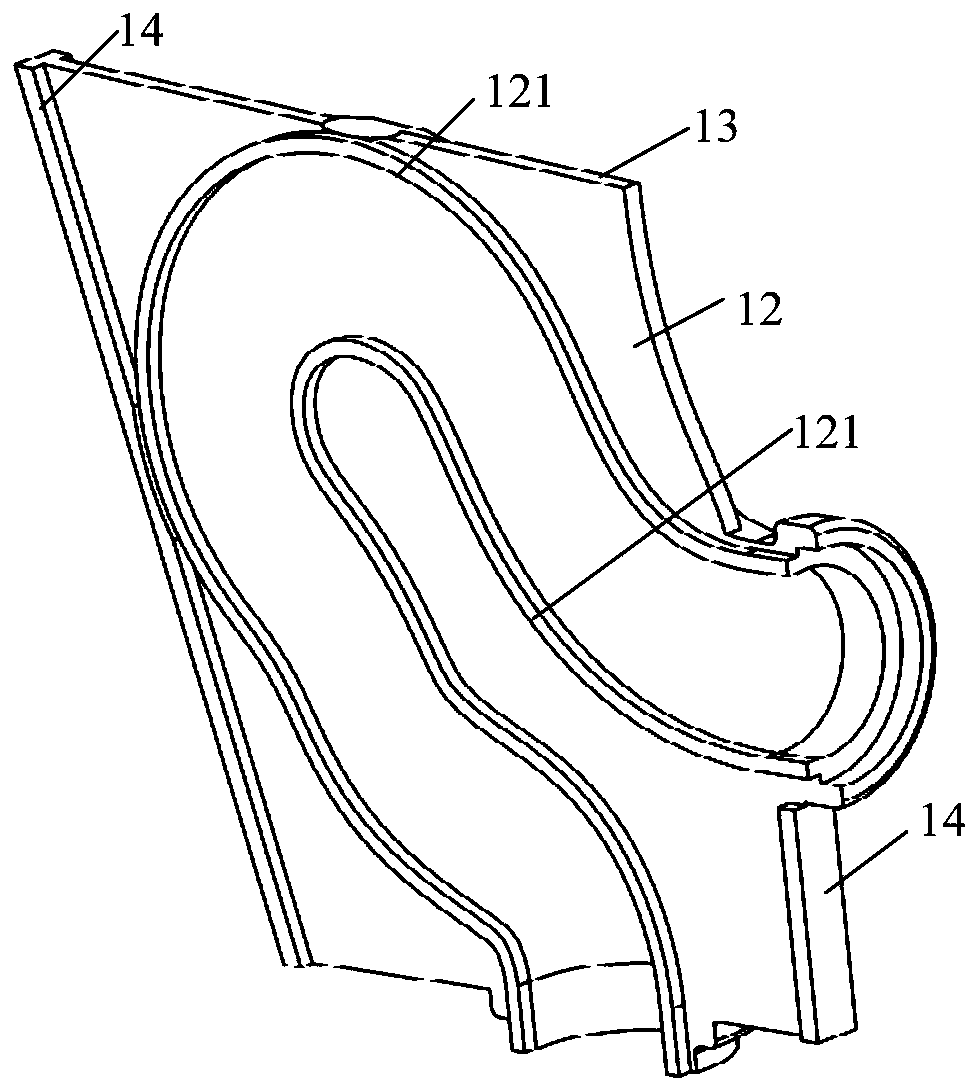

High-strength closestool and manufacturing method thereof

PendingCN110000894AConsistent densityStable supportWater closetsMould separation apparatusSlurryEngineering

The invention discloses a high-strength closestool and a manufacturing method thereof. The high-strength closestool comprises a closestool main body, a bent pipe and a side wall, wherein the closestool main body and the side wall are separately and integrally formed; the bent pipe comprises a first half pipe and a second half pipe, and the first half pipe and the second half pipe are bonded to form the bent pipe; and the first half pipe and the second half pipe are of a double-sided slurry structure. The strength of the closestool can be improved, and the yield of closestools can also be improved.

