Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Guaranteed Peel Strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

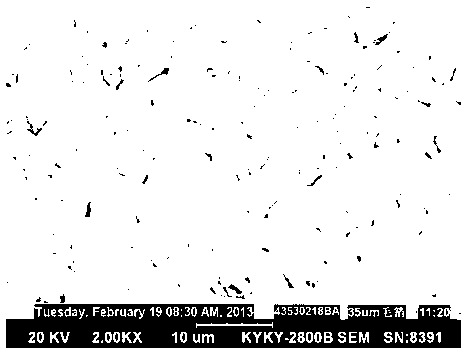

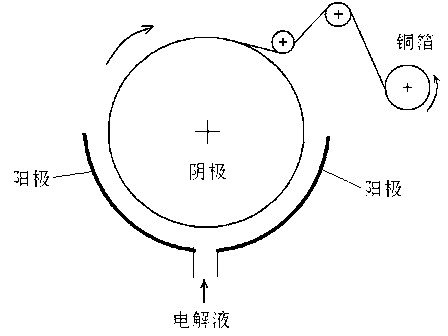

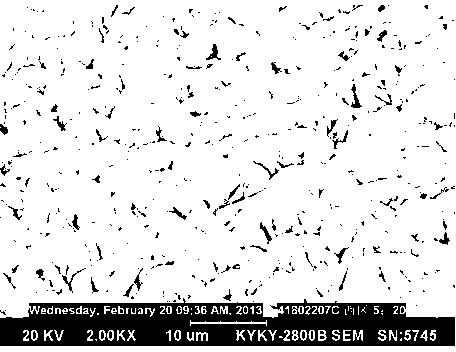

Mixed additive for removing internal stress of electrolytic copper foil and method for producing low-stress copper foil

ActiveCN103173812AThe production process is easy to controlProduct quality is stableCopper foilHydroxyethyl cellulose

The invention relates to a mixed additive for removing internal stress of an electrolytic copper foil and a method for producing a low-stress copper foil and belongs to the technical field of production of a high-precision electrolytic copper foil. The mixed additive for removing internal stress of the electrolytic copper foil comprises gelatin, hydroxyethyl cellulose and liquid additive. The method for producing the low-stress copper foil by using the mixed additive comprises the steps of preparing high-purity cathode copper and sulfuric acid into mixed solution of sulfuric acid and copper sulfate at 60-95 DEG C under the condition of stirring in the presence of air, wherein Cu<2+> is 85-100g / L and H2SO4 is 100-120g / L; adjusting the temperature of electrolyte to 45-60 DEG C and the flow to 50-70m<3> / h; adding 20-50mg / L of Cl<->, adding the mixed additive, with a drum titanium tube which continuously rotates as a cathode and arc titanium as an anode, carrying out copper electrolytic deposition and lastingly stripping to obtain 12-70 microns copper foil under the condition of the direct current of which the current density is 55-70A / dm<2>. The thickness of the copper foil is controlled by adjusting the rotation speed of the cathode; and the obtained copper foil has excellent performances.

Owner:SHANDONG JINBAO ELECTRONICS

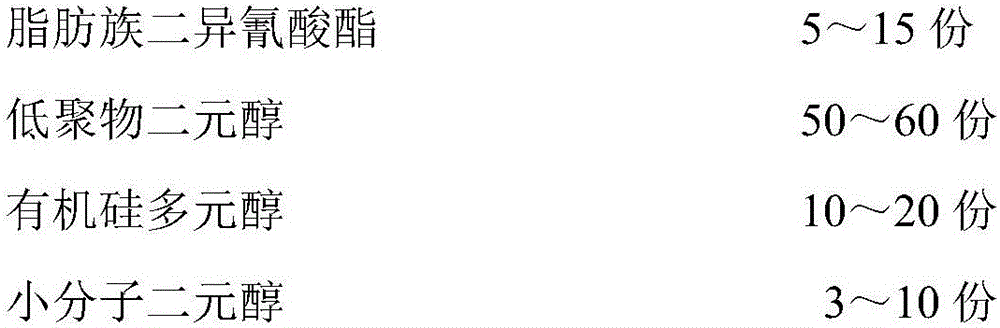

Carbon fiber modified non-solvent polyurethane surface layer resin for sports shoe leather, as well as preparation method and application of carbon fiber modified non-solvent polyurethane surface layer resin

ActiveCN106397722AGuaranteed to be environmentally friendlyGuaranteed stabilityPolyurea/polyurethane coatingsFootwearPolyresinHydrolysis

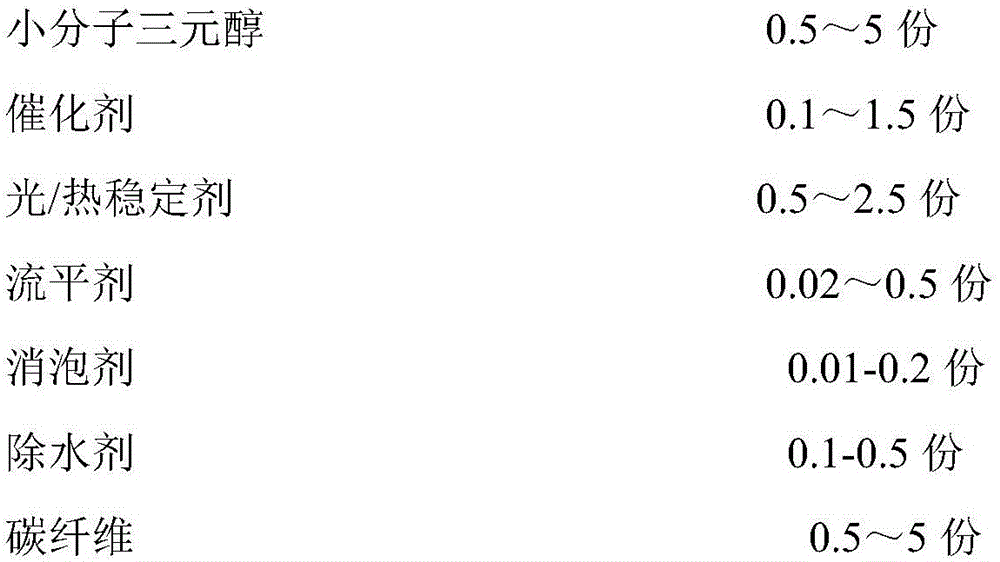

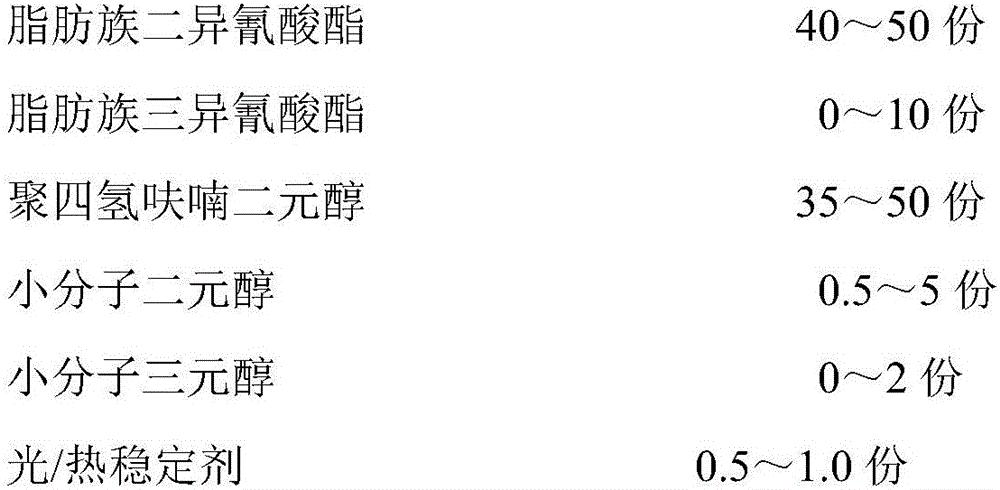

The invention belongs to the field of synthetic leather, and provides carbon fiber modified non-solvent polyurethane surface layer resin for sports shoe leather. The resin is formed by mixing a component A and a component B according to mass percent being 2:1 to 1:2, wherein the component A comprises 5 to 15 parts of aliphatic diisocyanate, 50 to 60 parts of low polymer dihydric alcohol, 10 to 20 parts of organosilicone polyhydric alcohol, 3 to 10 parts of micromolecule dihydric alcohol, 0.5 to 5 parts of micromolecule trihydric alcohol, 0.1 to 1.5 parts of a catalyst, 0.5 to 2.5 parts of a light / heat stabilizer, 0.02 to 0.5 part of a flatting agent, 0.01 to 0.2 part of a defoamer, 0.1 to 0.5 part of a dehydrator, and 0.5 to 5.0 parts of carbon fiber; the component B comprises 40 to 50 parts of aliphatic diisocyanate, 0 to 10 parts of triisocyanate, 35 to 50 parts of polytetrahydrofuran dihydric alcohol, 0.5 to 5 parts of micromolecule dihydric alcohol, 0 to 2 parts of micromolecule trihydric alcohol, and 0.5 to 1.0 part of a light / heat stabilizer. The invention further provides a preparation method and application of the resin. The tangential breaking strength of carbon fiber modified resin coating can reach 130kN / m or above; for non-solvent sports shoe leather prepared through the method, the peeling strength can reach 90N / 3 cm or above and the hydrolysis resistance can reach 10 weeks or above.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

High practicality lithium nickel manganese oxide and preparation method thereof

InactiveCN104900865ASmall specific surface areaGuaranteed cycle performanceCell electrodesSecondary cellsCarbon layerMaterials processing

The invention discloses a high practicality lithium nickel manganese oxide and a preparation method thereof. The lithium nickel manganese oxide is characterized in that manganese source, lithium source, nickel source and a certain amount of grinding aid are blended by a dry grinding mode, the lithium nickel manganese oxide material with low specific surface area is prepared by using the characteristics of slow crystal nucleation rate and little nucleation of a precursor, contact area of the material and an electrolyte is increased, cycle life of the material is increased; cation disorder degree and crystal structure dislocation of the crystal can be controlled through a multi-step calcining technology for guaranteeing the multiplying power performance of the material; the obtained lithium nickel manganese oxide coats the surface of a carbon layer by using a vapour deposition method, anchoring strength of the material and a current collector is enhanced, peeling intensity of pole sheet is enhanced, material processing property is ensured, and multiplying power performance is increased. The material has the advantages of long service life and good processing property, and is the lithium nickel manganese oxide material with high practicality, the preparation method is economic and easy to operate, and is suitable for commercialization popularization.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

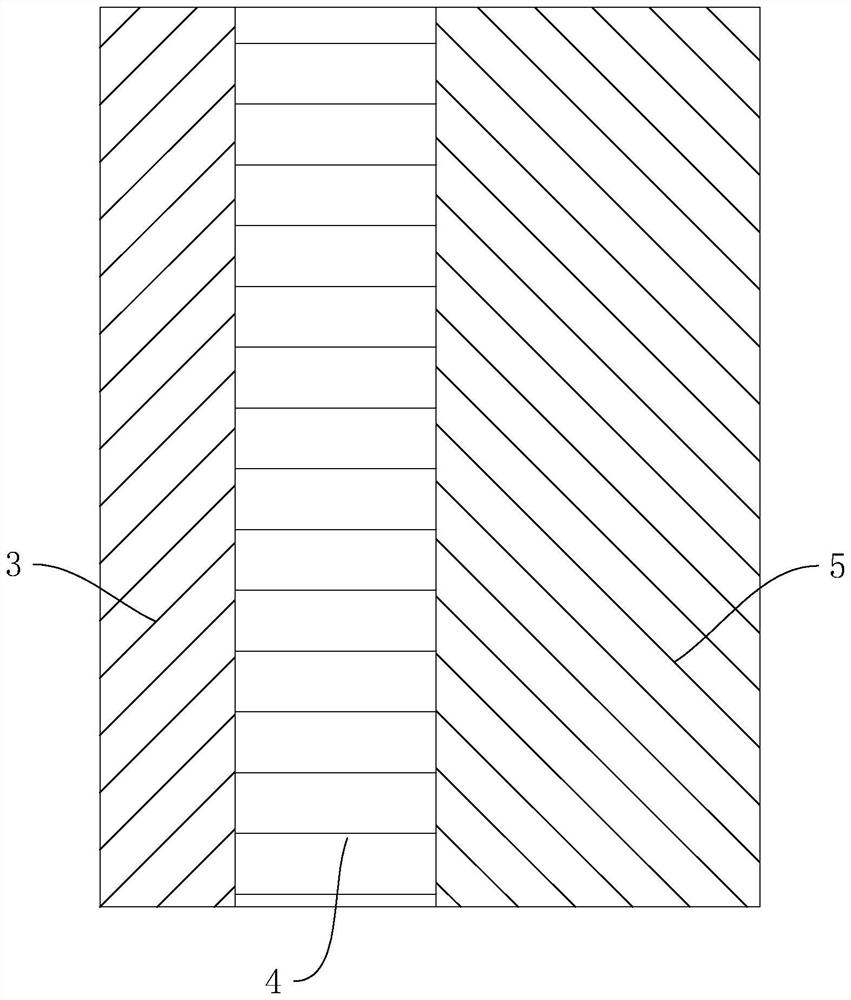

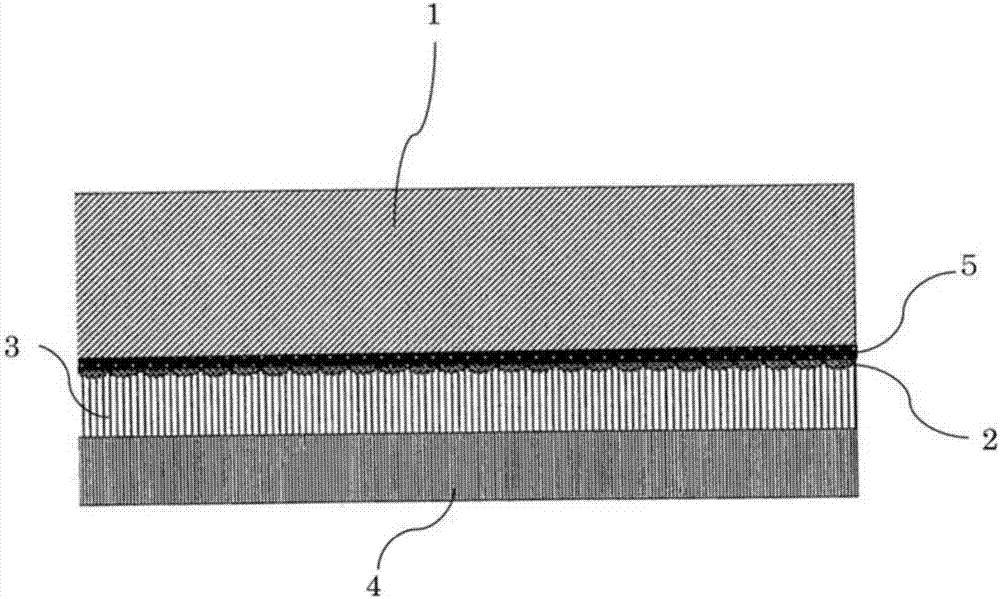

Copper foil provided with carrier

ActiveCN104619889AGuaranteed Peel StrengthOptimize spaceCircuit precursor manufactureElectroforming processesCopper foilFine pitch

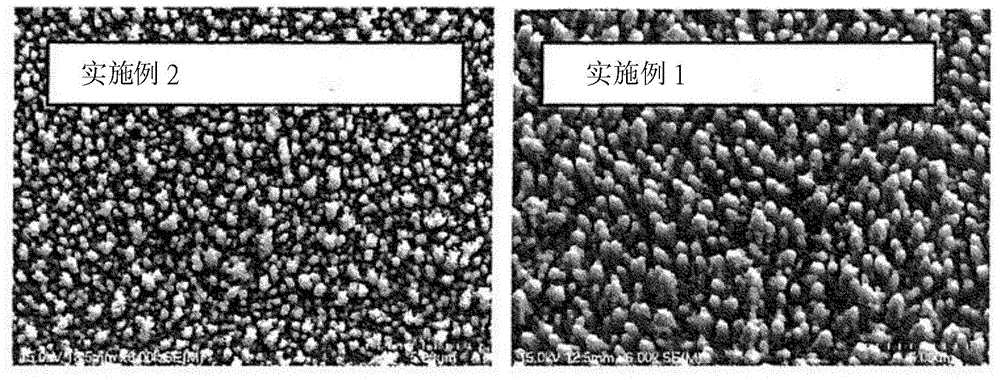

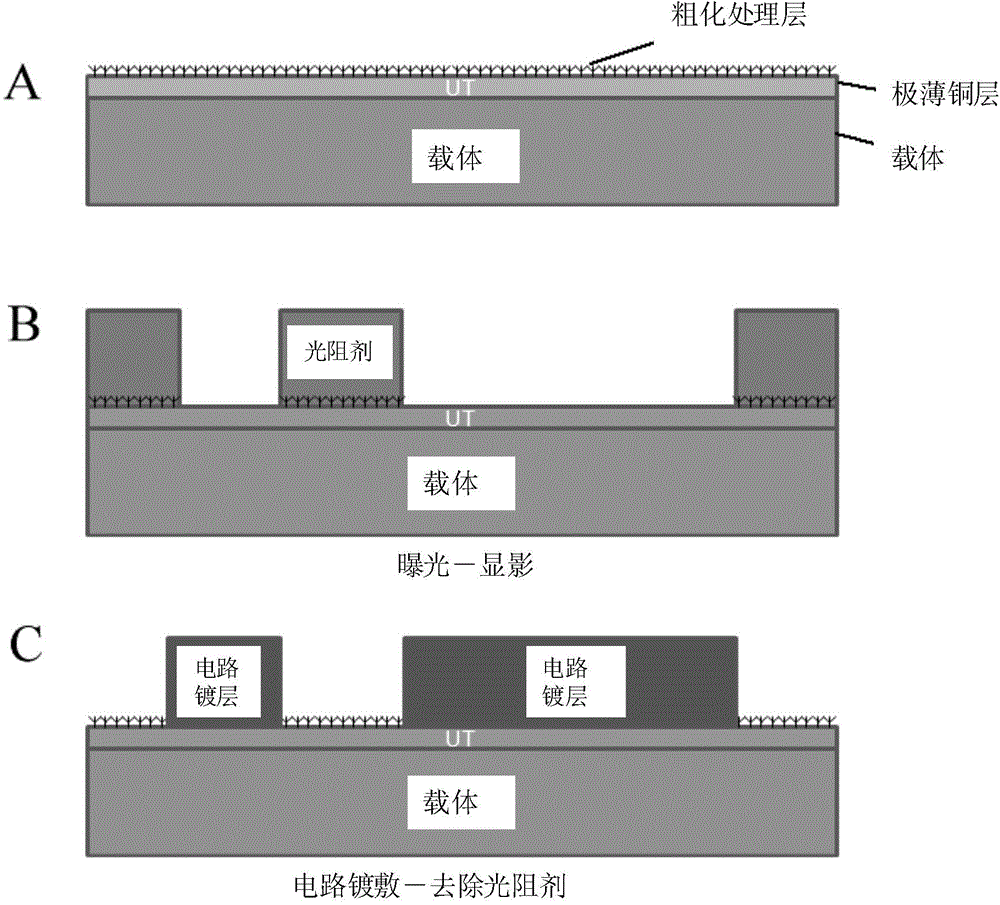

Provided is a copper foil provided with a carrier, suitable for forming a fine pitch. A copper foil provided with a carrier, comprising a copper foil carrier, a release layer layered onto the copper foil carrier, and a very thin copper layer layered onto the release layer; wherein the very thin copper layer has been roughened and the Rz of the very thin copper layer surface is 1.6 μm or less as measured with a non-contact roughness meter.

