Water-based gravure yellow ink for soft PVC decoration film, and preparation method thereof

A technology of yellow ink and decorative film, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of inability to achieve decoration and protection, low resolubility of water-based ink, lack of adhesion to substrates, etc., to improve sticking phenomenon, Easy to control and not easy to block the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

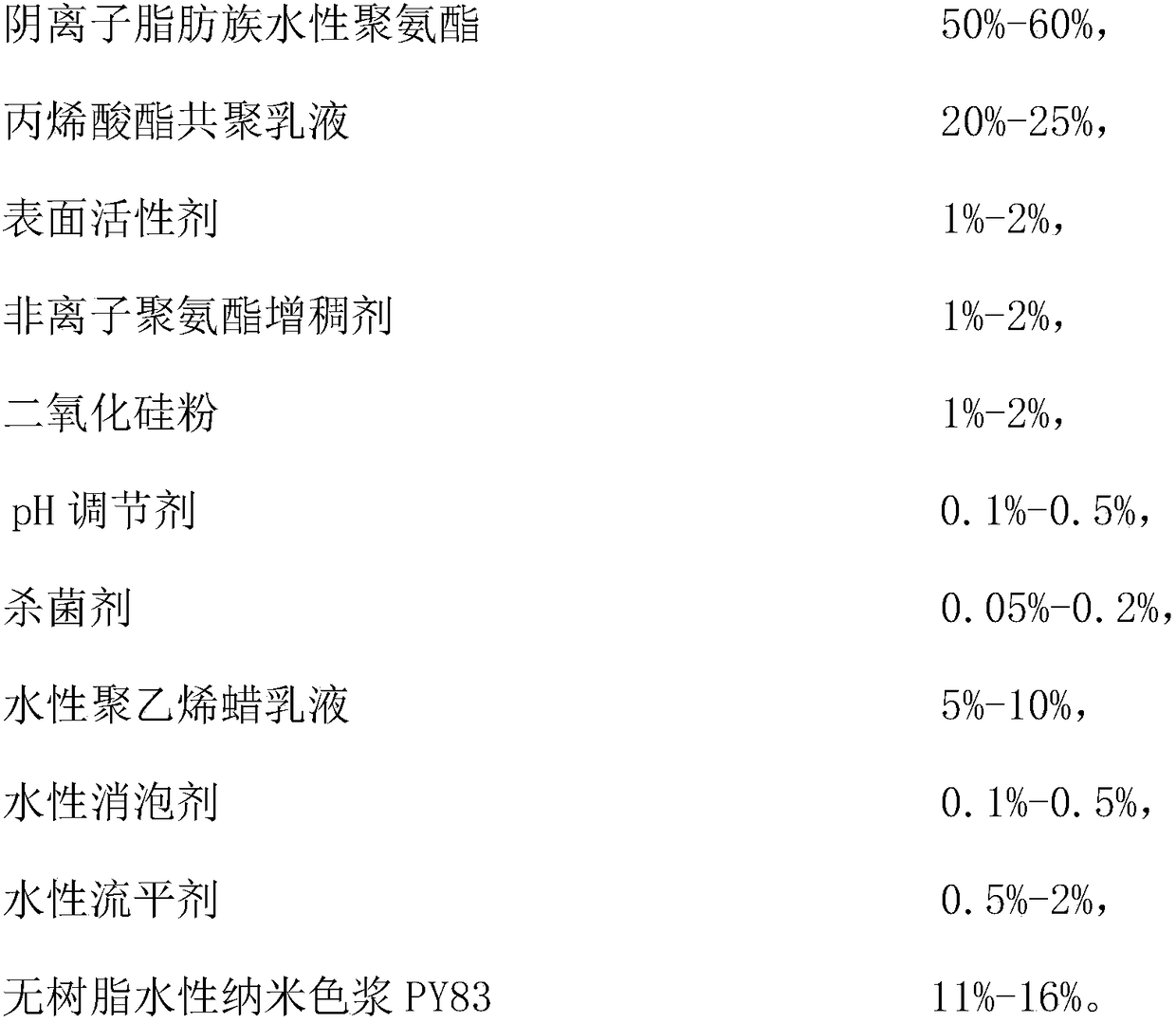

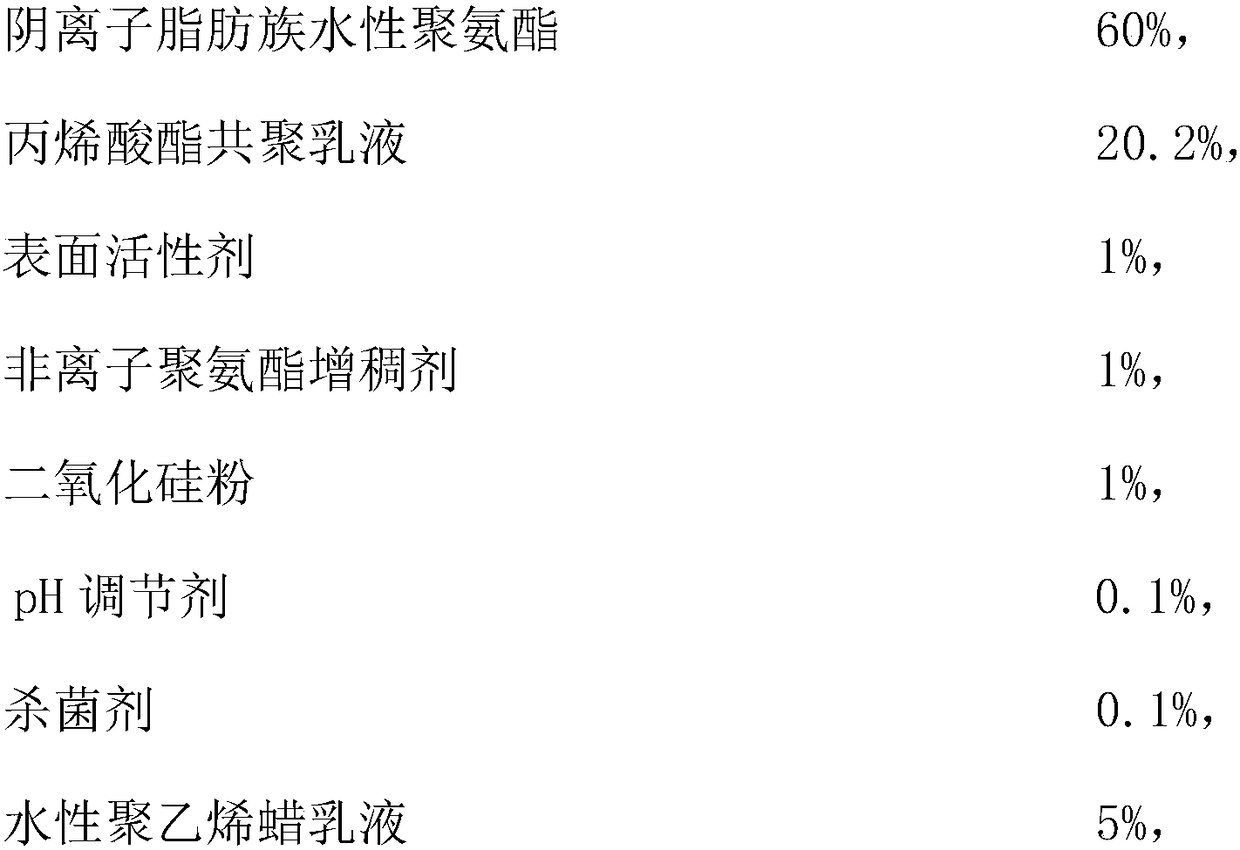

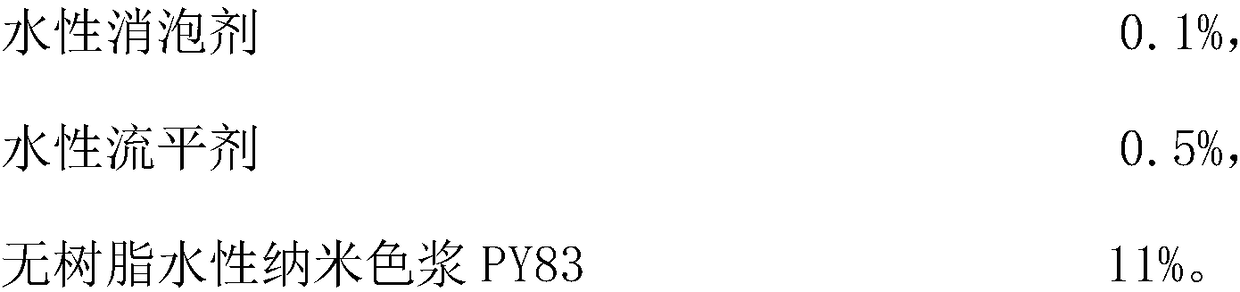

[0040] Weigh the raw materials according to the mass percentage of the following formula components: 60% of anionic aliphatic waterborne polyurethane, 20.2% of acrylate copolymer emulsion, 1% of surfactant, 1% of nonionic polyurethane thickener, 1% of silica powder, pH Conditioner 0.1%, bactericide 0.1%, water-based polyethylene wax emulsion 5%, water-based defoamer 0.1%, water-based leveling agent 0.5%, resin-free water-based nano-color paste PY83 11%.

