Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164results about How to "Guaranteed particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

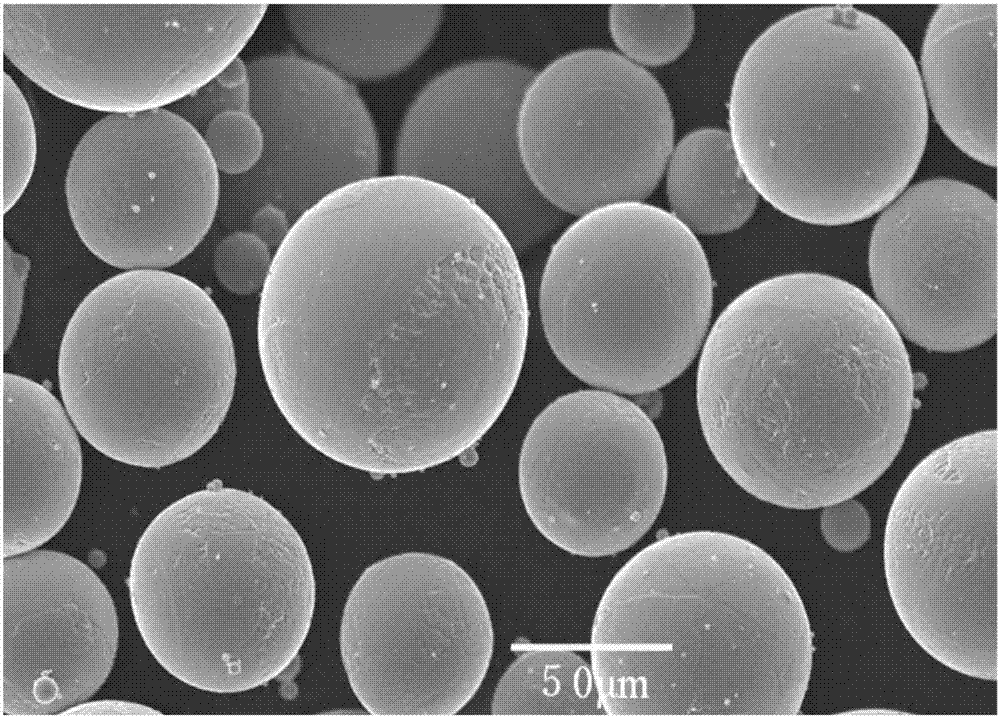

Metal powder preparation method and device based on plasma atomization technology

InactiveCN107175337AGuaranteed sphericityGuaranteed Particle SizeAdditive manufacturing apparatusPlasma torchMelting point

The invention discloses a method for preparing metal powder based on plasma atomization technology and a device thereof. The device includes a feeding chamber, an induction heating melting chamber, a plasma torch chamber, an atomization chamber and a powder collection chamber, and an induction heating device and a magnetic restraint device are arranged in the induction heating melting chamber. Frequency smelting technology, magnetic levitation technology and plasma atomization preparation technology are combined to maximize the effect of plasma atomization technology to prepare high-sphericity and high-quality metal particles. Compared with traditional plasma atomization preparation technology, it is guaranteed Under the premise of the sphericity and particle size of metal particles, the production volume of high melting point metal powder can be increased exponentially.

Owner:加拿大艾浦莱斯有限公司 +1

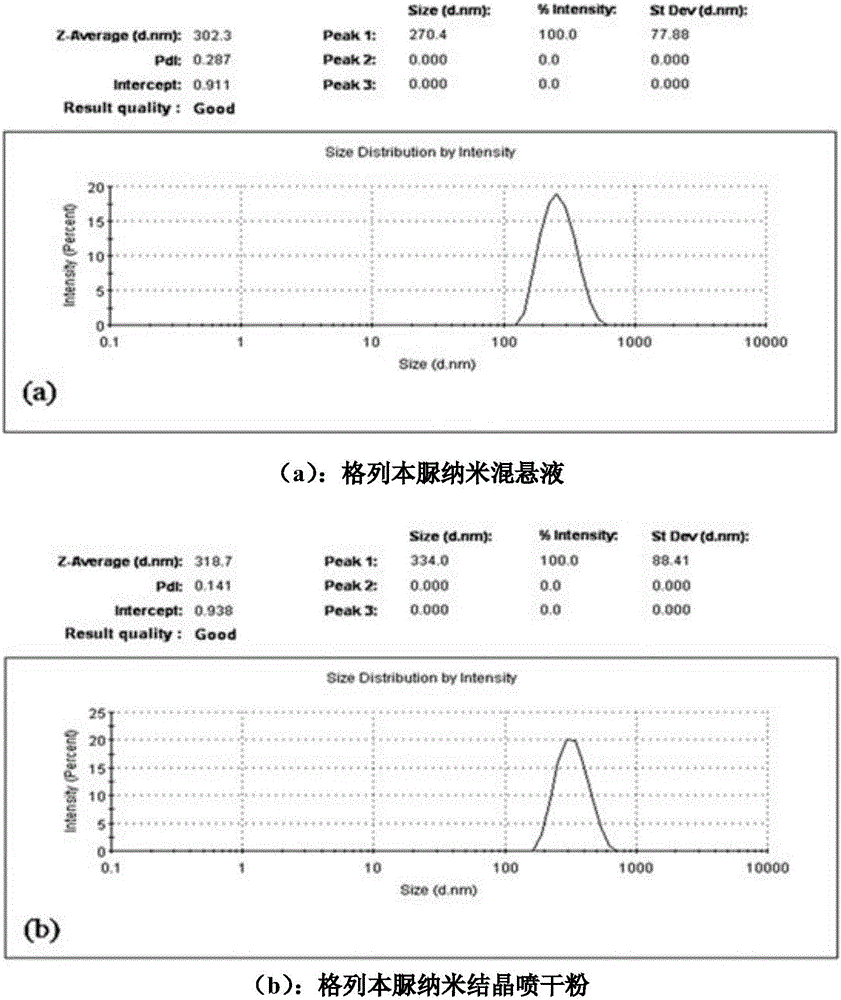

A treating method for a nanometer suspension solidification process

ActiveCN105902496AInhibit aggregationGuaranteed Particle SizePowder deliverySulfonylurea active ingredientsPharmaceutical formulationSURFACTANT BLEND

The invention discloses a treating method for a nanometer suspension solidification process, and belongs to the field of medicine preparations. The nanometer suspension comprises a medicine, a stabilizing agent and water. The method includes adding a surfactant into the medicine nanometer suspension before solidification, and solidifying. Before solidification of the nanometer suspension, 0.01-10% (w / v) of the surfactant is added to inhibit particle aggregation in the solidification process and to maintain the particle size, thus preparing nanometer crystal powder uniform in particle size distribution and easy in redispersion. The method reduces the using amount of a conventional solidification protective agent, and even can fully replace the conventional protective agent, thus increasing the medicine content in the nanometer crystal powder, reducing the cost of auxiliary materials and improving medicine taking compliance.

Owner:SHENYANG PHARMA UNIVERSITY

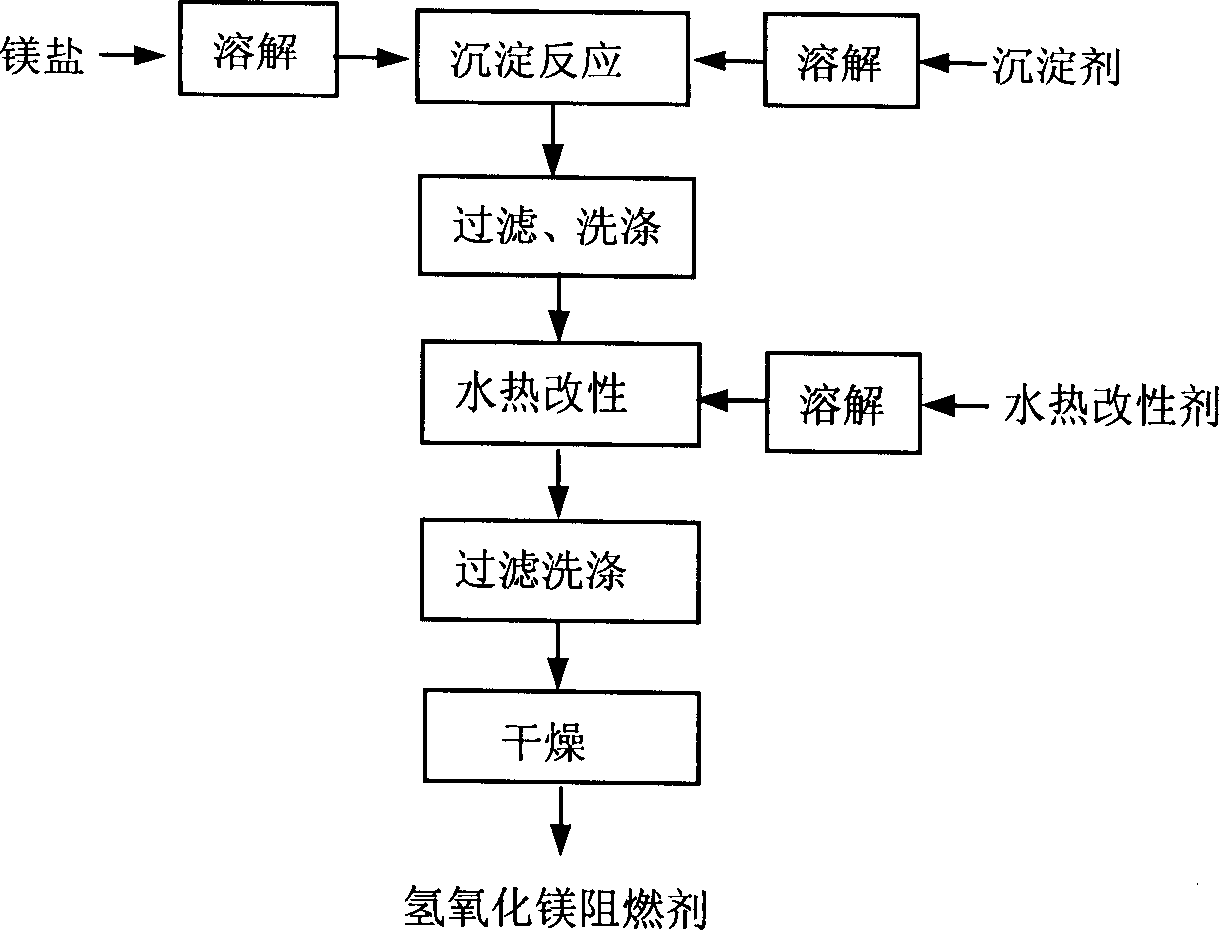

Process for preparing high dispersion flake magnesium hydroxide

A process for preparing high-dispersity flaky magnesium hydroxide from inorganic magnesium salt includes liquid-phase preciptiation of inorganic magnesium salt and inorganic alkali or sulfur hydride at 25-90 deg.C, adding water-soluble flocculant to obtain irregularly coagulated magnesium hydroxide, and hydrothermal modifying in the modifier solution at 100-250 deg.C. The product has features of high purity (97%), high dispersity, and low cost.

