Light emitting diode and production method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to vacuum evaporation plating, coatings, semiconductor devices, etc., can solve problems such as process parameter adjustment and difficulty, and achieve the effects of ensuring stress release, ensuring adhesion, and improving light extraction efficiency.

Active Publication Date: 2013-04-03

ANHUI SANAN OPTOELECTRONICS CO LTD

View PDF4 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductor | aaaaa | aaaaa |

Login to View More

Abstract

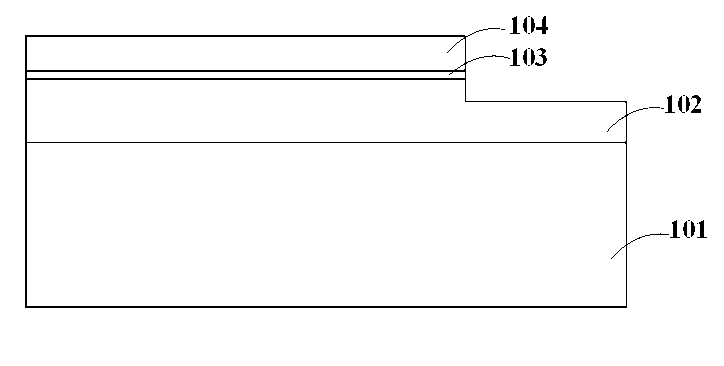

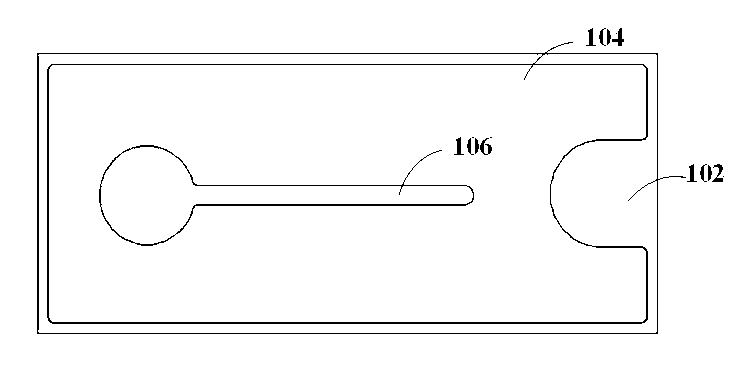

The invention discloses a light emitting diode (LED) with a transparent conducting layer and a production method thereof. The LED comprises a substrate; a luminous epitaxial layer which is formed by sequentially stacking a first limit layer, a luminous layer and a semiconducting material layer of a second limit layer from the bottom up, and is formed above the substrate; a current barrier layer which is formed above a local area of the luminous epitaxial layer; a transparent conducting structure which is formed above the current barrier layer, extends out of the surface of the luminous epitaxial layer and is divided into a luminous zone and a non-luminous zone; and an electrode P which is formed above the non-luminous zone of the transparent conducting structure, wherein the non-luminous zone is corresponding to the current barrier layer, the thickness of the non-luminous zone is larger than that of the luminous zone, and therefore the transparent conducting structure is enabled to form good ohmic contact with the luminous epitaxial layer, and decreases absorption of light. The structure can guarantee current expansibility, reduce working voltage, and decrease the absorption of the light.

Description

technical field [0001] The invention relates to a light-emitting diode and a manufacturing method thereof, more particularly to a light-emitting diode with a transparent conductive layer and a manufacturing method thereof. Background technique [0002] After years of development, light-emitting diodes (LEDs) have been widely used in different fields such as display, indication, backlight, and lighting. Group III-V compounds are currently the mainstream semiconductor materials for making light-emitting diodes, among which gallium nitride-based materials and aluminum gallium indium phosphide-based materials are the most common. The current spreading performance of traditional p-type III-V semiconductor materials is generally poor. In order to allow the current to be uniformly injected into the light-emitting layer, it is often necessary to add a transparent conductive layer on the p-type material layer. Among many materials that can be used as transparent conductive layers, s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L33/38H01L33/00

CPCH01L33/38H01L2933/0016C23C14/086C23C14/24C23C14/5806C23C14/024C23C14/35H01L33/42C23C14/58H01L33/005H01L2933/0025H01L2933/0066

Inventor 尹灵峰林素慧郑建森洪灵愿刘传桂欧毅德陈功

Owner ANHUI SANAN OPTOELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com