A kind of shielding electrode used for gas sleeve anti-corona and its preparation process

A technology of shielding electrodes and gas sleeves, which is applied to devices, circuits, and electrical components coated with liquid on the surface, which can solve problems such as electrical aging, reduce electric field strength, reduce process difficulty, and improve electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

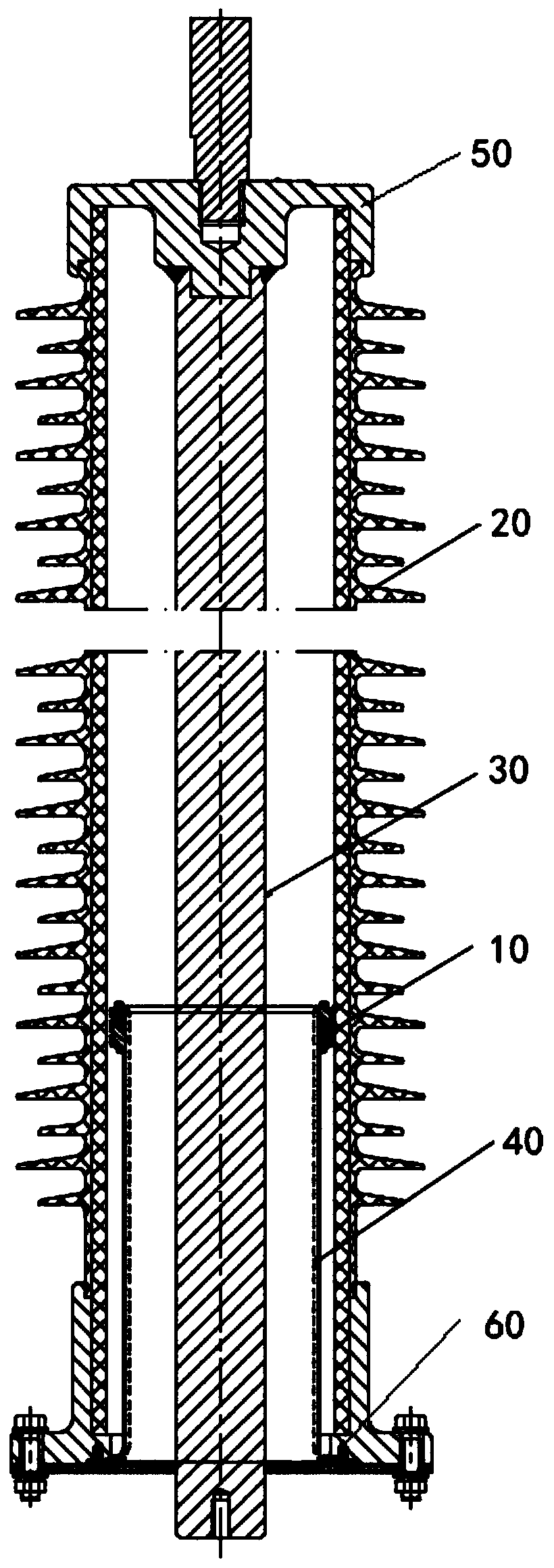

[0034] The traditional shielding electrode without surface treatment has limited processing accuracy, and there are tiny burrs on the surface, resulting in local electric field distortion. When the electric field is high, the insulating gas here will be broken down first and discharge. Spraying insulating varnish on the surface can solve the problem of surface burrs, but the insulating varnish coating after spraying is prone to electrical aging when it withstands a large field strength for a long time under normal operating conditions. Therefore, this embodiment provides a shielding electrode for gas sleeve anti-corona, such as figure 1 As shown, the shielding electrode 10 is arranged at the bottom of the gas sleeve 20, and the conductive rod 30 is fixed on the upper flange 50 and penetrates inside the gas sleeve 20. The shielding electrode 10 is surrounded by the bottom end of the conductive rod 30 and fixed On the lower flange 60, a layer of semi-conductive layer 40 is spray...

Embodiment 2

[0039] Embodiment 2 is a preferred embodiment of embodiment 1

[0040] This embodiment provides a shielding electrode for anti-corona of the gas sleeve, the shielding electrode 10 is arranged inside the gas sleeve 20, the gas sleeve 20 is provided with a conductive rod 30, and the surface of the shielding electrode 10 is provided with a semi-conductive layer 40.

[0041] In some embodiments, the shielding electrode 10 is made of aluminum alloy.

[0042] Preferably, the surface resistivity of the semiconducting layer 40 is 10 3 Ω~10 5 Ω.

[0043] Of course, according to different gas insulating sleeves and shielding electrodes of different materials or structures, the preference of the surface resistivity of the semiconductive layer should also be adjusted accordingly.

