Additive for electrolytic copper foil, ultra-low peak HVLP copper foil and preparation method of ultra-low peak HVLP copper foil

A technology of electrolytic copper foil and additives, applied in electrolytic process, electroforming and other directions, can solve the problems of reducing transmission loss and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

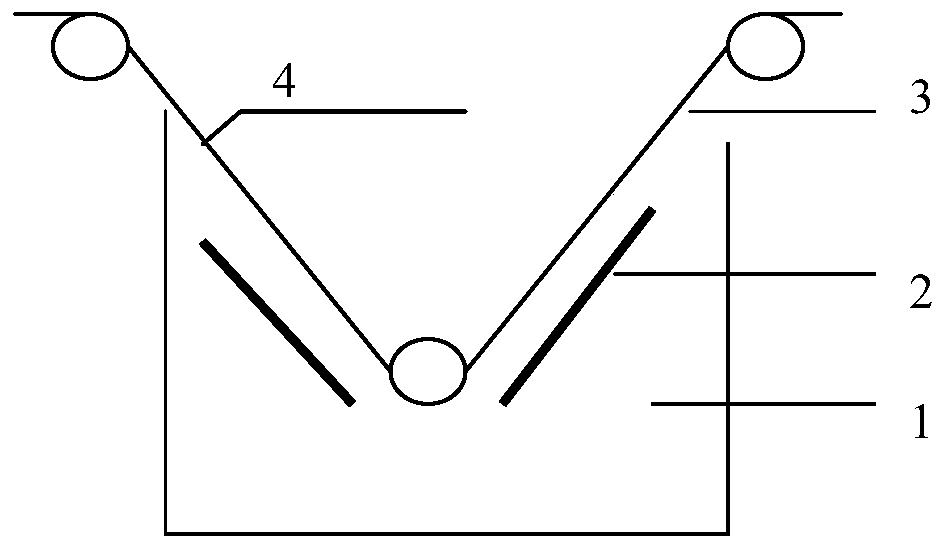

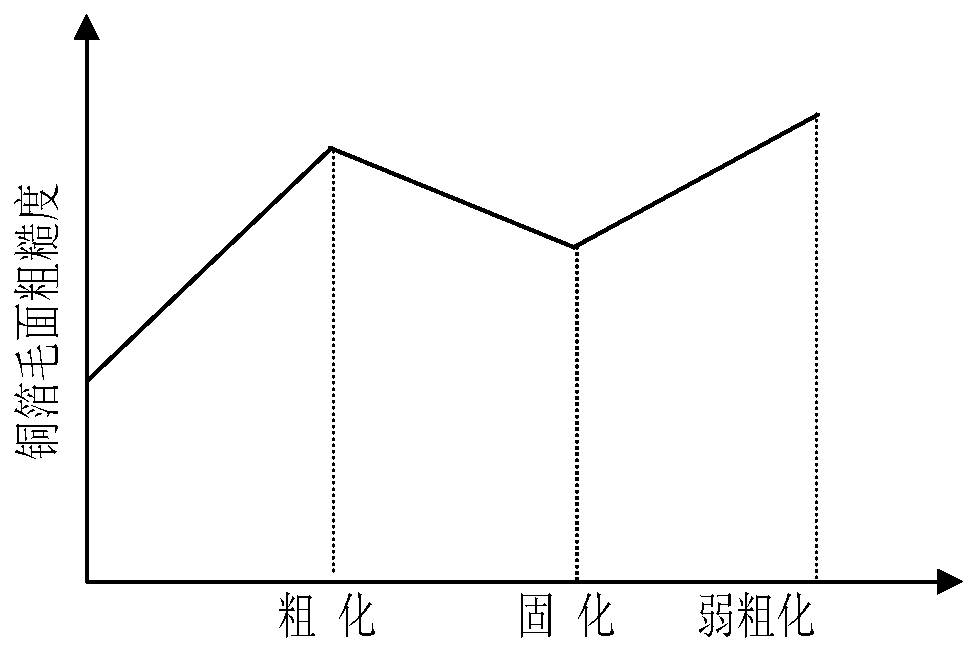

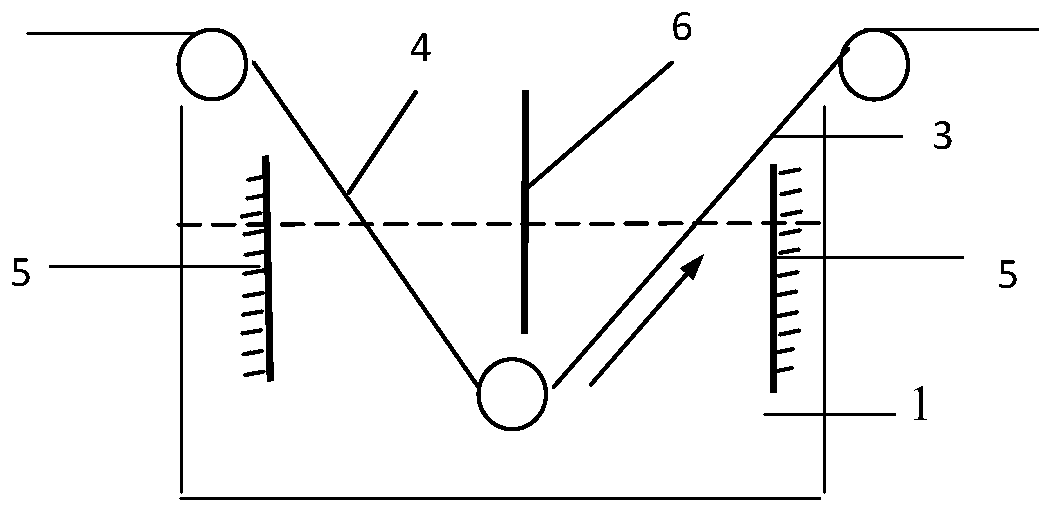

Method used

Image

Examples

Embodiment 1

[0117] An additive for electrolytic copper foil, comprising the following components: fatty amine ethoxy sulfonate 0.005g / L, PN polyethyleneimine alkyl salt 0.01g / L, SP sodium polydithiodipropane sulfonate 0.01g / L L, small molecular weight collagen (3000 Daltons) 0.05g / L, chloride ion 10ppm.

[0118] Preparation of 12 micron ultra-low peak HVLP copper foil:

[0119] (1) Preparation of electrolytic solution: copper is added in the solution containing sulfuric acid to obtain electrolytic solution in copper-dissolving tank; the copper content of described electrolytic solution is 60g / L, and sulfuric acid content is 80g / L, and chloride ion content is 15ppm, The temperature is 40°C.

[0120] (2) Surface grinding of the cathode roller: the cathode roller is mechanically polished, and the surface finish of the cathode roller is 0.2 μm;

[0121] (3) Raw foil electroplating: the electrolyte is sent to the electrolytic tank, the additive is added to the electrolyte, and the flow of th...

Embodiment 2

[0126] An additive for electrolytic copper foil, comprising the following components: PN polyethyleneimine alkyl salt 0.02g / L, SP sodium polydithiodipropanesulfonate 0.5g / L, H1 thiazolethione 0.001g / L , Cowhide polypeptide 1.0g / L, chloride ion 20ppm.