Owner:JX NIPPON MINING & METALS CO LTD

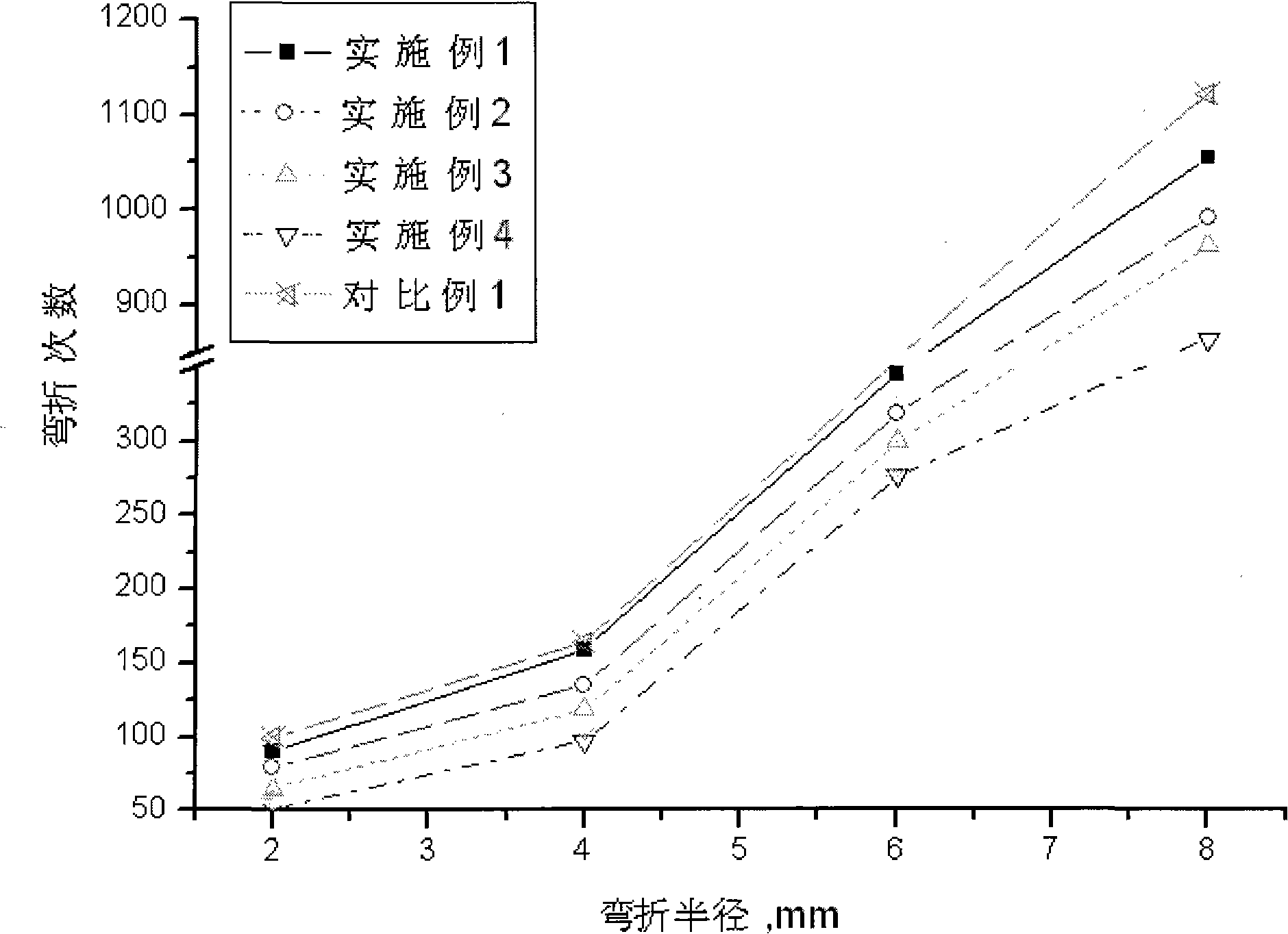

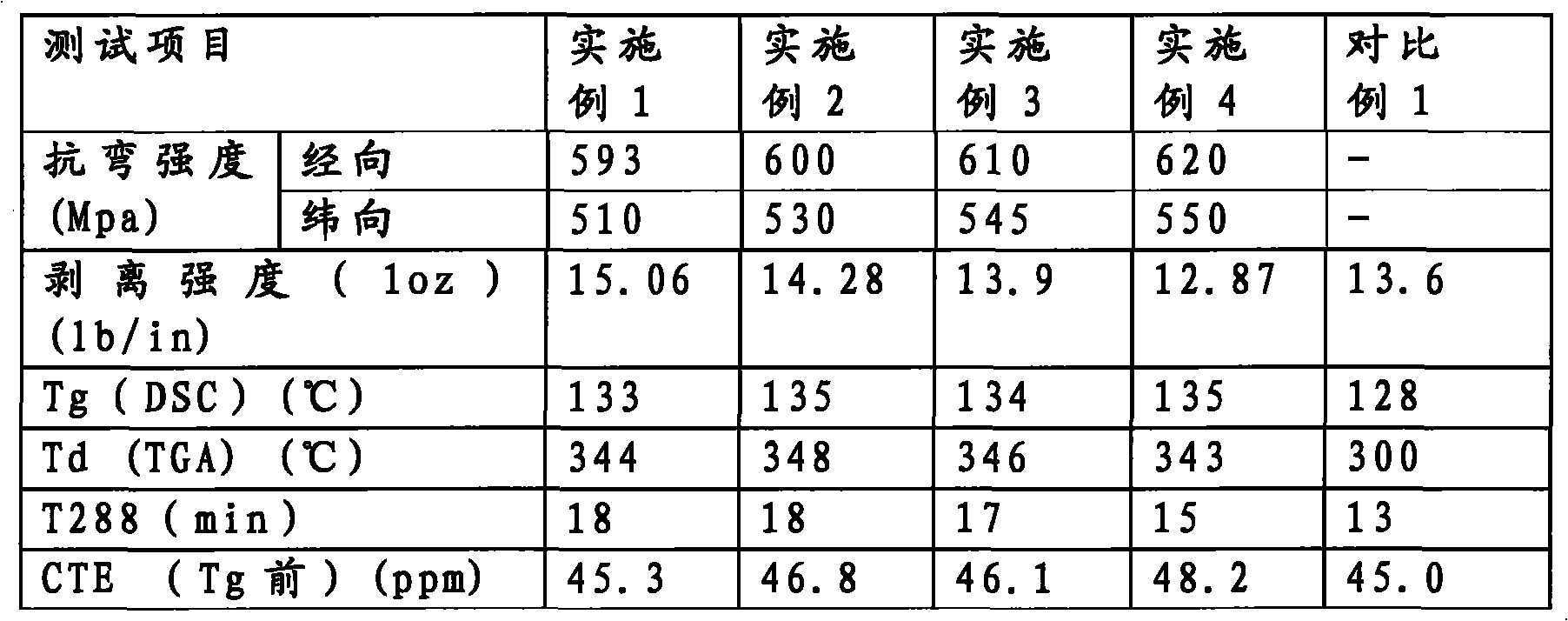

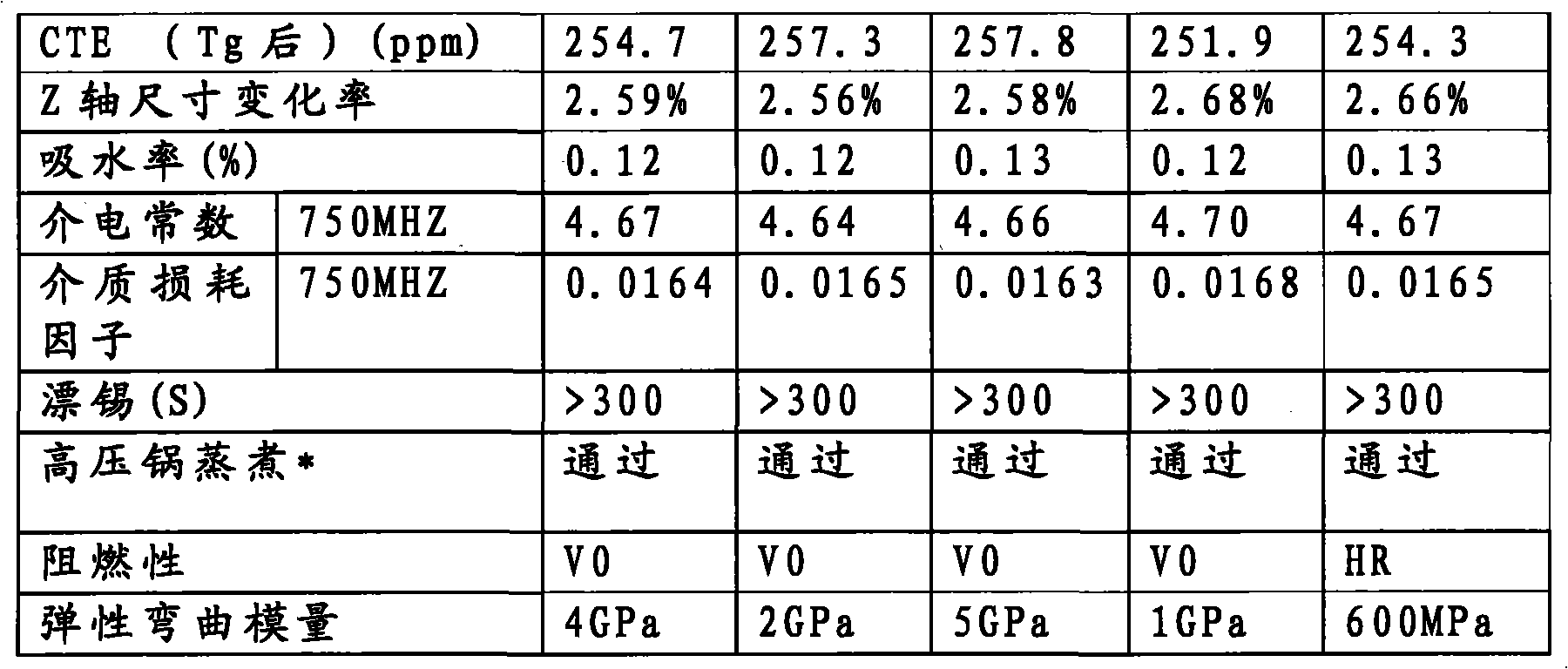

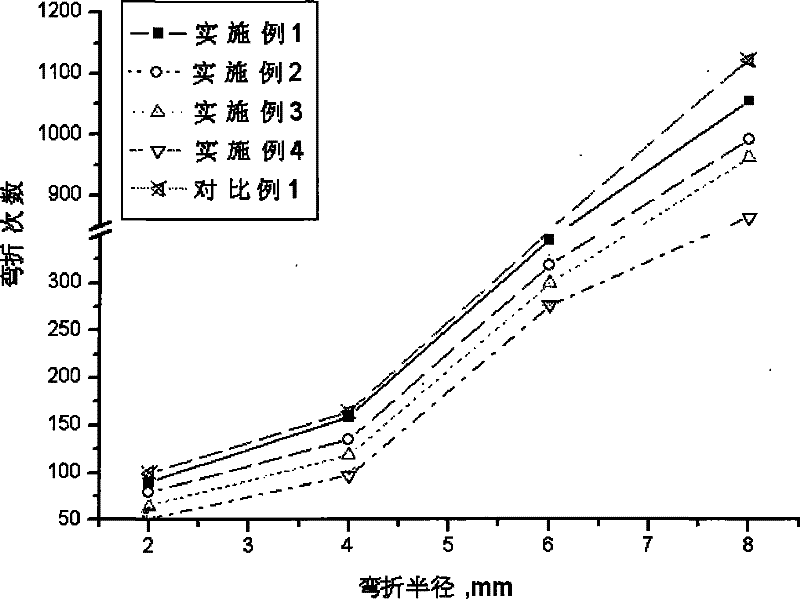

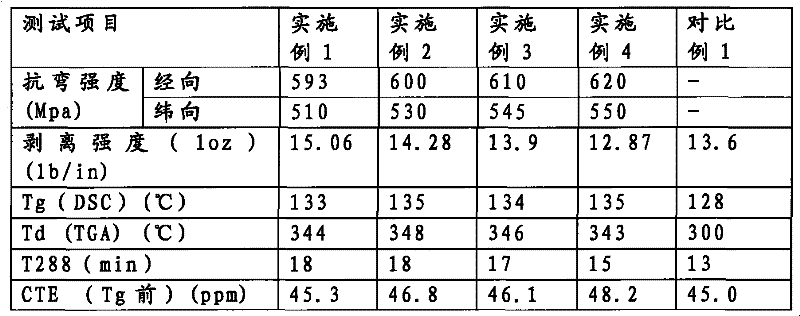

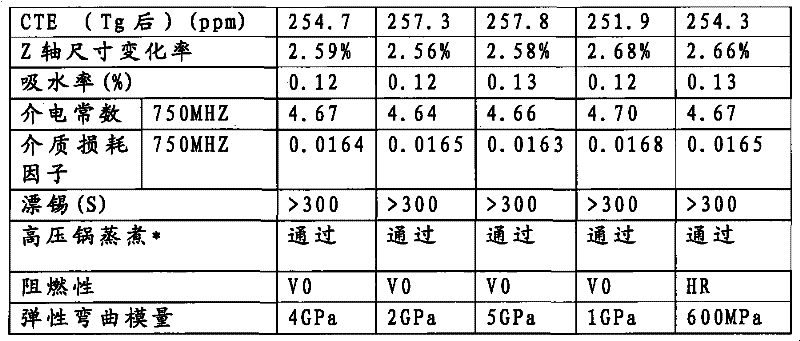

Manufacturing method of copper-clad plate and glue solution for copper-clad plate

ActiveCN101808466AFlexibleReduce manufacturing costPrinted circuit manufactureEpoxy resin adhesivesEpoxyGlass fiber

The invention relates to a manufacturing method of a copper-clad plate and glue solution for the copper-clad plate. The manufacturing method takes glass cloth as base cloth and successively comprises the steps of preparing glue solution, sizing base cloth and hot forming. The glue solution comprises 100 parts of epoxy resin, 10-40 parts of organic fire retardant, 1-30 parts of curing agent, 0.005-0.05 part of curing accelerator and 10-50 parts of dissolvent, wherein the epoxy resin is composed of 25-75 wt% of nitrile rubber modified epoxy resin and 25-75 wt% of bromination epoxy resin, and the content of nitrile rubber in the nitrile rubber epoxy resin is 30-60%. The invention provides a 'semi-soft plate' with medium elasticity bending modulus. The semi-soft plate has certain flexibility, has the supporting performance provided by a rigid copper-clad plate, is especially suitable for electronic connection devices without very high flexibility requirements and has the advantages of low manufacturing cost and convenient installation and connection.

Owner:VENTEC ELECTRONICS SUZHOU

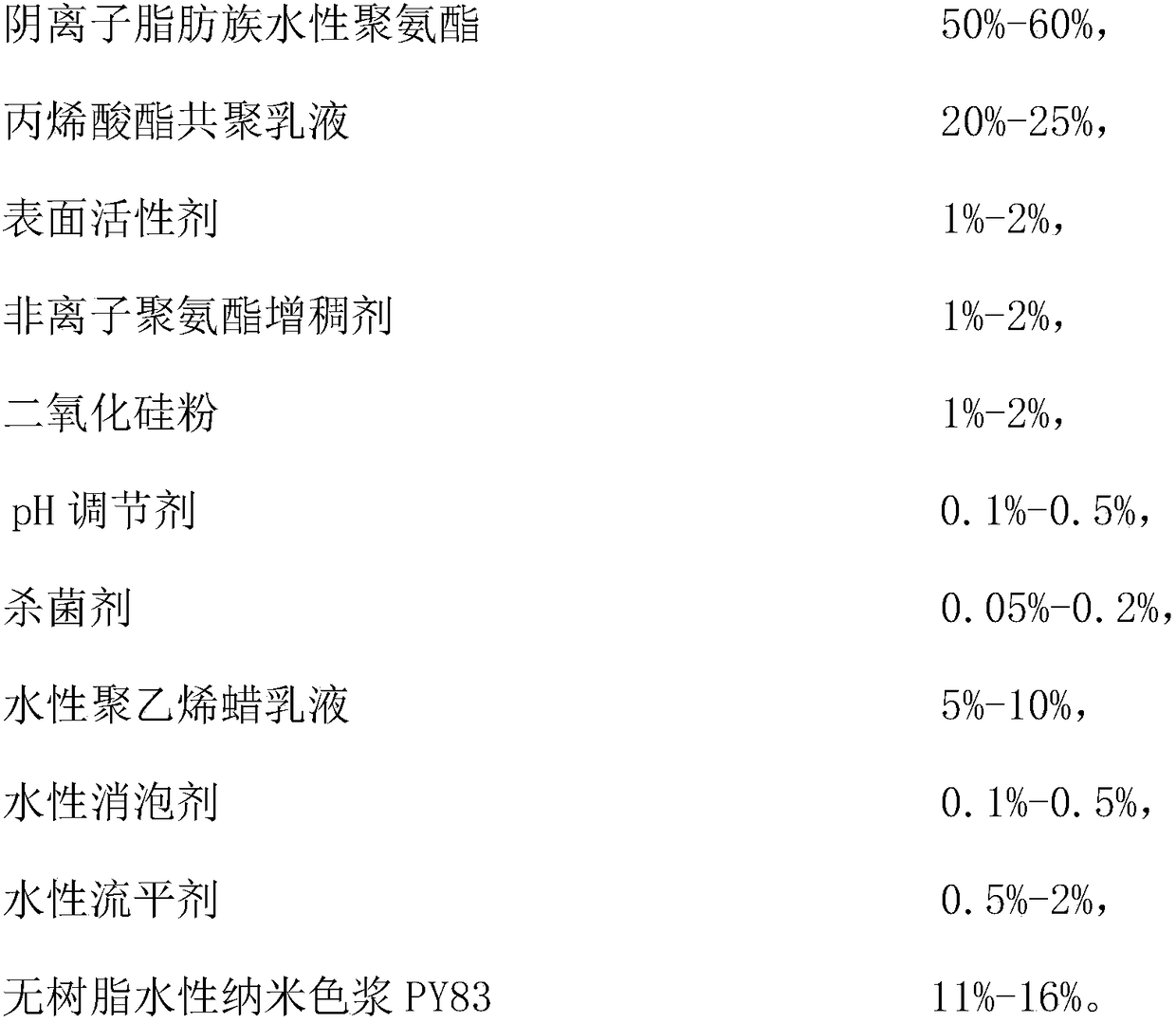

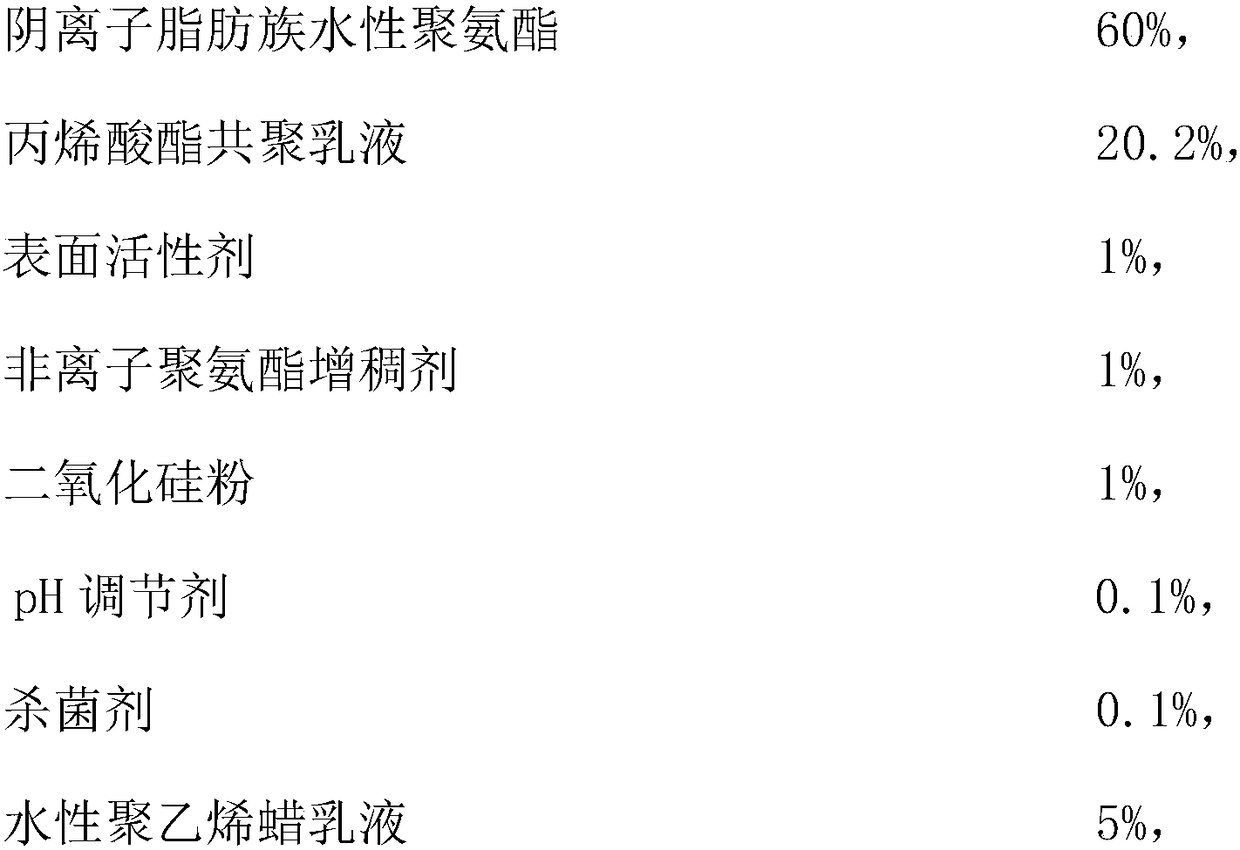

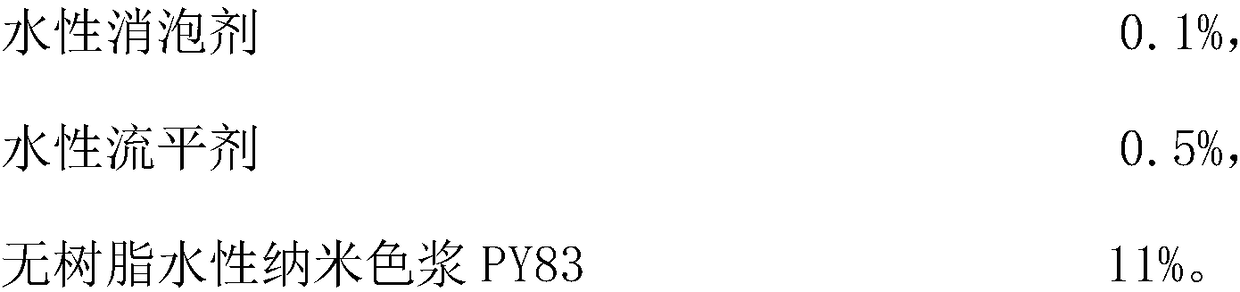

Water-based gravure yellow ink for soft PVC decoration film, and preparation method thereof

The invention relates to a water-based gravure yellow ink for a soft PVC decoration film. The water-based gravure yellow ink comprises, by mass, 50-60% of anionic aliphatic waterborne polyurethane, 20-25% of an acrylate copolymer emulsion, 1-2% of a surfactant, 1-2% of a nonionic polyurethane thickener, 1-2% of silica powder, 0.1-0.5% of a pH adjuster, 0.05-0.2% of a bactericide, 5-10% of an aqueous polyethylene wax emulsion, 0.1-0.5% of an aqueous defoamer, 0.5-2% of an aqueous leveling agent and 11-16% of a resin-free aqueous nanometer color paste PY83. The invention also provides a preparation method of the aqueous gravure yellow ink. The ink has the advantages of good resolubility, no clogging, good adhesion to a substrate, no after-tack, few bubbles in the use process, convenience inpackaging and construction, high bonding strength, and excellent resistance to yellowing and weathering; and the preparation method has the advantages of simplicity, easiness in control, no grinding process, and improvement of the production efficiency.

Owner:中山创美涂料有限公司

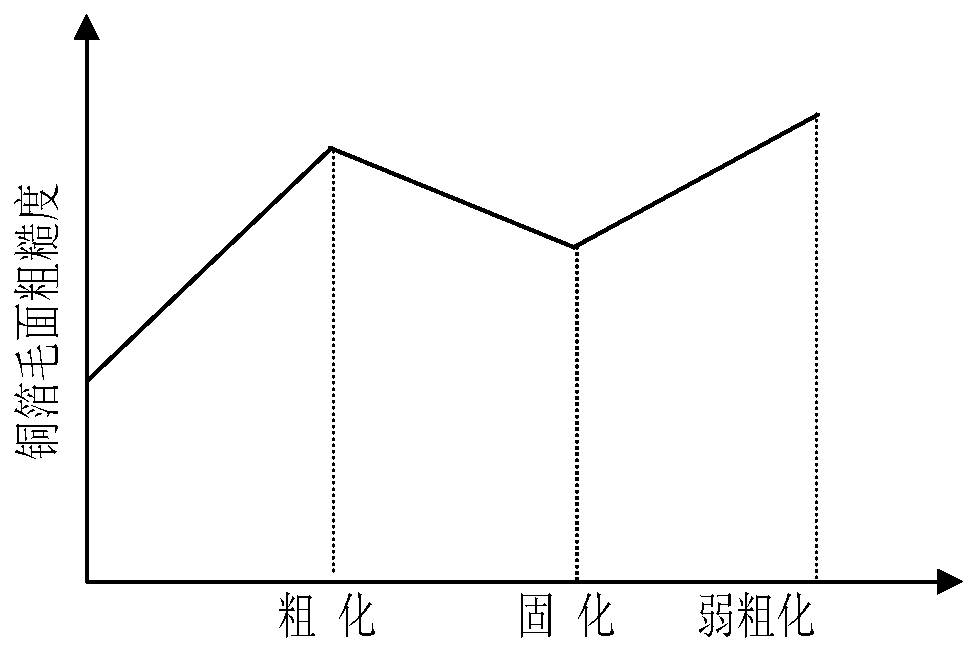

Additive for electrolytic copper foil, ultra-low peak HVLP copper foil and preparation method of ultra-low peak HVLP copper foil

InactiveCN110724979ASolve the problem of high roughnessImprove ductilityElectroforming processesElectrolysisThiazole

The invention relates to the technical field of electrolytic copper foils, in particular to an additive for electrolytic copper foil, an ultra-low peak HVLP copper foil and a preparation method of theultra-low peak HVLP copper foil. The additive comprises at least four of an acid copper throwing agent, a terahydrozoline thioketone, a monosodium salt, a 3,3'-dithiobis-1-propanesulfonicacidisodiumsalt, a collagen and a cowhide polypeptide as well as chloridion. The additive for the electrolytic copper foil, the ultra-low peak HVLP copper foil and the preparation method of the ultra-low peak HVLP copper foil have the advantages of low roughness, excellent mechanical property and good oxidation resistance.