Owner:SHUNDE AREA FOSHAN LEHUA CERAMIC SANITARY WARE

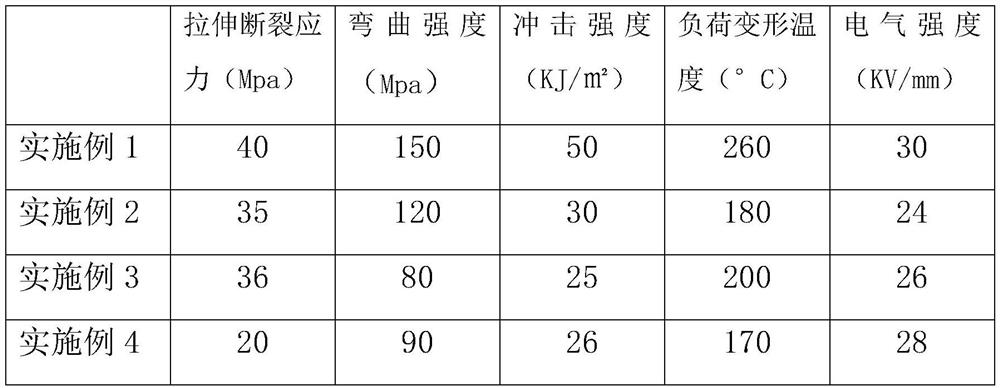

Bulk molding plastic and preparation method thereof

PendingCN114181507AImproved impact resistance of unsaturated polyester fiber reinforcementImprove impact resistanceFiberFirming agent

The invention relates to a bulk molding compound, which is characterized by comprising the following raw materials by weight: 30-40 parts of unsaturated resin, 10-20 parts of a low shrinkage agent, 10-20 parts of glass fiber, 5-10 parts of an initiator, 10-15 parts of a thickener, 5-8 parts of aluminum hydroxide, 10-20 parts of calcium carbonate, 1-10 parts of color paste, 8-15 parts of a curing agent, 10-20 parts of a flame retardant, 15-20 parts of a heat resistant agent, and 45-60 parts of a filler. The bulk molding compound has the beneficial effects that the load deformation temperature is 260 DEG C, the bulk molding compound is resistant to high temperature, the impact strength reaches 50 kJ / m < 2 >, the impact resistance and bending strength are high, the bending strength reaches 150 Pa, the tensile fracture stress is 40 MPa, the electrical strength is 30 KV / mm, and the bulk molding compound has the advantages of high toughness, high strength, high temperature resistance and high electrical strength; the impact resistance of the unsaturated polyester fiber reinforced bulk molding compound is effectively improved. The potential application range of the device in the aspects of electric appliances, motors, radio, instruments, machinery manufacturing, chemical equipment, buildings, transportation, national defense and the like is also enlarged.

Owner:浙江南方塑胶制造有限公司

Method for producing resin composition

PendingUS20220243044A1High bend elastic modulusHigh bending strengthVegetal fibresPolymer chemistryPolymer science

Owner:NIPPON PAPER IND CO LTD

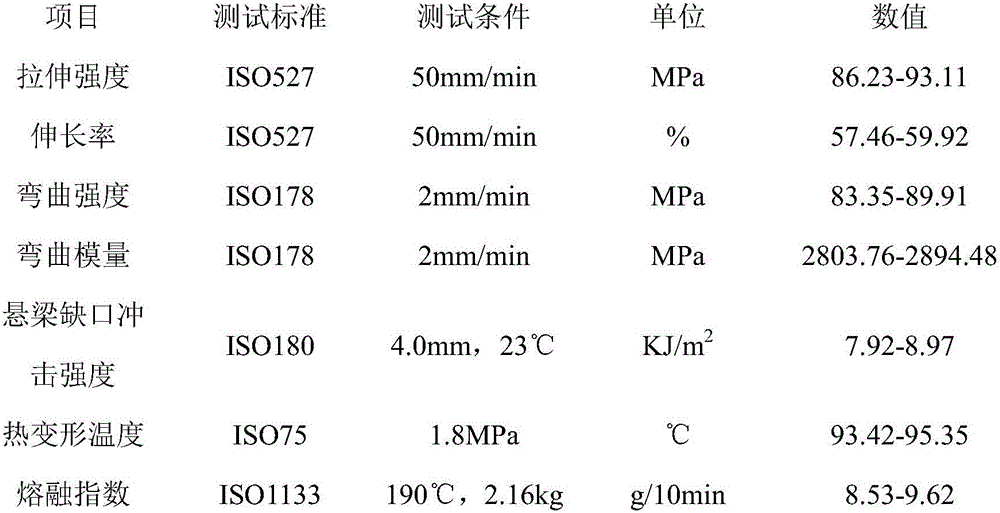

Graphene three-dimensional printing material with high bending strength

InactiveCN106633719AImprove bending strengthHigh heat distortion temperatureAdditive manufacturing apparatusHeat deflection temperaturePolymer science

