Acrylic acid polymer emulsion for industrial protective finish paint and production process thereof

An acrylic polymer, industrial protection technology, applied in the direction of coating, etc., can solve problems such as insufficient hardness, low gloss, poor decorative effect, etc., achieve product performance green environmental protection, improve paint film compactness, excellent paint film compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

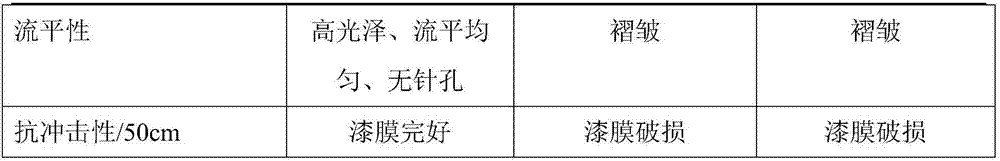

Examples

Embodiment 1

[0037] An acrylic polymer emulsion for industrial protective topcoats, comprising 2% of emulsion polymer A with a particle diameter of 5-25nm and 98% of emulsion polymer B with a particle diameter of 95-105nm in weight percent.

[0038]Emulsion polymer A includes, in parts by weight, 100 parts of methyl methacrylate, 30 parts of styrene, 35 parts of n-butyl acrylate, 50 parts of isooctyl acrylate, 5 parts of AAEM, 4 parts of methacrylic acid, and 540 parts of water , 33 parts of reactive anionic emulsifier containing EO segment, 2.3 parts of persulfate, 3 parts of octanol, 0.5 part of defoamer and 0.8 part of bactericide.

[0039] The emulsion polymer B, in parts by weight, includes 395 parts of water, 1 part of reactive anionic emulsifier containing EO segment, 1 part of persulfate, shell pre-emulsion, core layer pre-emulsion, bactericide 1 1 part, defoamer 1 part.

[0040] The core layer pre-emulsion includes 30 parts of styrene, 150 parts of methyl methacrylate, 30 parts o...

Embodiment 2

[0058] An acrylic polymer emulsion for industrial protective topcoat, comprising 4% of emulsion polymer A with a particle diameter of 5-25nm and 96% of emulsion polymer with a particle diameter of 95-105nm by weight percentage.

[0059] Emulsion polymer A includes, in parts by weight, 130 parts of methyl methacrylate, 40 parts of styrene, 55 parts of n-butyl acrylate, 140 parts of isooctyl acrylate, 7 parts of AAEM, 5 parts of methacrylic acid, and 530 parts of water , 35 parts of reactive anionic emulsifier containing EO chain segment, 2.5 parts of persulfate, 3 parts of octanol, 1 part of defoamer and 1 part of bactericide.

[0060] The emulsion polymer B, in parts by weight, includes 485 parts of water, 2 parts of reactive anionic emulsifiers containing EO segments, 1.5 parts of persulfate, shell pre-emulsion, core layer pre-emulsion, bactericide, defoamer.

[0061] The core layer pre-emulsion includes 60 parts of styrene, 210 parts of methyl methacrylate, 40 parts of n-bu...

Embodiment 3

[0078] An acrylic polymer emulsion for industrial protective topcoat, comprising 6% of emulsion polymer A with a particle diameter of 5-25nm and 94% of emulsion polymer B with a particle diameter of 95-105nm by weight percentage.

[0079] Emulsion polymer A includes, in parts by weight, 150 parts of methyl methacrylate, 70 parts of styrene, 40 parts of n-butyl acrylate, 70 parts of isooctyl acrylate, 15 parts of AAEM, 7 parts of methacrylic acid, and 560 parts of water , 23 parts of reactive anionic emulsifier containing EO chain segment, 2.7 parts of persulfate, 4 parts of octanol, 1.2 parts of defoamer and 1.3 parts of bactericide.

[0080] The emulsion polymer B, in parts by weight, includes 495 parts of water, 3 parts of reactive anionic emulsifiers containing EO segments, 1.7 parts of persulfate, shell pre-emulsion, core layer pre-emulsion, bactericide, defoamer.

[0081] The core layer pre-emulsion includes 70 parts of styrene, 200 parts of methyl methacrylate, 80 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com