Owner:TSINGHUA UNIV

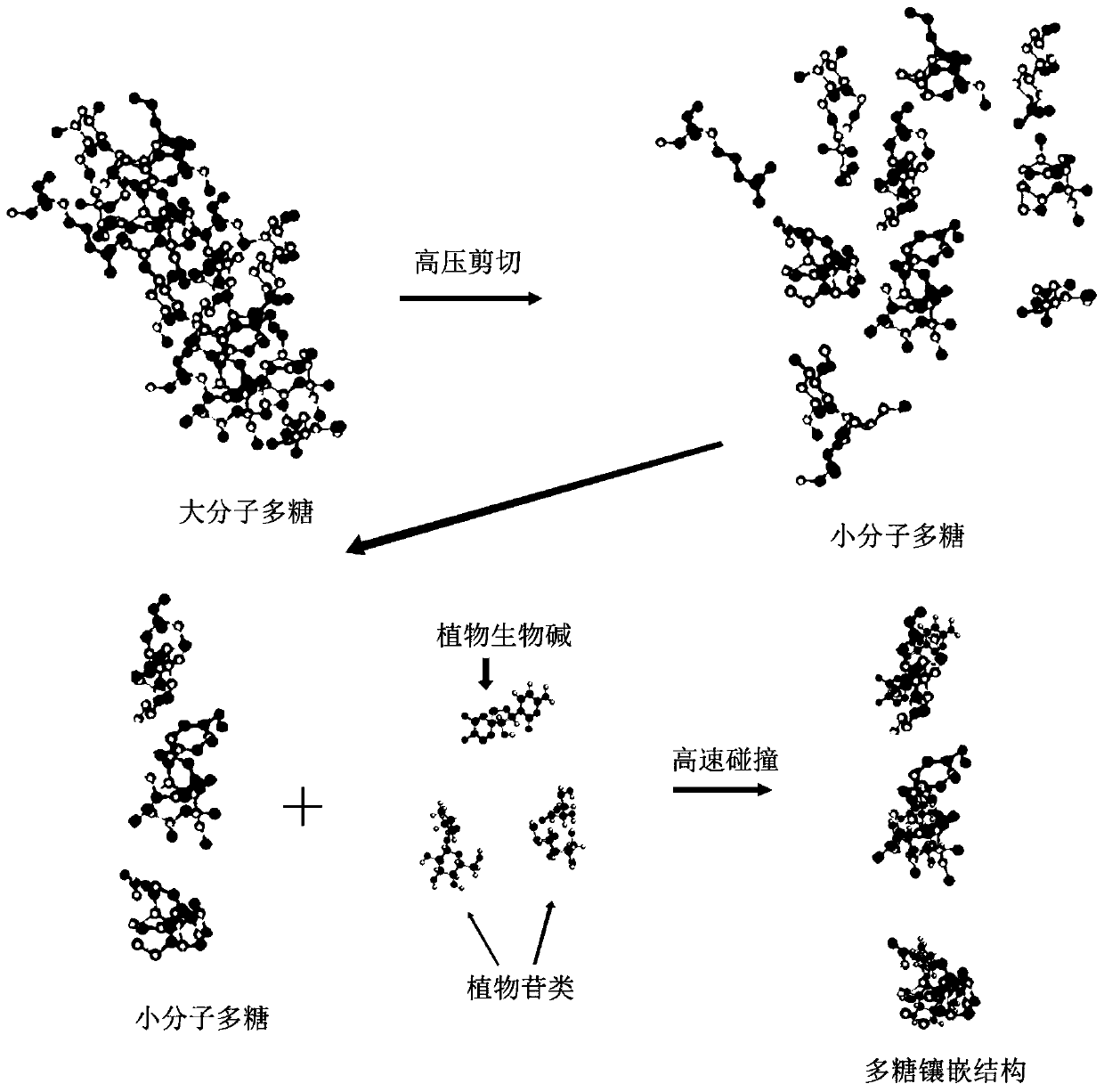

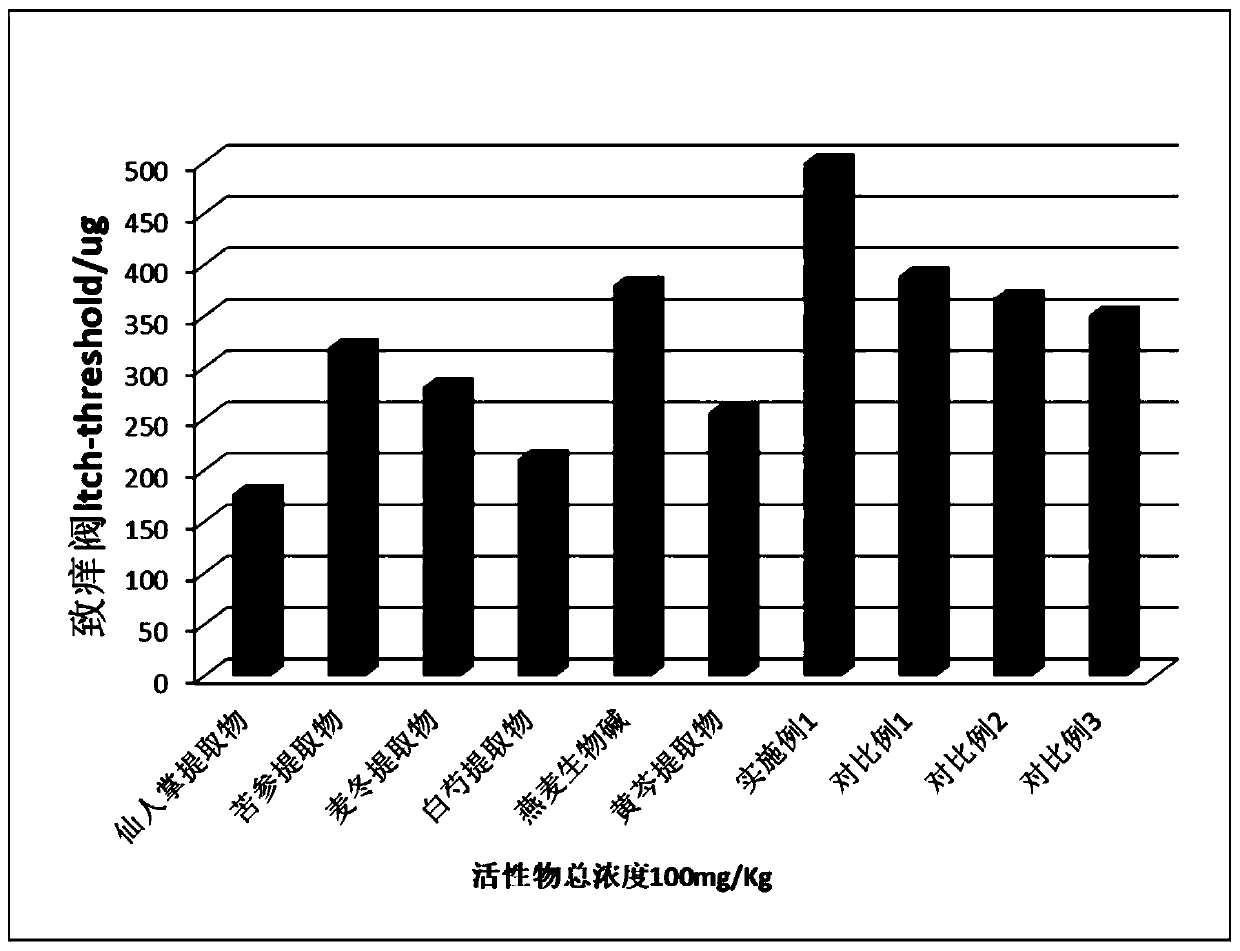

Anti-inflammation and allergy-relieving repair composition and preparation method and application thereof

ActiveCN110200830AHas analgesiaEnhanced barrier functionCosmetic preparationsToilet preparationsSide effectFiltration

The invention discloses an anti-inflammation and allergy-relieving repair composition and a preparation method and an application thereof. The composition consists of a cactus extract, an oat bran extract, a sophorae flavescentis extract, an ophiopogon japonicus root extract, a peony root extract, a scutellaria baicalensis root extract, butanediol, pentanediol and water. The preparation method comprises the following steps: 1) preparing a sophorae flavescentis extract solution; 2) carrying out super-high pressure homogenization of the cactus extract, the oat bran extract, the ophiopogon japonicus root extract, the peony root extract, the scutellaria baicalensis root extract, butanediol and pentanediol to obtain a plant extract mixed solution; and 3) carrying out mixing, super-high pressurehomogenization and filtration of the plant extract mixed solution and the sophorae flavescentis extract solution. The anti-inflammation and allergy-relieving repair composition has anti-inflammatory,anti-allergic and analgesic effects, can enhance skin barrier function, enhances the skin self-protection ability, effectively repairs inflammatory skin, especially skins suffered from hormone-dependent dermatitis and cannot produce drug resistance, dependence and side effects after being used for a long time.

Owner:中科厚朴(广州)科技发展有限公司 +1

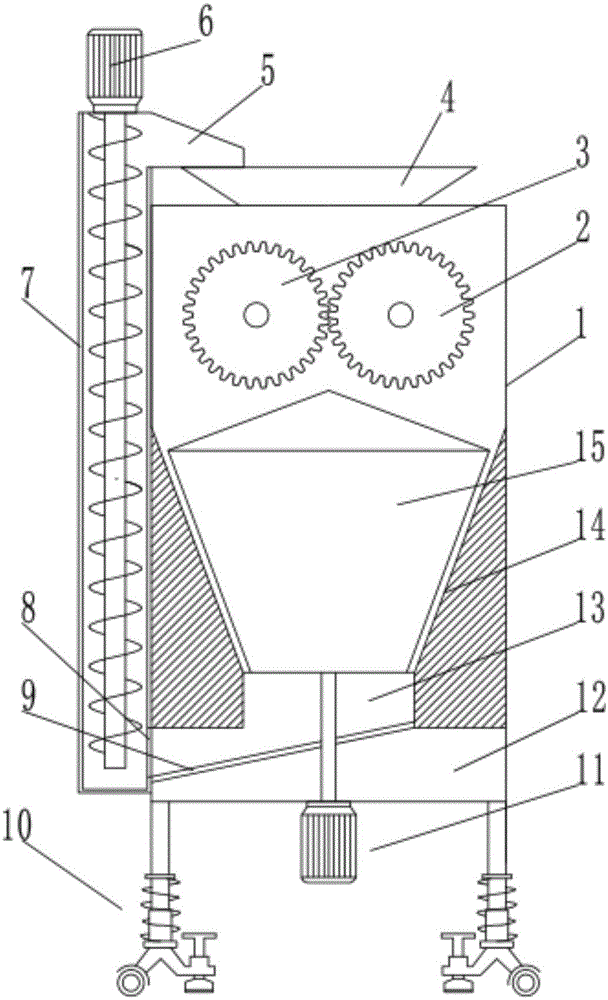

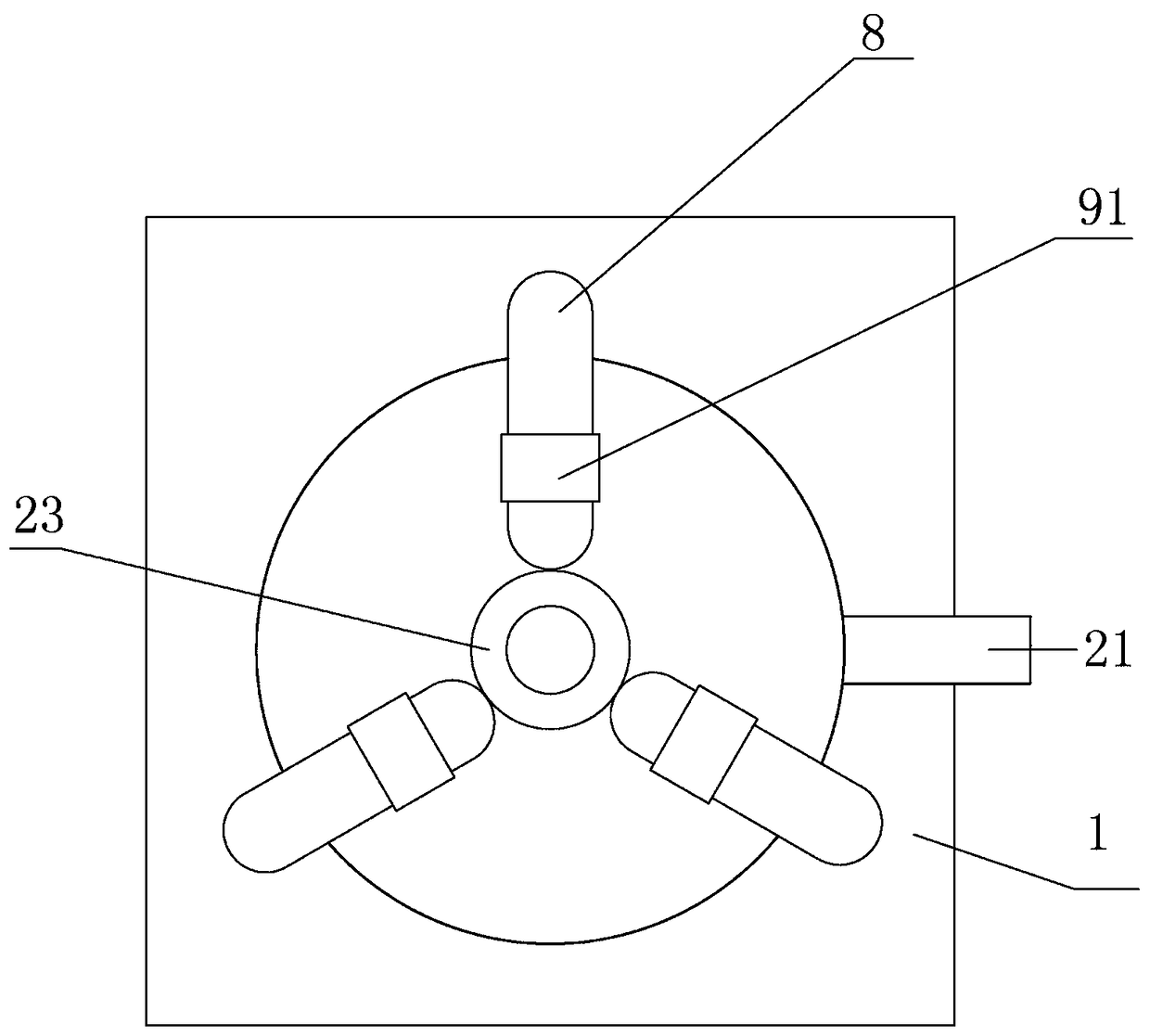

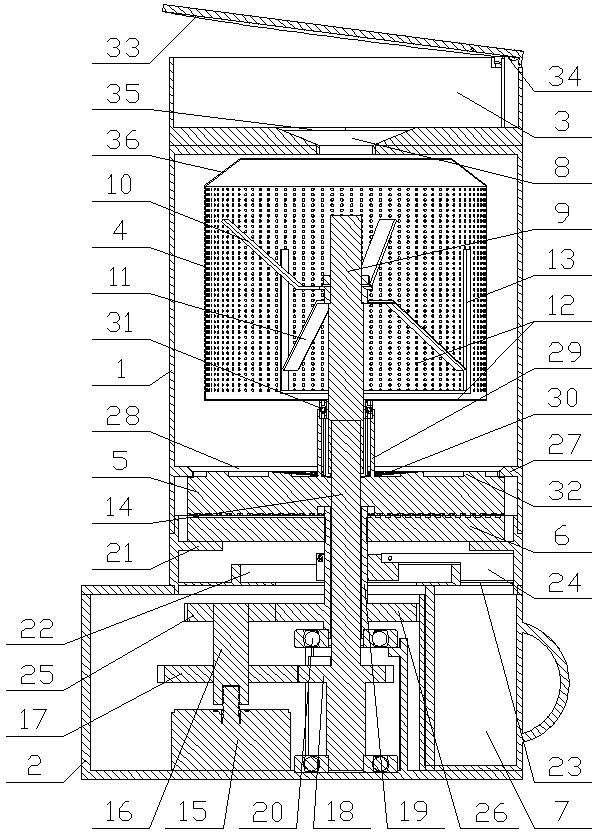

Mobile vibration reduction type high-precision flour milling device

PendingCN107520033AGuaranteed Particle SizeImprove grinding qualityNon-rotating vibration suppressionGrain treatmentsGrindingElectric machinery

The invention discloses a mobile vibration reduction type high-precision flour milling device. The device comprises a flour milling box; a funnel-shaped milling cavity is formed in the flour milling box; a milling cone is arranged in the milling cavity; a working gap is reserved between the milling cone and the milling cavity; the milling cone is driven to operate by a flour milling motor mounted at the bottom of the flour milling box; a driving crushing roller and a driven crushing roller with opposite positions are mounted above the milling cone in the flour milling box; a feeding hopper for feeding is arranged at the top of the flour milling box; an unloading channel communicating with the milling cavity is formed below the milling cavity; and the unloading channel is kept communicating with a discharge channel for discharging. The device has the following beneficial effects: cut materials can be renewedly fed from the feeding hopper by a return auger for crushing and flour milling again, so that the particle size of final finished products can be effectively guaranteed, and the flour milling quality is improved; and the device is convenient to move, meanwhile, is excellent in vibration reducing effect, and can be widely applied to fine grinding of materials.