The invention discloses a graphene three-dimensional printing material with high bending strength, and belongs to the technical field of materials for three-dimensional printing. The graphene three-dimensional printing material with high bending strength is prepared from the following raw materials in parts by weight: 5.3 to 7.9 parts of graphene, 26 to 31 parts of waste plastics, 34 to 42 parts of polylactic acid, 16 to 24 parts of potassium tripolyphosphate, 21 to 25 parts of butyl cellosolve acetate, 12 to 19 parts of a specific synthesis agent and 6 to 9 parts of a starch synthesis agent. The graphene three-dimensional printing material prepared in the invention has the characteristics of high tensile strength, high bending strength and high notch impact strength, high heat deflection temperature and high melt index and the like, and the product printed through a three-dimensional printing technology is high in quality, high in impact and high in strength and has a broad market prospect.

Owner:GUANGXI ZHUMENG SANTI TECH CO LTD

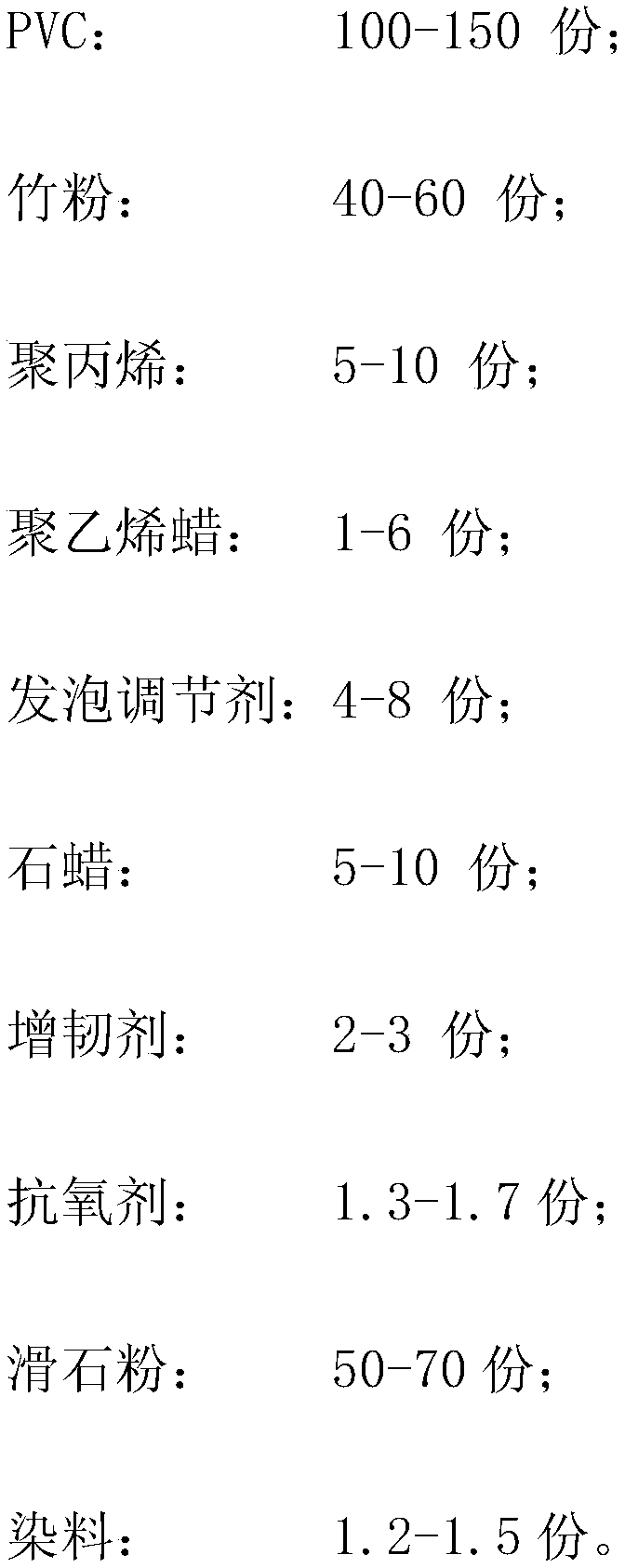

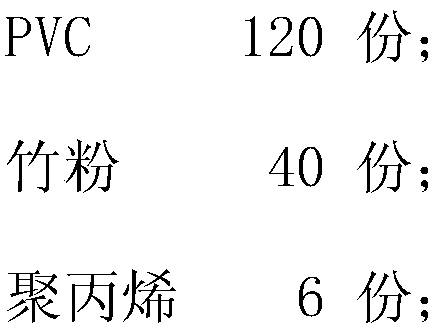

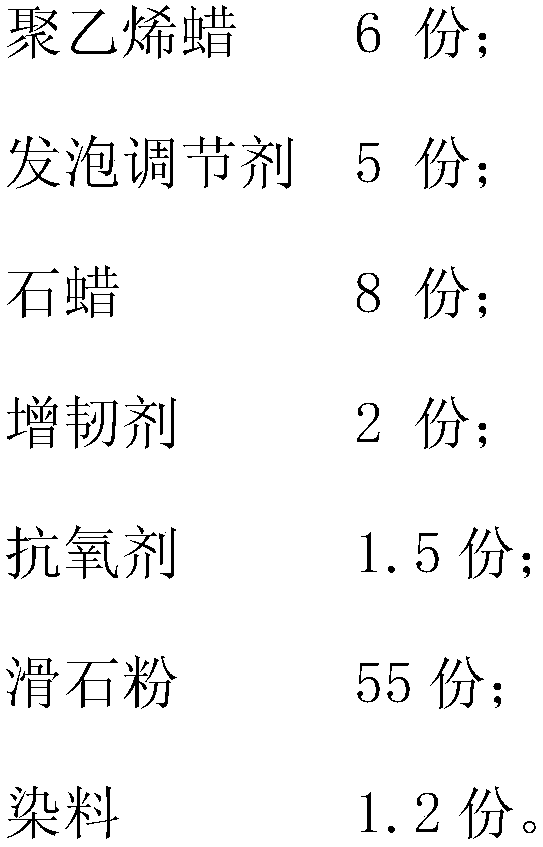

Flame-retardant recyclable environment-friendly plate

The invention relates to the field of environment-friendly materials, particularly to a flame-retardant recyclable environment-friendly plate, which comprises the following components in parts by weight: 100-150 parts of PVC; 40-60 parts of bamboo powder; 5-10 parts of polypropylene; 1-6 parts of polyethylene wax; 4-8 parts of a foaming regulator; 5-10 parts of paraffin; 2-3 parts of a tougheningagent; 1.3-1.7 parts of an antioxidant; 50-70 parts of talcum powder; and 1.2-1.5 parts of dye. The flame-retardant recyclable environment-friendly plate has the advantages that the flame-retardant recyclable environment-friendly plate can replace traditional conventional indoor decoration materials, the requirement for environmental protection during decoration can be met, and the flame-retardantrecyclable environment-friendly plate has high bending strength and good impact resistance in the using process.

