Process for preparing high dispersion flake magnesium hydroxide

A technology of magnesium hydroxide and high dispersion, applied in directions such as magnesium hydroxide, can solve problems such as restricting industrial applications, and achieve the effects of convenient operation, low cost, and large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

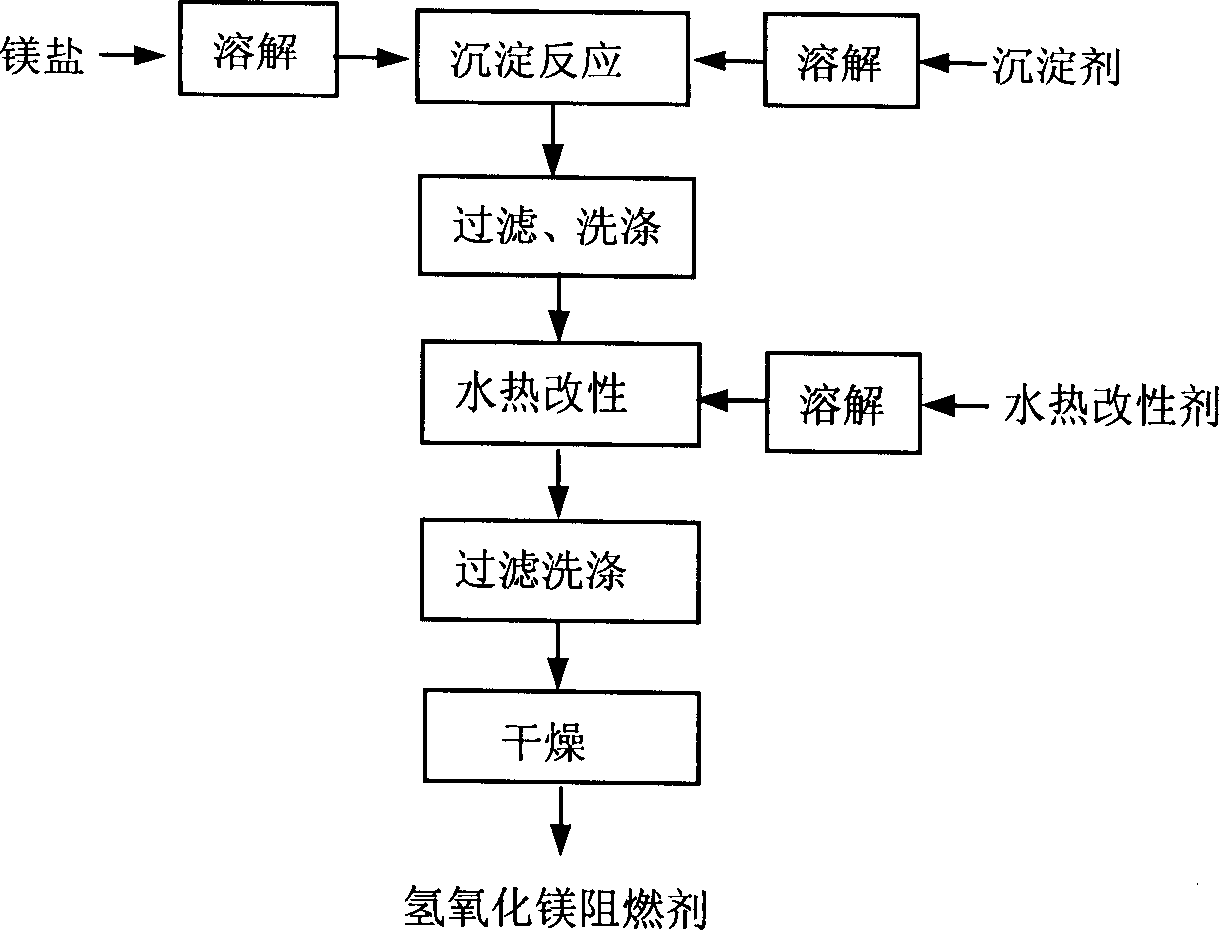

Method used

Image

Examples

Embodiment 1

[0031] Prepare 100ml of 40% (w / v) magnesium chloride solution, 100ml of 40% (w / v) potassium hydroxide solution, 5ml of 0.1% (w / v) polyaluminum chloride solution, 0.1% (w / v) of chlorinated Sodium solution 100ml. The magnesium chloride solution was added to the sodium hydroxide solution at 25° C. under stirring (300 rpm), and the rate of adding the magnesium chloride solution was 20 ml / min. After the addition was complete, the reaction was stopped after continuing to insulate and stir for 1 hour. Add the polyaluminum chloride solution to the above suspension, stir for 10 minutes and then let it settle for 2 hours. Cool the resulting suspension, filter it, wash it with deionized water for 3 times, put it into a sodium chloride solution, stir (300rpm) and disperse for 30 minutes, then place it in a high-pressure hydrothermal reactor, and perform hydrothermal modification treatment at 100°C for 1 hour . Then cool, filter, wash 3 times with deionized water, and dry at 105°C for 4...

Embodiment 2

[0033] Prepare 5% (w / v) magnesium sulfate magnesium chloride solution 100ml, 5% (w / v) ammonium hydroxide solution 100ml, 5% (w / v) polyacrylamide solution 5ml, 25% (w / v) chlorine Calcium solution 100ml. Add the magnesium chloride solution to the sodium hydroxide solution at 80° C. under stirring (300 rpm), and the rate of adding the magnesium chloride solution is 1.0 ml / mn. After the addition was complete, the reaction was stopped after continuing to insulate and stir for 1 hour. Add the polyacrylamide solution to the above suspension, stir for 10 minutes and then let it settle for 2 hours. The obtained suspension was filtered, washed with deionized water for 3 times, put into calcium chloride solution, stirred (300rpm) and dispersed for 30 minutes, then placed in a high-pressure hydrothermal reactor, and subjected to hydrothermal modification treatment at 250°C for 8 hours. Then cool, filter, wash 3 times with deionized water, and dry at 105°C for 4 hours under air atmospher...

Embodiment 3

[0035] Prepare 10% (w / v) magnesium chloride solution 100ml, 10% (w / v) potassium hydroxide solution 100ml, 0.5% (w / v) polyferric chloride solution 5ml, 10% (w / v) magnesium chloride solution 100ml. Add the magnesium chloride solution to the sodium hydroxide solution at 90° C. under stirring (300 rpm), and the rate of adding the magnesium chloride solution is 3.0 ml / min. After the addition was complete, the reaction was stopped after continuing to insulate and stir for 1 hour. Add the polyferric chloride solution to the above suspension, stir for 10 minutes and then let it settle for 2 hours. The resulting suspension was filtered, washed with deionized water for 3 times, then placed in a magnesium chloride solution, stirred (300 rpm) for 30 minutes, placed in a high-pressure hydrothermal reactor, and hydrothermally modified at 180°C for 4 hours. Then cool, filter, wash 3 times with deionized water, and dry at 105°C for 4 hours in an air atmosphere to obtain a primary average pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com