[0041] Specific preparation method: Add anionic aliphatic water-based polyurethane, acrylate copolymer emulsion, surfactant, non-ionic polyurethane thickener, pH regulator, bactericide, water-based polyethylene wax emulsion, water-based defoamer, water-based Leveling agent, resin-free water-based nano-color paste PY83, silica powder, set the stirring speed at 900-1000r / min, stir at high speed for 60 minutes until evenly stirred, and then get the water-based gravure yellow ink.

Embodiment 2

[0043] Weigh the raw materials according to the mass percentage of the following formula components: 53.75% of anionic aliphatic waterborne polyurethane, 22% of acrylate copolymer emulsion, 1% of surfactant, 2% of nonionic polyurethane thickener, 1% of silica powder, pH Conditioner 0.1%, bactericide 0.05%, water-based polyethylene wax emulsion 6%, water-based defoamer 0.1%, water-based leveling agent 1%, resin-free water-based nano-color paste PY83 13%.

[0044] Specific preparation method: Add anionic aliphatic water-based polyurethane, acrylate copolymer emulsion, surfactant, non-ionic polyurethane thickener, pH regulator, bactericide, water-based polyethylene wax emulsion, water-based defoamer, water-based Leveling agent, resin-free water-based nano-color paste PY83, silica powder, set the stirring speed at 900-1000r / min, stir at high speed for 50 minutes until evenly stirred, and then the water-based gravure yellow ink is obtained.

Embodiment 3

[0046]Weigh the raw materials according to the mass percentage of the following formula components: 50.6% of anionic aliphatic waterborne polyurethane, 20% of acrylate copolymer emulsion, 2% of surfactant, 1% of nonionic polyurethane thickener, 1% of silica powder, pH Conditioner 0.3%, bactericide 0.1%, water-based polyethylene wax emulsion 8%, water-based defoamer 0.5%, water-based leveling agent 0.5%, resin-free water-based nano-color paste PY83 16%.

[0047] Specific preparation method: Add anionic aliphatic water-based polyurethane, acrylate copolymer emulsion, surfactant, non-ionic polyurethane thickener, pH regulator, bactericide, water-based polyethylene wax emulsion, water-based defoamer, water-based Leveling agent, resin-free water-based nano-color paste PY83, silica powder, set the stirring speed at 900-1000r / min, stir at high speed for 70 minutes until evenly stirred, and then the water-based gravure yellow ink is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tinctorial strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com