Owner:XINGHUA ZHENGFU PLASTIC IND

A kind of chest cavity indwelling drainage tube and preparation method thereof

The invention discloses a chest cavity indwelling drainage tube and a preparation method thereof. Using ether as a solvent, under the protection of argon gas, hydroxypropyl methylcellulose phthalate, isophorone diisocyanate and diethylene glycol Add alcohol dimethacrylate to ether, add potato starch, cellulose acetate, ethylene glycol, initiator and catalyst to form a prepolymer solution, then add chitin, polylactic acid, and then add ethylene glycol, 2,3 ‑Diphenyl‑4‑methyl‑1‑pentene, emulsifier, thickener, buffering agent participate in the reaction, impurity removal, drying; and coupling agent, plasticizer, antioxidant and accelerator Put it into a granulator to granulate, extrude, and make a finished product. The prepared thoracic indwelling drainage tube has great tensile strength and elastic modulus, even under acidic or alkaline conditions, it still has relatively large tensile strength and elastic modulus.

Owner:WENZHOU CENT HOSPITAL

Wood-fiber-toughened poly dimethyl terephthalate automotive interior material and preparation method thereof

The invention discloses a wood-fiber-toughened poly dimethyl terephthalate automotive interior material and a preparation method thereof. According to the interior material, poly dimethyl terephthalate, ramie, modified wood fiber and fullerene are used as main ingredients, and calcined kaolin, hydroxyethyl methyl cellulose ether, basalt fiber, calcined talc, 3-triethoxysilylpropylamine silane, cordierite, nano-zinc oxide, aluminum triphosphate, erucyl amide, talcum powder and other inorganic and organic materials are selected to act synergistically with the main ingredients. The automotive interior material is light, safe, environmentally friendly, resistant to scrubbing, good in toughness and high in strength.