Owner:东强(连州)铜箔有限公司

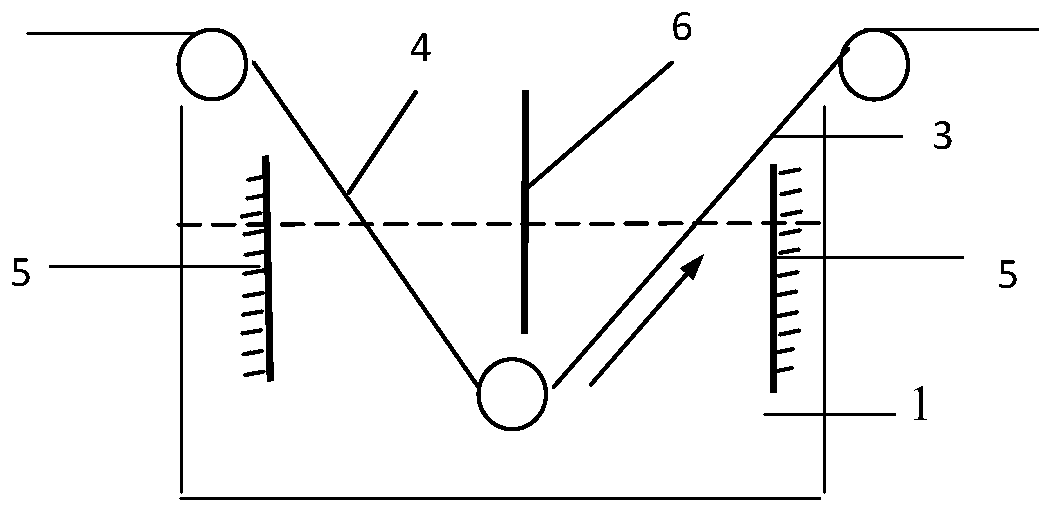

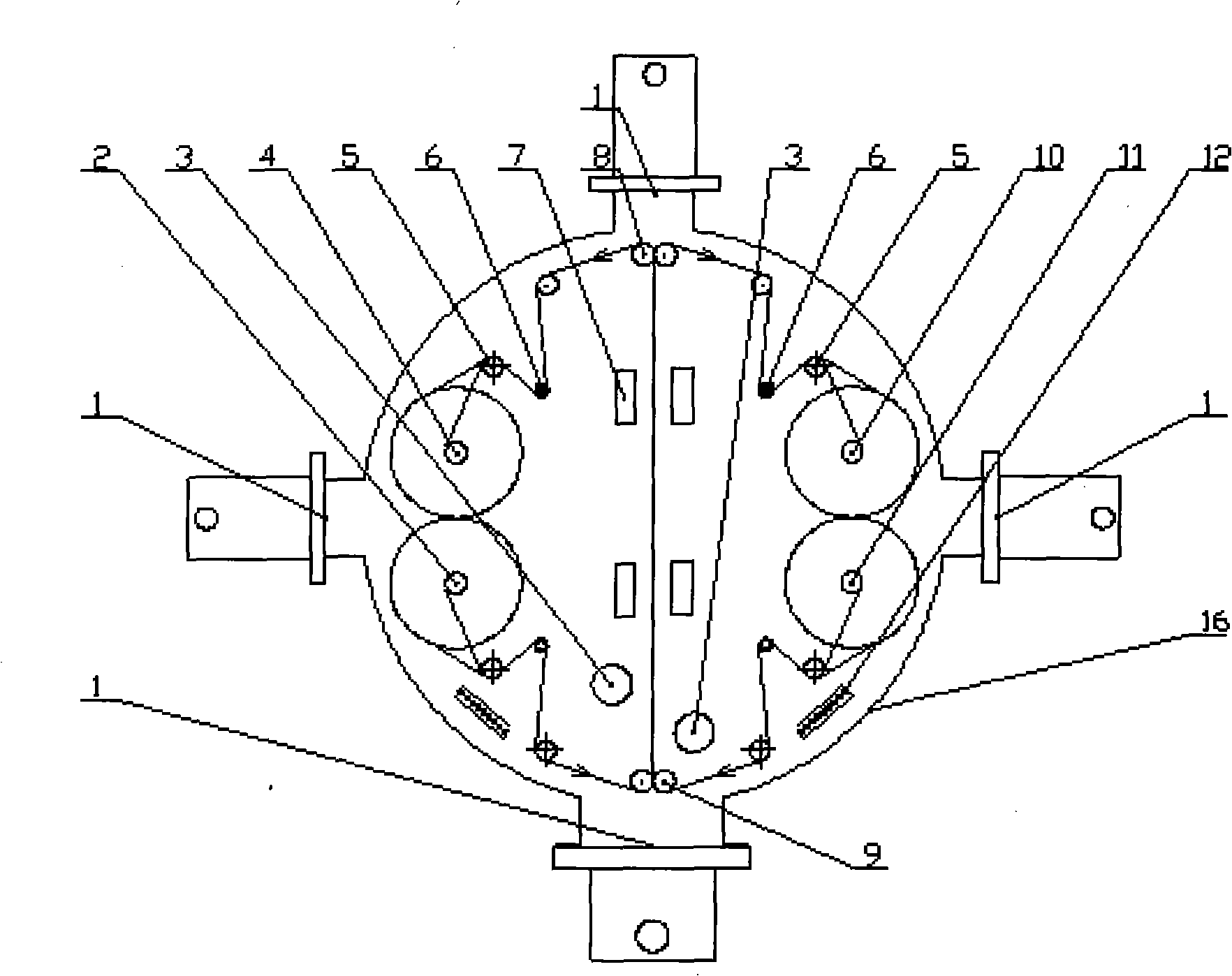

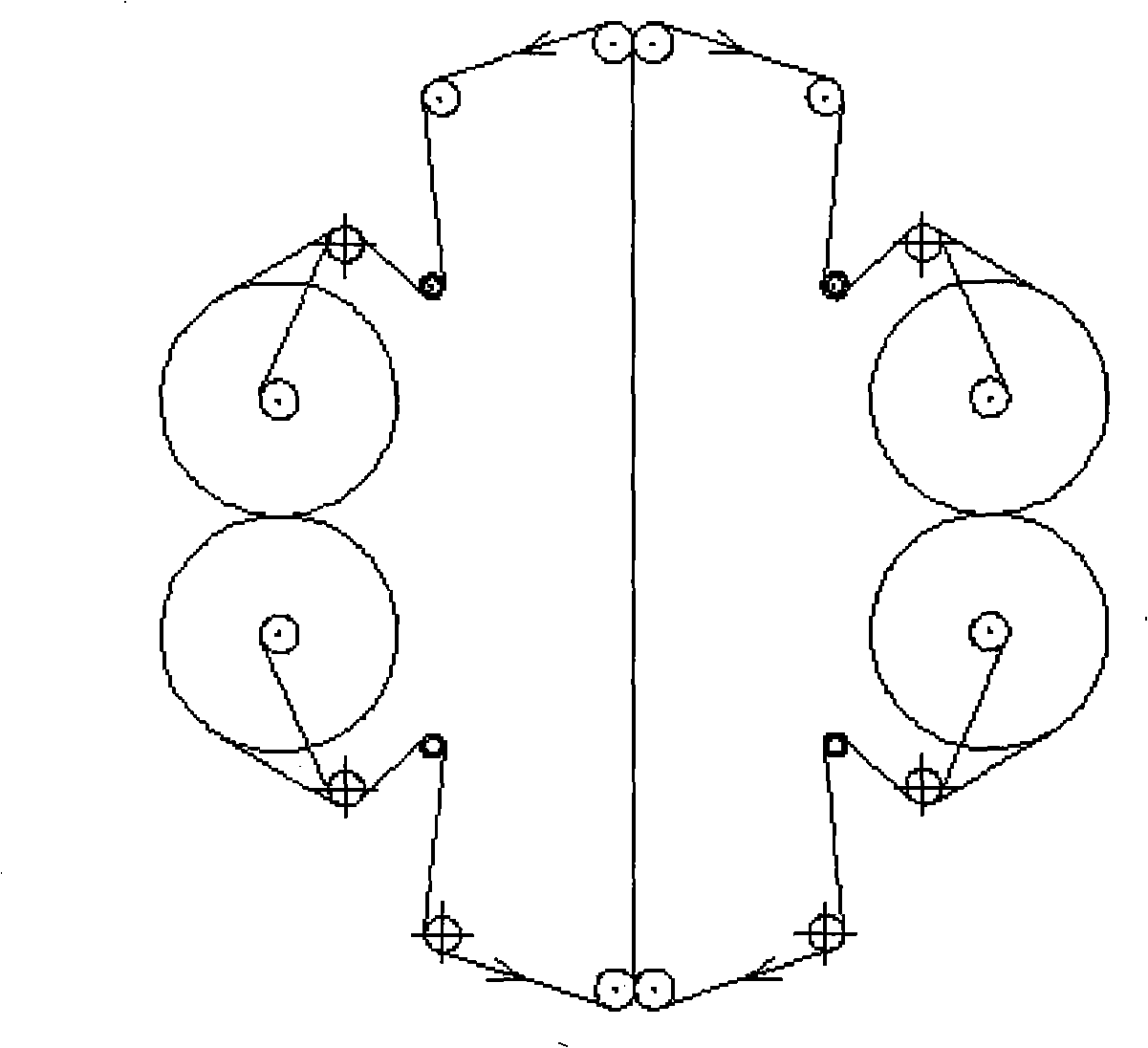

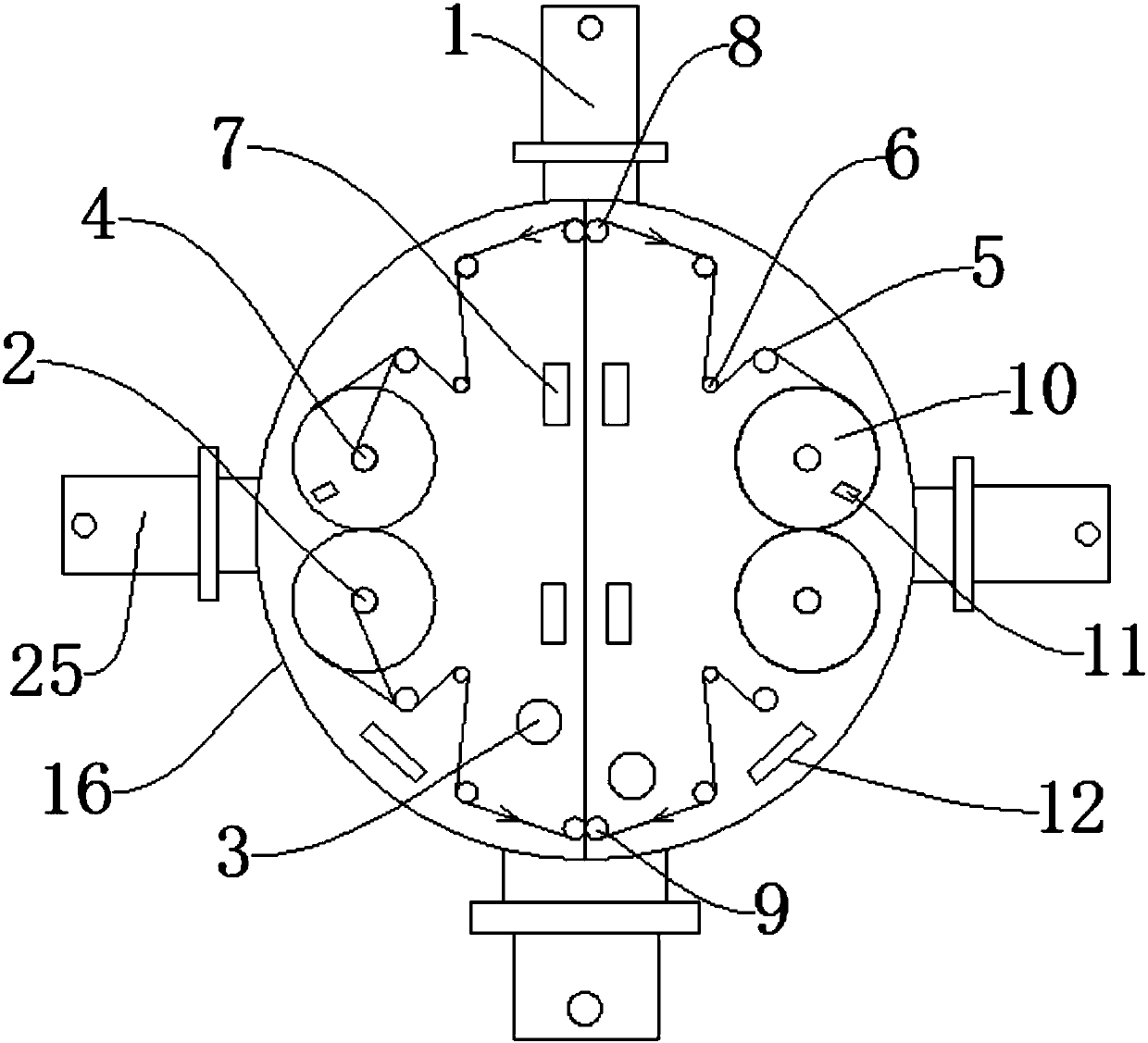

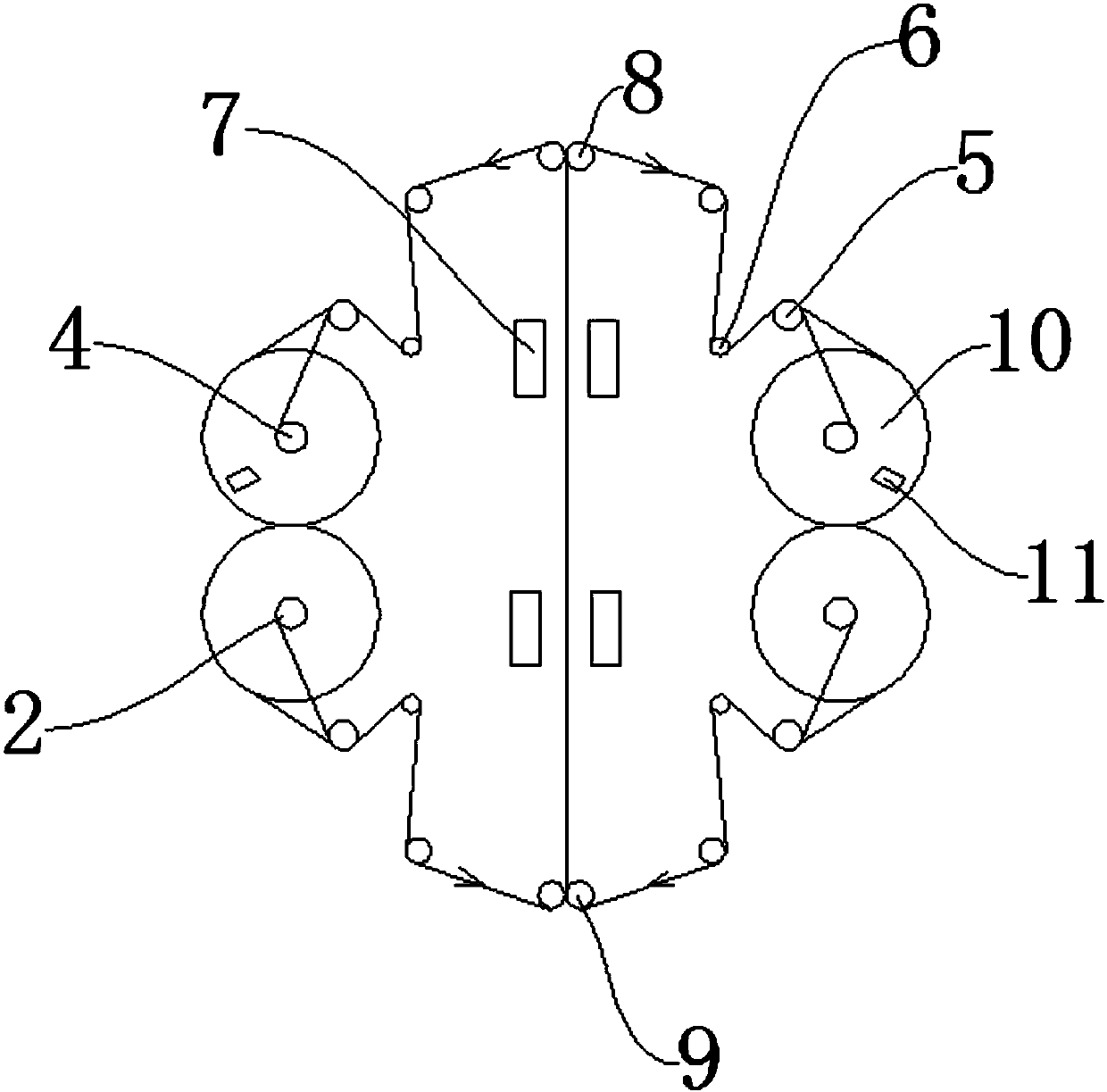

Vacuum magnetron sputtering coil film coating apparatus

ActiveCN101492809AIncrease pumping speedUniform vacuumVacuum evaporation coatingSputtering coatingIon bombardmentSurface roughness

A vacuum magnetron sputtering winding coating device comprises a vacuum cavity, a vacuum generating system, target electrodes, and a winding and unwinding system, wherein, the vacuum generating system is arranged on the vacuum cavity to cause the interior of the vacuum cavity to be in vacuum state at work, the target electrodes for magnetron sputtering are arranged at the magnetron sputtering area in the vacuum cavity, two rows of target electrodes are arranged, and the winding and unwinding system is respectively arranged at the tow sides of the magnetron sputtering area. The invention has the advantages that: (1) the vacuum cavity is designed as round to provide uniform vacuum degree without forming air suction dead angles; oil returning doses not appear in the vacuum chamber; and the work efficiency is improved; (2) two winding and unwinding systems are adopted to satisfy dual-coating of one roll and single-coating of two rolls with full width of the magnetron sputtering area as well as single-and dual-coating of two rolls with half width of the coating area, so that the function is comprehensive; (3) ion bombardment is carried out on the base material surface to enhance the surface roughness of the base material and guarantee the peel strength between the base material and the film.