Owner:ZHENGZHOU UNIV

Modified polypropylene material for high-performance thin-wall automobile door panel and preparation method thereof

The invention belongs to the technical field of plastics modification and particularly relates to a modified polypropylene material for a high-performance thin-wall automobile door panel and a preparation method thereof. The material is prepared from, by mass, 5%-10% of homopolymerized PP, 20%-30% of first copolymerized PP, 15%-25% of second copolymerized PP, 12%-18% of toughening agent, 1%-2% of compatilizer, 0.4%-0.6% of antioxidant, 0.2-0.4% of weather resistance agent, 3%-6% of melting index regulator, 20%-25% of mineral enhancer, 1.5-3% of scratch resistant agent and 1-2% of other assistants. The preparation method of the modified polypropylene material comprises the steps of mixing, extrusion and granulation. The material prepared by adopting the preparation method has high liquidity, rigidity and toughness, can well meet the usage requirements of the thin-wall automobile door panel and is low in cost. Compared with the prior art, a high-liquidity allyl elastomer is used as the melting index regulator, the liquidity of the material is remarkably improved, and the thin-wall door panel forming requirements are met. In addition, high-liquidity polypropylene and a low surface energy polymer are used in a mixed mode, and the tiger skin stripe defects on the surface of the thin-wall door panel can be basically eliminated.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

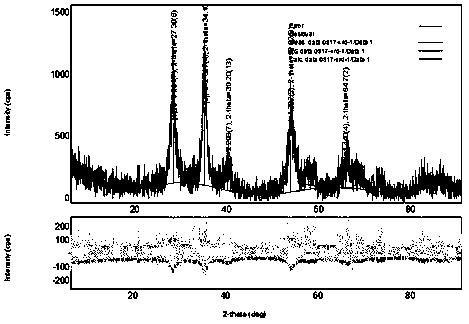

Titanium and aluminum based alloy powder material for additive manufacturing and preparation method thereof

ActiveCN107400802AImprove oxidation resistanceImproves strength and ductilityAdditive manufacturing apparatusTitaniumSystems design

The invention provides a titanium and aluminum based alloy powder material for additive manufacturing. The titanium and aluminum based alloy powder material is prepared from the following raw materials in percentage by atom: 47 to 56 percent of Al, 1.6 to 2.3 percent of Cr, 1.6 to 2.0 percent of Mo, 0.6 to 1.2 percent of TiB2 and the balance of Ti and unavoidable impurity. In addition, the invention also provides a method for preparing the alloy powder material. The method comprises the following steps of I, protecting the inner wall of a graphite flow guiding pipe by adopting a ceramic flow guiding inner core; II, preparing high-temperature-preventing carbonized coatings at the end surfaces of the graphite flow guiding pipe and then loading the graphite flow guiding pipe into a smelting chamber; III, preparing an ingot blank by adopting vacuum self-consuming arc smelting; IV, smelting to prepare an alloy melt by adopting a water-cooled copper crucible; V, carrying out atomization treatment, so that the titanium and aluminum based alloy powder material for the additive manufacturing is obtained. The alloy powder material is an alloy system designed for the additive manufacturing process and various properties of a product manufactured through the additive manufacturing technique by adopting the alloy powder material can reach expected effects.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Cationic-nonionic water-based polyurethane-polyacrylate composite emulsion and preparation method thereof

ActiveCN104004142AGuaranteed Particle SizeAchieve self-emulsificationFibre treatmentCoatingsWater basedAcrylic resin

The invention discloses a cationic-nonionic water-based polyurethane-polyacrylate composite emulsion and a preparation method thereof. The polyurethane resin has the defects of poor water resistance of the coated film and lower mechanical strength than the acrylic resin; and the polyacrylic resin has the defects of poor resistance to organic solvents, high tendency to sticking at high temperature, high tendency to embrittlement at low temperature and the like. The preparation method comprises the following steps: inoculating hydroxyl-terminated acrylate and a sealant into an NCO-terminated prepolymer, adding acetic acid to perform quaternization, and adding deionized water to perform emulsification, thereby obtaining the chemical-bond-combined self-emulsified PU (polyurethane) seed emulsion; and adding an unsaturated hydrophobic monomer and a molecular weight regulator, adding a proper amount of emulsifier to perform pre-emulsification, and finally, adding an initiator to initiate polymerization, thereby obtaining the stable cationic-nonionic water-based polyurethane-polyacrylate composite emulsion. The preparation method is advanced, and can be used for preparing the copolymerized emulsion which has obvious core-shell characteristics and can achieve forced compatibility and molecular synergy on the molecular level.

Owner:传化智联股份有限公司 +2

Lithium titanate composite material and preparation method thereof

InactiveCN101759227AThe first discharge specific capacity is highImprove rate discharge performanceMaterial nanotechnologyAlkali titanatesElectrochemistryImpurity

Owner:BYD CO LTD

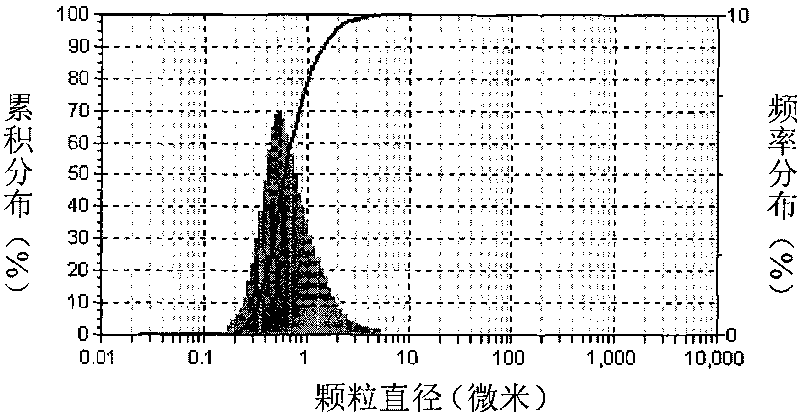

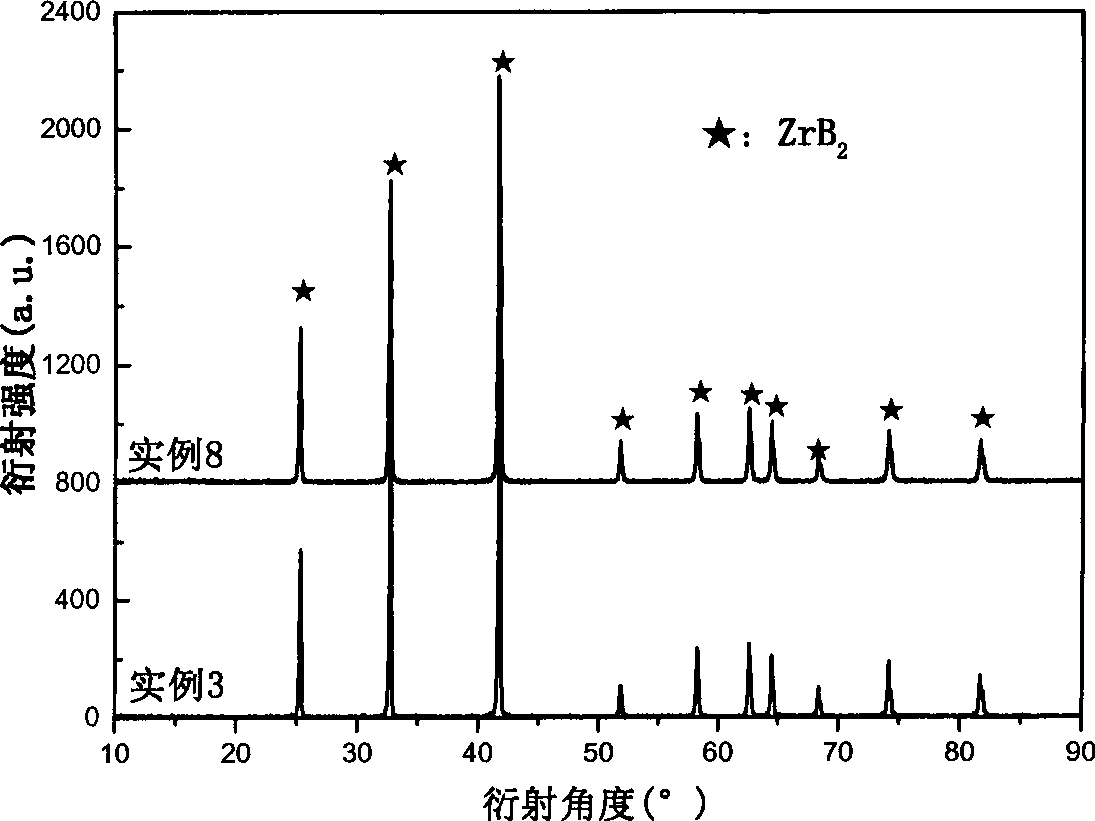

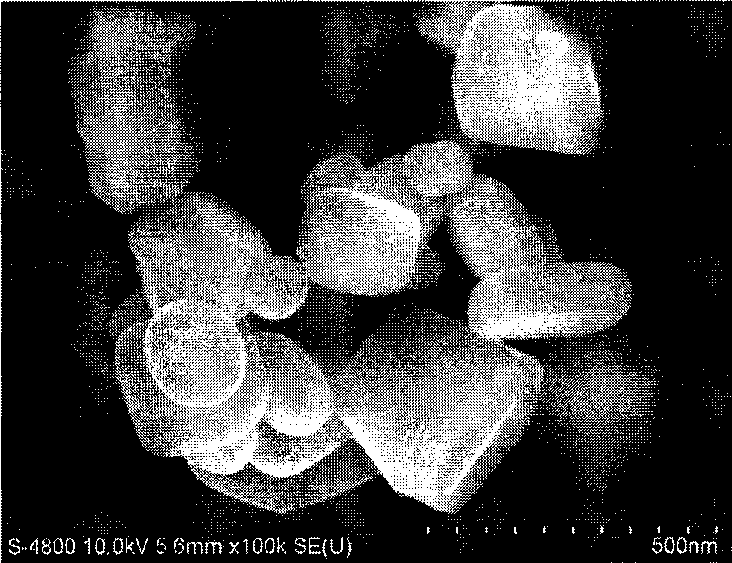

Preparation of nano zirconium diboride ceramic powder

InactiveCN101486577ASynthesis temperature is lowGuaranteed normal productionMetal boridesChemical treatmentCoprecipitation

The invention relates to a preparation method for nano zirconium diboride ceramic powder, which is characterized by comprising the following steps: 1) selecting materials: selecting according to a mol ratio of 1 : 3 to 1 : 5 between Zr and amorphous boron powder in soluble zirconium salt; 2) selecting one of the two methods as follows: a) using a coprecipitation method for gel forming to obtain xerogel; b) using a sol-gel method for gel forming to form the xerogel; 3) preparing precursor powder; 4) synthesizing quickly: arranging the materials into a large current reaction synthesizer; the inside of a black lead reactor is protected by vacuum or insert gases; applying a large current directly on the black lead reactor, quickly heating to 800 and 1500 DEG C at the temperature rising speed of 50 to 500 DEG C / min, preserving the temperature for 0 to 60 minutes to obtain a powder sample; and 5) chemical processing for obtaining the nano zirconium diboride ceramic powder. The method has the characteristics of quick synthesizing speed and high efficiency; the purity of the obtained nano zirconium diboride ceramic powder is high (equal to or more than 95 percent); and the grain diameters of the obtained nano zirconium diboride ceramic powder are uniform and thin(the average grain diameter is equal to or less than 300nm).

Owner:WUHAN UNIV OF TECH

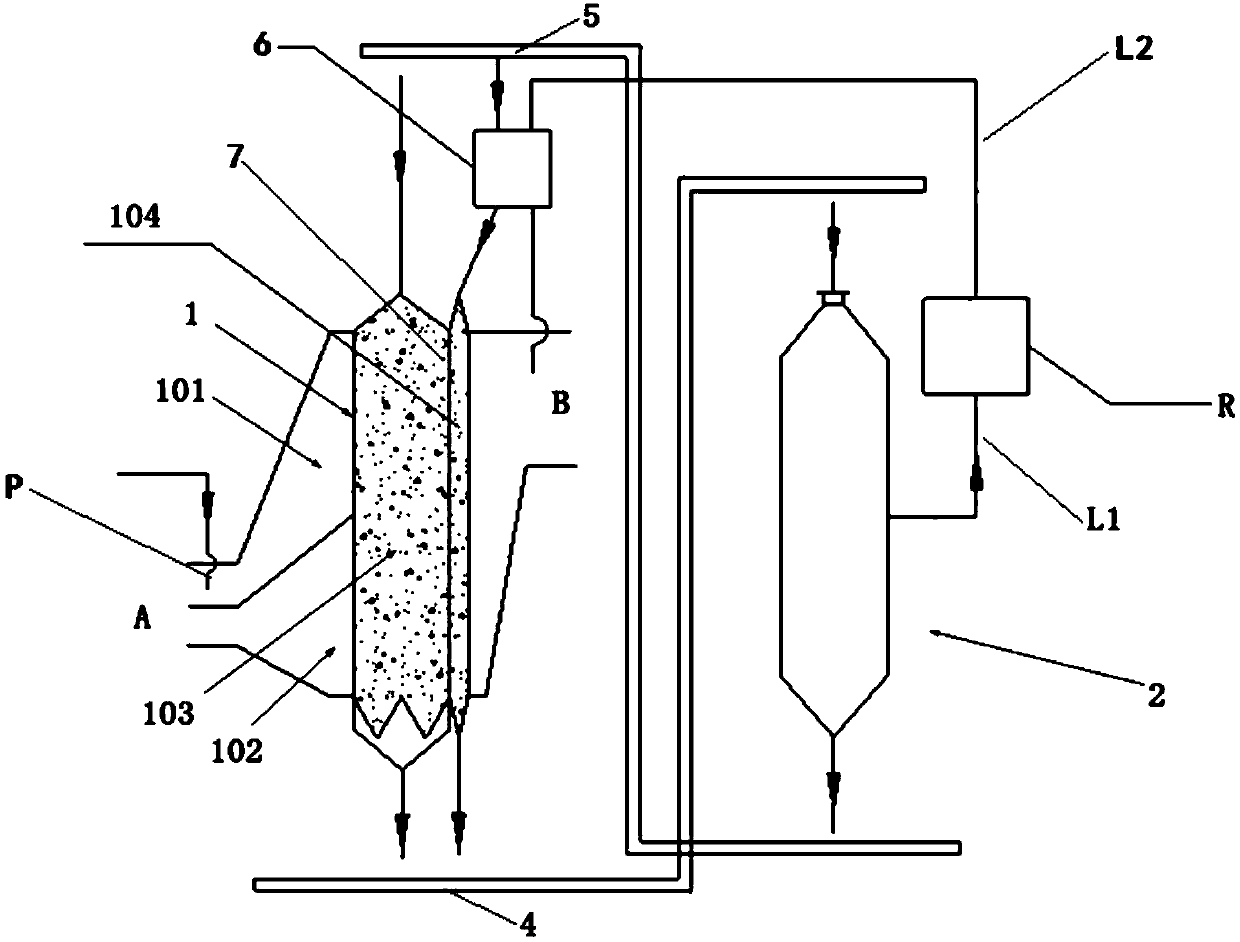

Desulfurization and denitration ammonia-removing system

ActiveCN108479344ACapturePrevent escapeGas treatmentDispersed particle separationActivated carbonDesorption

The invention discloses a desulfurization and denitration ammonia-removing system. The system comprises an adsorption tower, a desorption tower, a distributor, a first activated carbon conveyer and asecond activated carbon conveyer. One side of the adsorption tower is provided with a smoke inlet A, and the other side of the adsorption tower is provided with a smoke outlet B, the interior of the adsorption tower is provided with an adsorption cavity and an ammonia-removing cavity, the adsorption cavity is installed at one side adjacent to the smoke inlet A, the ammonia-removing cavity is installed at one side adjacent to the smoke outlet B, the first activated carbon conveyer is connected with a discharging port of the adsorption tower and a feeding port of the distributor, the second activated carbon conveyer is connected with a discharging port of the desorption tower and a feeding port of the adsorption cavity, a discharging port of the distributor is respectively connected with a feeding port of the ammonia-removing cavity and a feeding port of the desorption tower. The system adopts a mode that the adsorption tower is divided to two functional areas. The adsorption reaction cavity is capable of achieving the functions of desulfurization, denitration, dust removal and the like. The ammonia-removing cavity is filled with fresh activated carbon or acidic activated carbon, andis capable of gathering ammonia in smoke passing through an adsorption reaction layer, and effectively preventing the ammonia at the outlet from escaping.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

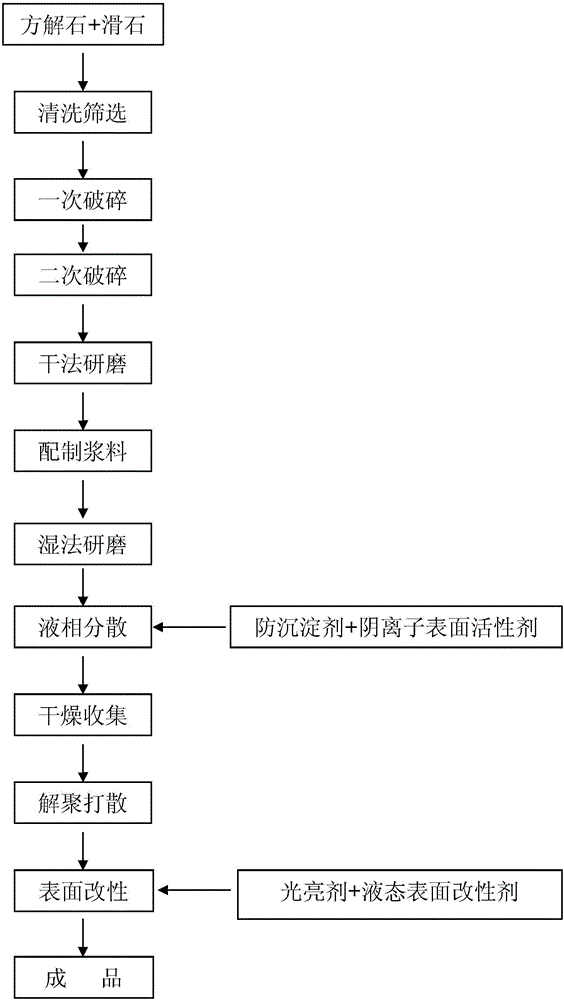

Preparation method of modified calcium carbonate

ActiveCN106317963AGood printabilityEvenly dispersedPigment treatment with organosilicon compoundsPigment physical treatmentDispersityCalcite

The invention provides a preparation method modified calcium carbonate. The preparation method includes: mixing and crushing calcite and talcum, performing dry grinding to obtain raw slurry with solid content being 70-75%, performing constant-temperature stirring and grinding to obtain processed slurry with average particle size being 0.9-1.1 micrometers, adding naphthalene sulfonate type anti-precipitation agent and anionic surfactant into the processed slurry to perform liquid-phase dispersing, drying, collecting, depolymerizing and dispersing, adding brightener and liquid surface modifier to perform wrapping treatment, and stirring to obtain the modified calcium carbonate. By the preparation method, the modified calcium carbonate which is good in printing performance, good in dispersity, good in surface brightness and applicable to films adhered to car bodies can be prepared.