Owner:嘉善贝马五金配件有限公司

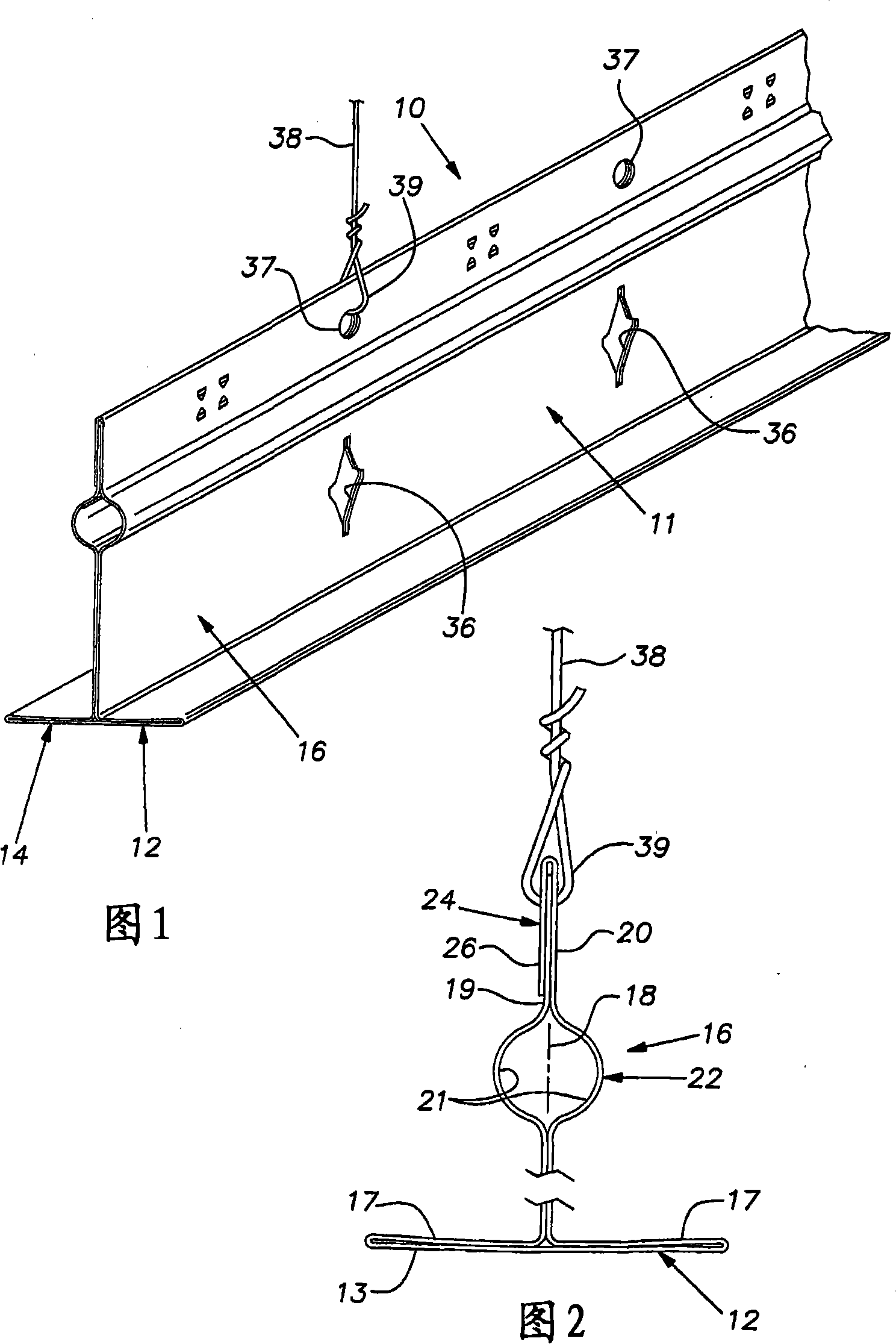

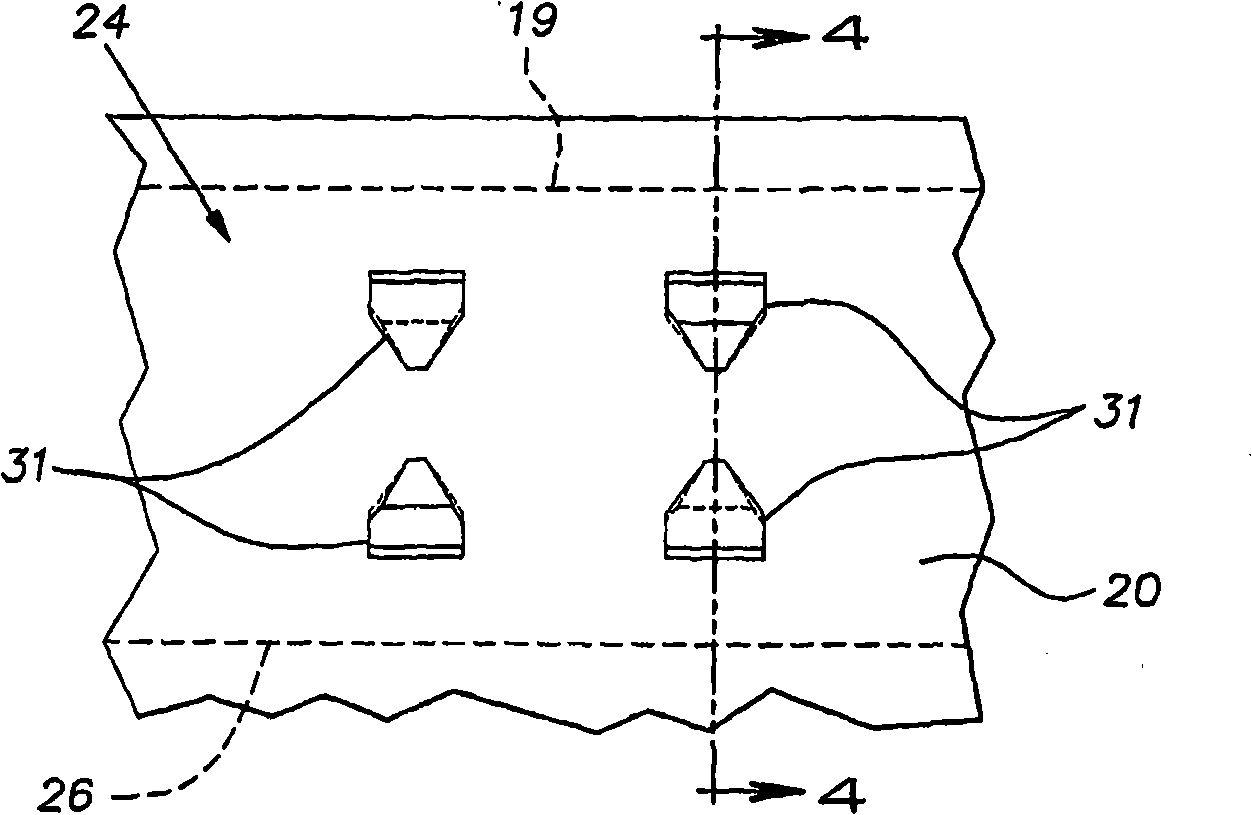

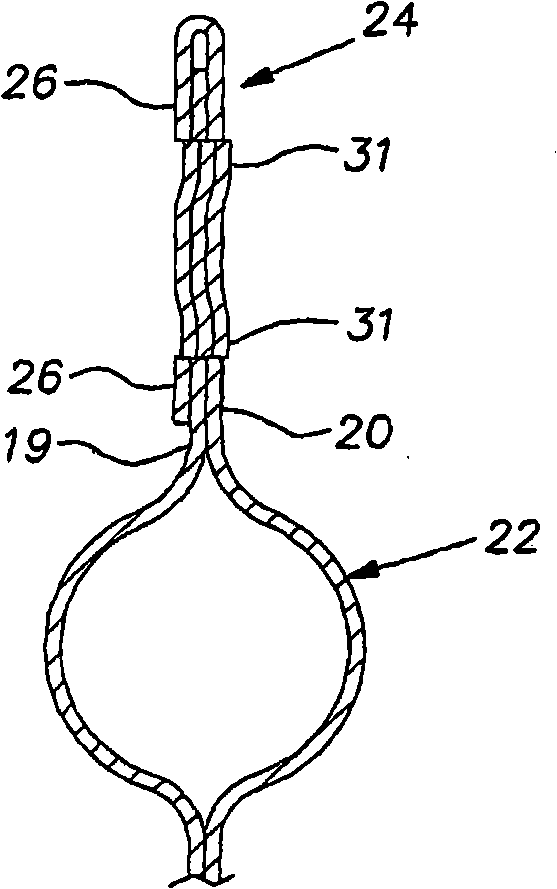

Grid tee for suspension ceiling

ActiveCN101351602AIncreased torsional stiffnessHigh breaking strengthCeilingsWallsBreaking strengthEngineering

A roll-formed sheet metal tee for grid type suspended ceilings with the face of its flange integral with the stem and the layers of the stem fixed together for improved torsional strength. An upper region of the stem can have one or more of its layers folded to increase suspension wire breakout strength. A stiffening bulb is below suspension wire receiving holes so that a loop of the suspension wire through the tee has a narrow profile and thereby avoids interference with ceiling panels during their installation or removal.