Owner:GUANGZHOU FANGBANG ELECTRONICS

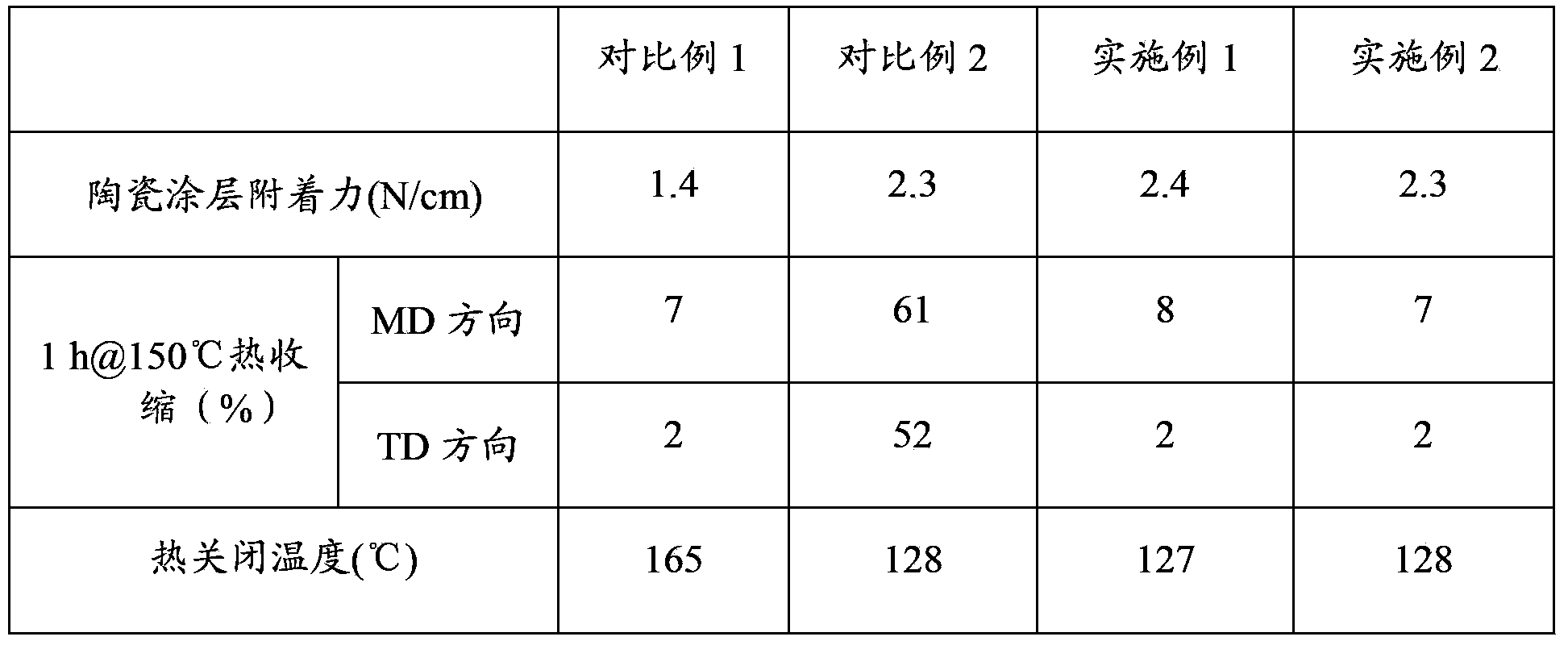

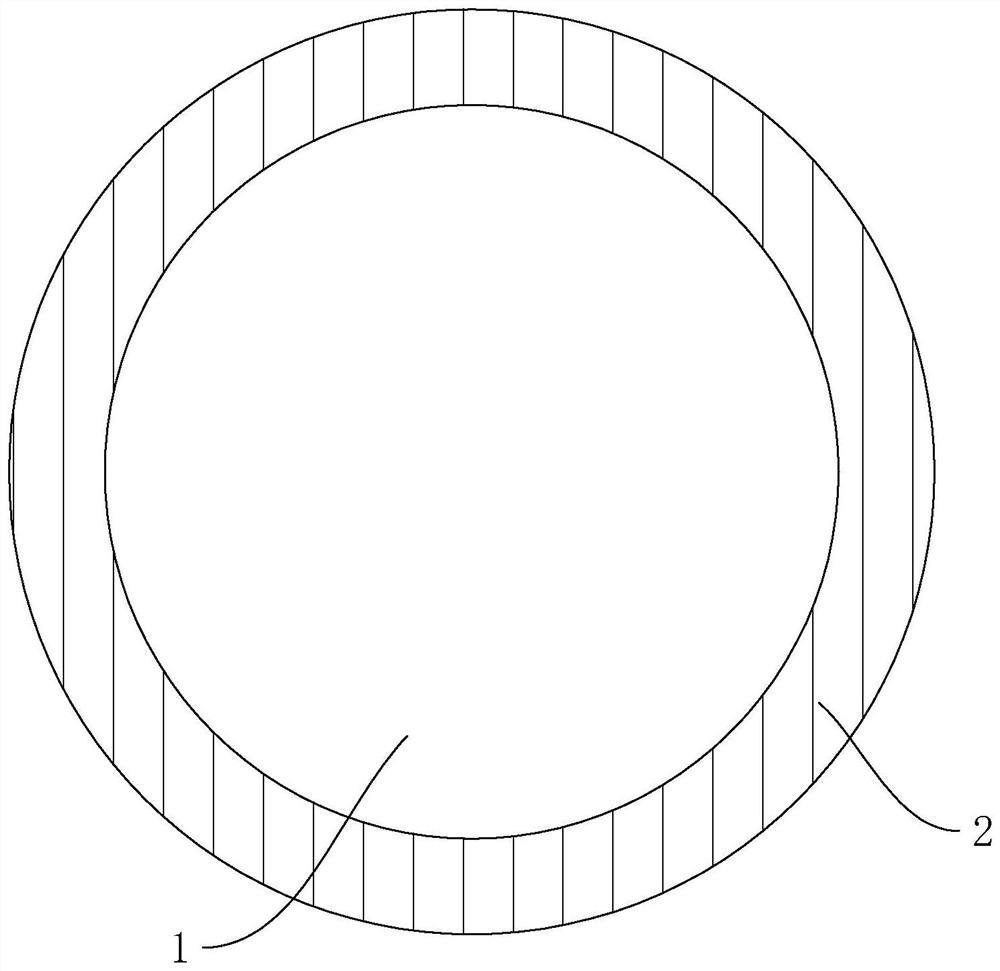

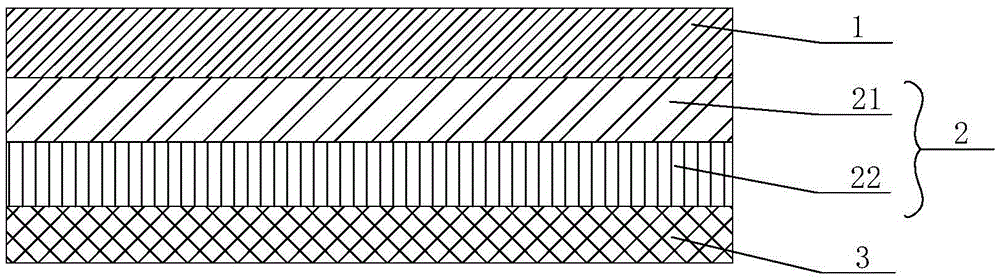

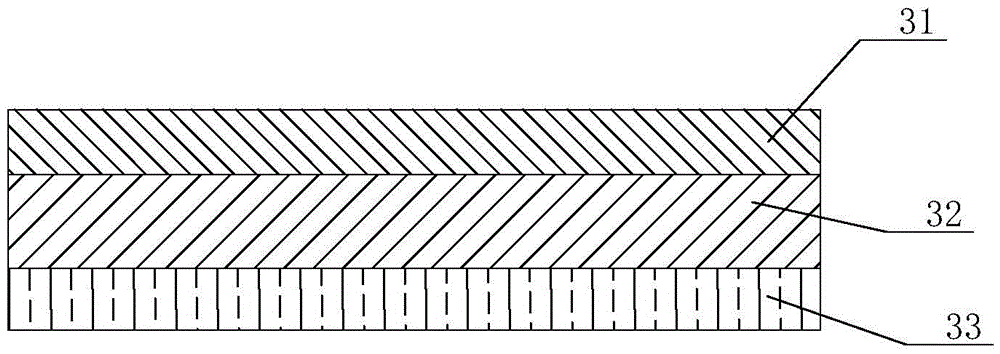

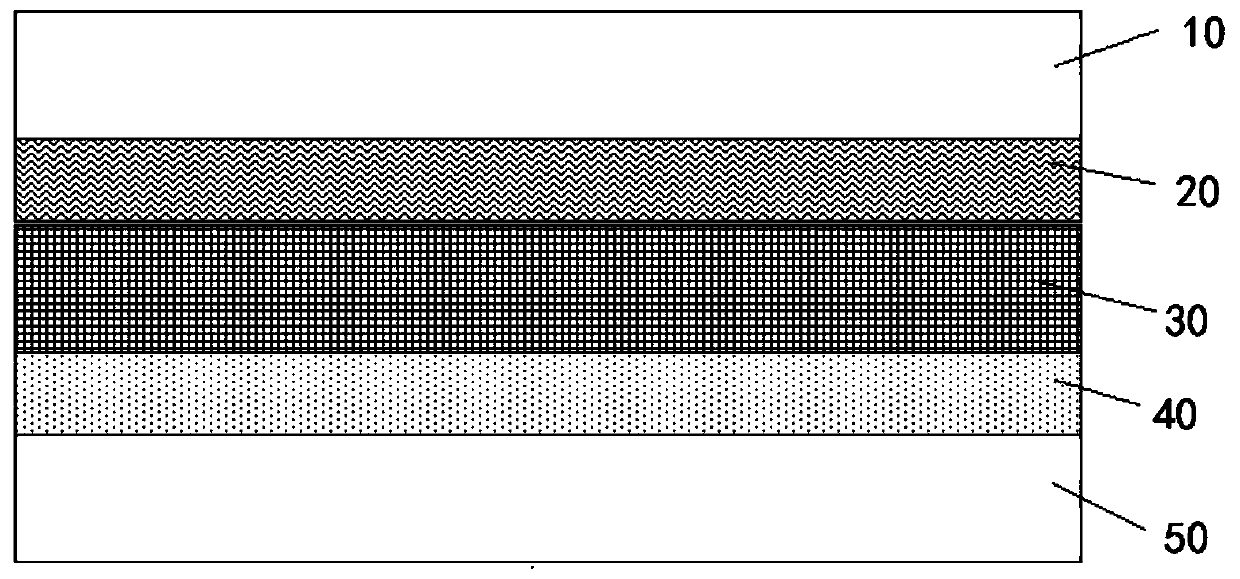

Three-layer membrane for lithium ion battery

InactiveCN103354279AGuaranteed Peel StrengthGuaranteed stabilityCell component detailsCeramic coatingHeat resistance

The application discloses a three-layer membrane for a lithium ion battery. The membrane is composed of 3 composite layers, wherein a second composite layer is interlaid between a first composite layer and a third composite layer; the first composite layer comprises at least a heat-resistance layer with a porous structure; the second composite layer comprises at least a closed layer with a porous structure; the third composite layer comprises at least a ceramic layer with a porous structure. According to the membrane, the ceramic layer is in direct contact with the closed layer with a good surface coating property, thereby ensuring the peel strength and stability of the membrane. The heat-resistance layer can be used for guaranteeing the temperature resistance and mechanical strength of the membrane. Compared with a single-layer PP microporous membrane and a composite membrane with a ceramic coating, the three-layer membrane has the advantage that the high stability and the high tearing strength are guaranteed as the coating is unlikely to fall off. Compared with a single-layer PE microporous membrane and a composite membrane with a ceramic coating, the three-layer membrane has the advantage of better high temperature resistance.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

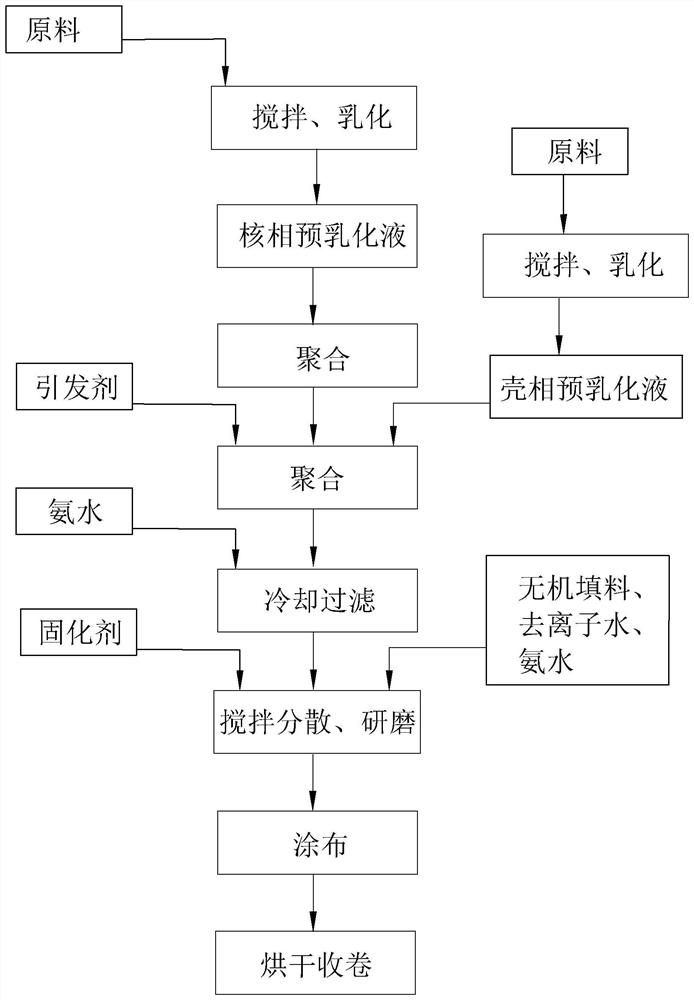

Pure adhesive film with core-shell structure and preparation method thereof

PendingCN113980587AImprove heat resistanceHigh peel strengthFilm/foil adhesives without carriersFilm/foil adhesive release linersPolymer scienceFlexible circuits

The invention relates to the technical field of flexible circuit boards, and particularly discloses a pure adhesive film with a core-shell structure and a preparation method thereof. The preparation method of the polyacrylate pure adhesive film with the core-shell structure comprises the steps: pre-emulsifying to prepare a core-phase pre-emulsion and a shell-phase pre-emulsion, then adding a cross-linking agent, polymerizing to prepare a polymerized emulsion with the core-shell structure, and then adding a curing agent, an inorganic filler and the like to prepare an adhesive; and finally coating a first release film with the adhesive, carrying out thermocompression bonding on the first release film and a second release film, and rolling to obtain the pure adhesive film with the core-shell structure. The prepared pure adhesive film with the core-shell structure has the advantages of high heat-resistant stability and high peel strength, is free of performance defects, is suitable for market popularization and use, and meets market requirements.

Owner:深圳市科泰顺科技有限公司

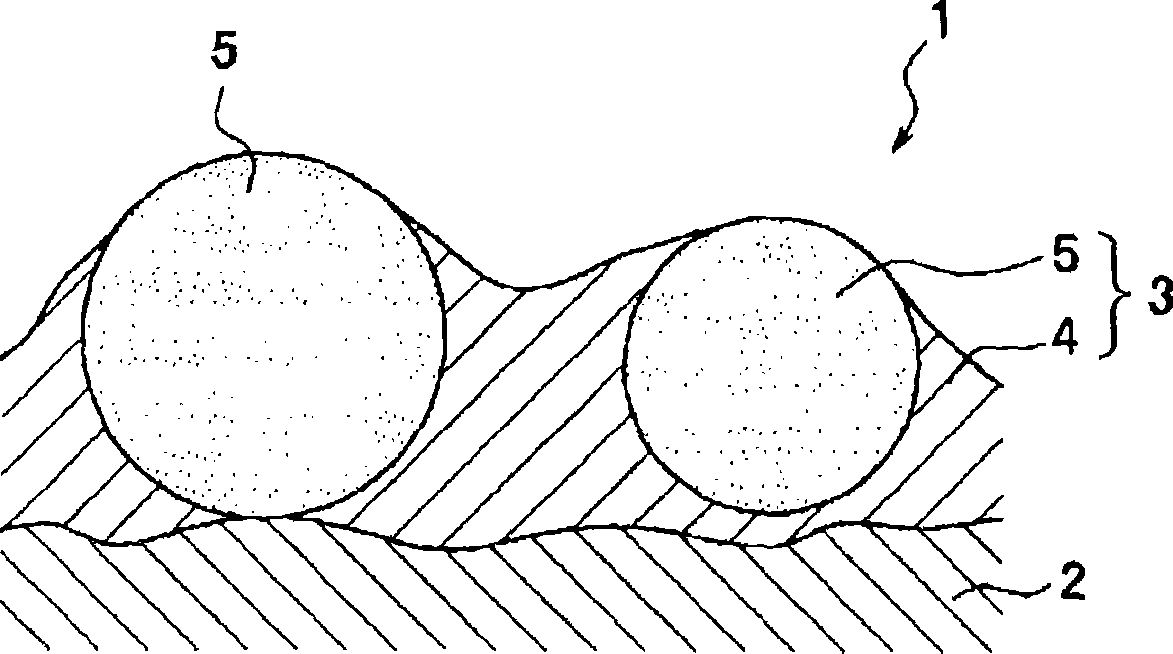

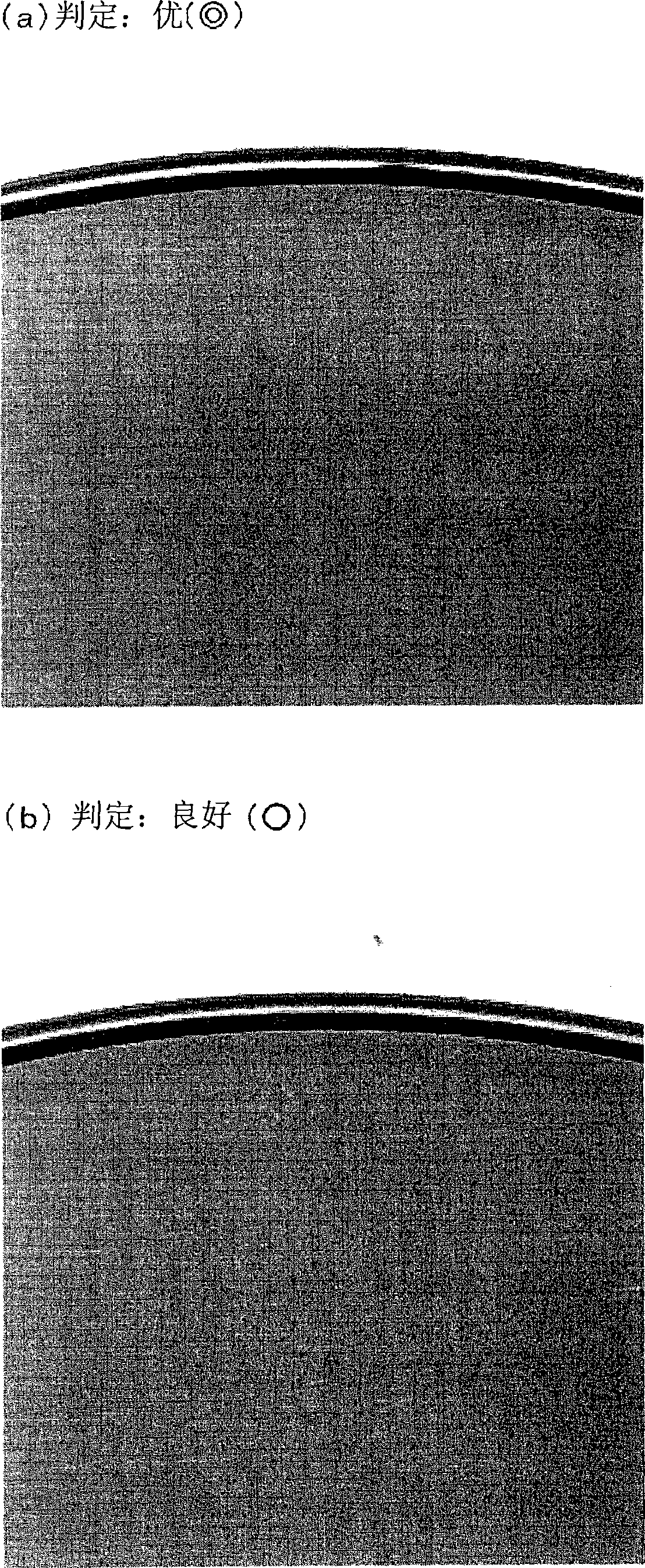

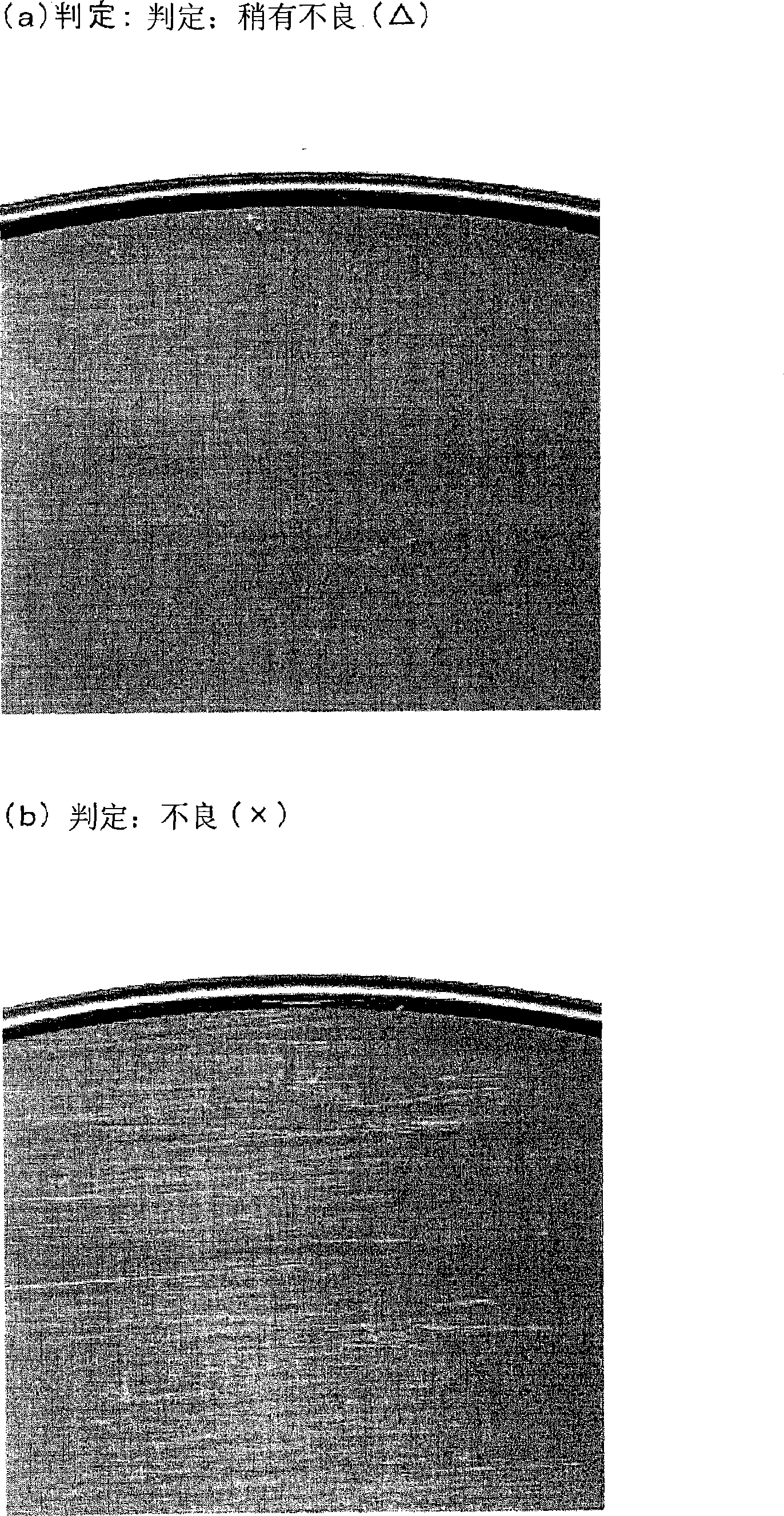

Precoated metal plate

InactiveCN101384427AGood formabilityHigh peel strengthLiquid surface applicatorsAnti-corrosive paintsResin matrixMetal

This invention provides a precoated metal plate that can prevent the occurrence of defects in an optical disk, and, at the same time, can maintain high peel strength of an adherend to a resin film, and can realize easy adhesion of the adherend to the surface of the resin film. The precoated metal plate comprises a metal plate and a resin film provided on the surface of the metal plate. The resin film comprises an epoxy resin matrix layer and soft beads dispersed in the epoxy resin matrix layer. For the soft beads, the compressive strength at single bead 10% deformation by a microcompression test is not more than 10 MPa. The content of the soft beads is not less than 5% by mass and not more than 50% by mass based on the epoxy resin matrix layer, and the average particle diameter of the soft beads is not less than 1.1 times and not more than 5 times the average thickness of the epoxy resin matrix layer.

Owner:KOBE STEEL LTD

High-resistance high-speed auto-inflation food packaging film and production process thereof

PendingCN110065269AHigh barrierHigh peel strengthFlexible coversWrappersHigh resistanceLow-density polyethylene

The invention relates to a high-resistance high-speed auto-inflation food packaging film and a production process thereof. The packaging film is formed by compounding an aluminum-plated PE film and aPET printing film in a dry mode. The aluminum-plated PE film comprises a corona layer, a middle layer and a heat seal layer. The corona layer comprises linear low density polyethylene and polycycloolefin according to the mass ratio of (83-87):(13-17). The middle layer comprises linear low density polyethylene, low density polyethylene and high density polyethylene according to the mass ratio of (48-52):(23-27):(23-27). The heat seal layer comprises low density polyethylene, an olefin plastic body, linear low density polyethylene, silicone and a processing agent according to the mass ratio of (48-52):(23-27):(23-27):(1.3-1.7):(0.1-0.3). The packaging film is suitable for meeting the requirements of a high-speed packaging device and has high resistance, low heat seal temperature, high heat seal strength, high in pressure resistance and low in broken package air leakage rate.

Owner:HUANGSHAN NOVEL

Composite salad sauce packaging membrane and preparation method thereof

InactiveCN106273955AHigh composite strengthExcellent medium resistanceSynthetic resin layered productsDomestic containersChemistryHigh-density polyethylene

The invention discloses a composite salad sauce packaging membrane and a preparation method thereof and belongs to the technical field of packaging materials. The composite salad sauce packaging membrane comprises a PET printing film layer of 12 microns, a functional polyethylene film layer of 15-20 microns and a PE film layer of 60-80 microns which are sequentially connected and tightly adhered. The functional polyethylene film layer is of a double-layer co-extrusion composite structure, and the side, bonded with the PET printing film layer, of the functional polyethylene film layer is an ethylene acrylic acidcopolymer layer. The side, bonded with thePE film layer, of the functional polyethylene film layer is a low-density polyethylene and white masterbatch blended layer, and the weight ratio of low density polyethylene to white masterbatch is 20-24 to 3. The composite salad sauce packaging membrane has the excellent properties of high sealing strength, low cost, good sealing effect, good flatness, pollution resistance and the like and also has the advantages of being goodin medium resistance effect, low in cost, not prone to layering and the like.

