Anti-bending, anti-slip and anti-static type plastic-wood composite material and preparation method thereof

A wood-plastic composite material and anti-bending technology, which is applied in the field of anti-bending, anti-slip, and antistatic wood-plastic composite materials, can solve the problems of being unable to have both anti-bending, surface anti-slip and antistatic properties, and achieve enhanced mechanical properties. Strength and antistatic ability, enhanced bending resistance, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

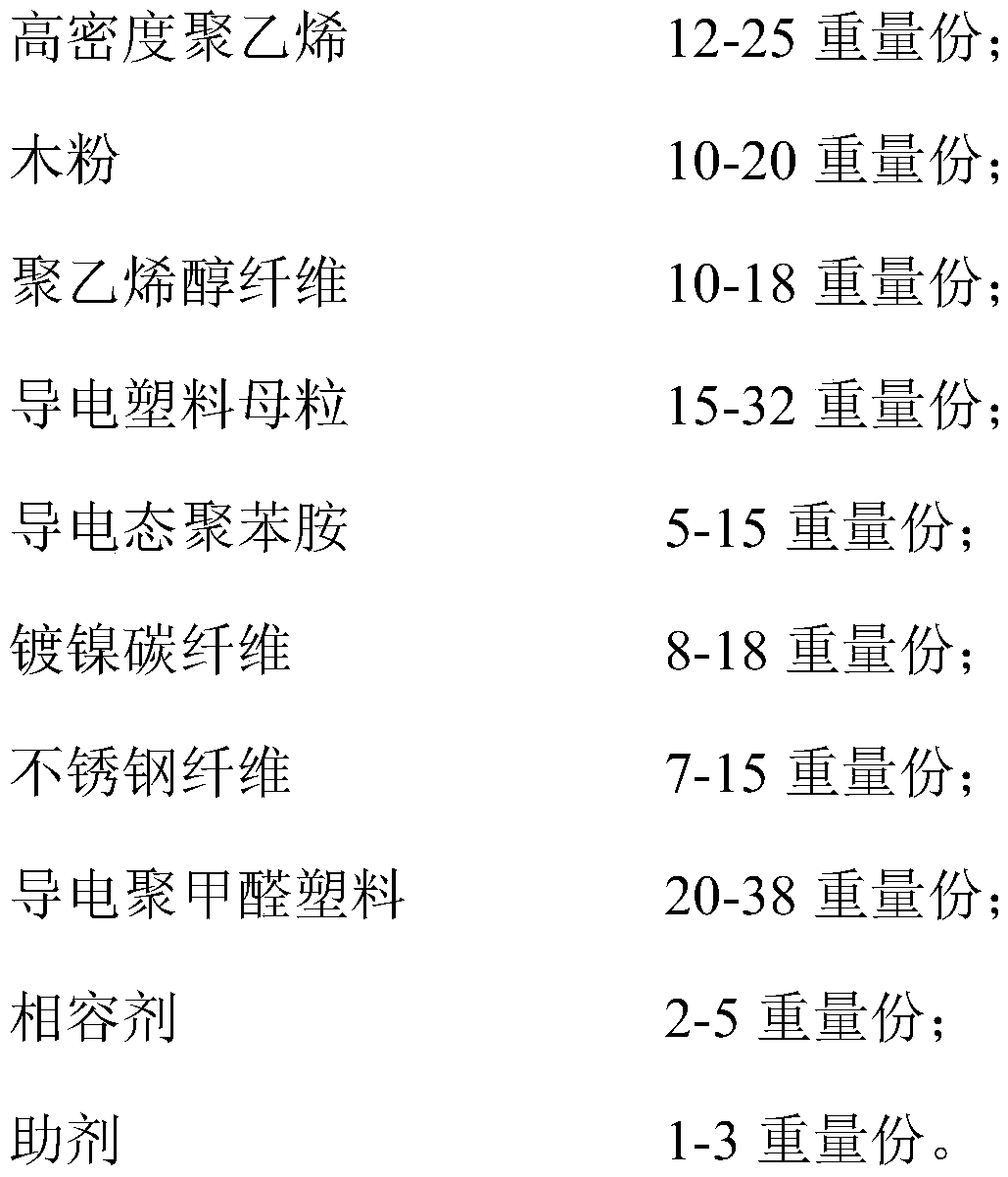

[0049] The anti-bending, anti-skid, and antistatic wood-plastic composite material described in this embodiment, its preparation raw materials include the following components by weight:

[0050]

[0051] The preparation method of anti-bending, anti-skid, anti-static type plastic-wood composite material described in this embodiment comprises the following steps:

[0052] (1) Get the high-density polyethylene, wood powder, polyvinyl alcohol fiber, conductive plastic masterbatch, conductive polyaniline, nickel-plated carbon fiber, stainless steel fiber, conductive polyoxymethylene plastic, compatibilizer and auxiliary agent, at temperature Vacuum dry for 3 hours at 85°C, vacuum degree -0.095Mpa, and set aside;

[0053] (2) Take the selected amount of high-density polyethylene, wood flour, nickel-plated carbon fiber, and stainless steel fiber and fully mix them at room temperature, and place them in a parallel twin-screw extruder. Rotating speed 320rpm carries out extruding g...