Owner:USG INTERIORS INC

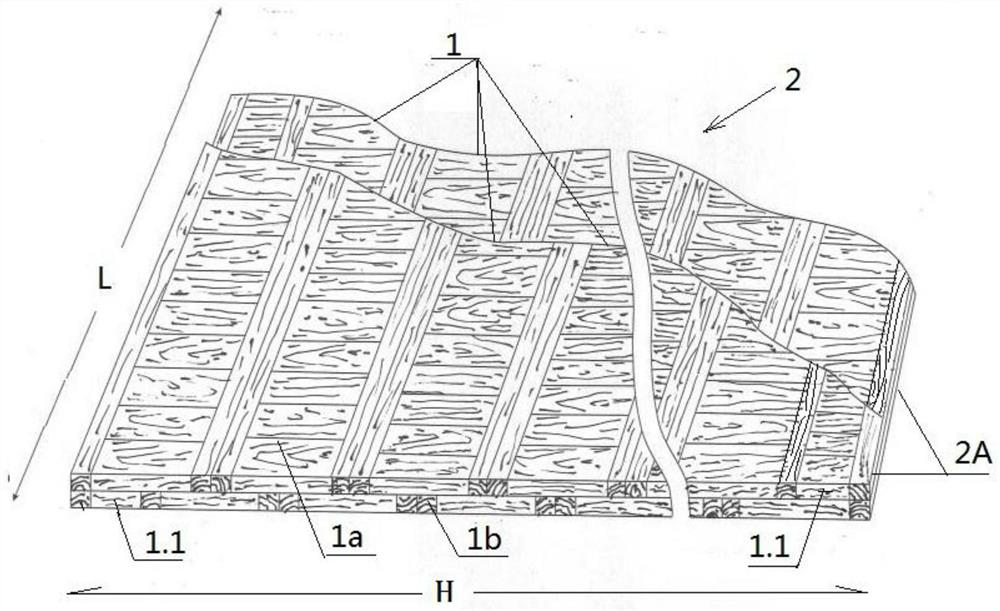

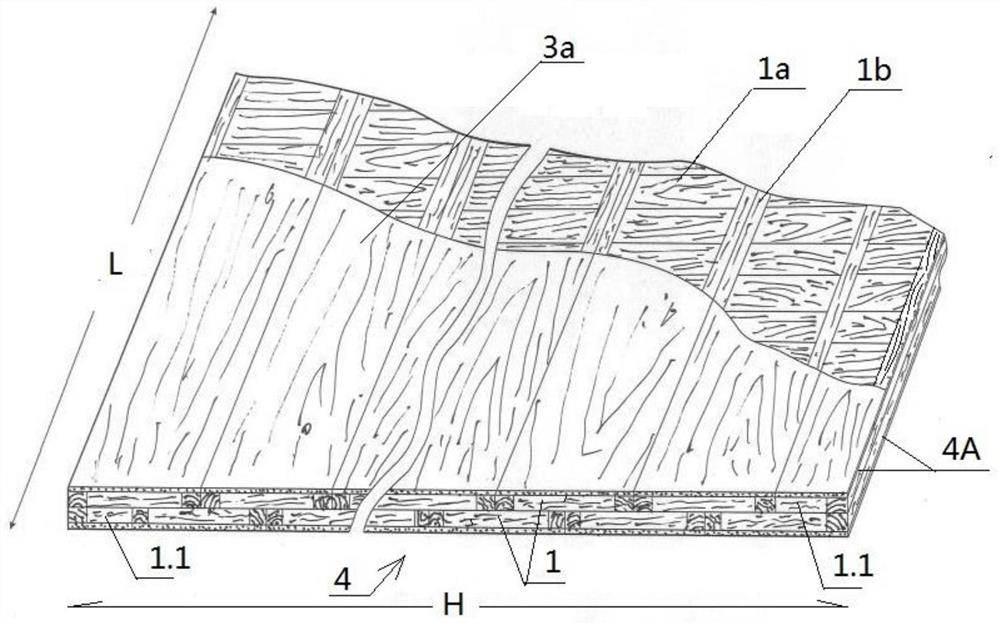

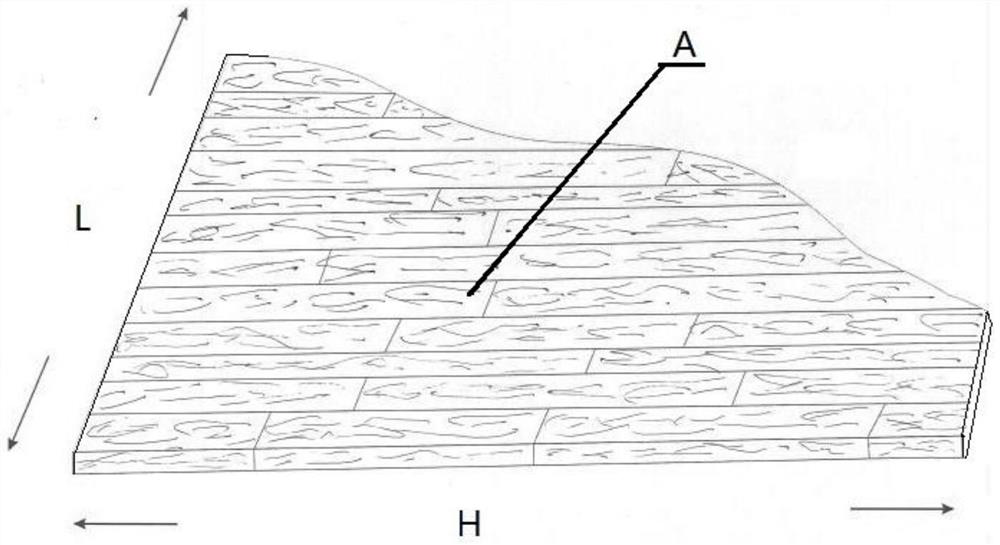

Solid wood composite core board with wood fiber directions being symmetrically staggered and longitudinally and transversely laminated, solid wood composite board and manufacturing method

PendingCN111730933ASave resourcesEliminate deformation stressLamination ancillary operationsLaminationSolid woodWood fibre

The invention relates to a solid wood composite core board with wood fiber directions being symmetrically staggered and longitudinally and transversely laminated, a solid wood composite board and a manufacturing method. The solid wood composite core plate comprises transverse grain core materials and longitudinal grain core materials, and the core plate is formed by laminating an upper core material single-layer plate and a lower core material single-layer plate, wherein each core material single-layer plate is formed by transversely splicing N + 1 / 2 core material units, and N is the number ofthe core material units; wherein each core material unit is formed by splicing a transverse grain core material unit and longitudinal grain core strips on one side or two sides, and each transverse grain core material unit is formed by connecting and splicing edges of a plurality of longitudinal grain plate strips; when N + 1 / 2 core material units are transversely spliced, one half of the core material unit is located on one side, and longitudinal grain core strips are arranged on the outer sides of the two sides of the core material unit; the upper core material single-layer plate and the lower core material single-layer plate have the same structure; the upper core material single-layer plate and the lower core material single-layer plate are staggered and laminated in the same direction, namely, the upper core material