Owner:GUANGDONG BAOJIALI COLOR PRINTING IND CO LTD

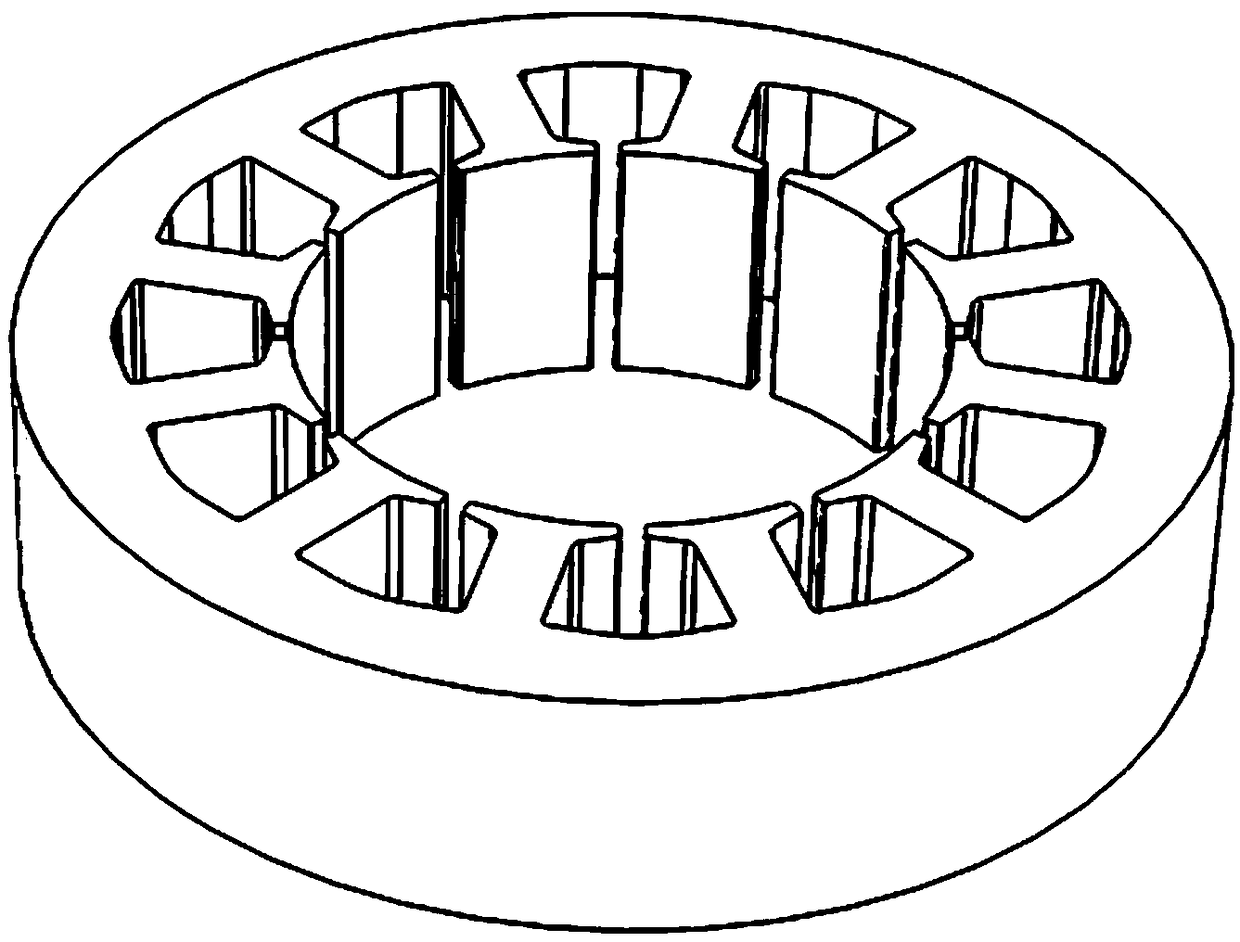

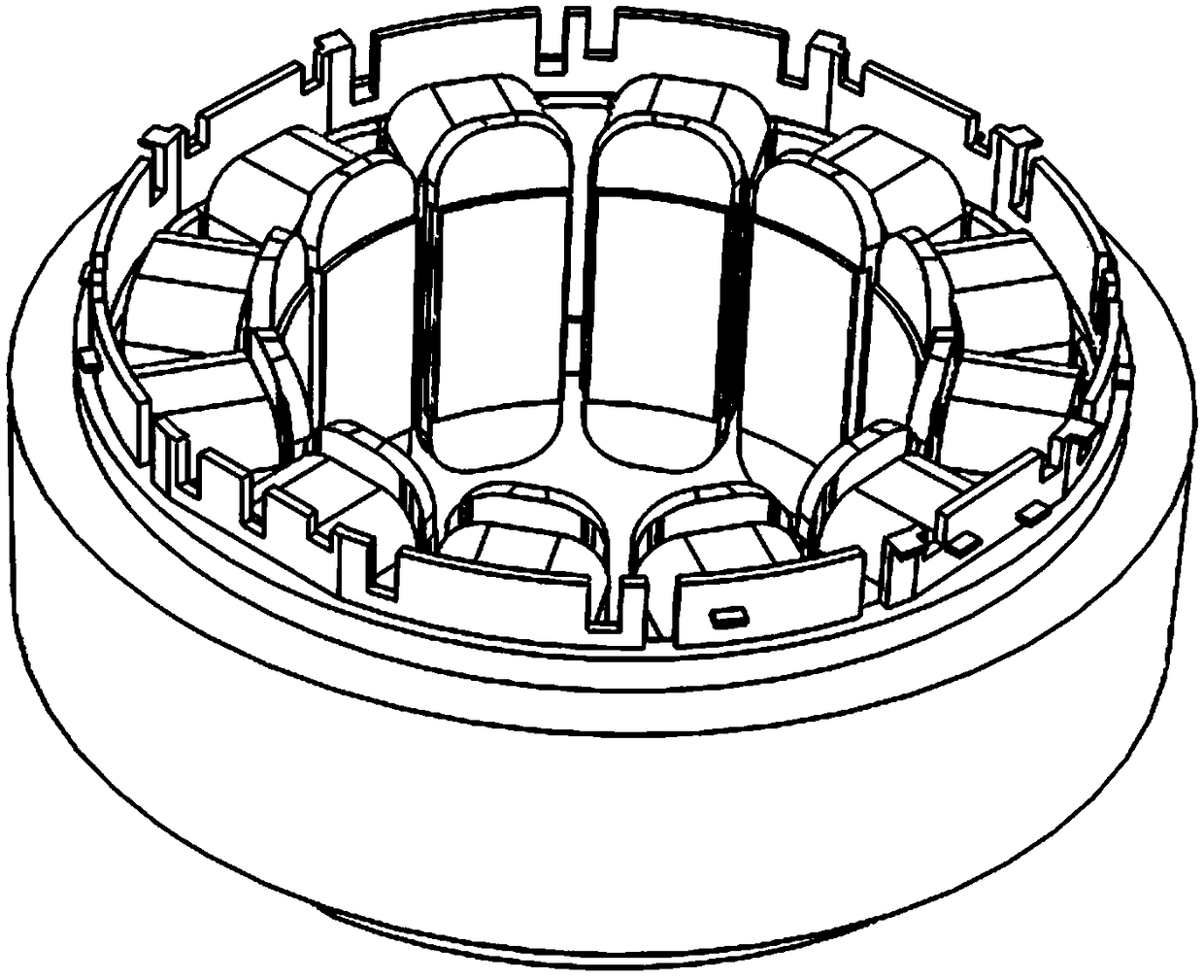

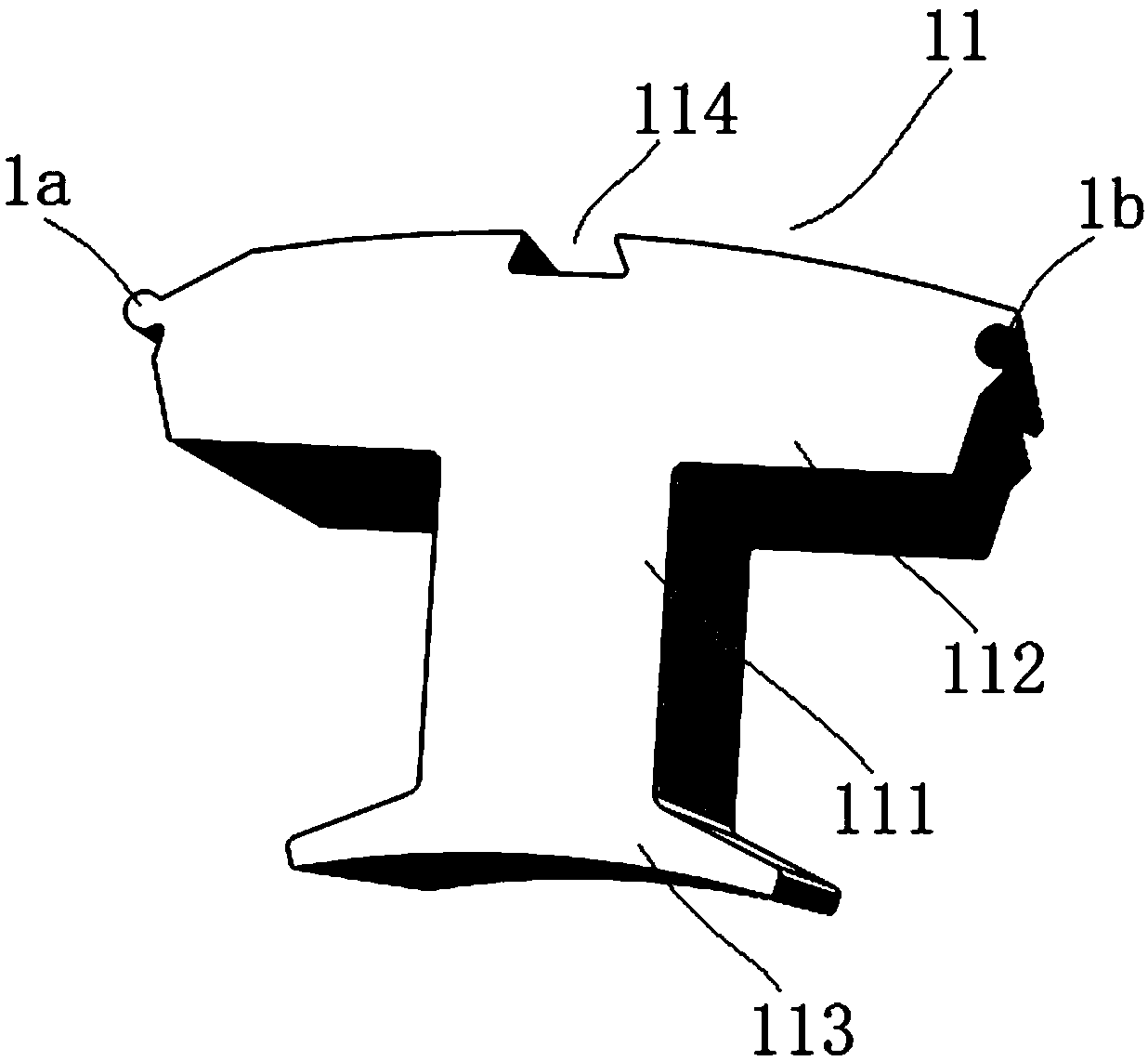

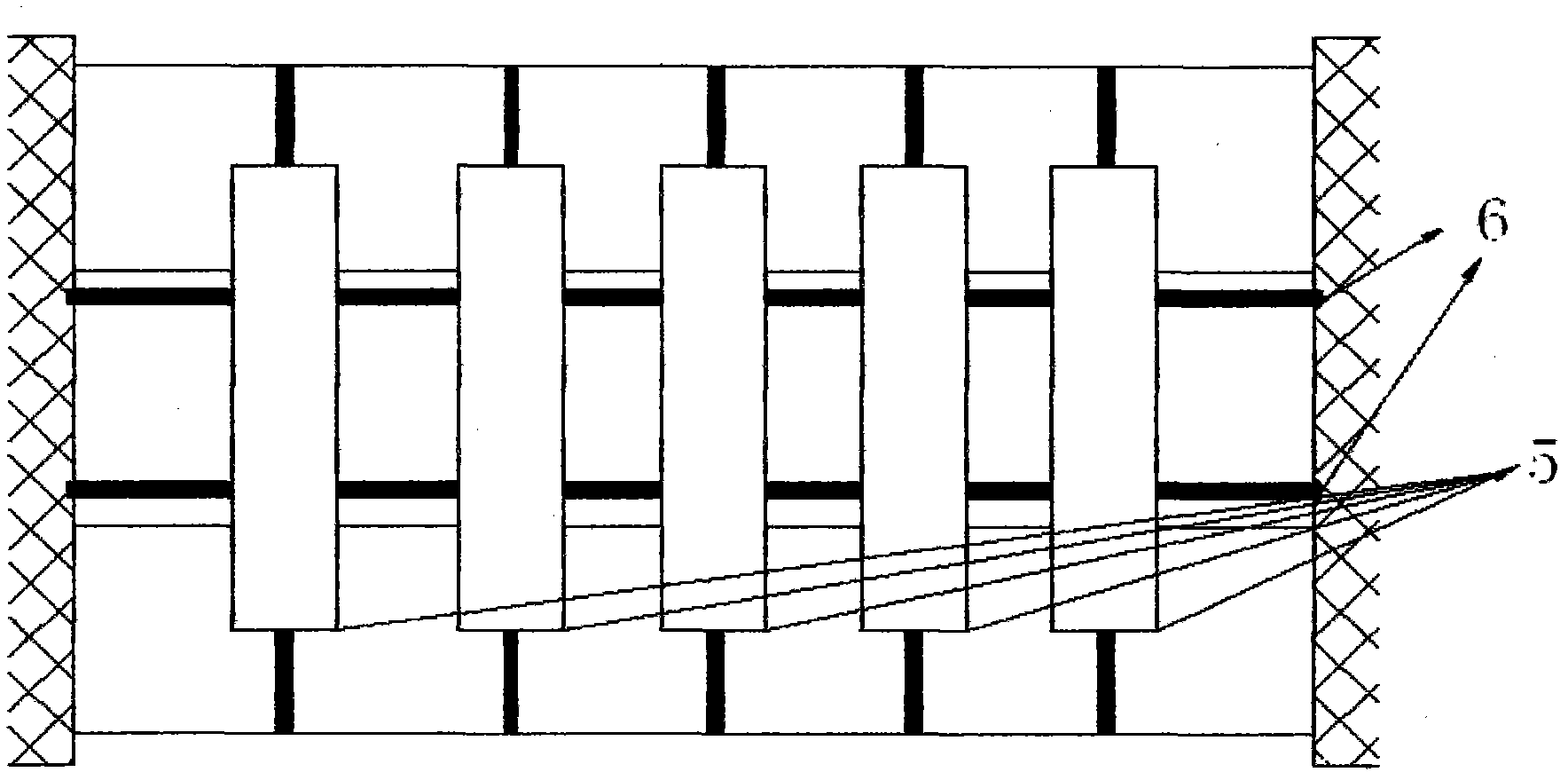

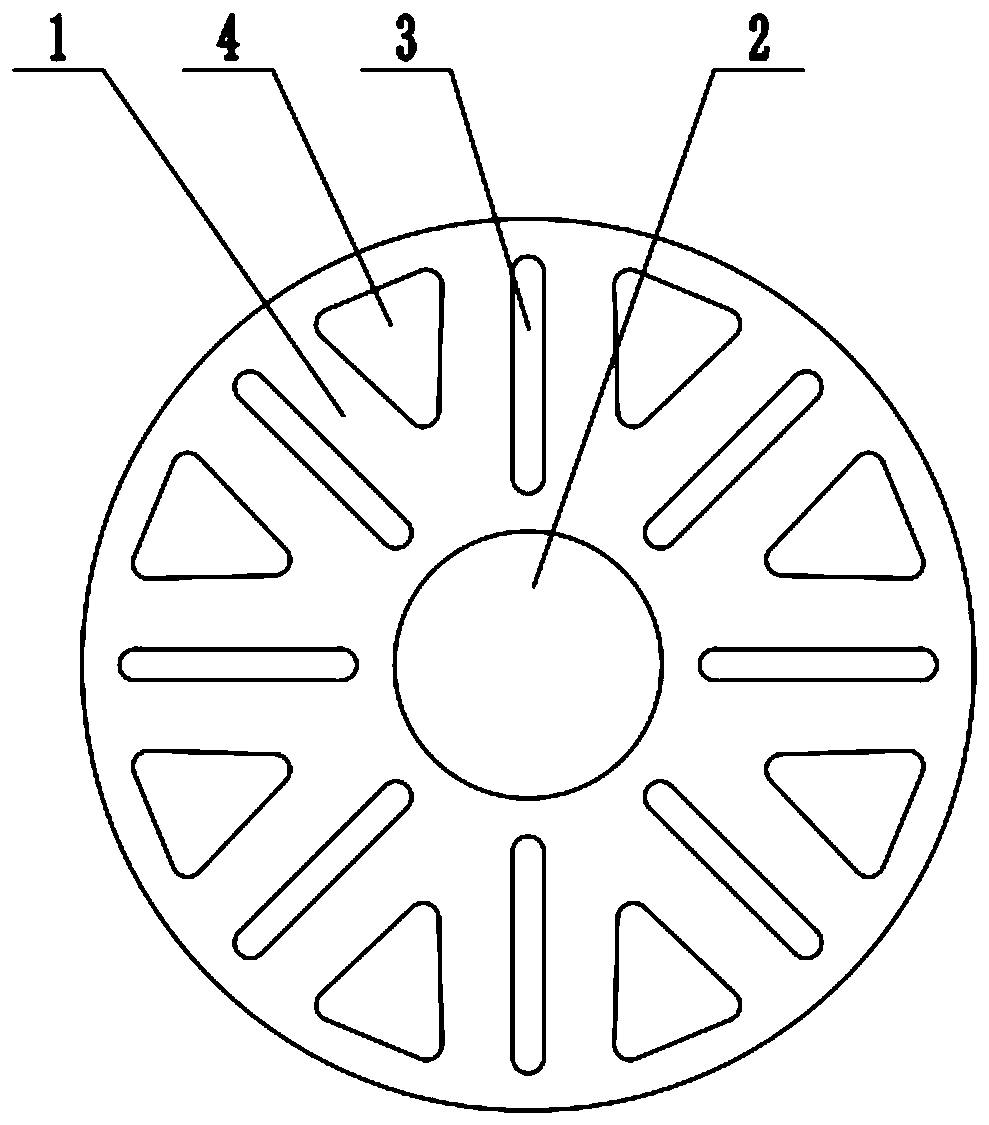

Hinge type stator and circle forming method thereof

PendingCN109412284AWill not failOptimize space layoutMagnetic circuit stationary partsManufacturing stator/rotor bodiesManufacturing cost reductionStator coil

The invention discloses a hinge type stator structure, and relates to the field of motors. At present, a circle forming method of a motor stator structure generally adopts welding, and the cost is high, and a welding process generates large amount of heat, which affects insulation performance of the motor. The hinge type stator comprises a stator core and a stator coil. The stator core is formed by assembling a plurality of stator core blocks with grooves and flanges on two ends through the grooves and the flanges in sequence. Each stator core block is formed by stator teeth, a stator yoke anda pole shoe. A gap between two adjacent stator core blocks forms a stator slot, and the stator coil is wound around the stator teeth through the stator slot. The stator core blocks on the head and the tail, which are wounded with the stator coils, are embedded with each other through the grooves and the flanges to form the hinge type stator. The circle forming method of the technical scheme is very simple, and the stator core has high torsional strength after being rounded, and inner and outer roundness of the stator core is good, and a conventional welding process is not required. The methodreduces manufacturing cost, and effectively improves comprehensive performance of the motor.

Owner:WOLONG ELECTRIC GRP CO LTD +1

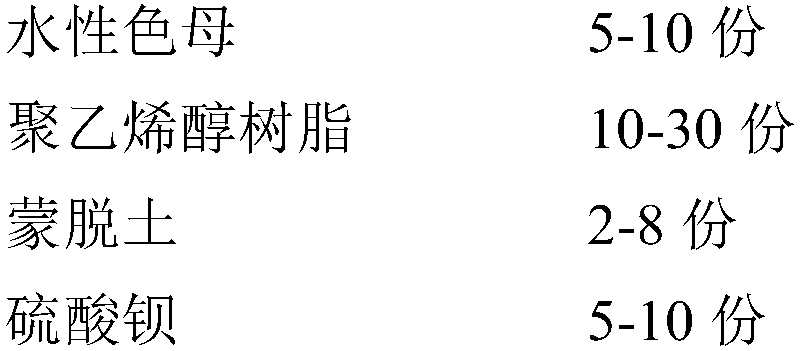

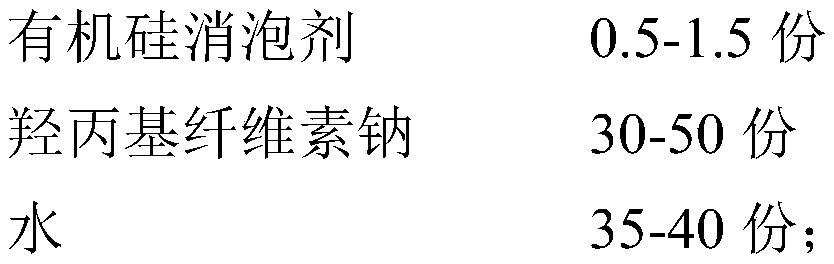

Aqueous ink PVC floor

The invention discloses an aqueous ink PVC floor. The aqueous ink PVC floor is composed of an aqueous ink layer, a PVC floor film layer and a PVC wear-resistant sheet layer. Water-based ink patterns are transferred and printed on the PVC floor film layer, the PVC floor film layer and PVC wear-resistant sheets are laminated through a rolling hot press at 130 DEG C, and the laminated product is cooled to the room temperature so that the PVC floor is obtained. The aqueous ink has a superior formula so that the printing quality and the peeling strength of the PVC floor film and the PVC wear-resistant sheet are guaranteed.

Owner:江苏尚珩达科技有限公司

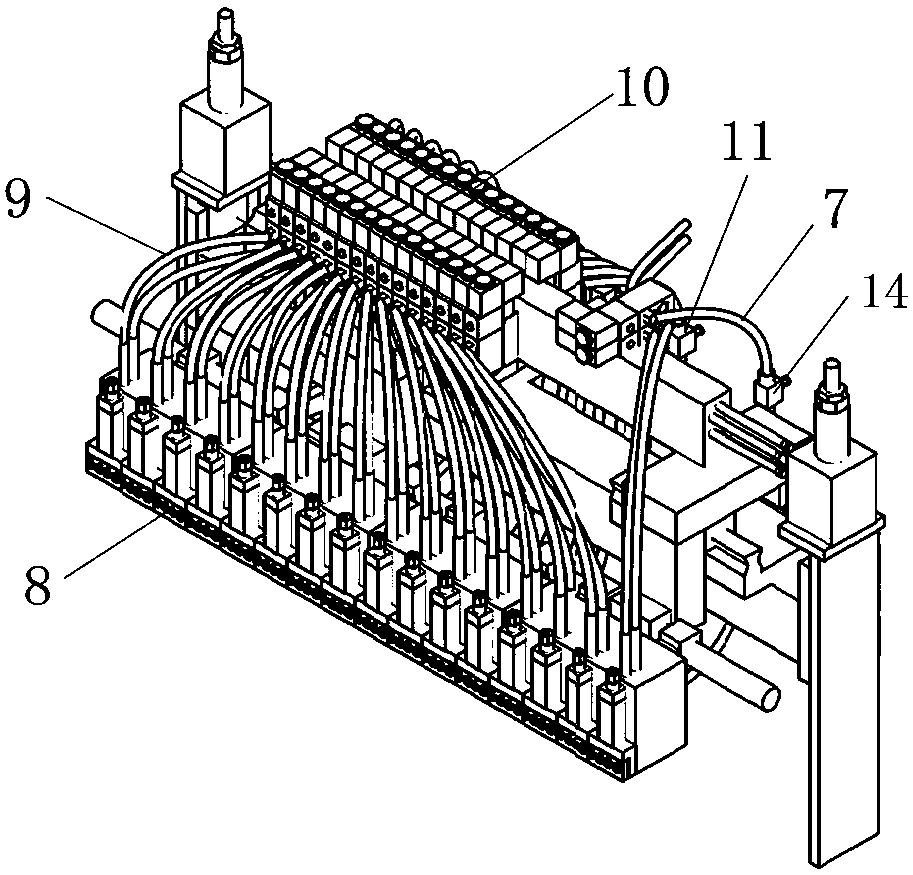

Non-gel double-faced flexible copper clad laminate production equipment

InactiveCN107841718ANo oil returnIncrease pumping speedVacuum evaporation coatingSputtering coatingIon bombardmentSurface roughness

The invention discloses non-gel double-faced flexible copper clad laminate production equipment. The non-gel double-faced flexible copper clad laminate production equipment comprises a vacuum cavity and winding and unwinding systems. A target electrode vehicle is arranged on one side of the vacuum cavity, a target electrode is arranged on the target electrode vehicle, and a second sealing elementis arranged between the target electrode vehicle and the vacuum cavity. The non-gel double-faced flexible copper clad laminate production equipment has the beneficial effects that (1) the cavity is ina circular shape, an air exhaust dead angle cannot be formed, and the vacuum degree is even; a vacuum obtaining system is a molecular pump oil-free system, and it is ensured that no return oil existsin a vacuum chamber; a configured cryogenic pump can increase the pumping speed of base material air bleeding in the continuous film plating process, and therefore the working efficiency is improved;(2) the double winding and unwinding systems are adopted, the requirements for full-width one-roll double-faced plating and two-roll single-faced plating of a magnetron sputtering area can be met, the requirements for half-width two-roll single-faced plating and double-faced plating of a plating area can further be met, and the functions are comprehensive; and (3) an ion source treatment device is arranged at the position entering the magnetron sputtering area, ion bombardment is conducted on the surface of a base material, the roughness of the surface of the base material is improved, and the peel strength of a film and the base material is ensured.