Owner:JIANGXI GUANGYUAN CHEM

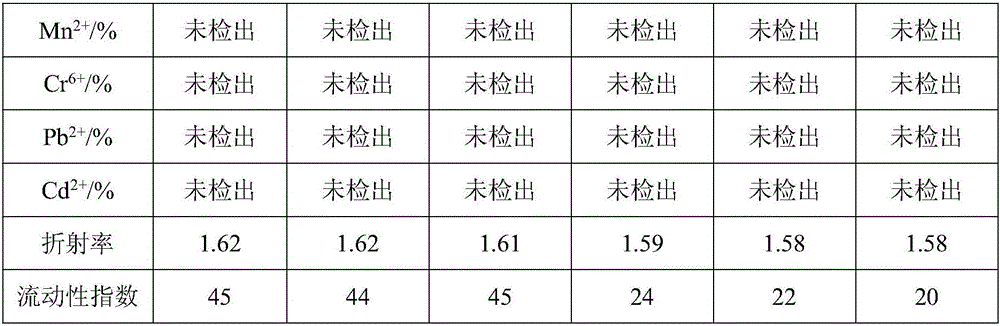

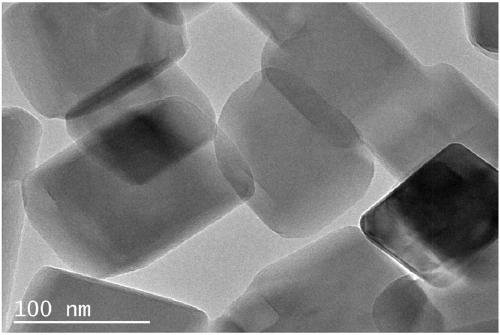

Preparation method of nano calcium carbonate for MS glue

InactiveCN109650431ADetermining performanceThe process steps are the sameCalcium/strontium/barium carbonatesNon-macromolecular adhesive additivesCarbonizationSlurry

The invention discloses a preparation method of nano calcium carbonate for MS glue, which comprises the following steps: removing impurities from calcium hydroxide (Ca (OH) 2) slurry obtained after the digestion reaction of quicklime (CaO) and water (H2O), preserving heat and aging, adding a crystal form control agent, performing primary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2), adding a post-treatment agent, aging for a certain time, performing secondary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2) to obtain calcium carbonate (CaCO3) cooked slurry, adding a modifier into the cooked slurry, performing filter pressing dehydration, drying, crushing and grading after the reaction is finished to obtain the nano calcium carbonate for MS glue. The nano calcium carbonate crystal prepared by the method is a standard cube, and the crystal is mono-disperse, and the average particle diameter is only 100-150nm, and the specific surface area is 16-18m <2 > / g, and the nano calcium carbonate crystal is used for MS glue, and the thixotropy is good, and the extrusion property is good, and the storage stability is good, and the surface finish after gluing is good, and the tensile strength is high, and the elongation is high and the bonding property is also good. The preparation method of nano calcium carbonate for MS glue has the advantages of simple and feasible process, low cost, low price and better economic benefit.

Owner:卢氏国嵩莱纳米科技有限公司

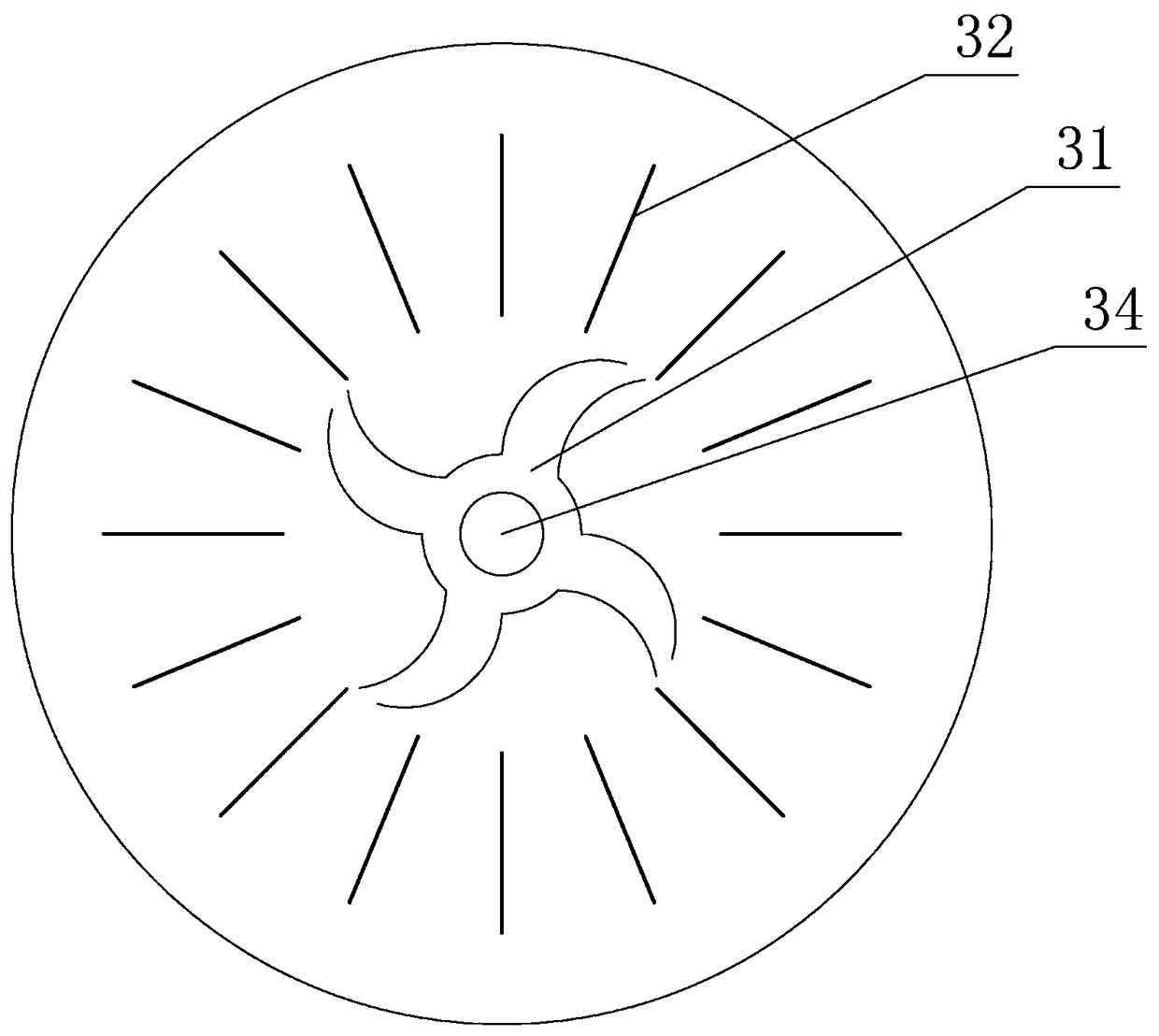

Crushing type blockage prevention device

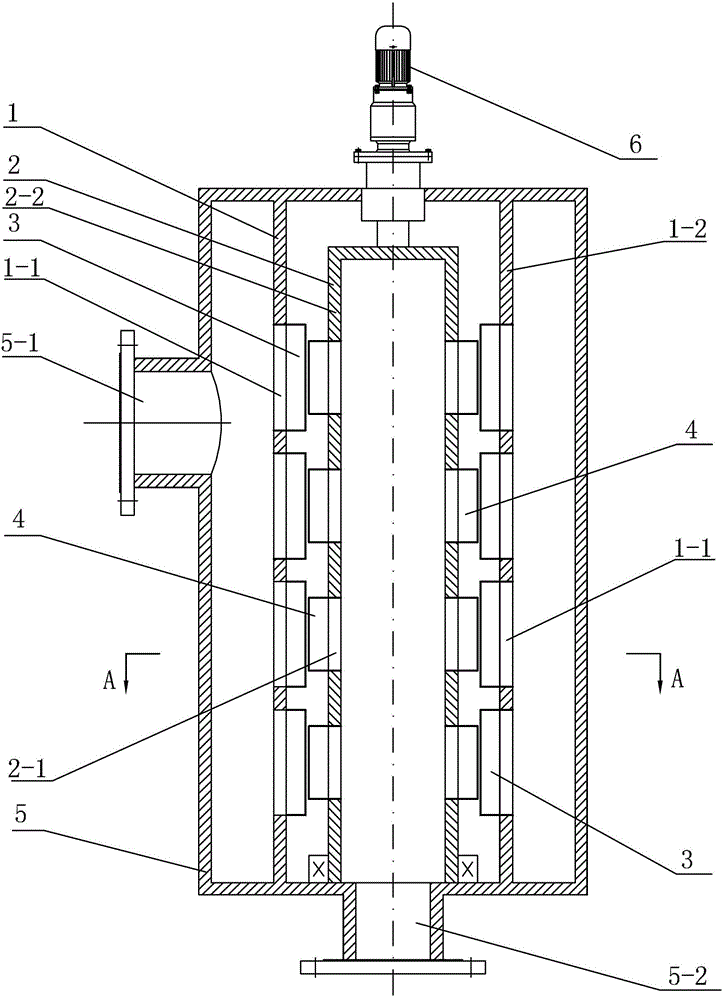

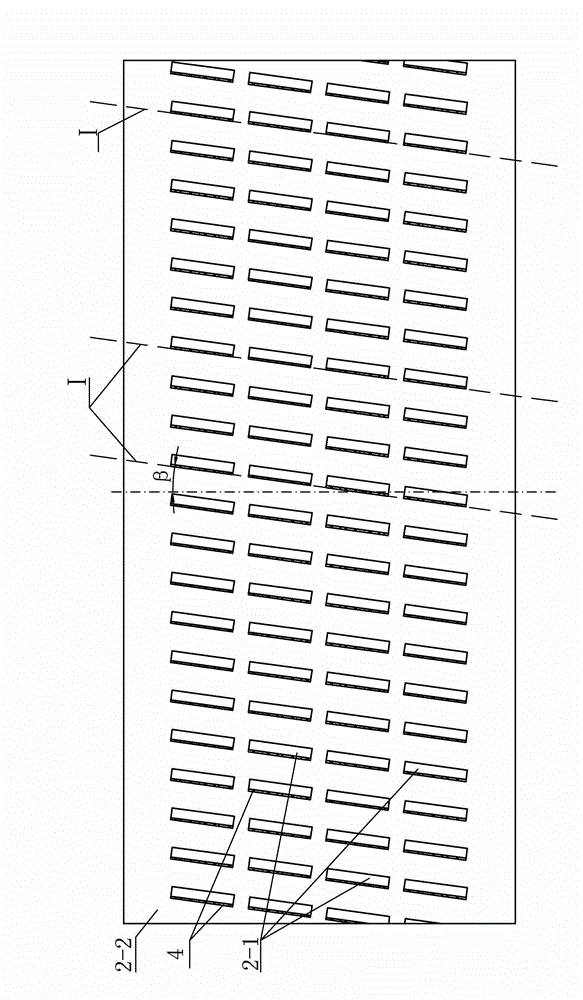

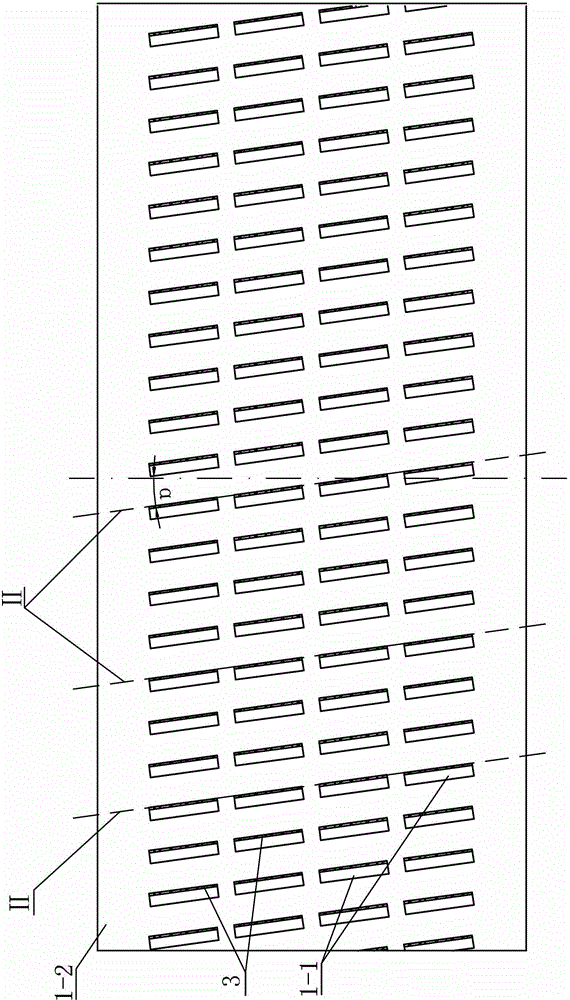

The invention discloses a crushing type blockage prevention device which relates to a blockage prevention device for a sewage heat exchange system and aims to solve the problems of incomplete filtration, miscellaneous clearing operation, big temperature difference loss of the water source and high operating cost in the prior art in the process of processing big-grain sundries contained in the sewage which enters the equipment such as heat exchange equipment. The crushing type blockage prevention device comprises a fixed outer cylinder, a rotary inner cylinder, a shell barrel, a driving device, a plurality of inner blades and equal number of outer blades. The rotary inner cylinder and the fixed outer cylinder are respectively arranged inside the shell barrel; the fixed outer cylinder is sleeved outside the rotary inner cylinder; the driving device is arranged on the upper end face of the shell barrel; the inner blades are distributed on the outer circumferential side face of the rotary inner cylinder; the outer blades which are equal in number with the inner blades and correspond with the inner blades one by one are distributed on the inner circumferential side face of the fixed cylinder; and the rotation direction of each inner blade which takes the shape of a right-handed spiral cylindrical plane is opposite to the rotation direction of the corresponding outer blade. The crushing type blockage prevention device is used for processing the big-grain sundries contained in the sewage which enters the heat exchange system.