unit and the lower core material unit which are half of the width are distributed on the two sides, so that the upper core material single-layer plate and the lowercore material single-layer plate form a symmetrical staggered longitudinal-transverse laminated structure in the wood fiber direction; the width h of each core material unit is equal to H / (N + 1 / 2), wherein H is the width of the whole solid wood composite board core board.

Owner:WUHAN WANGRENZHONG NOVEL SHEET MATERIAL INVESTMENT MANAGEMENT CO LTD +1

Preparation method of modified aluminium silicate ceramic fiber blanket for microwave expansion

ActiveCN103321051AImprove microwave permeabilityHigh tensile strengthFibre treatmentFiberFlexural strength

The invention discloses a preparation method of a modified aluminium silicate ceramic fiber blanket for microwave expansion. The preparation method comprises the following steps of: firstly, dissolving polyether sulfone and polyvinylpyrrolidone into N,N-dimethylacetamide solvent to prepare polyether sulfone solution; then conducting ultrasonic oscillation on aluminium oxide powder with average particle size of 1.5 mu m so that the aluminium oxide powder can be dispersed in the polyether sulfone solution to prepare mixed aluminium oxide-polyether sulfone solution; then dip-coating the mixed aluminium oxide-polyether sulfone solution into the aluminium silicate ceramic fiber blanket sold in the market; and naturally airing at atmospheric temperature. The prepared modified aluminium silicate ceramic fiber blanket is high in tensile strength and bending strength, excellent in microwave permeation property, and capable of meeting the high-temperature-resistant requirement of the expansion procedure. In addition, the preparation method has the advantages of being simple and convenient to operate, and low in cost.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com