Owner:深圳市西陆光电技术有限公司

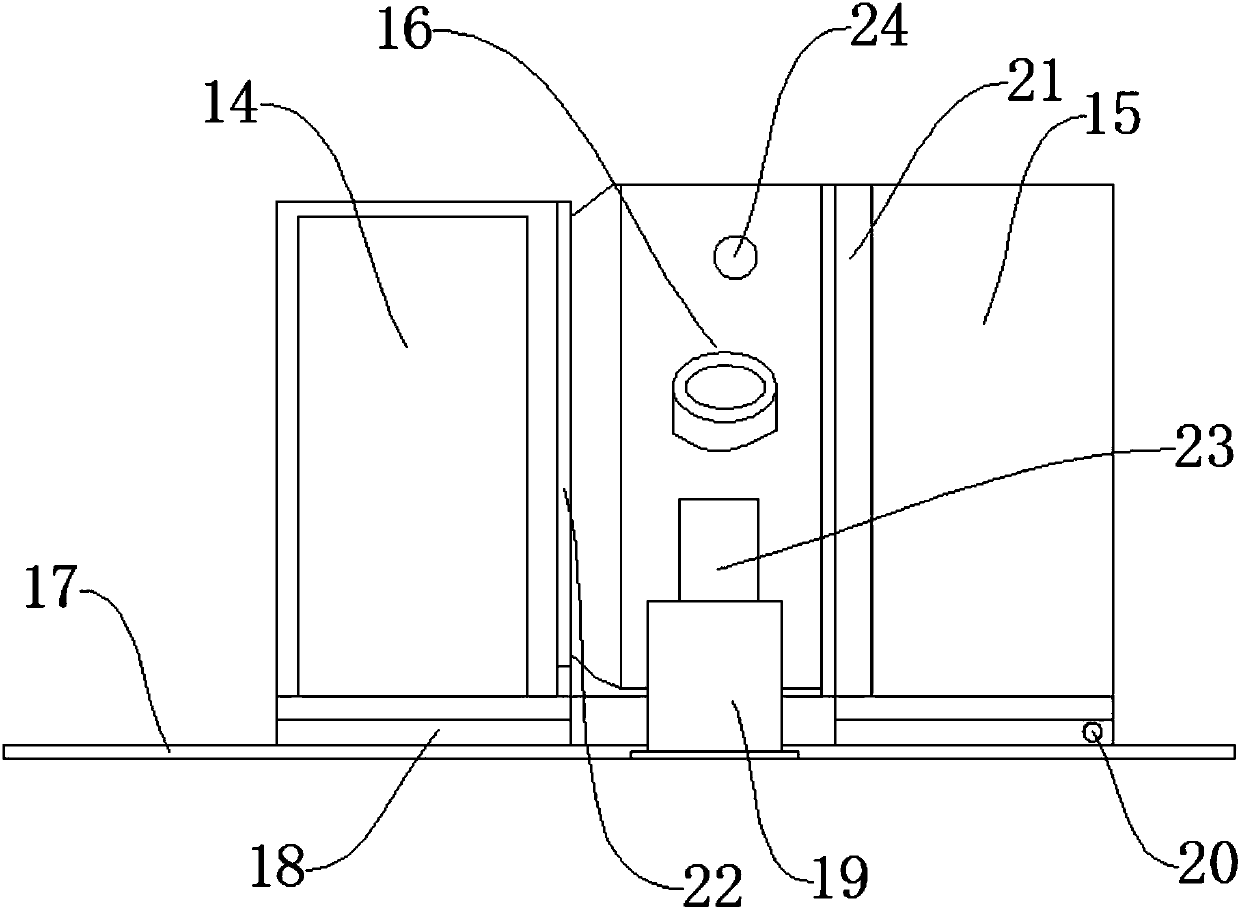

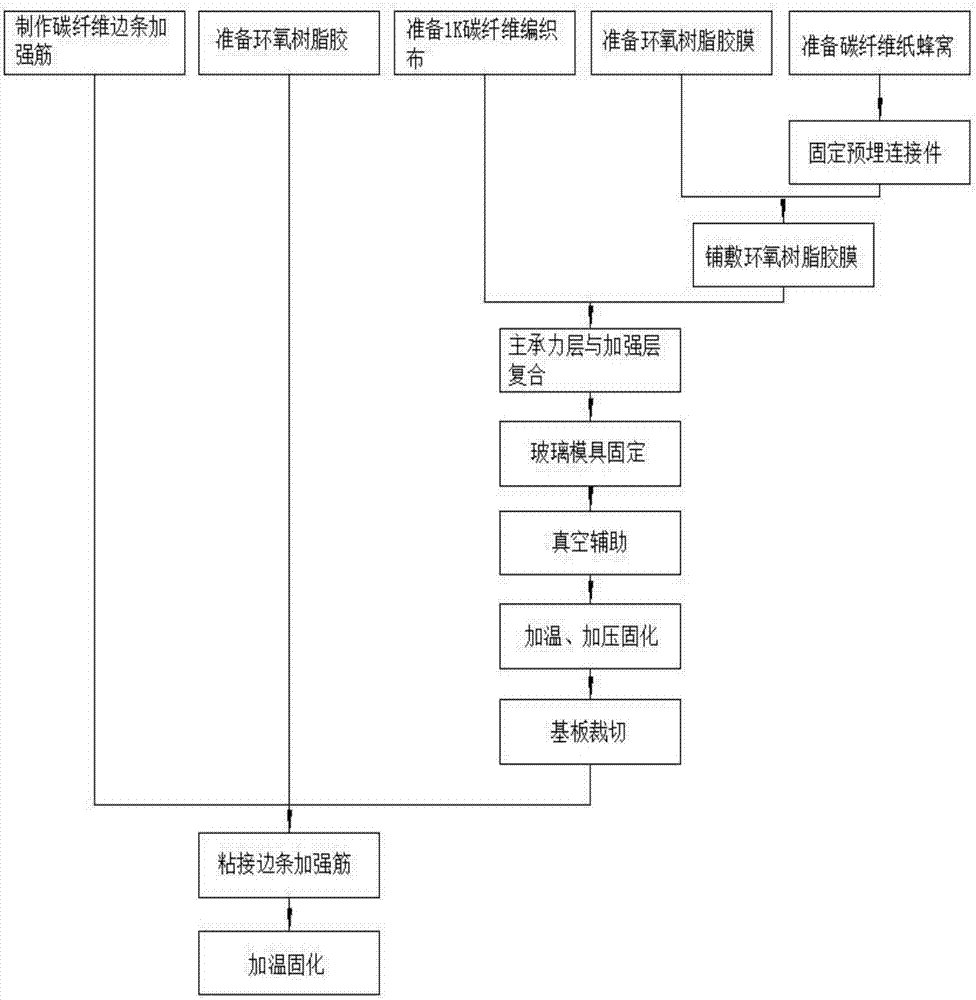

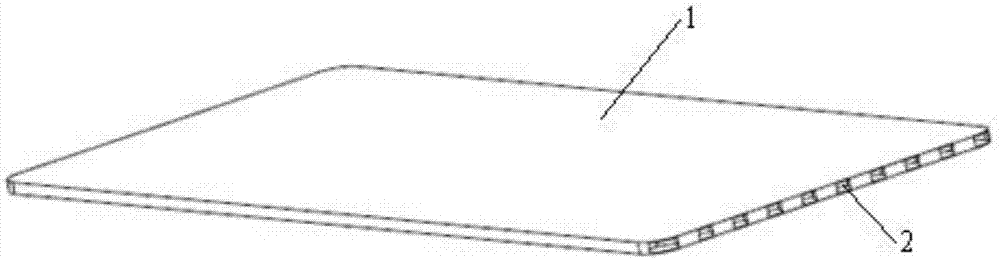

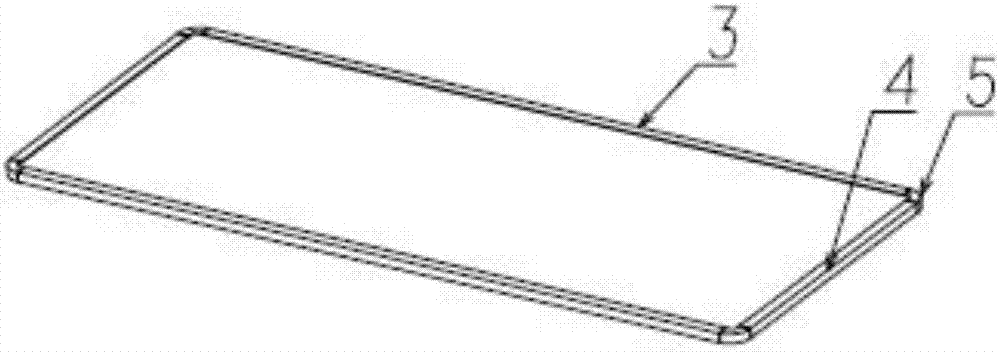

Manufacturing method of composite material ultra-light solar cell substrate

InactiveCN107039561AQuality improvementHigh strengthPhotovoltaic energy generationSemiconductor devicesCarbon fibersHoneycomb

The invention belongs to the technical field of a stratospheric aircraft and especially relates to a manufacturing method of a composite material ultra-light solar cell substrate. The method comprises the following steps: according to design requirements of the solar cell substrate, preparing edge reinforcing ribs, wherein the edge reinforcing ribs comprise long edge reinforcing ribs, short edge reinforcing ribs and round corner reinforcing ribs; according to laying requirements of the solar cell substrate, preparing carbon fiber pre-preg cloth; according to the requirements of the solar cell substrate, pre-burying and fixing connection members at the corresponding positions of an aramid paper honeycomb, wherein the connection members are obtained by machining a polycarbonate sheet; and paving epoxy resin adhesive films onto the upper and lower surfaces of the pre-burying-finished aramid paper honeycomb. The advantages are that a new method is provided for preparing the solar cell substrate of the stratospheric aircraft; the process is relatively simple; the finished product is good in quality, high in intensity and light in weight; and the manufacturing method is high in manufacturing efficiency.

Owner:青岛三合兴华科技发展有限公司

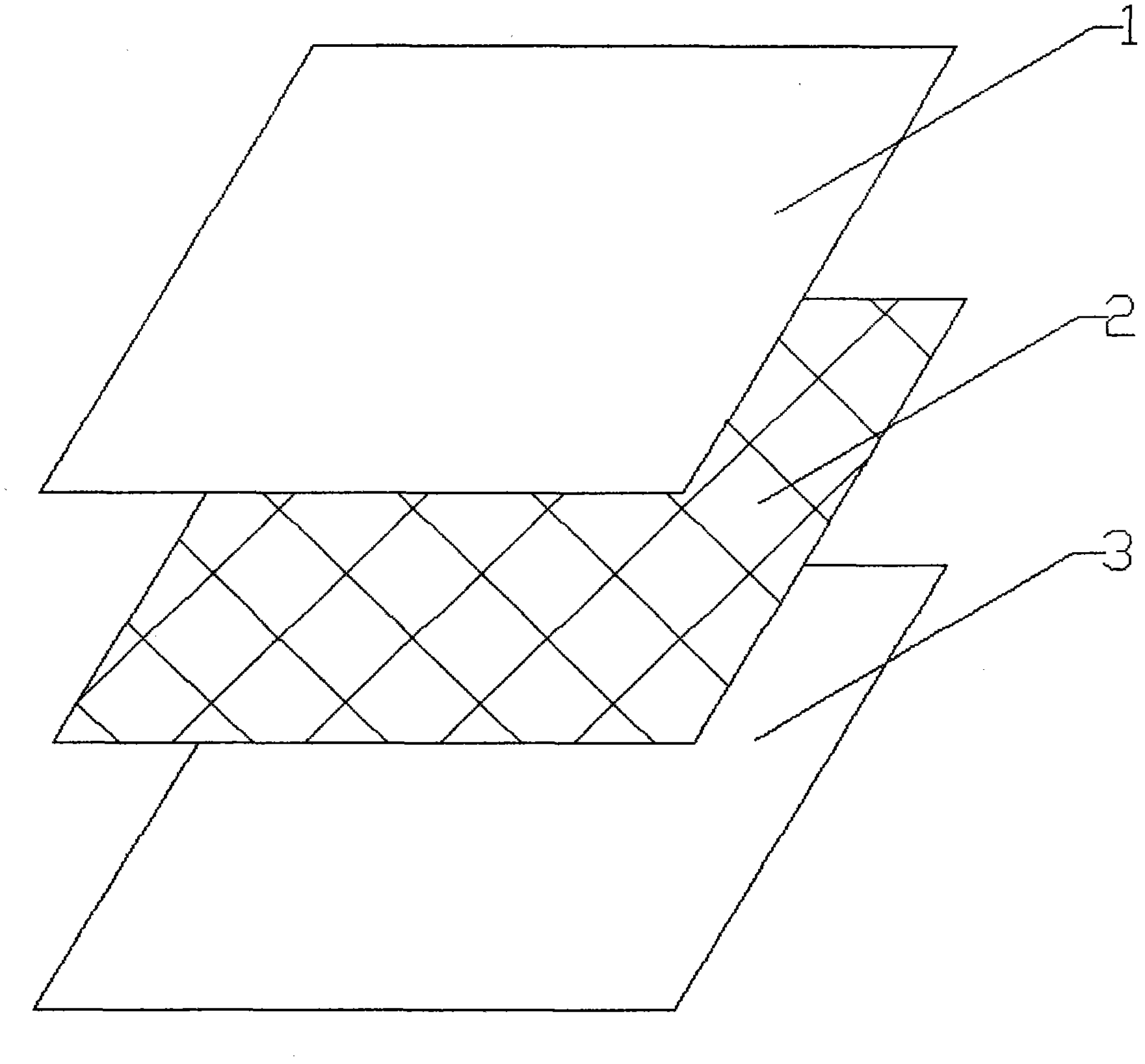

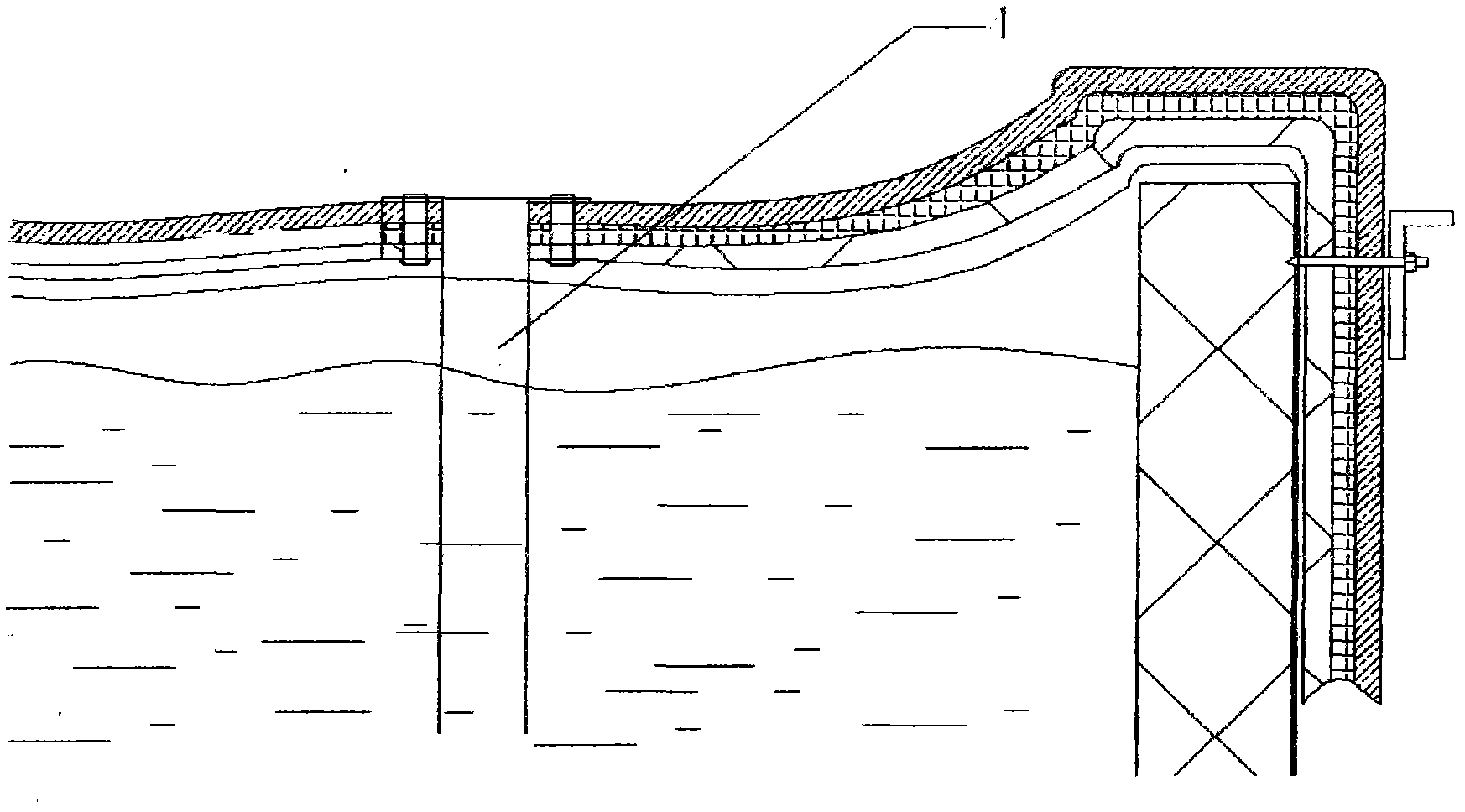

Anti-aging thermal-insulation sealing tent cover for float type sewage pool

ActiveCN102627347ASolve insulation problemsGuaranteed tensile strengthTreatment with anaerobic digestion processesEnergy based wastewater treatmentReinforced concreteThermal insulation

The invention relates to an anti-aging thermal-insulation sealing tent cover for a float type sewage pool, which comprises a tent body of a multilayer structure. The tent body at least comprises a sunshine anti-aging layer, a thermal-insulation layer and an anticorrosion layer which are sequentially arranged from top to bottom, wherein the sunshine anti-aging layer is made of building membrane materials, the thermal-insulation layer is made of foam thermal-insulation materials, and the anticorrosion layer is made of plastic plates. The anti-aging thermal-insulation sealing tent cover is free of steel structures, reinforced concrete and complex processes, low in cost, convenient in construction and especially suitable for sealing of used sewage pools and methane recovery of anaerobic sewage pools. The anti-aging thermal-insulation sealing tent cover can effectively resolve the problems of thermal-insulation sealing of sewage pools, foul gas environmental pollution reduction, sewage treatment methane recovery, sewage plant environment beautification, and the like.

Owner:德州六顺电气自动化设备有限公司

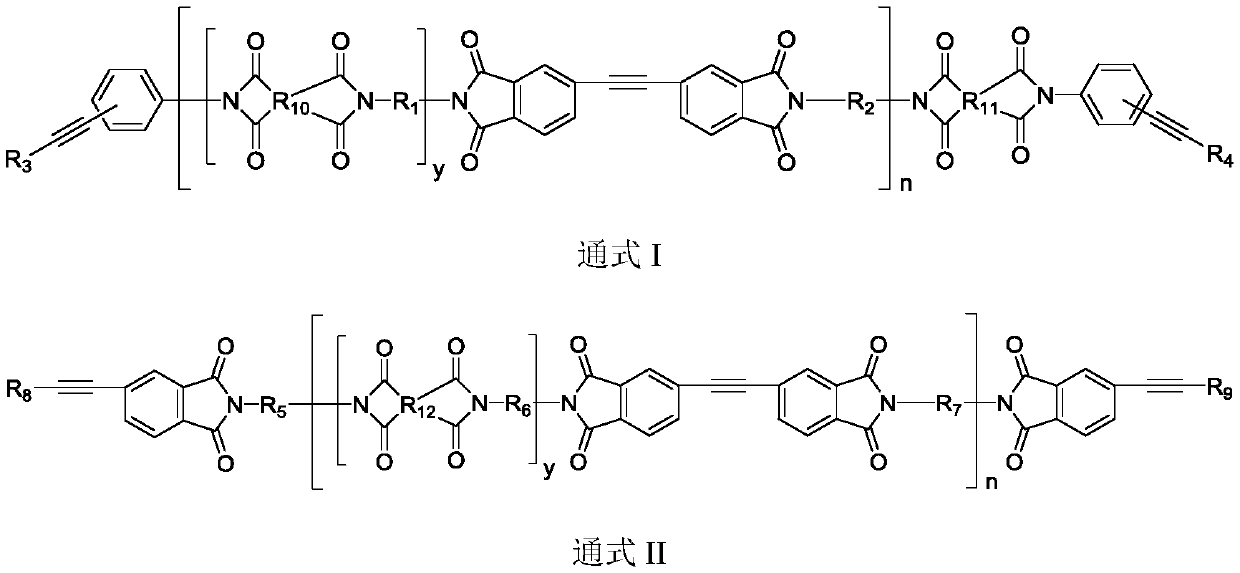

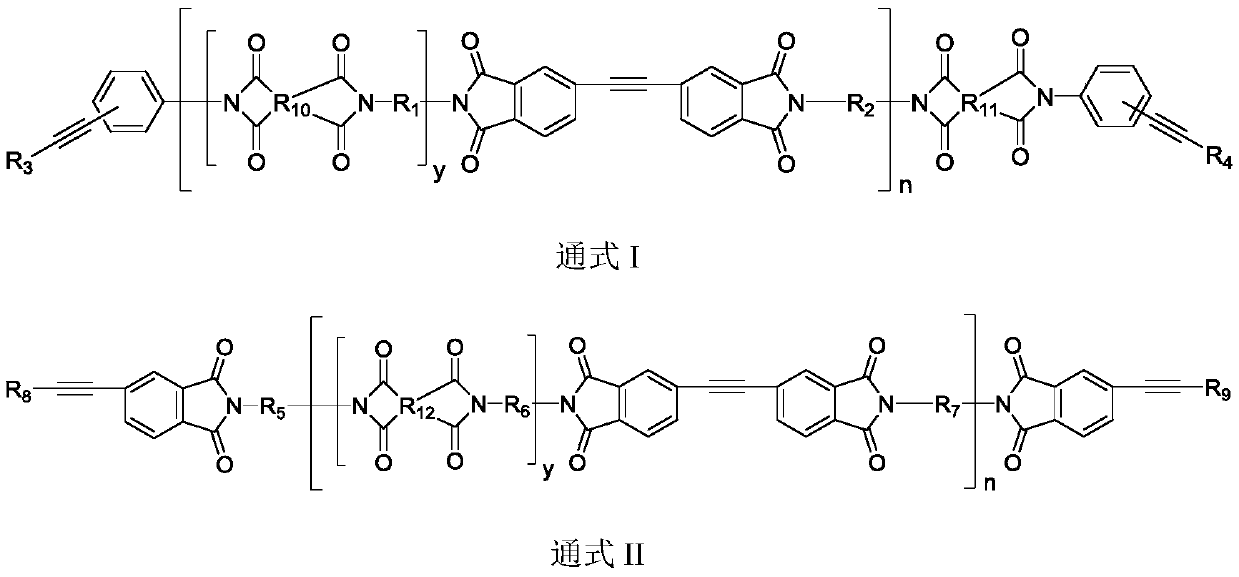

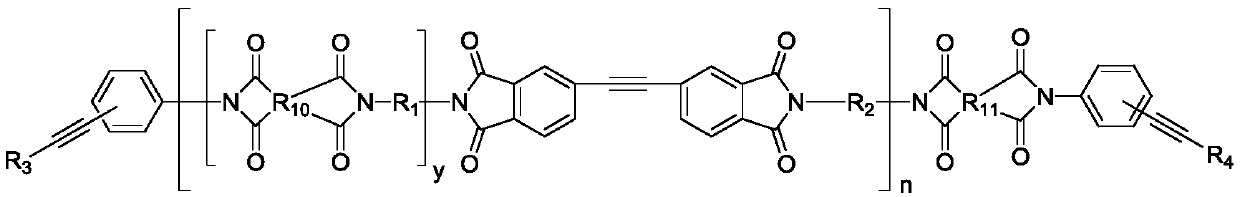

Polyimide, preparation method of precursor solution of polyimide and double-sided flexible copper-clad plate

ActiveCN111533908AImprove thermal conductivityEasy cross-linkingLaminationLamination apparatusImidePolymer science

The invention provides polyimide, a preparation method of a precursor solution of polyimide and a double-sided flexible copper-clad plate. Structural formula of the polyimide is shown as a general formula I or a general formula II, on one hand, the number of alkynyl groups inside and at the end of a polyimide molecular chain is increased; the density of crosslinking sites is improved, and the net-shaped structure formed after crosslinking forms a crystal-like structure in the microstructure of the polyimide, so that the heat conductivity coefficient of the polyimide is improved, and the production efficiency and the production speed of laminating preparation of the double-sided flexible copper-clad plate are improved; and on the other hand, the molecular chain rigidity strength and the glass-transition temperature of the polyimide resin can be adjusted by controlling the groups R1, R2, R5, R6, R7, R10, R11 and R12, so that the peeling strength, the tensile strength and the tensile modulus of the double-sided flexible copper-clad plate product are guaranteed, and meanwhile, the double-sided flexible copper-clad plate product also has good folding resistance.

