Reinforcing method for railway culvert

A technology for culverts and railways, applied in the reinforcement field of railway culverts, which can solve the problems of slab culvert bearing capacity reduction, shear strength reduction, poor stability, etc., and achieve high bearing capacity, large settlement and deformation, and strong earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

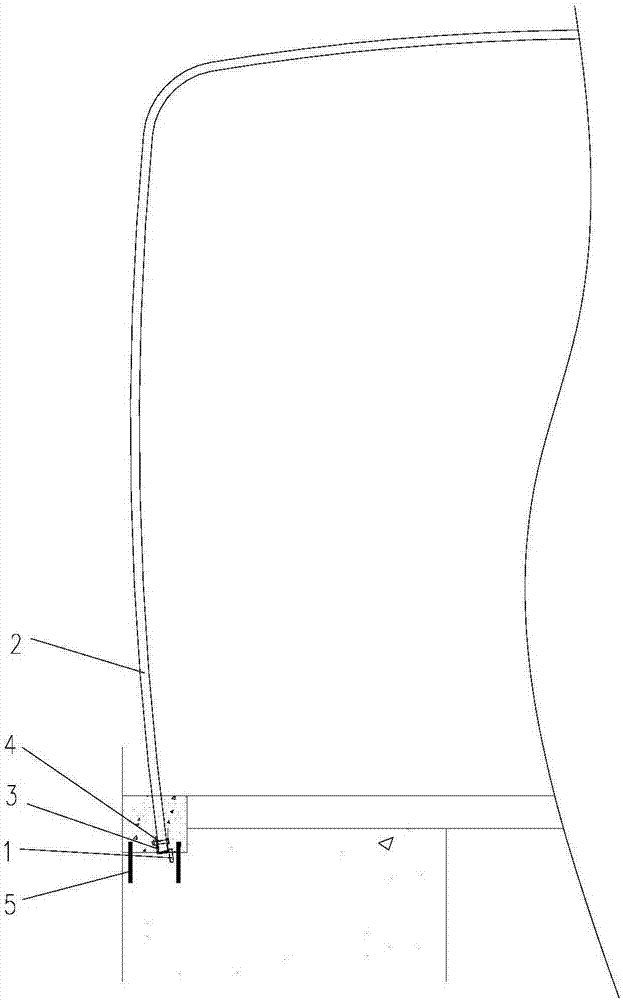

[0027] The present invention will be further described below in conjunction with accompanying drawing.

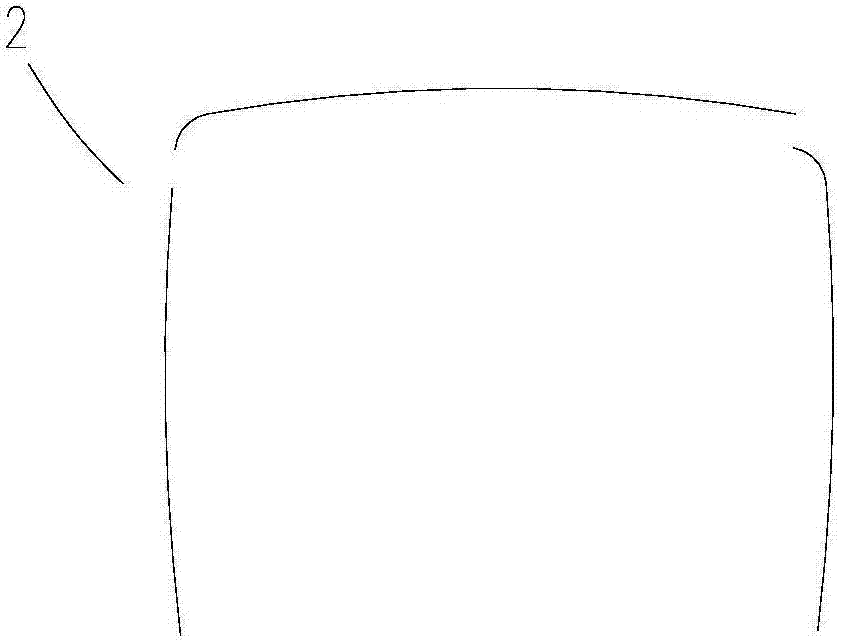

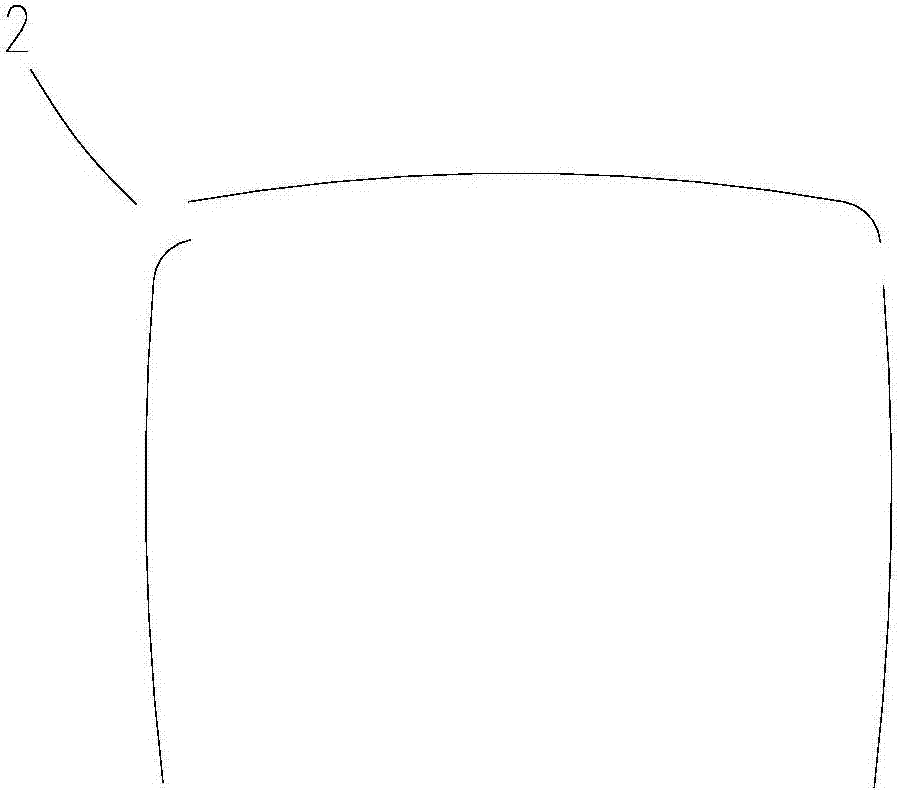

[0028] figure 1 An installation view of a corrugated plate assembly according to the present invention is shown. The following is based on figure 1 The reinforcement methods used for railway culverts are discussed in detail. The method includes the following steps. First, a foundation pit is excavated along the side wall on the inner side of the culvert, and the embedded part 1 is implanted on the bottom of the foundation pit. Then, a corrugated plate assembly 2 matching the shape of the culvert is arranged inside the culvert. Both sides of the corrugated plate assembly 2 are respectively fixedly connected with the embedded part 1 . Next, concrete is poured into the pit to form the foundation. Finally, fill the gap between the corrugated sheet assembly and the inner side of the culvert.

[0029] In a preferred embodiment, the foundation pit is excavated along the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com