Retaining structure of cement-soil pile-wall for rail beam and construction method

A technology for cement-soil piles and supporting structures, which is used in foundation structure engineering, sheet pile walls, excavation, etc., can solve the problems of increasing the diameter of the stirring pile, increasing the pulling resistance, and troublesome support and dismantling, and achieves high bending resistance. The effect of strength and stiffness, reduction of extraction stress, and easy and convenient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: An embodiment in which non-poured, in-situ-stirred cement-soil is selected as the steel-soil pile-wall support structure for rail beams.

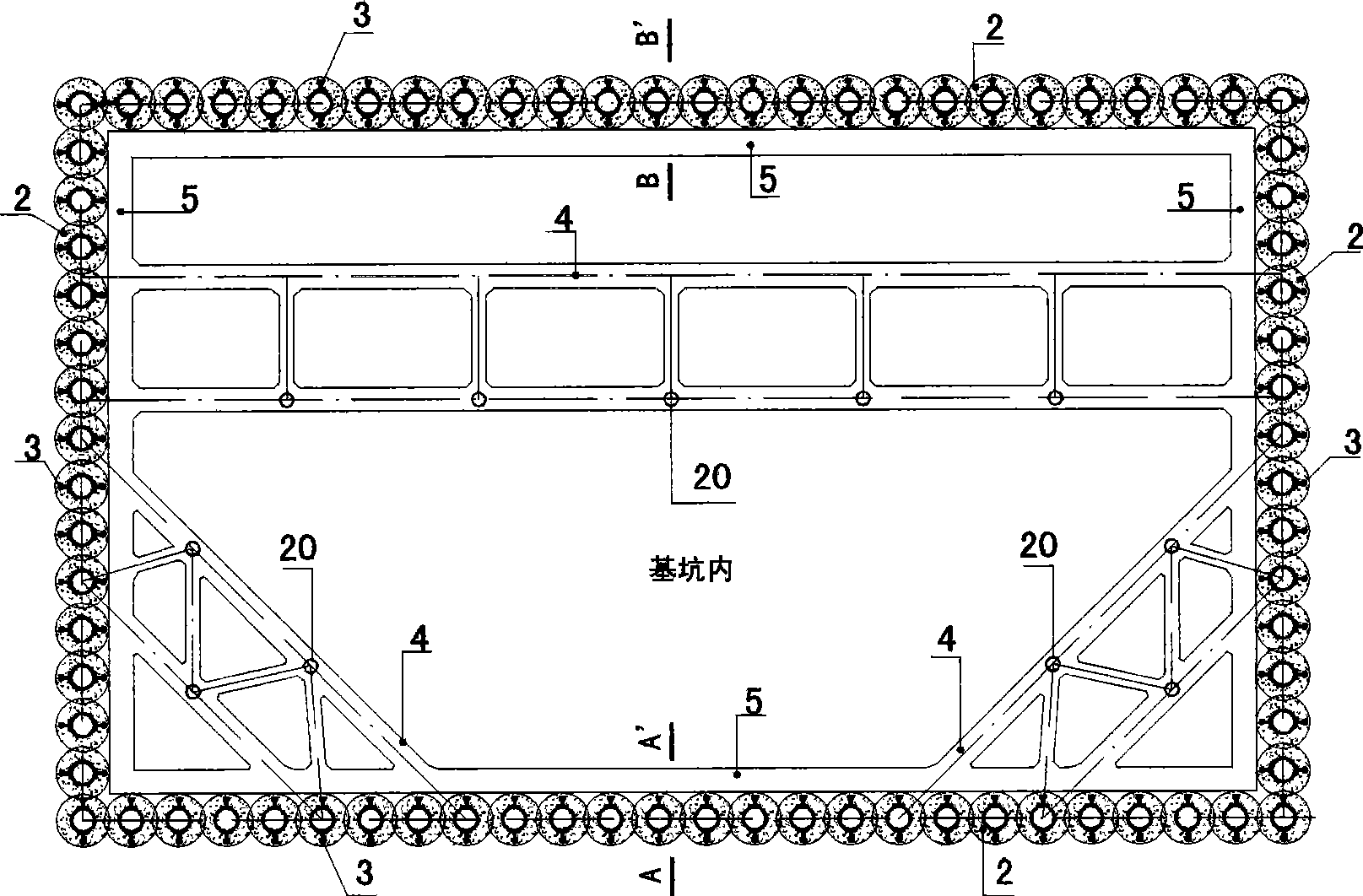

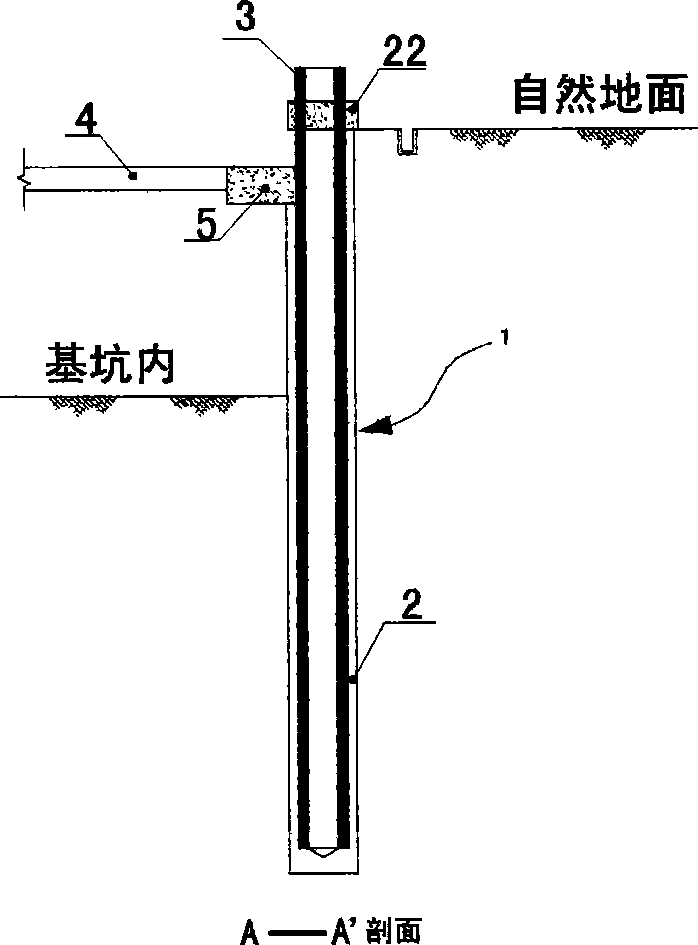

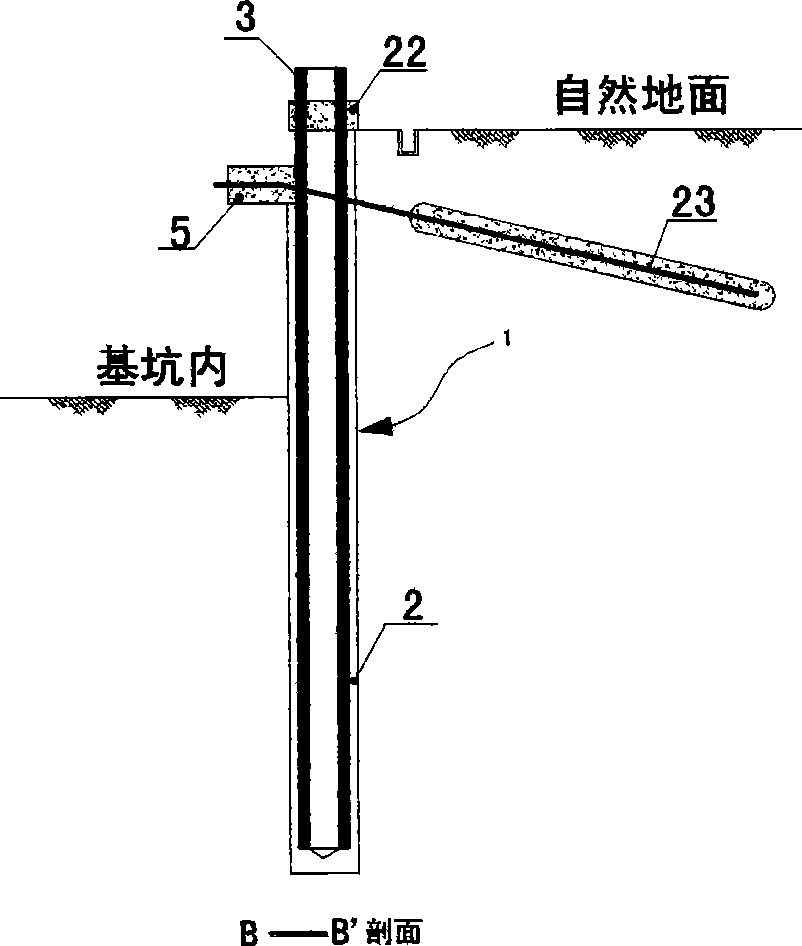

[0041] exist figure 1 , figure 2 , image 3 In the embodiment, when the rail beam cement-soil pile wall support structure is selected to adopt non-perfusion, cement-soil mixed in situ, the construction method of the present invention is:

[0042] 1. First, on the wall of the foundation pit, use a cement-soil mixing pile machine to stir the hole, and at the cement slurry mixing station, prepare the cement slurry according to the optimized proportion of the cement slurry provided by the laboratory, and then mix the prepared The cement slurry is transported to the cement-soil pile-forming mixer with a delivery pump, and the cement-soil pile-forming mixer makes a series of cement-soil piles in the stratum, and then, according to the rail provided in Figure 4, Figure 5, Figure 6, Figure 7, and Figure 8 The beam structure...

Embodiment 2

[0047] Embodiment 2: An embodiment in which poured, non-in-situ mixed cement-soil is selected as the cement-soil pile wall support structure of the rail beam.

[0048] exist figure 1 , figure 2 , image 3 In the embodiment, when the cement-soil pile wall support structure of the rail beam is selected to use poured, non-in-situ mixed cement-soil, the construction method of the present invention is: ① The construction process of the pile wall is: prefabricated rail beam 1. Brush the release agent on the surface of the beam, machine the hole, hang the rail beam into the hole, mix and transport the cement soil on site, pour the cement soil to the hole, and complete the pile formation; ②The construction process of rail beam removal is: a , When using commonly used ointment-like release agent, directly pull out the rail beam and lift it away. b. When the surface of the rail beam is painted with a solid hot-melt mineral wax release agent, when the rail beam is pulled out, the on-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com