Owner:HANGZHOU FIRST ELECTRONIC MATERIAL CO LTD

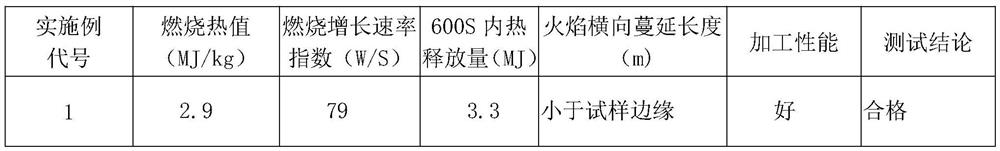

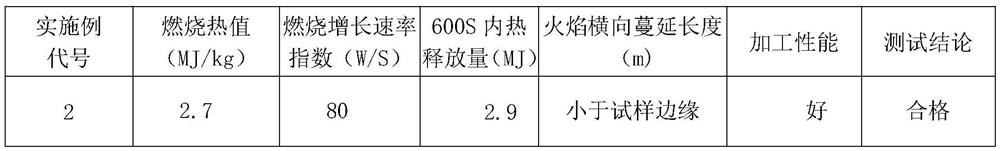

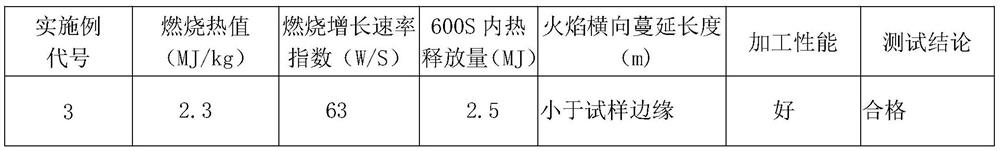

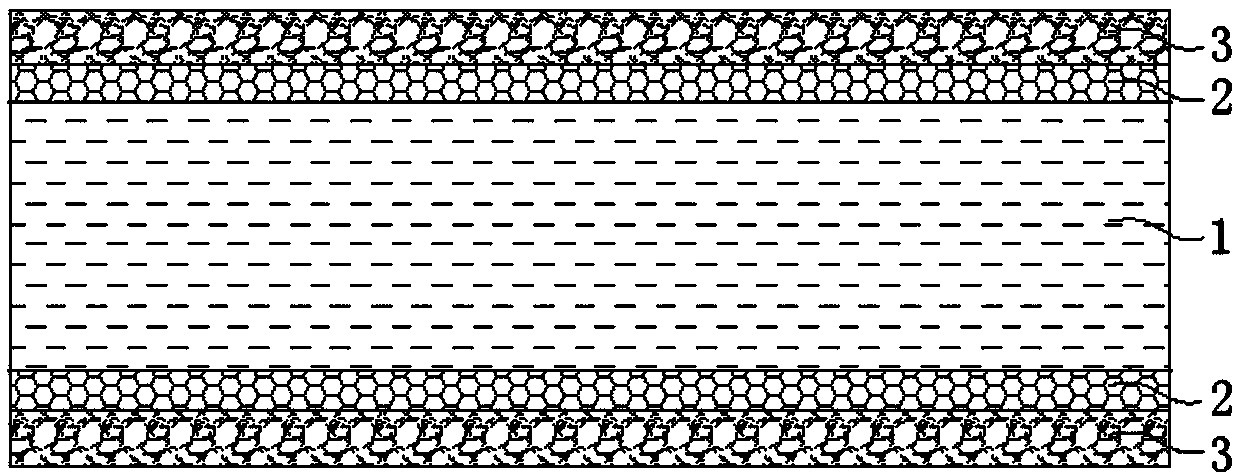

Fireproof core material and manufacturing method

The invention provides a fireproof core material and a manufacturing method. According to the fireproof core material, water-based emulsion is mixed with powder such as calcium carbonate, a flame retardant and the like, the use amount of the emulsion is reduced by reasonably matching the proportion of thick particles and fine particles of inorganic powder, the strength is ensured while the heat value of the material reaches the A2 standard requirement, and the fireproof effect is achieved; due to the fact that the flame-retardant components are all selected from inorganic powder particles, the flame-retardant components can synchronously extend along with the emulsion along with heating softening of the water-based emulsion condensate, so that corresponding toughness is provided, and bending and coiling are achieved; and the fireproof core material can meet the A2-level fireproof requirement, and can be continuously bent and rolled to be packaged and transported, so that the transportation and subsequent processing cost is effectively reduced.

Owner:JIANGSU ALUMEIGE NEW MATERIALS +1

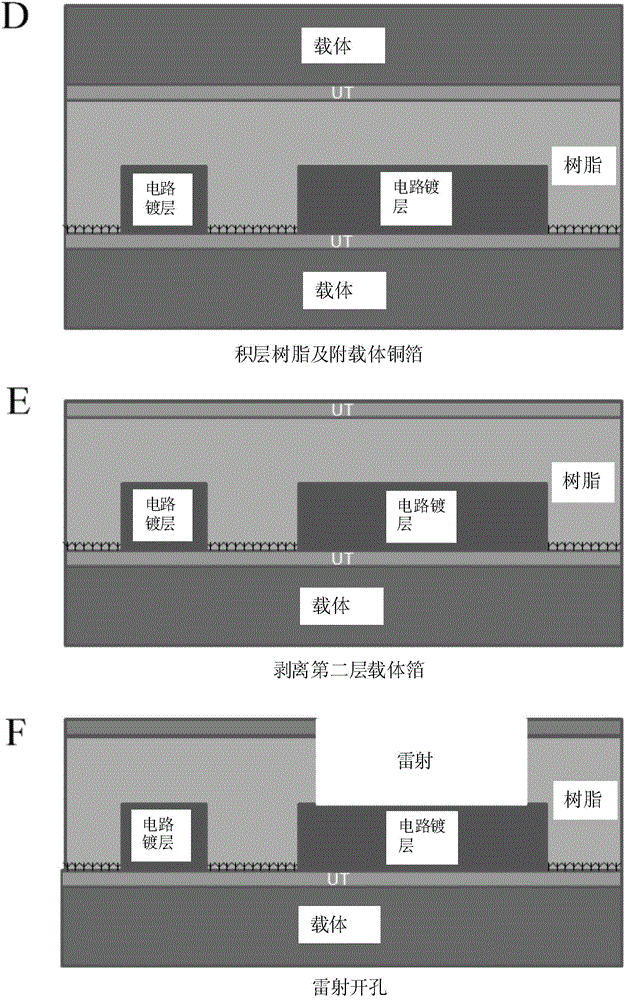

Method for preparing flexible copper clad laminate

InactiveCN109097751AHigh peel strengthGuaranteed Peel StrengthVacuum evaporation coatingSputtering coatingSputteringCopper foil

The present invention provides a method for preparing a flexible copper clad laminate. The flexible copper clad laminate comprising a base film layer, a sputter layer disposed on at least one surfaceof the base film layer, and a conductive copper foil arranged on the surface of the sputter layer, wherein the copper foil is disposed on the surface, away from the substrate film layer, of the sputter layer. The method for preparing the flexible copper clad laminate comprises the steps of: providing a base film layer, conducting corona treatment on the surface of the base film layer to obtain a surface-modified base film layer; depositing copper on the surface of the surface-modified base film layer through magnetron sputtering to form a sputter layer; and electroplating copper on the surfaceof the sputter layer to prepare a copper foil, wherein the copper electroplating is realized by two times of acid copper precipitation processes.

Owner:SHENZHEN KNQ SCI & TECH CO LTD

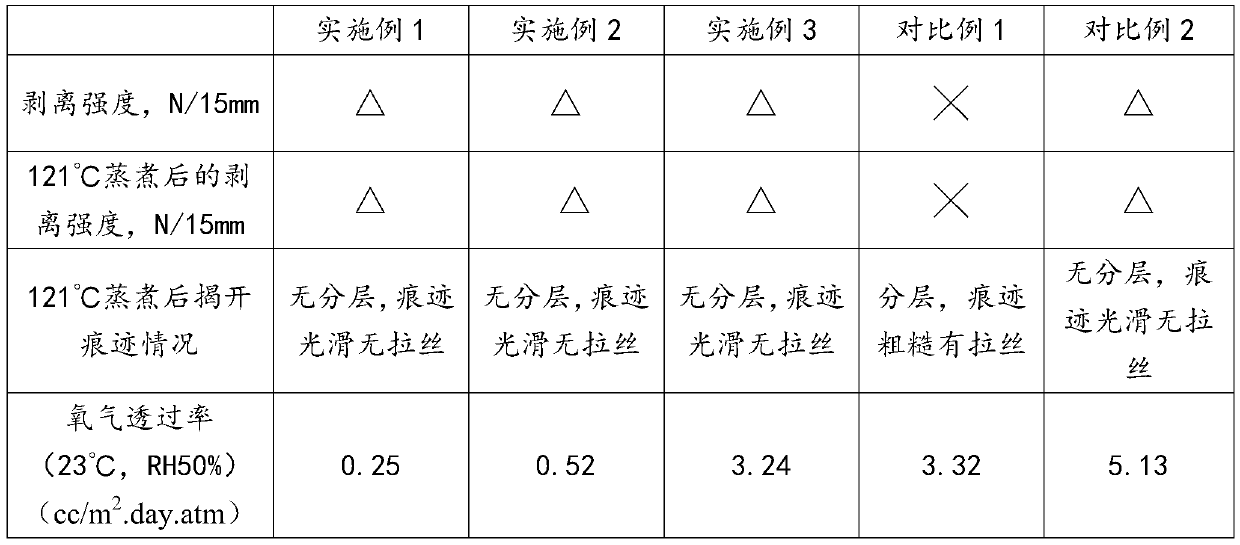

High-temperature cooking-resistant easy-peeling high-barrier nylon composite film and preparation method thereof

ActiveCN110588120AAchieving zero emissionsReduce pollutionSynthetic resin layered productsDomestic containersPolymer scienceComposite film

The invention relates to the field of flexible packaging materials, in particular to a high-temperature cooking-resistant easy-peeling high-barrier nylon composite film and a preparation method thereof. The composite film includes a modified polypropylene layer, an adhesive layer, a first barrier layer, a second barrier layer and a nylon layer from top to bottom, wherein the modified polypropylenelayer comprises homo-polypropylene, an ethylene-acrylic copolymer, a styrene block copolymer, a poly(4-methyl-1-pentene) structure unit-containing copolymer and other additives, high-temperature-resistant homo-polypropylene is adopted by the homo-polypropylene, the first barrier layer comprises copolymerized nylon and modified polyvinyl alcohol resin, and the second barrier layer is composed of EVOH and amorphous nylon resin. The nylon composite film has high oxygen barrier performance, and can withstand high-temperature cooking at 121 DEG C, and no delamination, no fiber drawing and uncovered smooth marks are generated after high-temperature cooking is performed; and the heat-sealing strength is appropriate when the nylon composite film is combined with a polypropylene sheet, easy uncovering is achieved, zero emission of VOCs is achieved, and the nylon composite film can be widely applied to food packaging and other fields.

Owner:厦门长塑实业有限公司

A kind of hot-melt pressure-sensitive adhesive for PVC electrical tape and preparation method thereof

ActiveCN105754526BGuaranteed Peel StrengthHigh peel strengthMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesPlasticizerThermoplastic elastomer

The invention discloses a hot-melt pressure-sensitive adhesive for PVC electrical adhesive tape and a preparation method.The hot-melt pressure-sensitive adhesive for the PVC electrical adhesive tape is prepared from, by weight, 10-100 parts of thermoplastic elastomers, 15-100 parts of tackifying agent, 5-50 parts of softener and 0.4-1.5 parts of antioxidant.According to the prepared hot-melt pressure-sensitive adhesive for the PVC electrical adhesive tape, the product is solid, the polarity of the adhesive is appropriate, migration of a plasticizer can be effectively resisted, the hot-melt pressure-sensitive adhesive is prevented from moving to the back of a membrane, and environment friendliness is good.Moreover, due to the fact that the prepared hot-melt pressure-sensitive adhesive is 100% solid without a solvent, cost is low, and after repeated tests in a laboratory and long-time storage on the PVC membrane, the hot-melt pressure-sensitive adhesive still has good pressure sensitivity.Besides, the preparation method of the hot-melt pressure-sensitive adhesive is simple, energy consumption is low, and work efficiency is high.

Owner:KUNSHAN JIUQING PLASTIC

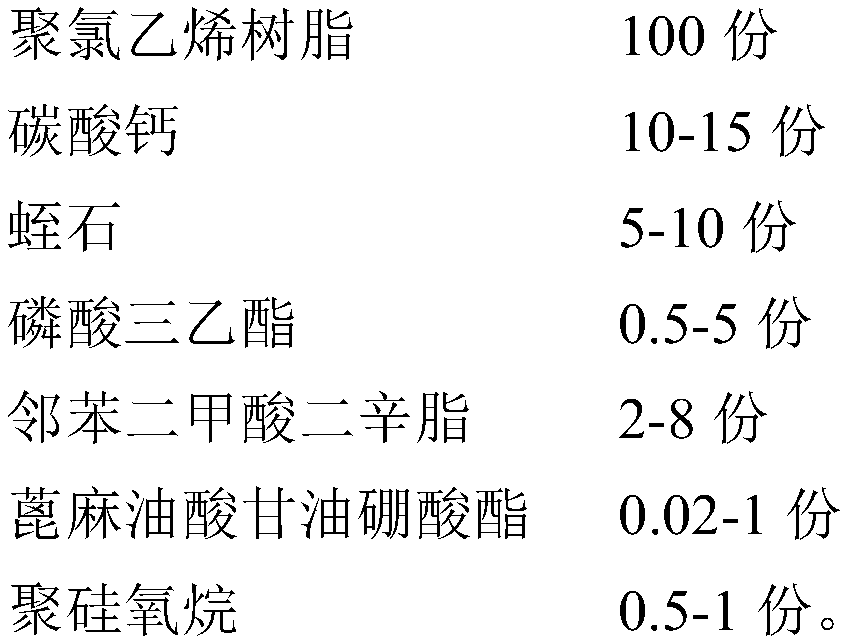

Novel MY-R soft PVC gravure ink and preparation method thereof

The invention discloses novel MY-R soft PVC gravure ink and a preparation method, and relates to the technical field of gravure ink, and the novel MYR soft PVC gravure ink is prepared by the following steps: weighing 50% of a binder, 38% of a pigment, 2% of a filler, 4% of a diluent, 1% of an anti-skinning agent, 1% of an anti-reverse printing agent, 2.2% of a slipping agent, 0.3% of a drying agent, 0.2% of a pH regulator, 0.3% of a dispersing agent, 0.3% of a catalyst, 0.2% of a surfactant, 0.2% of a defoamer, and 0.3% of a levelling agent; pouring the weighed binder into a reaction container, sequentially adding the filler, the anti-skinning agent, the anti-reverse printing agent, the slipping agent, the drying agent, the pH regulator, the dispersing agent, the catalyst and the surfactant, conducting reacting for 2-2.5 hours at the temperature of 20-25 DEG C, adding the defoamer and the leveling agent, and continuously conducting stirring for 15-20 minutes; and adding the pigment at the temperature of 20-25 DEG C, continuously conducting stirring for 20-25 minutes, adding the diluent, conducting stirring for 5-10 minutes, and collecting the material. The printing ink is not easy to block, good in adhesive force to a base material, free of after-tack, few in bubbles in the using process, high in bonding strength and simple in preparation method.

Owner:东莞市万润涂料有限公司

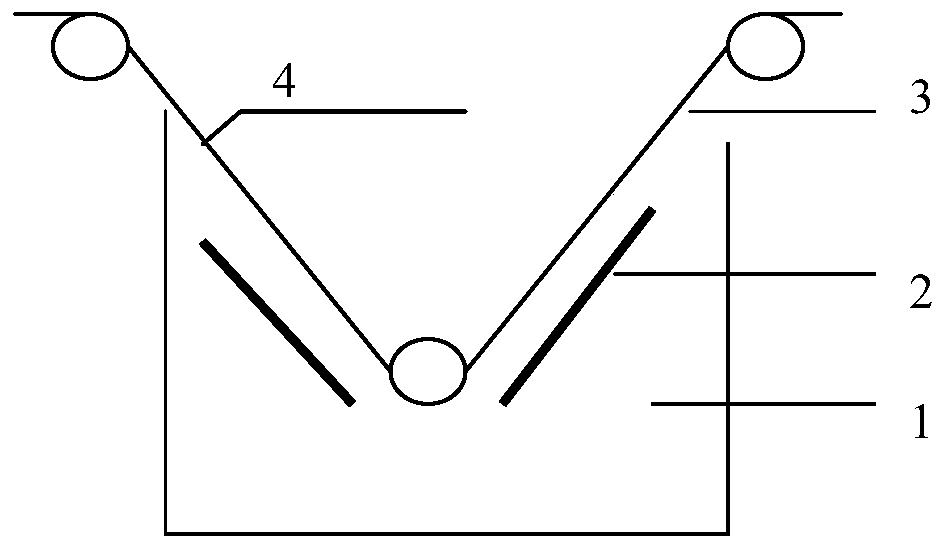

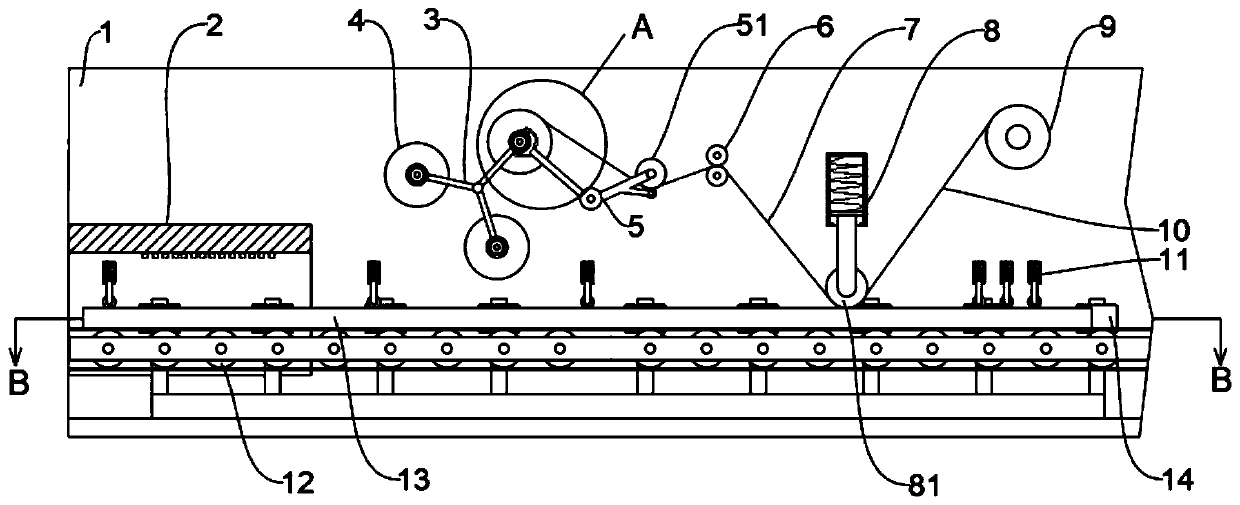

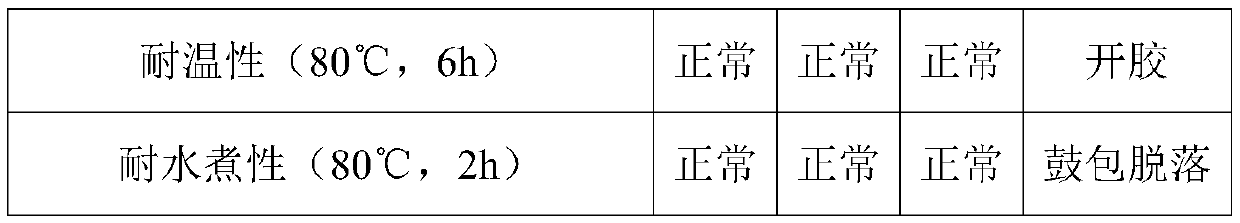

A2-grade fireproof metal film-coated decorative plate production line and production process thereof

ActiveCN111532008AAvoid rippleGuaranteed Peel StrengthLamination ancillary operationsLaminationProduction lineComposite material

The invention discloses an A2-grade fireproof metal film-coated decorative plate production line and a production process thereof. The A2-grade fireproof metal film-coated decorative plate productionline comprises an outer shell, a conveying device, a heating box, an unwinding device, a guide wheel set, a tensioning device, a film pressing device, a winding roller, a pressing device and a clamping device. The swing frame of the tensioning device swings left and right, and a decorative film can be in a tensioned state all the time, therefore, ripples are prevented from being formed after the decorative film is pressed on the plate; the unwinding device is provided with a plurality of groups of unwinding rollers, various decorative film winding drums with different widths can be installed,film replacement is more convenient, the clamping device can adjust the clamping distance according to plates with different widths, the plates can be guided and prevented from deviating, and in the production process, the plates are heated in advance, so that the peeling strength of the plates can be guaranteed, and the production efficiency is improved.