Owner:HARBIN INST OF TECH

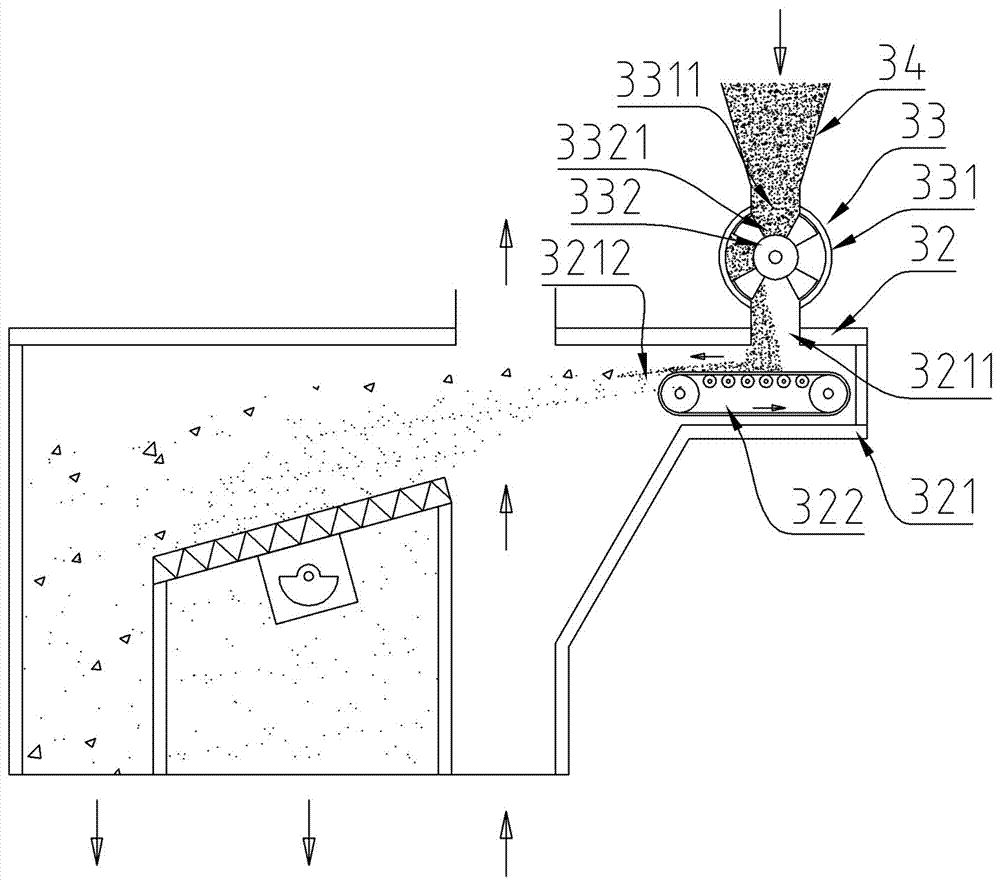

Cast type material separation method and device and separation bin

ActiveCN106984544AReduce work intensityReduced Power RequirementsSievingGas current separationCasting typesMixed materials

The invention relates to the field of material sorting equipment, in particular to a cast type material separation method and device and a separation bin. The cast type material separation method comprises the steps that at least one collecting area is provided with a screening device, a mixed material is cast through a cast device, the material falling into the collecting area where the screening device is located is screened through the screening device so that the material meeting the grain size requirement can be obtained. Compared with an existing material separation method, according to the cast type material separation method, the mixed material is preliminarily separated through the cast device, the screening device is arranged in the collecting area so as for further screen the material entering the collecting area, the effect that the grain size of the material obtained after screening is in the required range is guaranteed, and the problem that according to an existing cast type material separation method, due to the fact that further screening operation needs to be conducted, the production efficiency is low is solved.

Owner:ZHENGZHOU SANHE HYDRAULIC MACHINERY

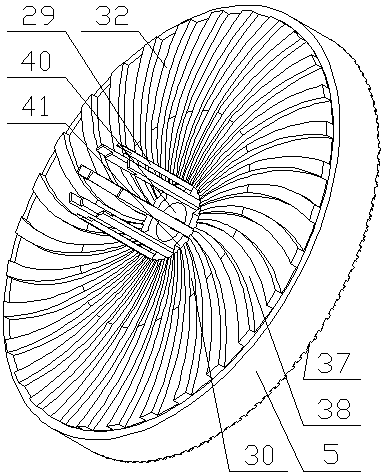

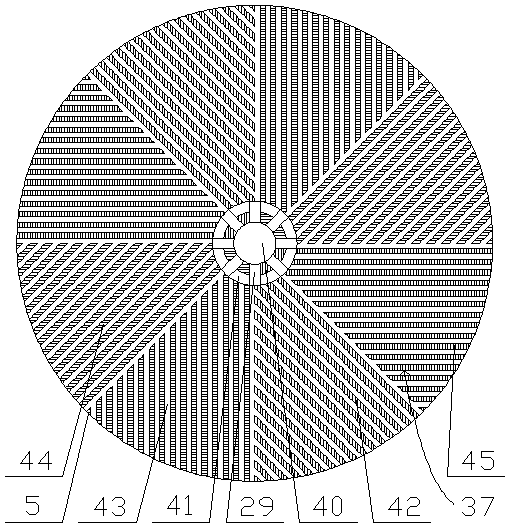

Cone-disc type waste concrete regenerated coarse aggregate mortar stripping device

ActiveCN109012867AWeaken protruding cornersReduce mud contentCocoaGrain treatmentsMetallurgyConstruction aggregate

The invention discloses a cone-disc type waste concrete regenerated coarse aggregate mortar stripping device. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device comprises a base, a material collection bin and a cone-disc type grinding disc, wherein the cone-disc type grinding disc is composed of an upper grinding disc and a lower grinding disc, the grinding surface of the lower grinding disc is of a convex cone type, the grinding surface of the upper grinding disc is of a concave cone type, and the grinding surface of the upper grinding disc is in fit with that of the lower grinding disc; the base is provided with a plurality of reverse-hook-shaped supports, the disc surface of the upper grinding disc is correspondingly provided with position-limiting holes, and reverse hooks of all the reverse-hook-shaped supports penetrate into the corresponding position-limiting holes to restrict the upper grinding disc to be only capable of sliding up and down; ahydraulic force transmitting device is arranged between the upper grinding disc and all the reverse-hook-shaped supports, and ascending and descending of the upper grinding disc are controlled through stretching and contracting adjustment of the hydraulic force transmitting device; and the center of the upper grinding disc is provided with a material inlet, the material inlet penetrates out of the top of the material collection bin, and the lower portion of the material collection bin is provided with a material outlet. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device is simple in structure, the aggregate mortar stripping effect is good, and the original particle size of coarse aggregate can be maintained to make the performance of the coarse aggregate be close to natural aggregate, so that the workability, strength and durability of freshly-mixed waste concrete are improved.

Owner:CHINA UNIV OF MINING & TECH

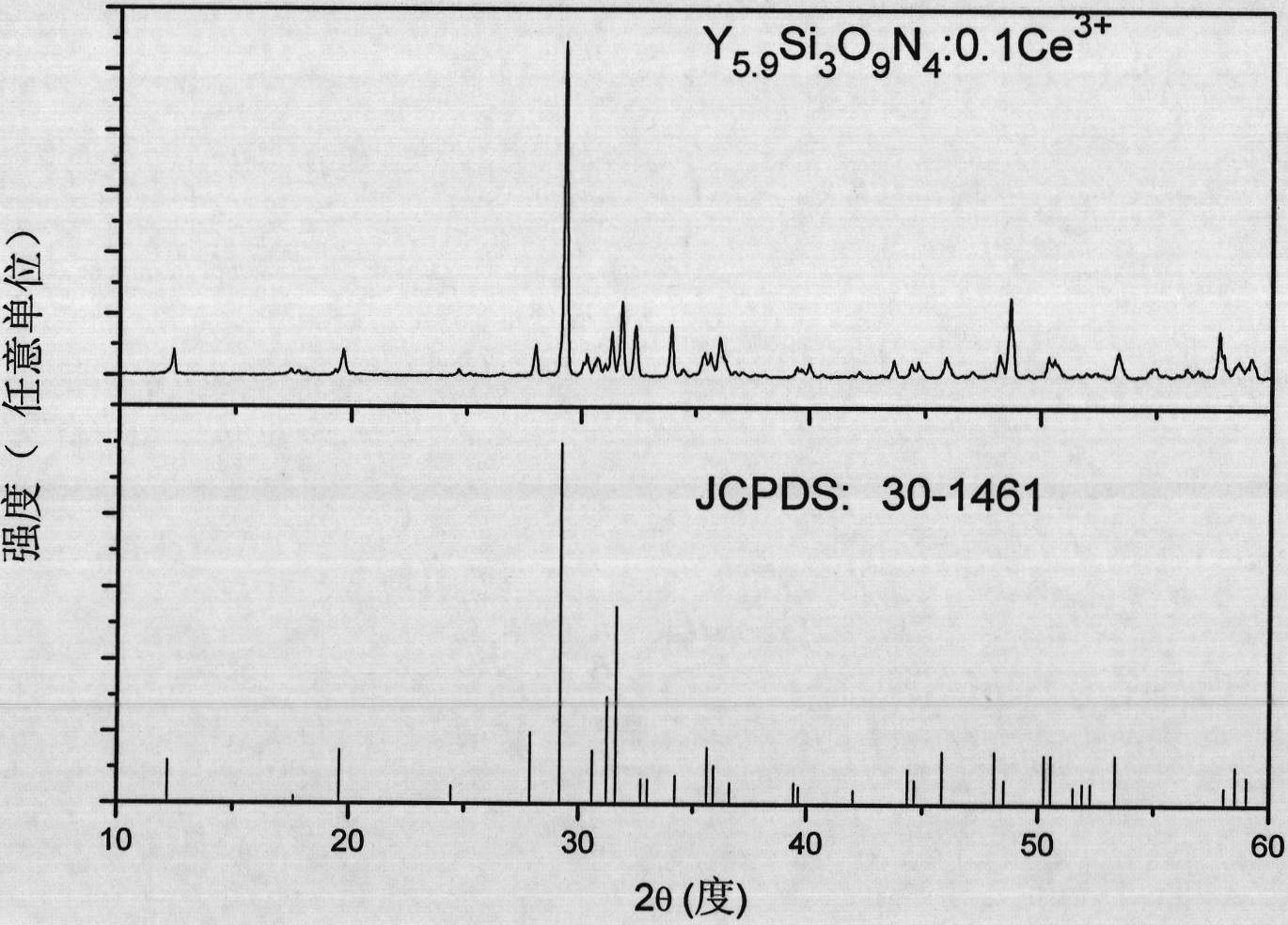

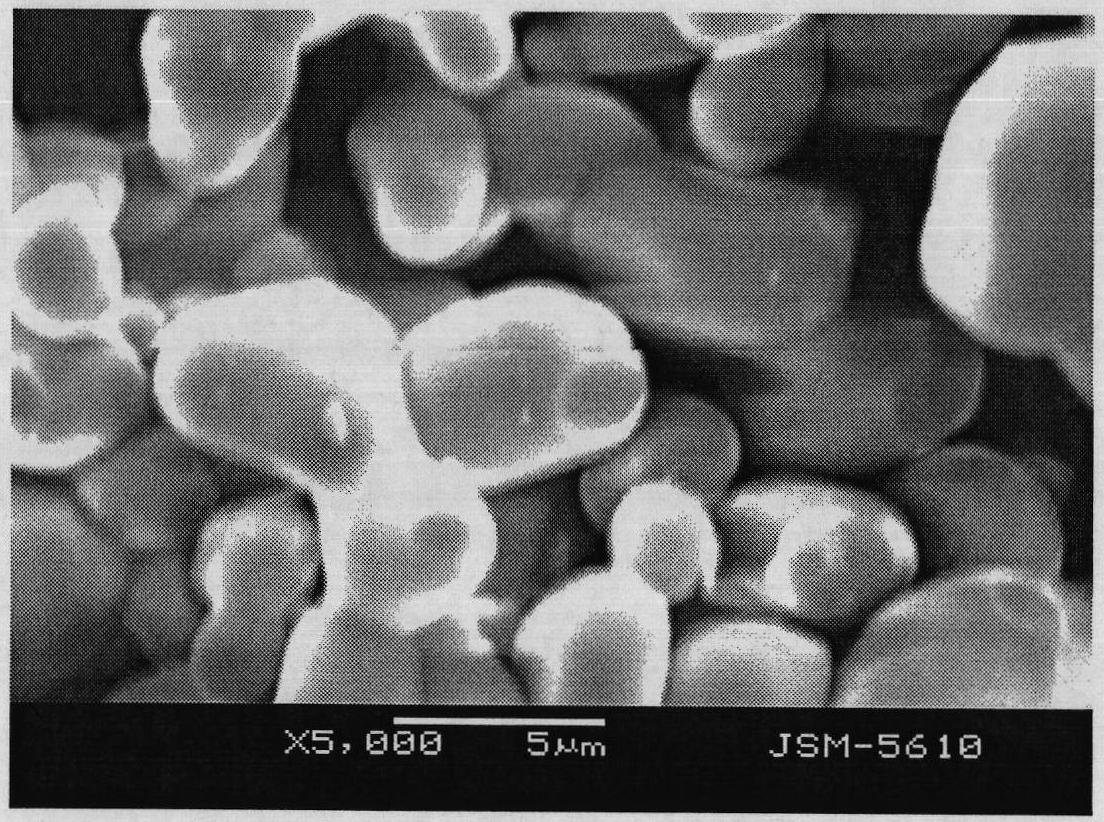

Method for preparing nitrogen oxide phosphor powder

InactiveCN101914379AImprove uniformityGuaranteed purityLuminescent compositionsFluorescencePolyethylene glycol

The invention discloses a method for preparing nitrogen oxide phosphor powder. Salt and nitride of a metal component in the nitrogen oxide phosphor powder to be prepared are taken as raw materials, and the method comprises the following steps of: weighing the raw materials according to the stoichiometric proportion of the phosphor powder to be prepared, and dissolving the raw materials in water to prepare first suspension; adding a dispersant polyethylene glycol into the first suspension, fully dispersing the dispersant to prepare second suspension, and controlling the volume ratio of the dispersant to the first suspension to be 5-8:100; dropping ammonia water into the second suspension to make the pH value of the second suspension be 5-6; ultrasonically oscillating the second suspension in ultrasonic waves to prepare uniform and stable third suspension; putting the third suspension into a heating furnace, and performing thermal treatment at the temperature of between 500 and 600 DEG C for 2 to 3 hours to prepare precursor powder; and putting the precursor powder into a crucible, and calcining in the reducing atmosphere at the temperature of between 1,300 and 1,400 DEG C for 4.5 to 7 hours to prepare the required phosphor powder.

