Continuous extrusion forming process for small-square-area brass special-shaped wire

A technology of extrusion molding and wire rod, which is applied in the field of continuous extrusion molding of small square brass special-shaped wire rods, can solve problems such as unstable quality, complicated process, labor and time-consuming, etc., and achieve improved product quality, simple process, and low energy consumption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

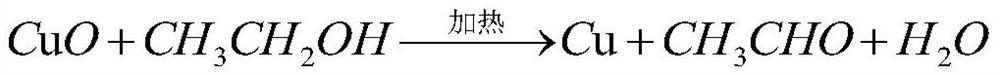

Method used

Image

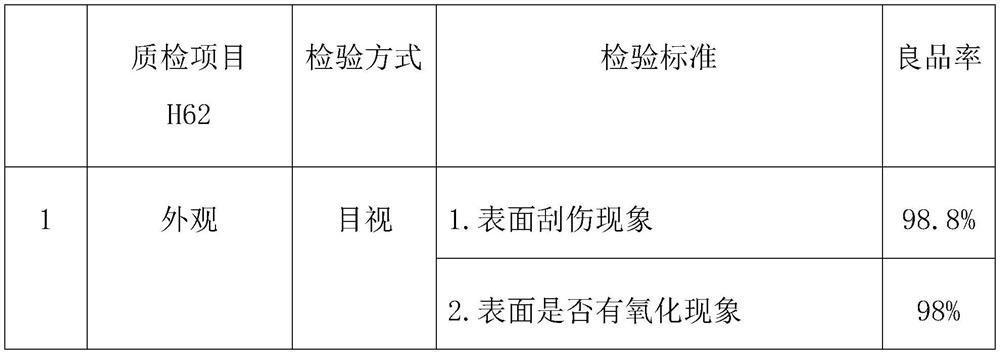

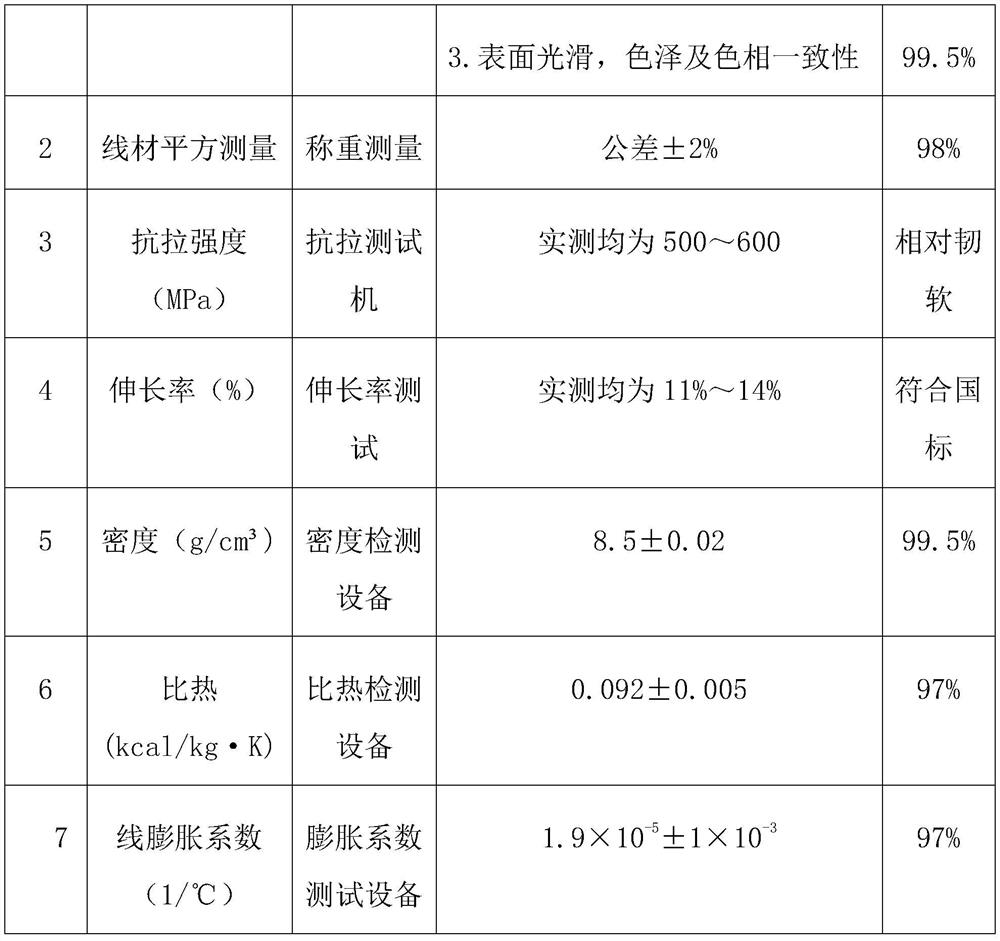

Examples

Embodiment 1

[0046] This embodiment provides a continuous extrusion molding process for a small square brass special-shaped wire rod, which is used to produce a small square brass special-shaped wire rod, which mainly includes the following steps:

[0047] 1) Preheating forming mold

[0048] Install the forming mold in a cavity, keep the forming mold flat in the cavity, put it into an electric heating box and heat it to 300°C, and then keep the constant temperature for 1h.

[0049] Among them, the specific heating process of the electric heating box is: first raise the temperature to between 100°C and 110°C, keep it for 10 minutes, then raise the temperature to 302°C, then lower the temperature to 300°C, and keep the constant temperature.

[0050] 2) Extrusion molding

[0051] Install the chamber after constant temperature treatment in the shoe seat of the extruder, check the pipeline of the extruder and turn on the extruder, take a number of heated brass rods with a length of 15cm, and a...

Embodiment 2

[0075] This embodiment provides a continuous extrusion molding process for a small square brass special-shaped wire rod, which is used to produce a small square brass special-shaped wire rod, which mainly includes the following steps:

[0076] 1) Preheating forming mold

[0077] Install the forming mold in a cavity, keep the forming mold flat in the cavity, put it into an electric heating box and heat it to 300°C, and then keep it for 1.2h.

[0078] Among them, the specific heating process of the electric heating box is: first raise the temperature to 105°C, keep it for 12 minutes, then raise the temperature to 304°C, then lower the temperature to 300°C, and keep the constant temperature.

[0079] 2) Extrusion molding

[0080] Install the chamber after constant temperature treatment in the shoe seat of the extruder, check the pipeline of the extruder and turn on the extruder, take a number of heated brass rods with a length of 20cm, and adjust the speed of the extruder to 6r / ...

Embodiment 3

[0104] This embodiment provides a continuous extrusion molding process for a small square brass special-shaped wire rod, which is used to produce a small square brass special-shaped wire rod, which mainly includes the following steps:

[0105] 1) Preheating forming mold

[0106] Install the forming mold in a cavity, keep the forming mold flat in the cavity, put it into an electric heating box and heat it to 300°C, and then keep the constant temperature for 1.5h.

[0107] Among them, the specific heating process of the electric heating box is: first raise the temperature to 110°C, keep it for 15 minutes, then raise the temperature to 305°C, then lower the temperature to 300°C, and keep the constant temperature.

[0108] 2) Extrusion molding

[0109] Install the chamber after constant temperature treatment in the shoe seat of the extruder, check the pipeline of the extruder and turn on the extruder, take a number of heated brass rods with a length of 20cm, and adjust the speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com