Owner:江苏卡普丹建筑装饰科技有限公司

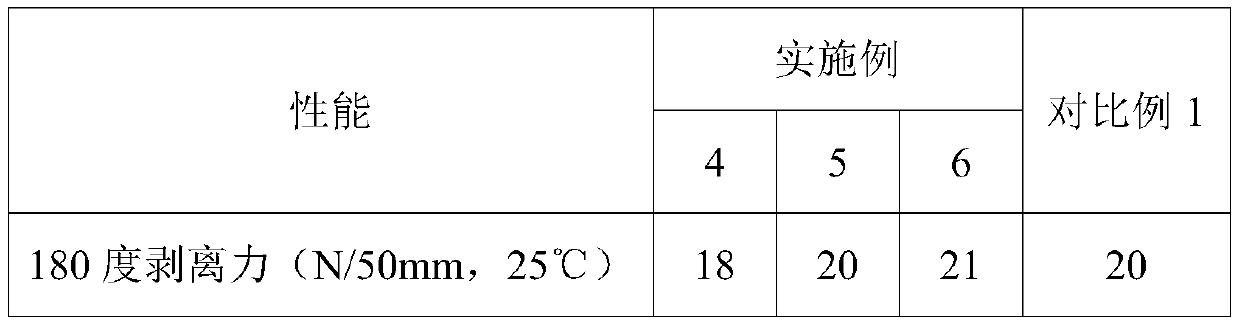

Two-component temperature-resistant water-based pressure-sensitive adhesive as well as preparation method and application thereof

InactiveCN111234739AImprove temperature resistanceGuaranteed Peel StrengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater basedAdhesive cement

The invention discloses a two-component temperature-resistant water-based pressure-sensitive adhesive as well as a preparation method and application thereof, and belongs to the technical field of adhesives. The double-component temperature-resistant water-based pressure-sensitive adhesive comprises a component A and a component B, and the mass ratio of the component A to the component B is 100: (2-15); wherein the component A comprises the following components in percentage by mass: 70%-90% of water-based acrylic pressure-sensitive emulsion, 5%-20% of tackifying emulsion, 1%-3% of a thickening agent, 0.1%-0.5% of a defoaming agent, 0.2%-1% of a bactericide and 0-1% of a pH value regulator, the sum of the mass fractions of the components is 100%; and the component B is polyisocyanate witha hydrophilic group. Compared with a single-component water-based pressure-sensitive adhesive, the double-component water-based pressure-sensitive adhesive prepared by taking polyisocyanate with a hydrophilic group as a component B has relatively good temperature resistance and boiling resistance.

Owner:上海都昱新材料科技有限公司

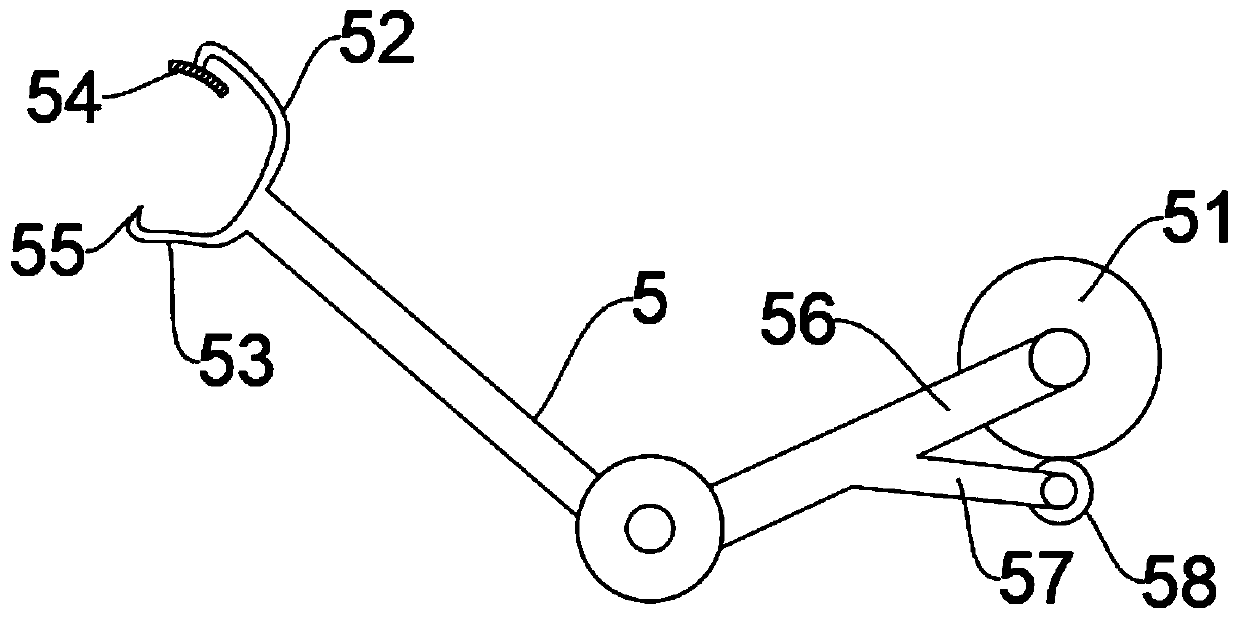

Automatic hot melt adhesive spraying device for screen cloth

InactiveCN110961316AGuaranteed Peel StrengthDoes not cause surface defectsLiquid surface applicatorsCoatingsAdhesive beltElectric machinery

The invention discloses an automatic hot melt adhesive spraying device for screen cloth. The device comprises a conveyor belt, a hot melt adhesive machine, a nozzle group, a sensing device, a motor and a control box, wherein the hot melt adhesive machine communicates with the nozzle group through an adhesive pipe, the sensing device is arranged on the front side of the nozzle group, the nozzle group comprises a plurality of adhesive spraying groups, each adhesive spraying group comprises a spray gun, an air pipe, an electromagnetic valve and an air pressure control valve, a spray sheet is arranged in each spray gun, and a plurality of adhesive spraying holes are formed in each spray sheet. The hot melt adhesive can be quantitatively sprayed in a mist mode, mist spraying is more uniform, under the condition that it is guaranteed that the peel strength reaches the standard after the fabric and a plate are bonded, surface defects caused by adhesive penetration are avoided, and surface unevenness and granular sensation do not exist.

Owner:浙江恋尚家居品有限公司

Manufacturing method of copper-clad plate and glue solution for copper-clad plate

ActiveCN101808466BFlexibleReduce manufacturing costPrinted circuit manufactureEpoxy resin adhesivesGlass fiberPolymer science

The invention relates to a manufacturing method of a copper-clad plate and glue solution for the copper-clad plate. The manufacturing method takes glass cloth as base cloth and successively comprises the steps of preparing glue solution, sizing base cloth and hot forming. The glue solution comprises 100 parts of epoxy resin, 10-40 parts of organic fire retardant, 1-30 parts of curing agent, 0.005-0.05 part of curing accelerator and 10-50 parts of dissolvent, wherein the epoxy resin is composed of 25-75 wt% of nitrile rubber modified epoxy resin and 25-75 wt% of bromination epoxy resin, and the content of nitrile rubber in the nitrile rubber epoxy resin is 30-60%. The invention provides a 'semi-soft plate' with medium elasticity bending modulus. The semi-soft plate has certain flexibility,has the supporting performance provided by a rigid copper-clad plate, is especially suitable for electronic connection devices without very high flexibility requirements and has the advantages of lowmanufacturing cost and convenient installation and connection.

Owner:VENTEC ELECTRONICS SUZHOU

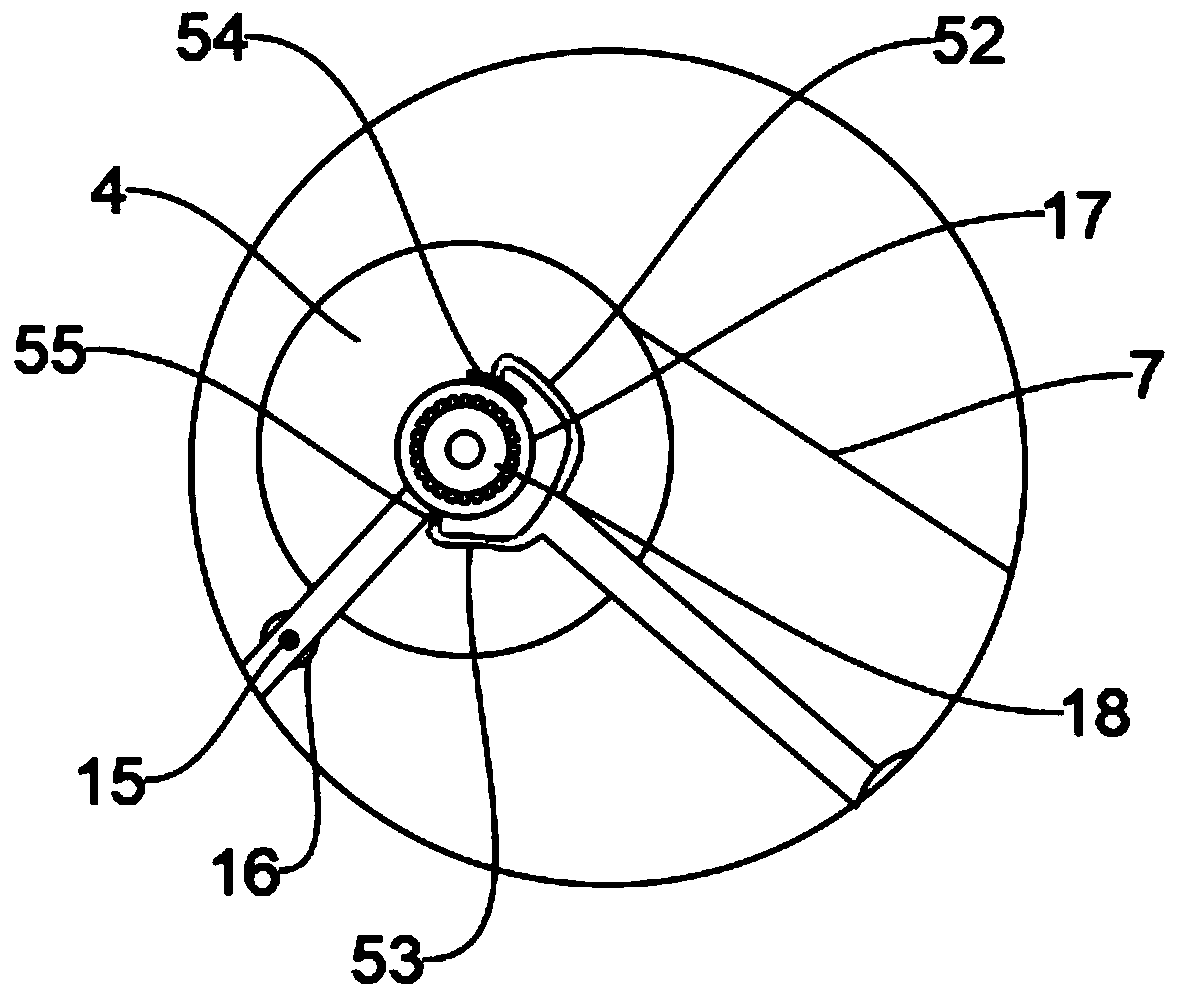

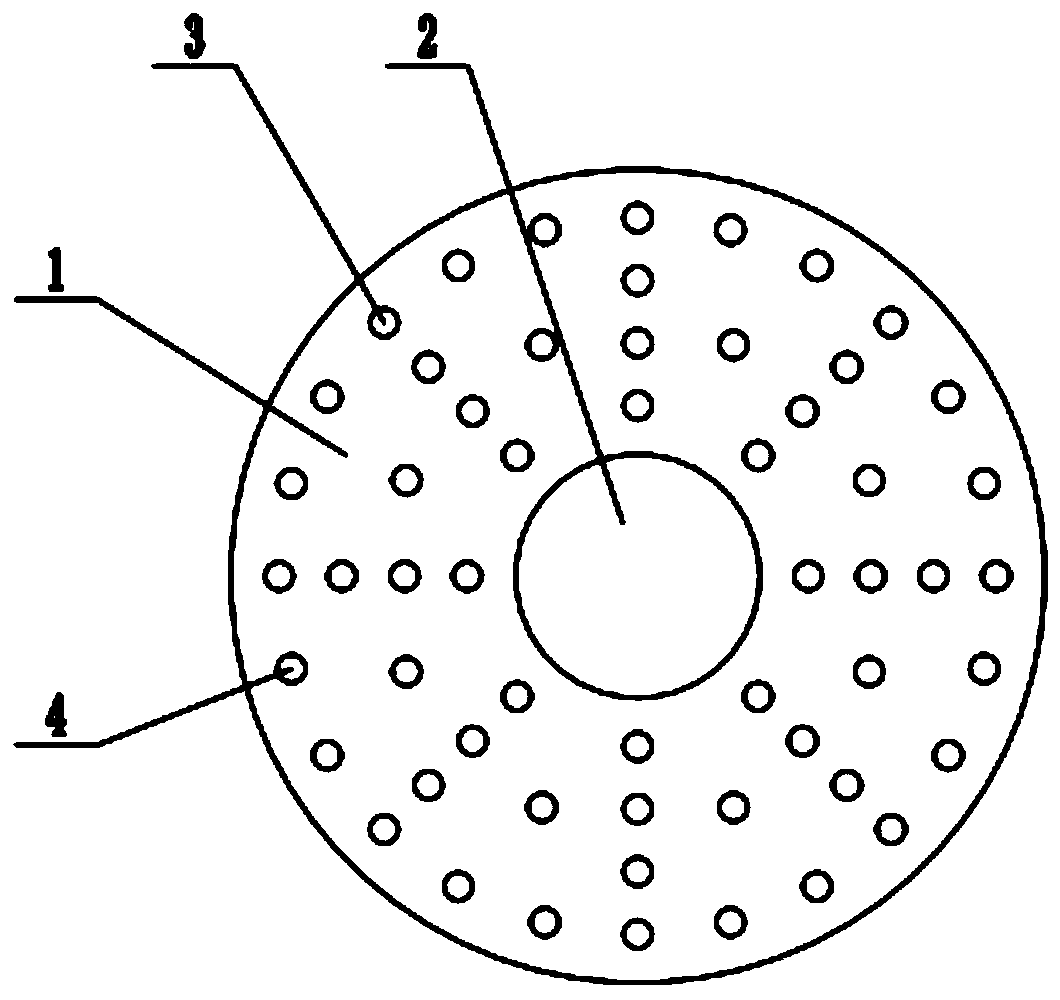

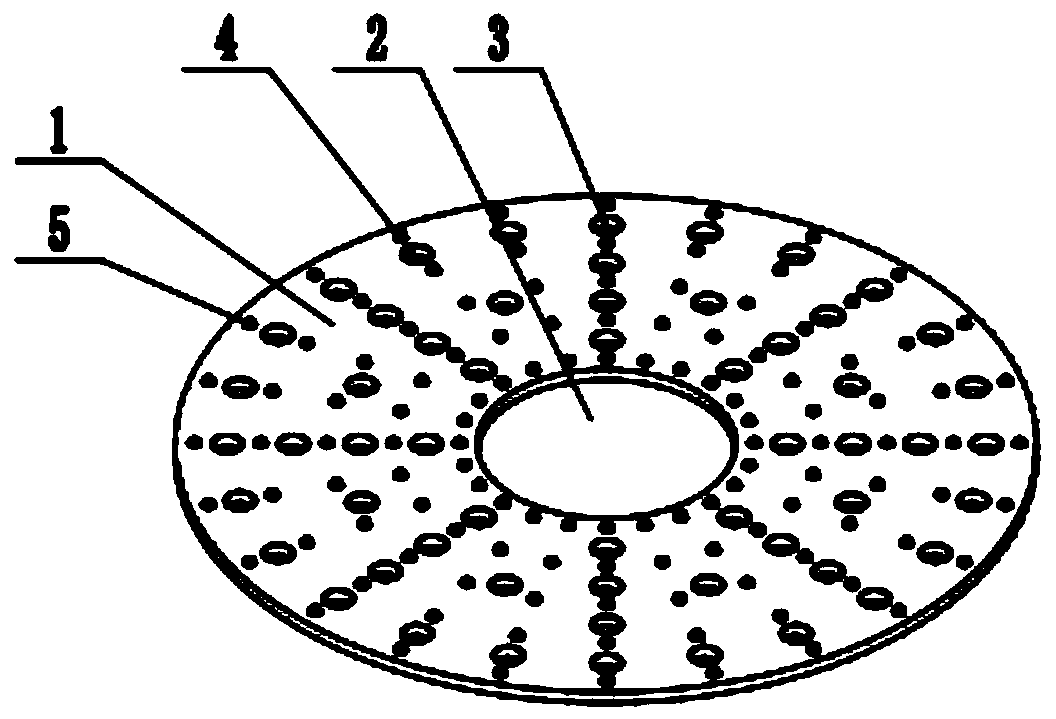

Three-layer flexible copper-clad plate hot baking tray

InactiveCN111010809AEvenly heatedGuaranteed peel strengthInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentMechanical engineeringMaterials science

The invention provides a three-layer flexible copper-clad plate hot baking tray, and mainly relates to the field of copper-clad plate preparation. The three-layer flexible copper-clad plate hot bakingtray comprises a base plate, the base plate is a circular plate, a main hole is formed in the center of the base plate, a plurality of columns of auxiliary holes are formed in the surface of the baseplate, the multiple columns of auxiliary holes are circumferentially and evenly distributed around the circle center of the base plate, and a set of multiple clamping holes are formed between every two adjacent columns of auxiliary holes. The product tray has the beneficial effects that a certain number of air holes are additionally formed in the product tray, so that high-temperature gas flow isincreased, the heat utilization efficiency of the product is improved, and the peel strength of the product is improved.

Owner:SHANDONG JINDING ELECTRONICS MATERIALS CO LTD

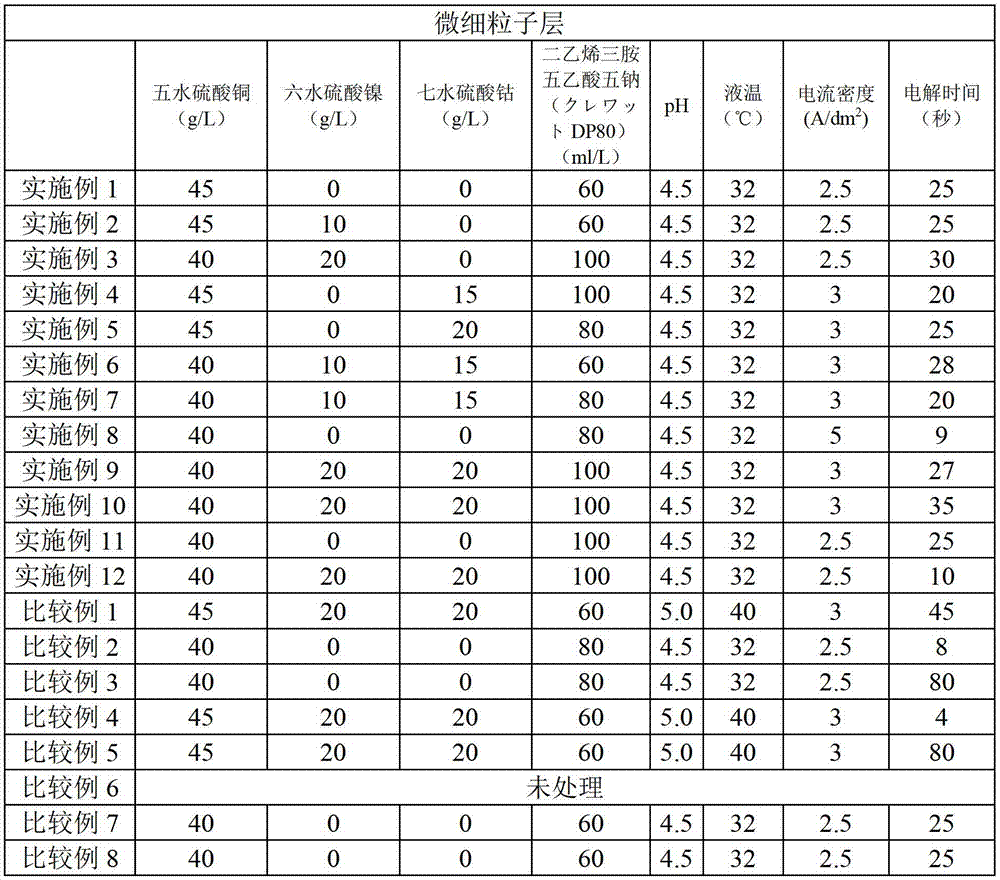

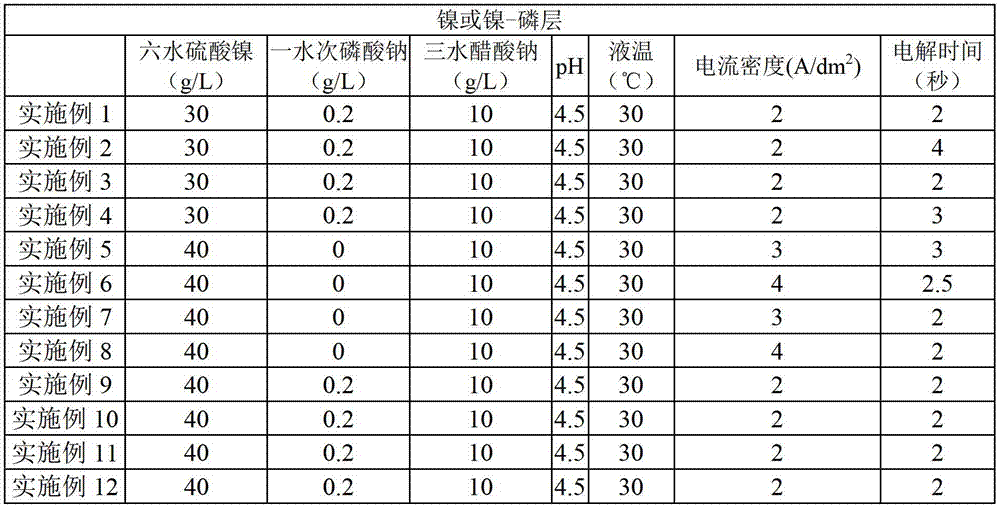

Surface-treated copper foil and printed wiring board using the surface-treated copper foil

ActiveCN103909696BGuaranteed Peel StrengthHas long-term rust resistanceMetallic pattern materialsMetal layered productsCopper foilCobalt

The invention provides a surface treatment copper foil and a printed wiring plate using the same. The surface treatment copper foil provided can obtain normal stripping strength even though a layer containing chromium content is not formed, and can maintain the stripping strength without power falling and with long-term anti-rust property even though in a high-temperature environment, in a wet state or in a state of being soaked in drug liquid. The surface treatment copper foil is characterized in that a micro-particle layer formed by copper particles, copper-nickel particles, copper-cobalt particles, and copper-nickel-cobalt particles, a layer formed by nickel or nickel-phosphorus, and a layer formed by alkali metal silicates and silane coupling agents are successively formed on one surface of the copper foil, the particle size of the micro-particle is less than 0.3 mum, and compared with the surface area of the copper foil formed by the micro-particle layer, the surface area of the micro-particle layer increases 60-900mum2 for every 177mum2.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com