Owner:CHINA JILIANG UNIV

Automatic sand drying machine

InactiveCN104864694AReduce equipment costsSimplify the production processSievingScreeningAir heaterMoisture sensor

The invention provides an automatic sand drying machine which comprises a drying chamber and a screening chamber. An air outlet and a sand inlet with a humidity sensor are arranged at the top of the drying chamber, a microcontroller and two opposite air inlets are formed in the side wall of the lower portion of the drying chamber, one air inlet is connected with a first air heater, the other air inlet is connected with a second air heater, the microcontroller is electrically connected with the humidity sensor, the first air heater and the second air heater, and ventilating dense screens inclined downwards are arranged on two opposite side walls in the drying chamber in a staggered mode. A coarse sand outlet and a fine sand outlet are arranged at the bottom of the screening chamber, a screen body and a vibration motor are arranged in the screening chamber, the screen body comprises a screen mesh and a flow guide plate, the screen mesh is obliquely arranged on the upper layer, the flow guide plate is located on the lower layer oppositely to the inclination direction of the screen mesh, and the vibration motor is connected with the flow guide plate. Drying equipment and screening equipment are arranged to a whole, sand can be automatically dried and screened after being added to the machine, equipment cost is lowered, and the production procedure is simplified.

Owner:CHENGDU GUANGMAI TECH

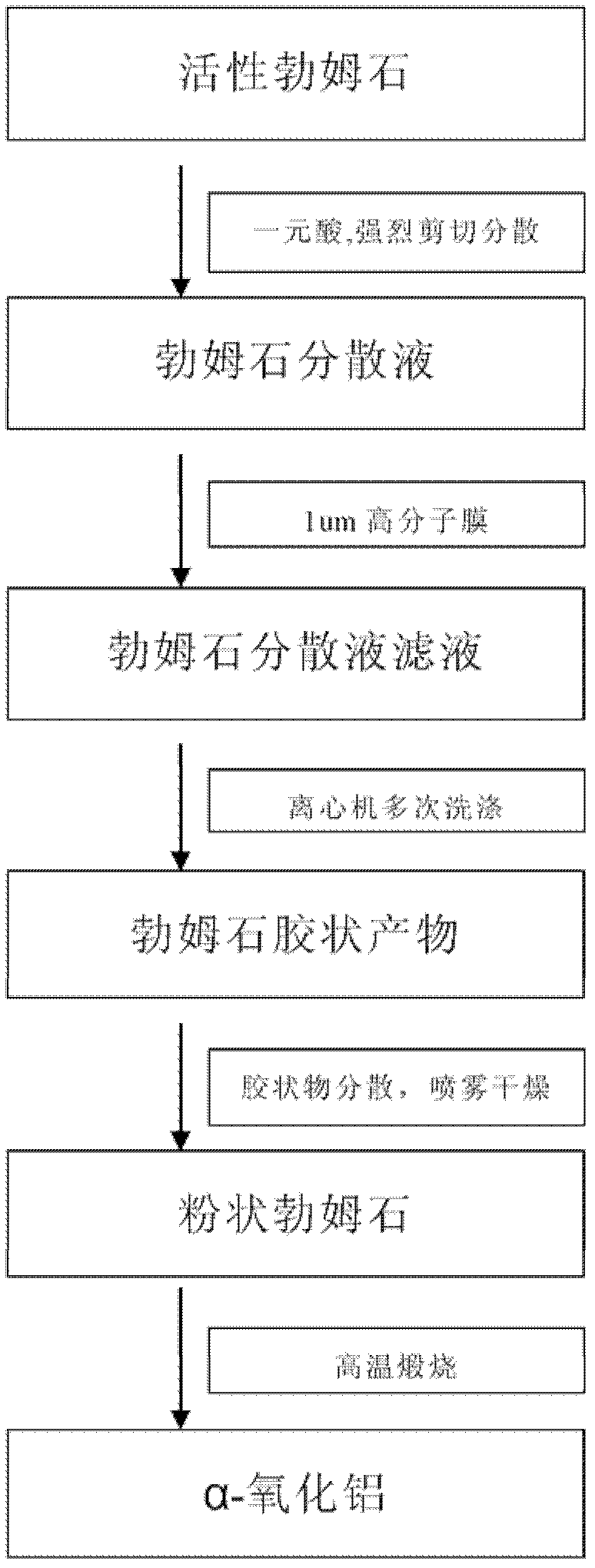

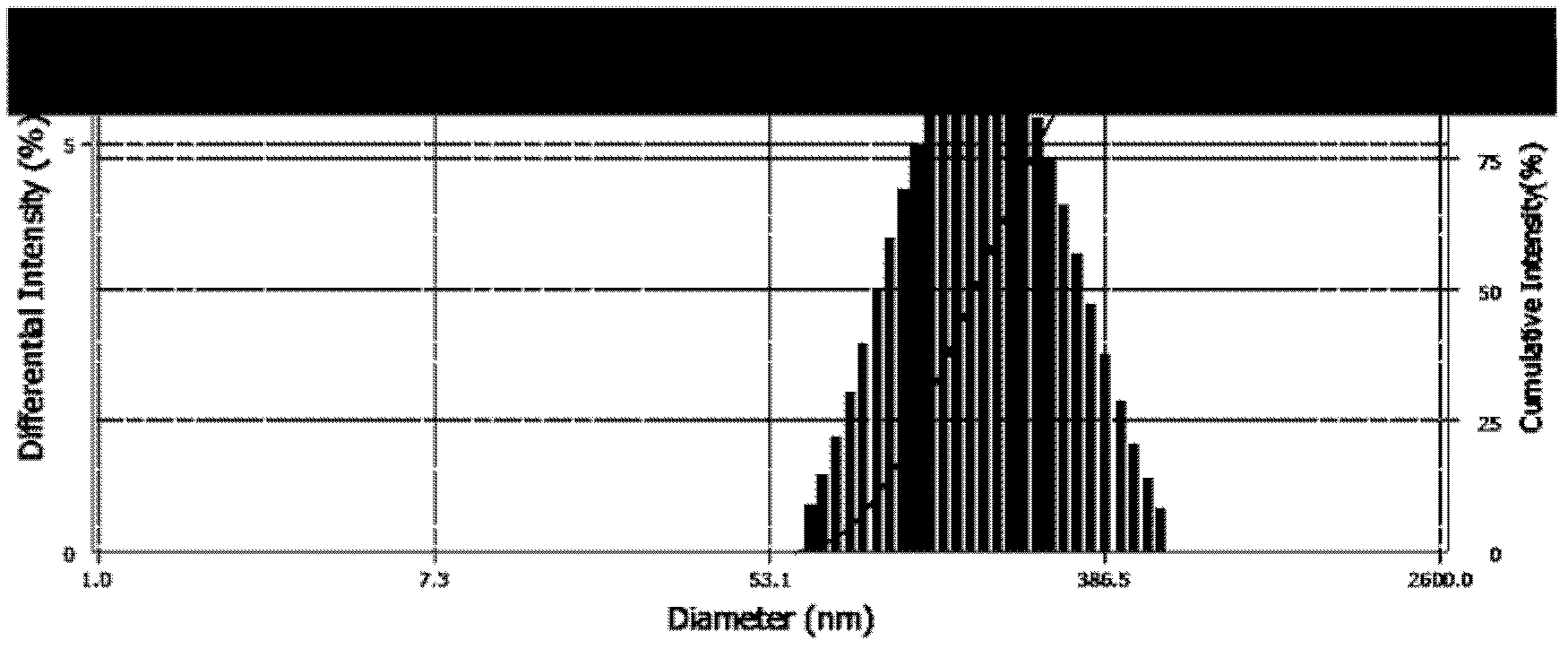

Industrial production method for superfine high-purity alpha-alumina

ActiveCN102583469AGuaranteed purityGuaranteed Particle SizeAluminium oxides/hydroxidesOrganic acidGranularity

The invention discloses an industrial production method for preparing superfine high-purity alpha-alumina. The industrial production method comprises the following steps that: (1) boehmite is dispersed in unitary organic acid; (2) an obtained dispersing agent of the boehmite is filtered; (3) the dispersing agent of the boehmite is subjected to solid-liquid separation, washing and redispersion; (4) the dispersing agent with impurities being removed is subjected to spray drying; and (5) the dried boehmite obtained in the step (4) is subjected to high-temperature calcination. According to the invention, the purity and the grain size of the produced alpha-alumina are well guaranteed, and the purity and the grain size of a final product can reach the using requirements in a high-end electronic industry.

Owner:GUANGZHOU HUMAN CHEM

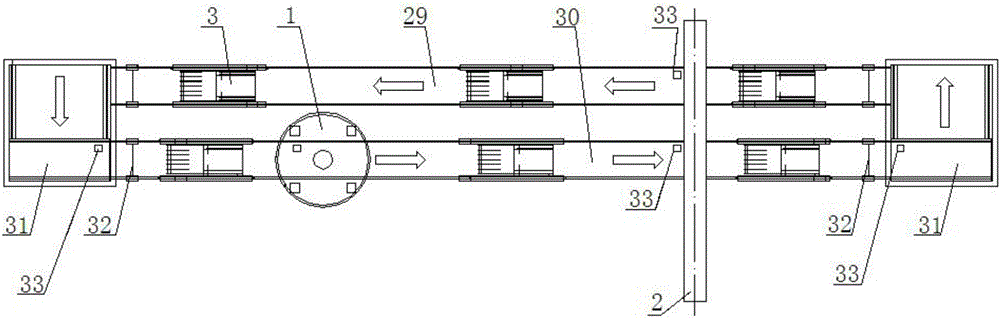

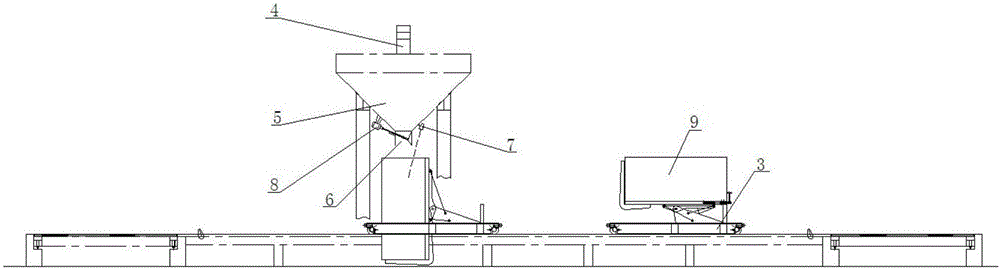

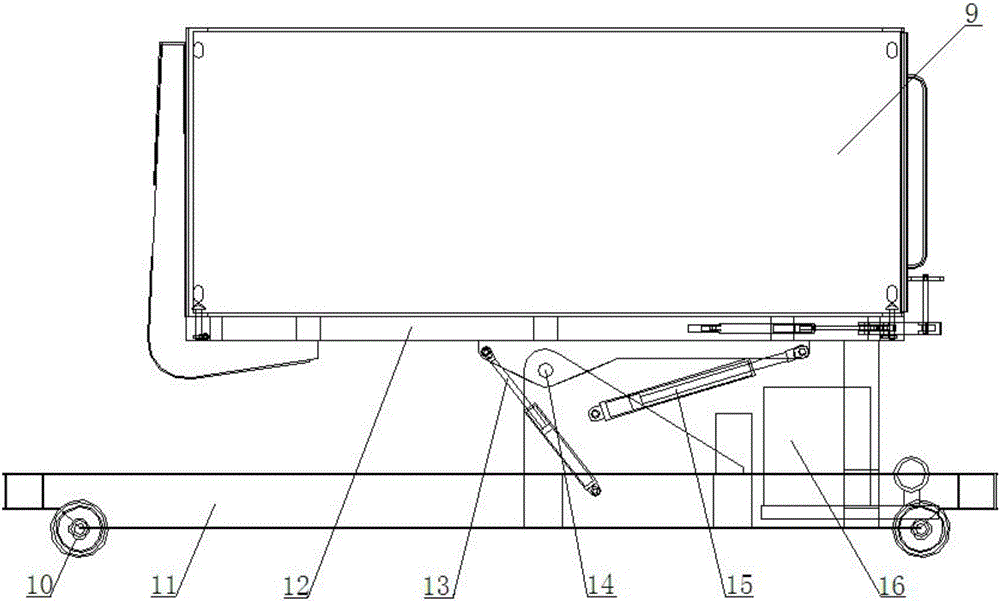

Lump coal boxing system and boxing method thereof

ActiveCN104986582AImprove dumping efficiencyAchieve brokenControl devices for conveyorsLoading/unloadingControl systemMechanical engineering

The invention discloses an automated lump coal boxing system and a boxing method thereof. A control system in the automated lump coal boxing system is connected with overturning trolleys (3) and trolley moving tables (31) respectively, detecting switches (33) are uniformly distributed on the trolley moving tables (31) in the lump coal boxing system, an empty trolley line (29) and a boxing line (30)which are under a hoisting device (2), and the boxing line (30) under a feeding mechanism (6), and the detecting switches (33) are connected with the control system; a hopper position detecting device (7) and a door opener (8) are arranged on a hopper (5) of a hopper device (1), and the hopper position detecting device (7) and the door opener (8) are respectively connected with the control system. The boxing method disclosed by the invention comprises the following steps: charging lump coal; controlling the overturning trolleys (3) to travel and overturn; and enabling a container (9) to be hoisted and placed to a transporting vehicle by the hoisting device (2). Through the adoption of the automated lump coal boxing system and the boxing method thereof, the overturning efficiency and the dismounting efficiency of the container are improved, and large-scale industrial production can be realized.

Owner:WUHAN POWER EQUIP WORKS

Ginkgolide B liposome medicinal composition

InactiveCN101912364AImprove therapeutic indexEvenly dispersedOrganic active ingredientsPharmaceutical product form changeVascular diseaseFreeze-drying

The invention aims to industrially produce ginkgolide B liposome medicinal composition injection and ginkgolide B liposome medicinal composition oral preparations through uniform formula, process and equipment by a molecule dispersing method. The invention provides a molar ratio formula of the component raw materials for preparing the ginkgolide B liposome medicinal composition, steps and method for preparing ginkgolide B liposome medicinal composition freeze-dried injection and oral preparations, and embodiments for preparation. The ginkgolide B liposome medicinal composition is used for treating cerebral and vascular diseases.

Owner:刘会梅

Preparation method for polystyrene-resin-loaded nano zero valent iron, and application of polystyrene-resin-loaded nano zero-valent iron to oily wastewater

InactiveCN102489267AGuaranteed Particle SizeEasy to prepareOther chemical processesWater/sewage treatment by sorptionPolystyrenePre treatment

The invention discloses a preparation method for polystyrene-resin-loaded nano zero valent iron, and application of the polystyrene-resin-loaded nano zero valent iron to oily wastewater. According to the preparation method, ferrous ions are reduced to nano zero valent iron by using sodium borohydride as a reducing agent, and reaction conditions, dripping speed and stirring speed are controlled to guarantee that the particle diameter of the nano zero valent iron particles formed by reaction is less than 100nm; and in the reaction process, pretreated strongly acidic polystyrene cation exchange resin is used as a loading material, and nano zero valent iron particles which are produced by reaction are fully dispersed and loaded on the resin by using pores of the resin. The preparation method has the advantages of simplicity, low cost, no special requirement on external environment condition and small occupied space; the prepared material is applied to treatment of the oily wastewater at low concentration, and integrates the adsorption performance of the resin and strong reducibility of nano zero valent iron; and the deoiling rate reaches over 90 percent and turbidity removal rate reaches over 75 percent.