[0127] Preparation of 18 micron ultra-low peak HVLP copper foil:

[0128] (1) Preparation of electrolytic solution: copper is added in the solution containing sulfuric acid to obtain electrolytic solution in the copper-dissolving tank; the copper content of described electrolytic solution is 100g / L, and sulfuric acid content is 150g / L, and chloride ion content is 30ppm, The temperature is 70°C.

[0129] (2) Surface grinding of the cathode roller: the cathode roller is mechanically polished, and the surface finish of the cathode roller is 0.1 μm;

[0130] (3) Raw foil electroplating: send the electrolyte to the electrolytic cell, add the additive to the electrolyte, and the flow of the electrolyte is 80m 3 / h, current density ...

Embodiment 3

[0135] An additive for electrolytic copper foil, comprising the following components: fatty amine ethoxy sulfonate 0.015g / L, PN polyethyleneimine alkyl salt 0.015g / L, SP sodium polydithiodipropane sulfonate 0.25g / L L, cowhide polypeptide 0.5g / L, chloride ion 12ppm.

[0136] Preparation of 12 micron ultra-low peak HVLP copper foil:

[0137] (1) Preparation of electrolytic solution: copper is added in the solution containing sulfuric acid to obtain electrolytic solution in copper-dissolving tank; the copper content of described electrolytic solution is 80g / L, and sulfuric acid content is 120g / L, and chloride ion content is 22ppm, The temperature is 55°C;

[0138] (2) Surface grinding of the cathode roller: the cathode roller is mechanically polished, and the surface finish of the cathode roller is 0.15 μm;

[0139] (3) Raw foil electroplating: the electrolyte is sent to the electrolytic cell, the additive is added to the electrolyte, and the flow of the electrolyte is 65m 3 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com