Embodiment 2

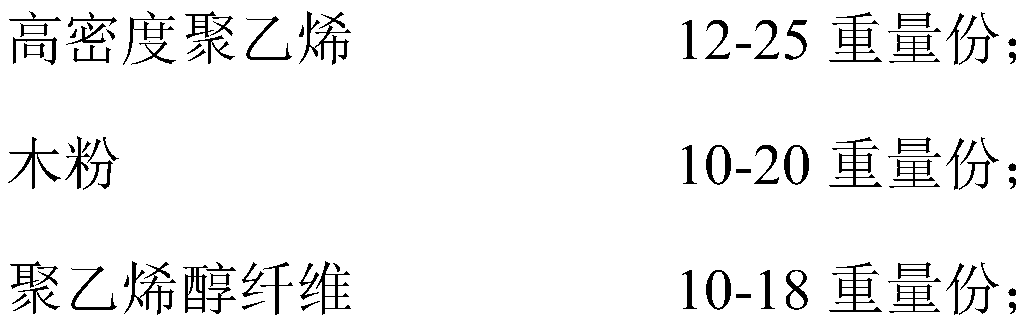

[0058] The anti-bending, anti-skid, and antistatic wood-plastic composite material described in this embodiment, its preparation raw materials include the following components by weight:

[0059]

[0060] The preparation method of anti-bending, anti-skid, anti-static type plastic-wood composite material described in this embodiment comprises the following steps:

[0061] (1) Get the high-density polyethylene, wood powder, polyvinyl alcohol fiber, conductive plastic masterbatch, conductive polyaniline, nickel-plated carbon fiber, stainless steel fiber, conductive polyoxymethylene plastic, compatibilizer and auxiliary agent, at temperature Vacuum dry for 4 hours at 80°C, vacuum degree -0.095Mpa, and set aside;

[0062] (2) Take the selected amount of high-density polyethylene, wood flour, nickel-plated carbon fiber, and stainless steel fiber and mix them thoroughly at room temperature, and place them in a parallel twin-screw extruder. Rotating speed 350rpm carries out extrud...

Embodiment 3

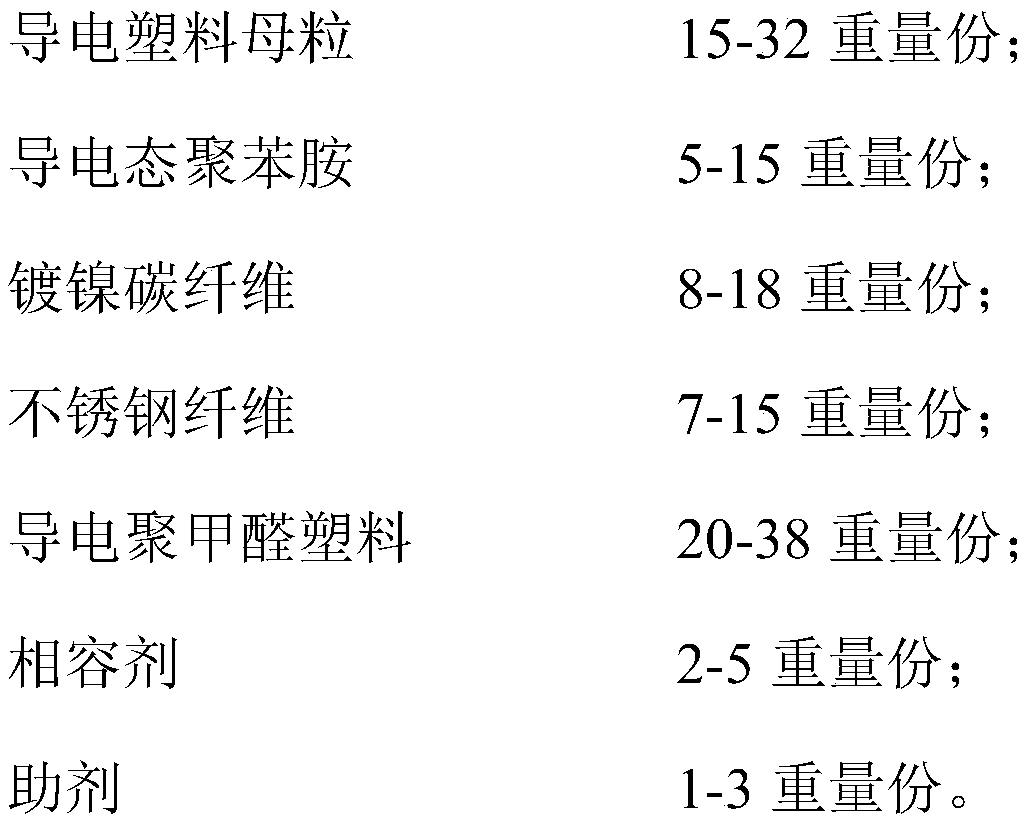

[0067] The anti-bending, anti-skid, and antistatic wood-plastic composite material described in this embodiment, its preparation raw materials include the following components by weight:

[0068]

[0069]

[0070] The preparation method of anti-bending, anti-skid, anti-static type plastic-wood composite material described in this embodiment comprises the following steps:

[0071] (1) Get the high-density polyethylene, wood powder, polyvinyl alcohol fiber, conductive plastic masterbatch, conductive polyaniline, nickel-plated carbon fiber, stainless steel fiber, conductive polyoxymethylene plastic, compatibilizer and auxiliary agent, at temperature Vacuum dry for 2 hours at 90°C, vacuum degree -0.095Mpa, and set aside;

[0072] (2) Take the selected amount of high-density polyethylene, wood flour, nickel-plated carbon fiber, and stainless steel fiber and mix them thoroughly at room temperature, and place them in a parallel twin-screw extruder. Rotating speed 300rpm carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com