Owner:HUNAN UNIV OF SCI & TECH

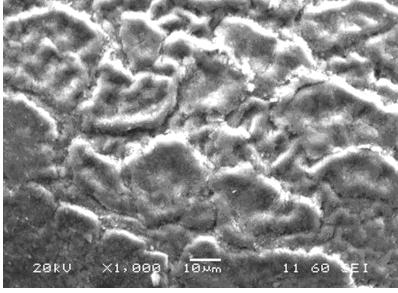

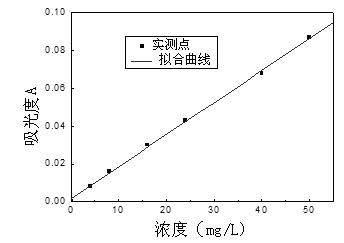

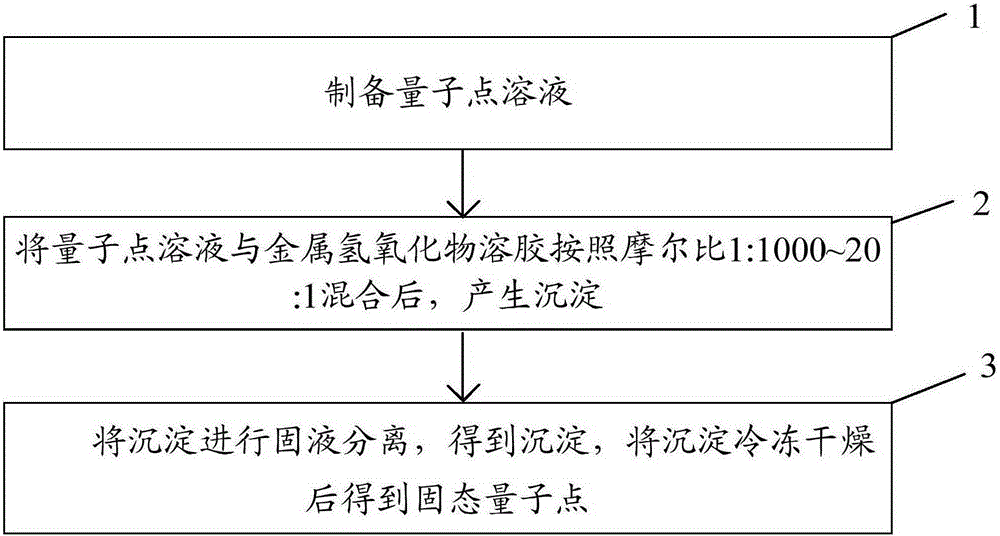

Preparing method for solid quantum dots

ActiveCN105199735AImprove luminous efficiencyHigh yieldNanoopticsLuminescent compositionsQuantum dotComputational chemistry

The invention discloses a preparing method for solid quantum dots and belongs to the field of light-emitting materials. The method comprises the steps that a quantum dot solution is prepared; after the quantum dot solution and metal hydroxide sol are mixed according to the mole ratio of 1:1000-20:1, precipitate is generated; solid-liquid separation is carried out on the precipitate to obtain precipitate, and the precipitate is dried in a frozen mode to obtain the solid quantum dots. According to the method, metal hydroxide is added into the quantum dot solution, the quantum dot solution can generate flocculent precipitate, and the precipitate can stop quantum dot nanometer particles from gathering; solid-liquid separation is carried out on the precipitate, the precipitate is dried in the frozen mode to obtain the solid quantum dots, in the freezing and drying processes, gathering of the quantum dots can be prevented, the morphology and the grain diameter of the quantum dot particles are kept unchanged, and therefore it is ensured that the solid quantum dots have high light-emitting efficiency.

Owner:JIANGHAN UNIVERSITY

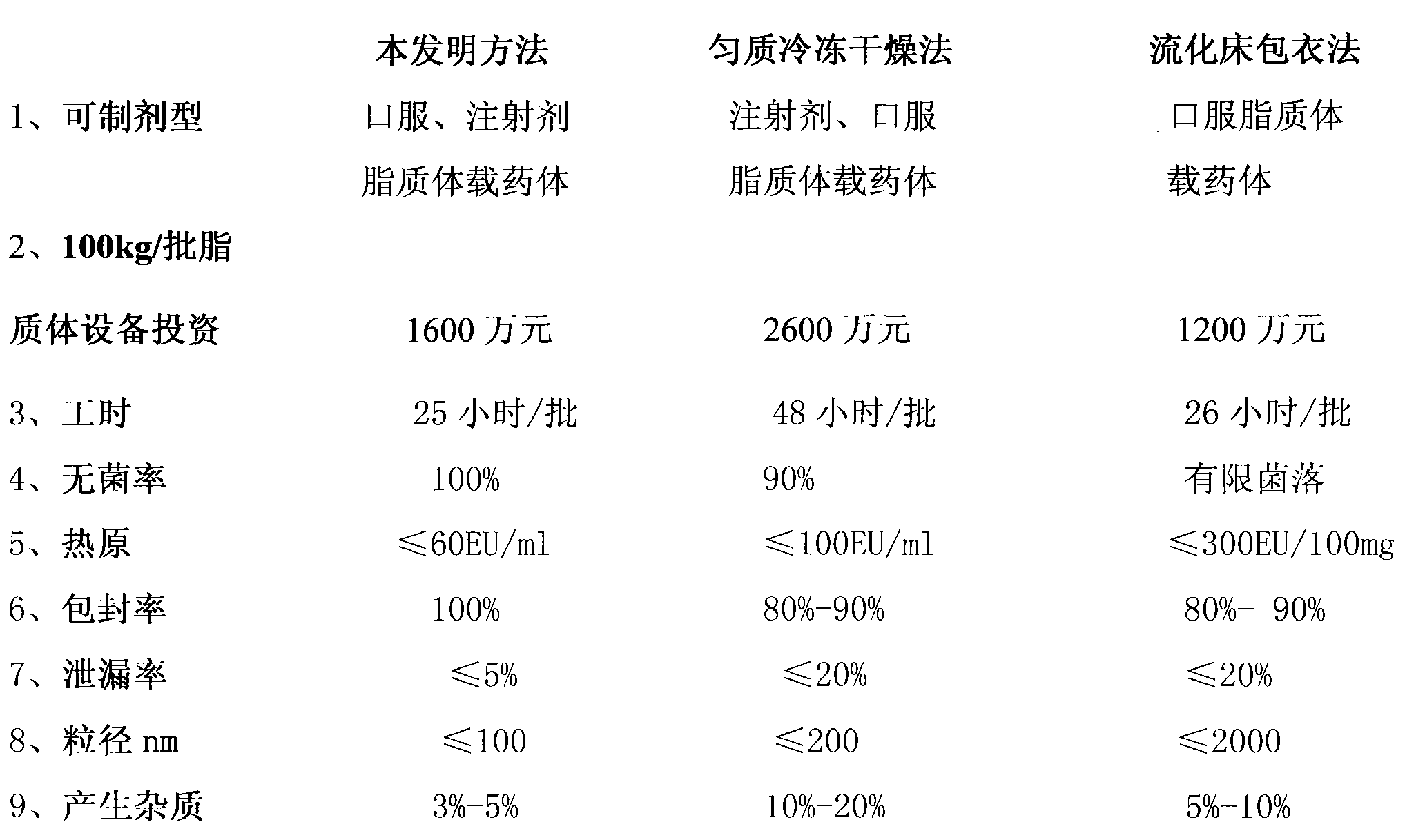

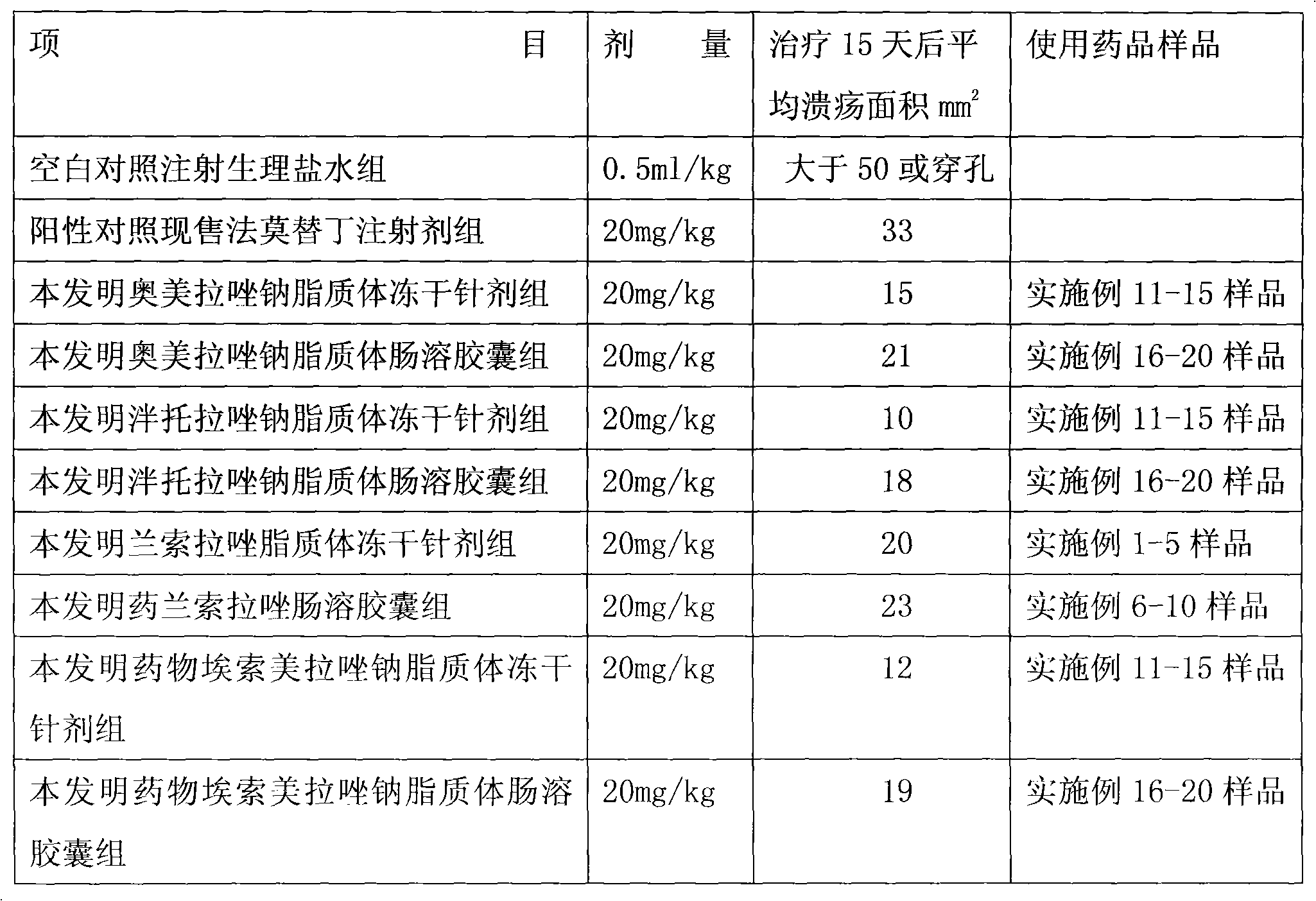

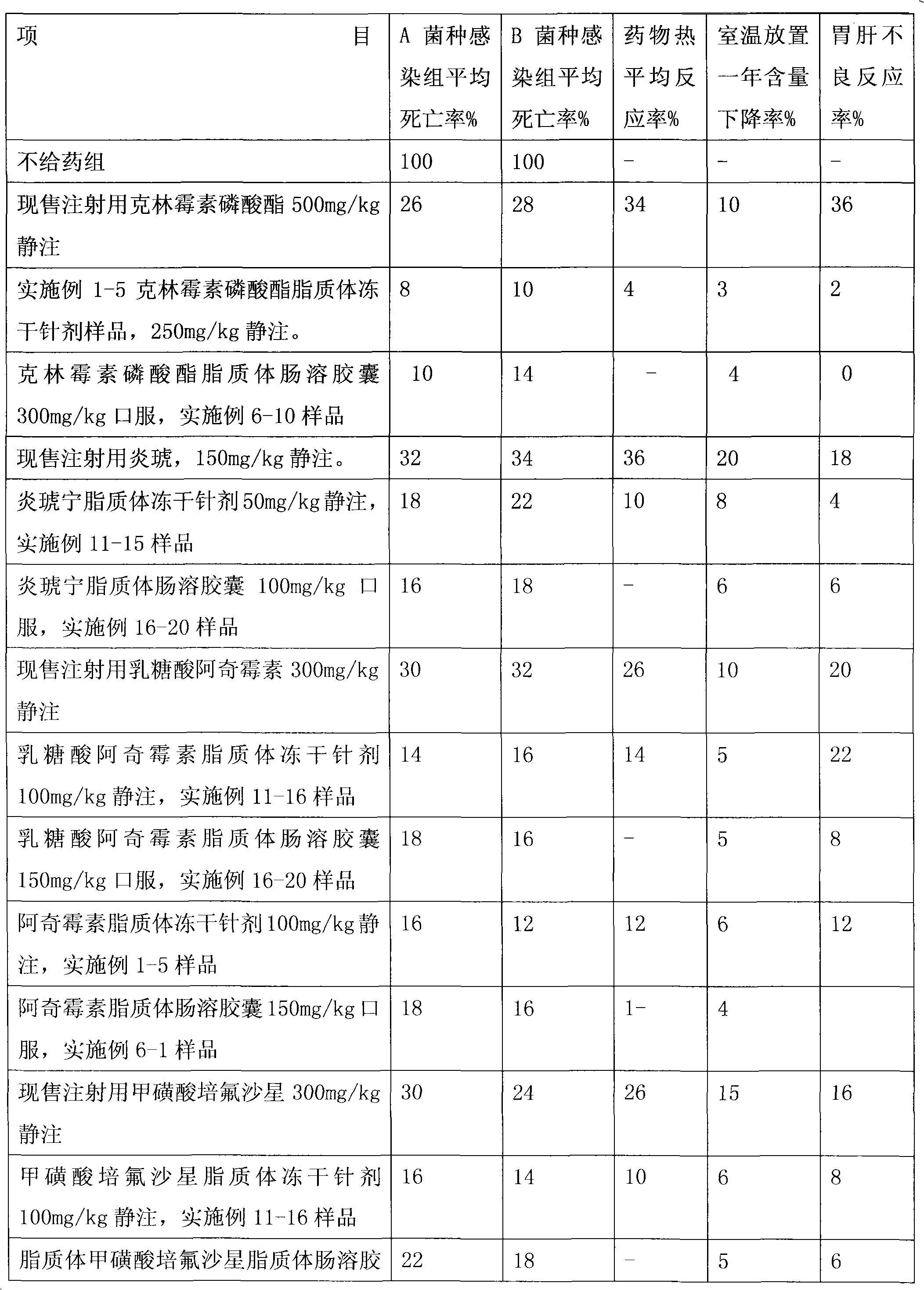

Liposome combination drugs, industrial production process of liposome combination drug through molecular dispersion method, and quality control

InactiveCN103446054AImprove therapeutic indexEvenly dispersedAntibacterial agentsOrganic active ingredientsAnti virusFreeze-drying

According to the invention, a liposome combination drug injection and an oral liposome combination drug preparation can be produced in a large industrialization manner through a molecular dispersion method with a unified formula, a unified process and unified equipment. The invention provides a formula of raw components for preparing liposome combination drugs in a molar ratio, provides freeze-drying injection and oral preparation processes for the prepared liposome combination drugs, and also provides twenty embodiments for preparing the liposome combination drugs, such as an anti-gastric-ulcer liposome combination drug, antibacterial and antifungal liposome combination drugs, an anti-tumor liposome combination drug, an anti-virus liposome combination drug, an anti-emetic liposome combination drug, a nutritional supplement liposome combination drug and hypoglycemic agent and cardiovascular medicine liposome combination drugs.

