Dissecting blade high in strength and hardness and used in ceramic surgical department and production process thereof

A production process and blade technology, which is applied in anatomical instruments, medical science, surgery, etc., can solve the problems of insufficient strength of blades and blades, unreasonable angle setting, and affecting the quality of surgery, etc., and achieve good biocompatibility and long service life , the effect of firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

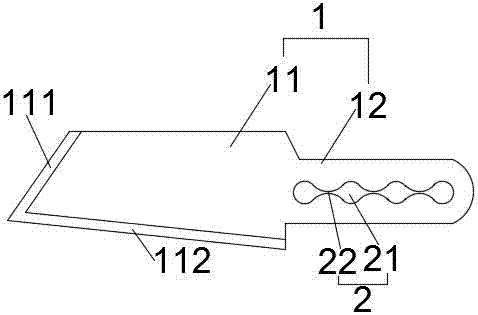

[0021] Such as figure 1 As shown, a high-strength and hard ceramic surgical scalpel blade described in this embodiment includes a scalpel blade body 1, and the scalpel blade body 1 is made of ceramic material and includes a blade portion 11 and a connecting portion 12. The blade part 11 and the connecting part 12 are integral structures; the blade part 11 includes a first blade part 111 and a second blade part 112, and the first blade part 111 is located at the left end of the scalpel blade body 1 and is inclined to the right Setting, the second blade portion 112 is located at the lower end of the scalpel blade body 1 and is arranged obliquely downward, the length of the first blade portion 111 is shorter than the length of the second blade portion 112 and the first blade portion 111 and the second blade portion The angle between the blade parts 112 is an acute angle; the left end of the connecting part 12 is fixedly connected with the blade part 11, and the right end is in a ...

Embodiment 2

[0029] Such as figure 1 As shown, a high-strength and hard ceramic surgical scalpel blade described in this embodiment includes a scalpel blade body 1, and the scalpel blade body 1 is made of ceramic material and includes a blade portion 11 and a connecting portion 12. The blade part 11 and the connecting part 12 are integral structures; the blade part 11 includes a first blade part 111 and a second blade part 112, and the first blade part 111 is located at the left end of the scalpel blade body 1 and is inclined to the right Setting, the second blade portion 112 is located at the lower end of the scalpel blade body 1 and is arranged obliquely downward, the length of the first blade portion 111 is shorter than the length of the second blade portion 112 and the first blade portion 111 and the second blade portion The angle between the blade parts 112 is an acute angle; the left end of the connecting part 12 is fixedly connected with the blade part 11, and the right end is in a ...

Embodiment 3

[0037] Such as figure 1As shown, a high-strength and hard ceramic surgical scalpel blade described in this embodiment includes a scalpel blade body 1, and the scalpel blade body 1 is made of ceramic material and includes a blade portion 11 and a connecting portion 12. The blade part 11 and the connecting part 12 are integral structures; the blade part 11 includes a first blade part 111 and a second blade part 112, and the first blade part 111 is located at the left end of the scalpel blade body 1 and is inclined to the right Setting, the second blade portion 112 is located at the lower end of the scalpel blade body 1 and is arranged obliquely downward, the length of the first blade portion 111 is shorter than the length of the second blade portion 112 and the first blade portion 111 and the second blade portion The angle between the blade parts 112 is an acute angle; the left end of the connecting part 12 is fixedly connected with the blade part 11, and the right end is in a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com