[0044] The beneficial effects obtained by the shielding electrodes provided above are basically consistent with those of the above embodiments, and will not be described here one by one.

Embodiment 3

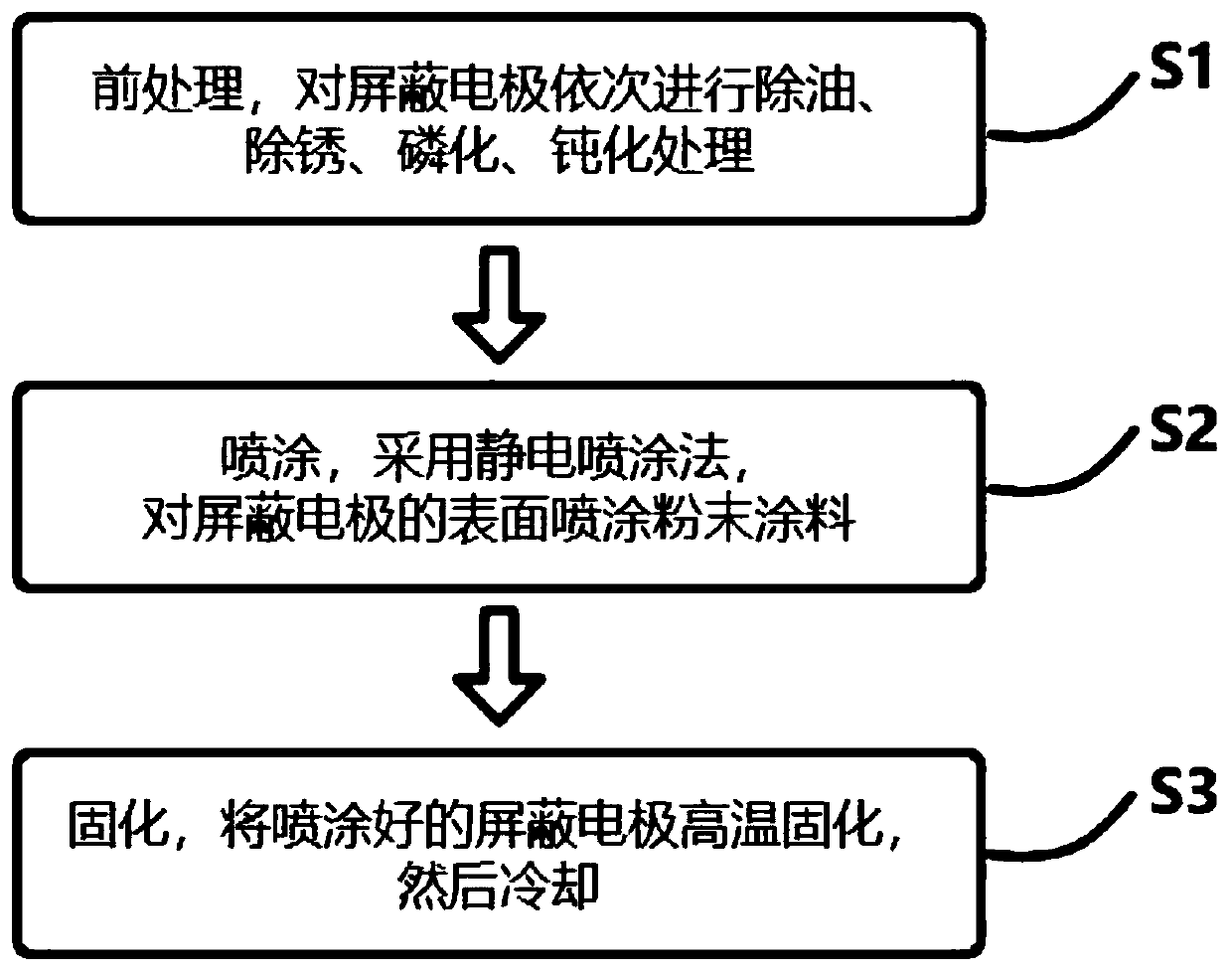

[0046]In this embodiment, on the basis of the above-mentioned embodiments, a preparation process of the shielding electrode used for the gas bushing to prevent corona is proposed, and the preparation process is used to obtain the shielding electrode used for the gas bushing to prevent corona. The preparation process adopts the electrostatic powder spraying method. The working principle of the electrostatic powder spraying method is: the paint sprayed by the electrostatic powder spray gun makes the powder particles negatively charged while the paint is dispersed, and the charged powder particles are affected by air flow (or centrifugal force and other effects) force) and electrostatic attraction, it is applied to the grounded object, and then heated, melted and solidified to form a film.

[0047] The specific spraying process is as follows:

[0048] Firstly, pre-treatment of electrostatic spraying is required, including degreasing, rust removing, phosphating and passivation; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com