Owner:蔡海德

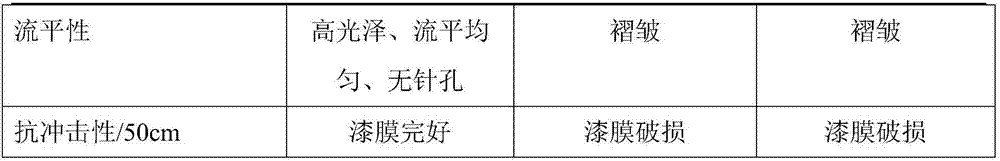

Quick dry intermediate paint for automotive repairing and preparation method of quick dry intermediate paint

InactiveCN105153912AGuaranteed response speedGuaranteed release speedAnti-corrosive paintsPolyurea/polyurethane coatingsCross-linkOrganic solvent

The invention relates to quick dry intermediate paint for automotive repairing and a preparation method of the quick dry intermediate paint, and belongs to the coating filed. The intermediate paint comprises components in weight of 15-30 parts of hydroxy resin, 20-40 parts of an organic solvent, 5-15 parts of a cross-linking curing agent, 35-55 parts of pigment, 0.5-3 parts of a dispersing agent, 0-3 parts of an anti-settling agent, 0.1-0.5 part of an antifoaming agent, 0-0.8 part of a flatting agent and 0.01-0.05 part of a drier. Compared with the prior art, the quick dry intermediate paint has a quick self-dry characteristic, and energy is saved; thicker film formation can be realized by one time, the construction time is shortened, the site utilization rate is improved, and the cost is saved; the quick dry intermediate paint has the advantages of good filling property, rubbing property, water resistance, anti-rust property and the like.

Owner:DONGLAI COATING TECH SHANGHAI

Tea powder grinding machine

ActiveCN109201283AImprove grinding efficiencyImprove grinding effectSievingScreeningEngineeringDrive motor

The invention discloses a tea powder grinding machine. The bottom of a machine case is communicated and provided with a base; a feeding groove is communicated and arranged in the top of the machine case; a material crushing device and a grinding device which are mutually communicated are arranged in the machine case from top to bottom; the crushing device and the grinding device are in coaxial arrangement and are respectively in transmission connection with a driving motor arranged in the base through a transmission shaft A; a feeding opening is formed in the bottom of the feeding groove; thefeeding opening is positioned above the material crushing device; a material containing notch used for placing a material container is arranged at the side wall of one side of the base; a dischargingopening communicated with the machine case is arranged on the top surface, positioned in the material containing notch position, of the base. Through the structure, the tea powder grinding machine hasthe advantages that the tea is fast crushed into crushed materials; then, the crushed materials are directly ground into powder; material discharging is performed; the tea grinding efficiency and grinding effect are improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Preparing technology of solid polymer water electrolysis oxygen evolution catalyst iridium oxide

InactiveCN108823589AGuaranteed purityGuaranteed Particle SizeMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectrolysisMagnesium salt

The invention discloses a preparing technology of solid polymer water electrolysis oxygen evolution catalyst iridium oxide. The preparing technology of solid polymer water electrolysis oxygen evolution catalyst iridium oxide is characterized by comprising the steps that iridium salt is dispersed in a dispersion agent with magnesium salt as a component, and dispersion liquid is formed; an iridium salt solid phase obtained through the dispersion liquid is subject to calcination and oxidation. In the preparing technology, the chemical state and the size of iridium salt are not changed, ant it isensured that finally, the purity and the grain size of iridium oxide are within the controllable range.

Owner:浙江高成绿能科技有限公司

Acrylic acid polymer emulsion for industrial protective finish paint and production process thereof

ActiveCN106995636ABalance performanceImprove densification performanceCoatingsIsooctyl acrylatePersulfate

The invention relates to acrylic acid polymer emulsion for industrial protective finish paint, and belongs to the technical field of acrylic acid polymer emulsion. The acrylic acid polymer emulsion is prepared from an emulsion polymer A with the particle size being 5 to 25nm and an emulsion polymer B with the particle size being 95 to 105nm through being metered in percentage by weight, wherein the emulsion polymer A is prepared from the following ingredients in parts by weight: 100 to 250 parts of methyl methacrylate, 30 to 100 parts of styrene, 30 to 60 parts of n-butyl acrylate, 50 to 150 parts of 2-ethylhexyl acrylate, 5 to 20 parts of crosslinking monomers, 3 to 8 parts of methacrylic acid, 460 to 640 parts of water, 18 to 35 parts of reactive anion emulsifiers containing EO chain segments, 2.3 to 4.9 parts of persulfate, 2 to 8 parts of octanol, 0.5 to 3 parts of antifoaming agents and 0.8 to 2 parts of sterilization agents; the emulsion polymer B is of a core shell emulsion structure and is prepared from the following ingredients in parts by weight: 395 to 495 parts of water, 1 to 3 parts of reactive anion emulsifiers containing EO chain segments, 1 to 2.6 parts of persulfate, 335 to 761 parts of shell layer pre-emulsion, 345 to 834 parts of core layer pre-emulsion, 1 to 3 parts of sterilization agents and 1 to 3 parts of antifoaming agents. The invention also discloses a production process of the emulsion. The emulsion does not contain APEO (alkylphenol ethoxylates); the production stability is high.

Owner:HENGSHUI XINGUANG CHEM

Nano-suspension of difficult-to-dissolve medicine as well as preparation method and application of nano-suspension

InactiveCN109432018AExtended storage timeImprove stabilityPowder deliveryHydroxy compound active ingredientsNanometreChemistry

The invention provides nano-suspension of a difficult-to-dissolve medicine as well as a preparation method and application of the nano-suspension. The nano-suspension is prepared from the following components: 10 to 15 parts of a stabilizer, 40 to 50 parts of difficult-to-dissolve medicine granules and the balance of water, wherein the stabilizer comprises a non-ionic stabilizer and an ionic stabilizer; the preparation method comprises the following steps: preparing raw materials according to the ratio; adding the stabilizer and the difficult-to-dissolve medicine granules into the water in sequence and stirring to obtain primary suspension; adding grinding beads and the primary suspension into a grinding pot in sequence and then putting the grinding pot into a grinding machine and grinding, so as to obtain the nano-suspension of the difficult-to-dissolve medicine. By adopting the nano-suspension of the difficult-to-dissolve medicine provided by the invention, the defects of existing nano-suspension that the stabilizer is not properly selected and the type is single, granule conglomeration and sedimentation of the nano-suspension are easy to occur so that the storage time is short are overcome; the nano-suspension of the difficult-to-dissolve medicine is used for preparing nano-suspension lyophilized powder and the nano-suspension is convenient to transport and preserve.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

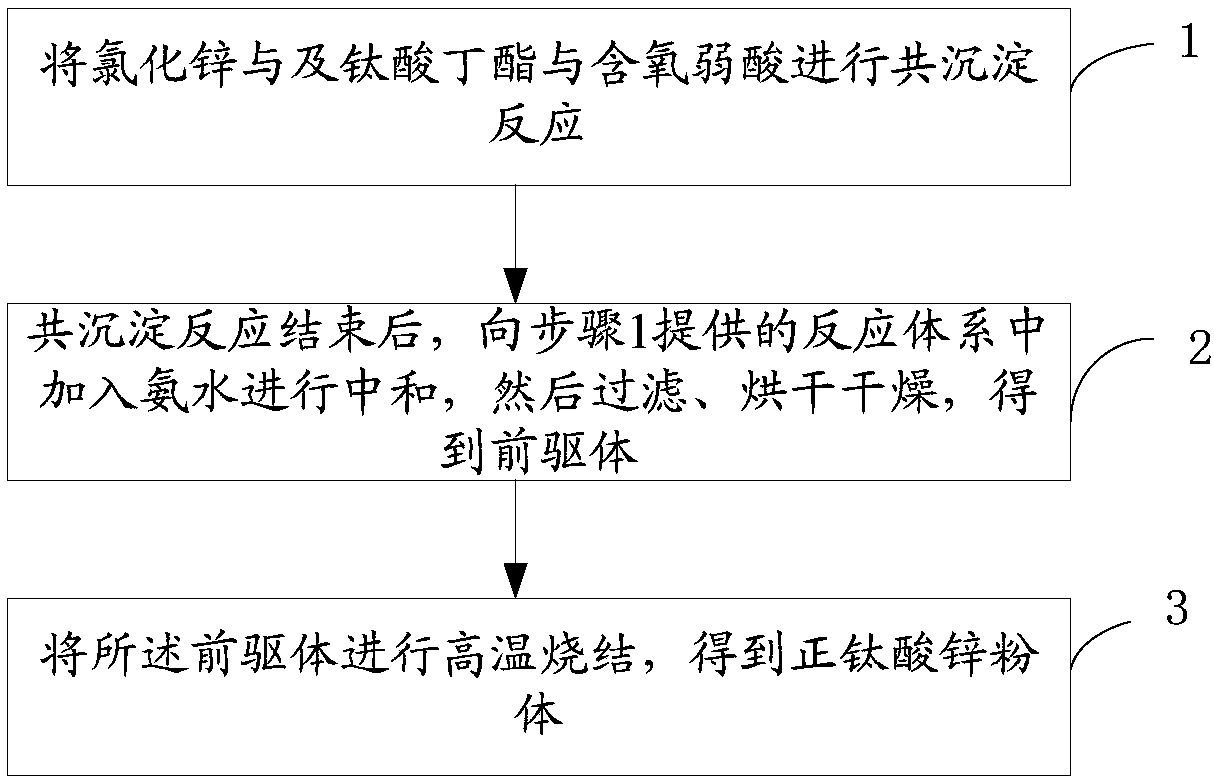

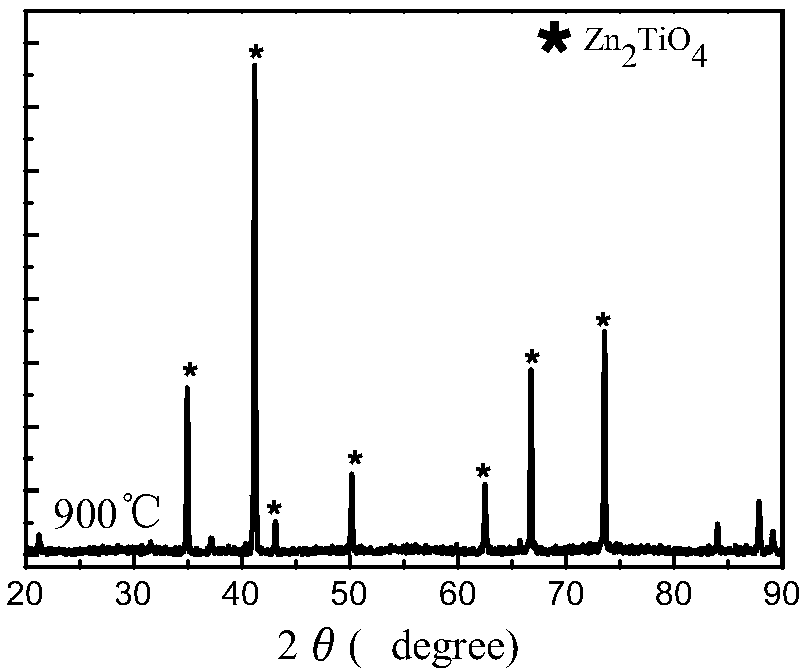

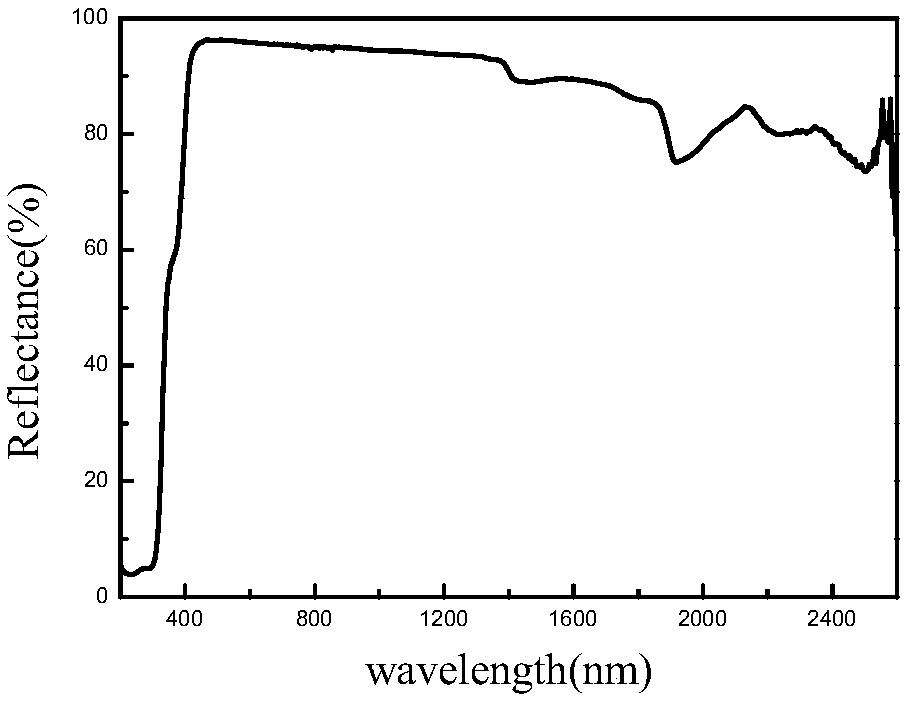

Preparation method of n-zinc titanate powder and application

The invention provides a preparation method of n-zinc titanate powder and application and belongs to the technical field of thermal control coatings of spacecrafts. The preparation method comprises the following steps: performing a co-precipitation reaction on zinc chloride and butyl titanate with a weak acid; after the co-precipitation reaction is completed, putting ammonium hydroxide into the reaction system provided by the step 1, implementing neutralization, filtring, and drying so as to obtain a precursor; performing high-temperature sintering on the precursor, thereby obtaining the n-zinc titanate powder. By adopting the preparation method of the n-zinc titanate powder provided by the embodiment of the invention, butyl titanate is adopted as a titanium source, n-zinc titanate powderwhich is relatively high in purity and small in particle size is prepared, and the powder is relatively low in sunshine absorption rate and good in space environment stability when being used as thermal control packing, and a thermal control coating prepared from the powder is relatively high in hardness and relatively good in stain resistance.

Owner:BEIJING SATELLITE MFG FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com