Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Prevent avalanche" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

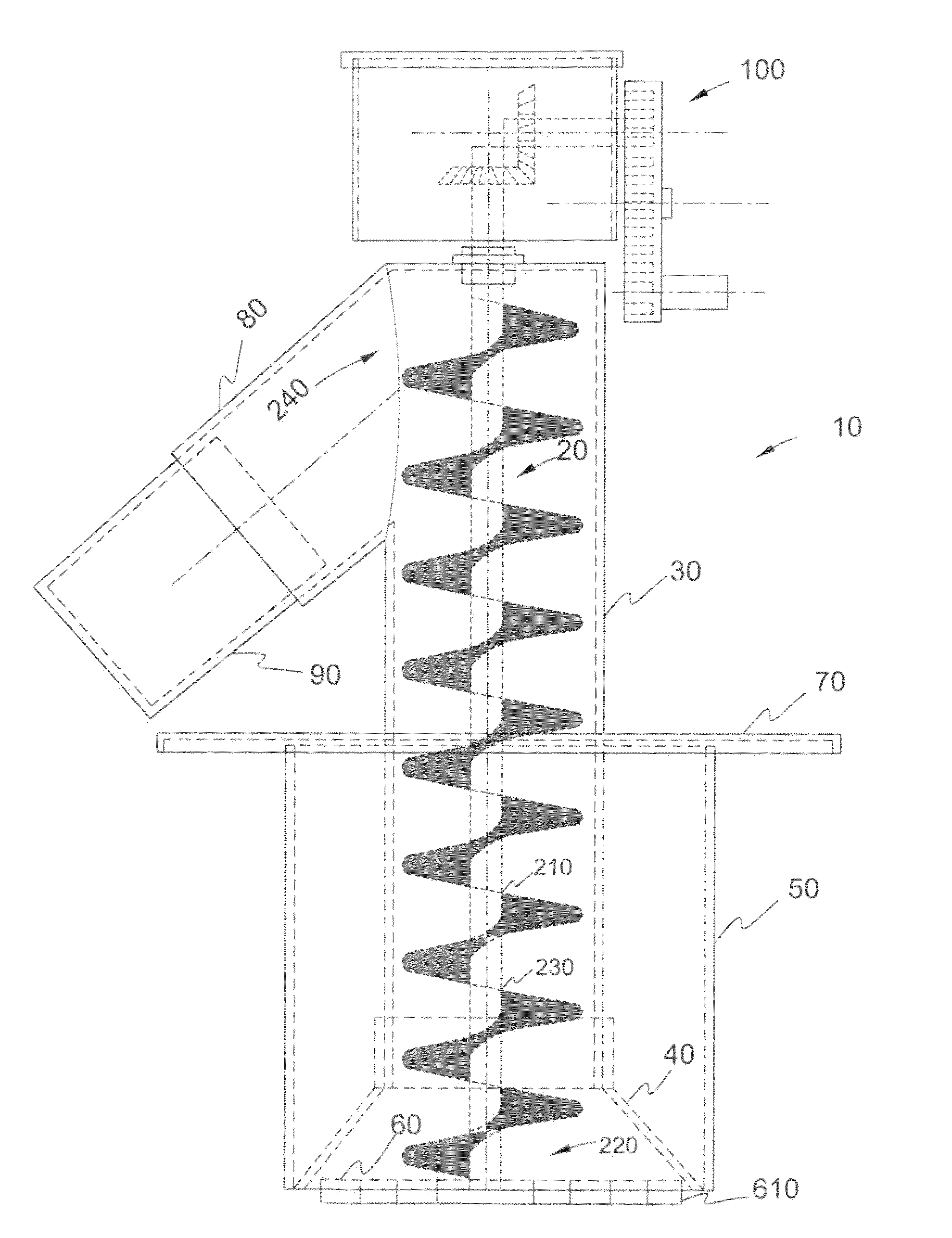

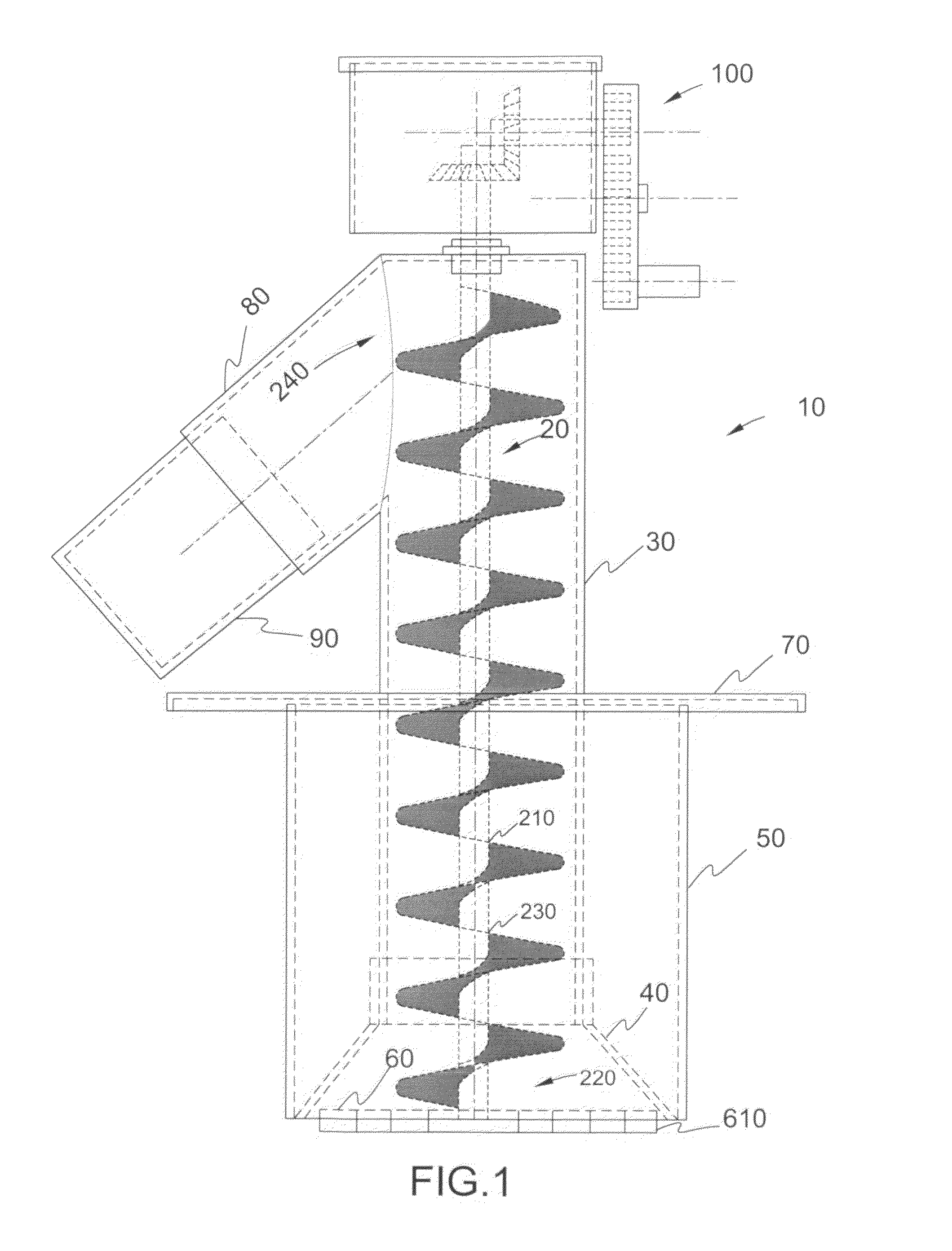

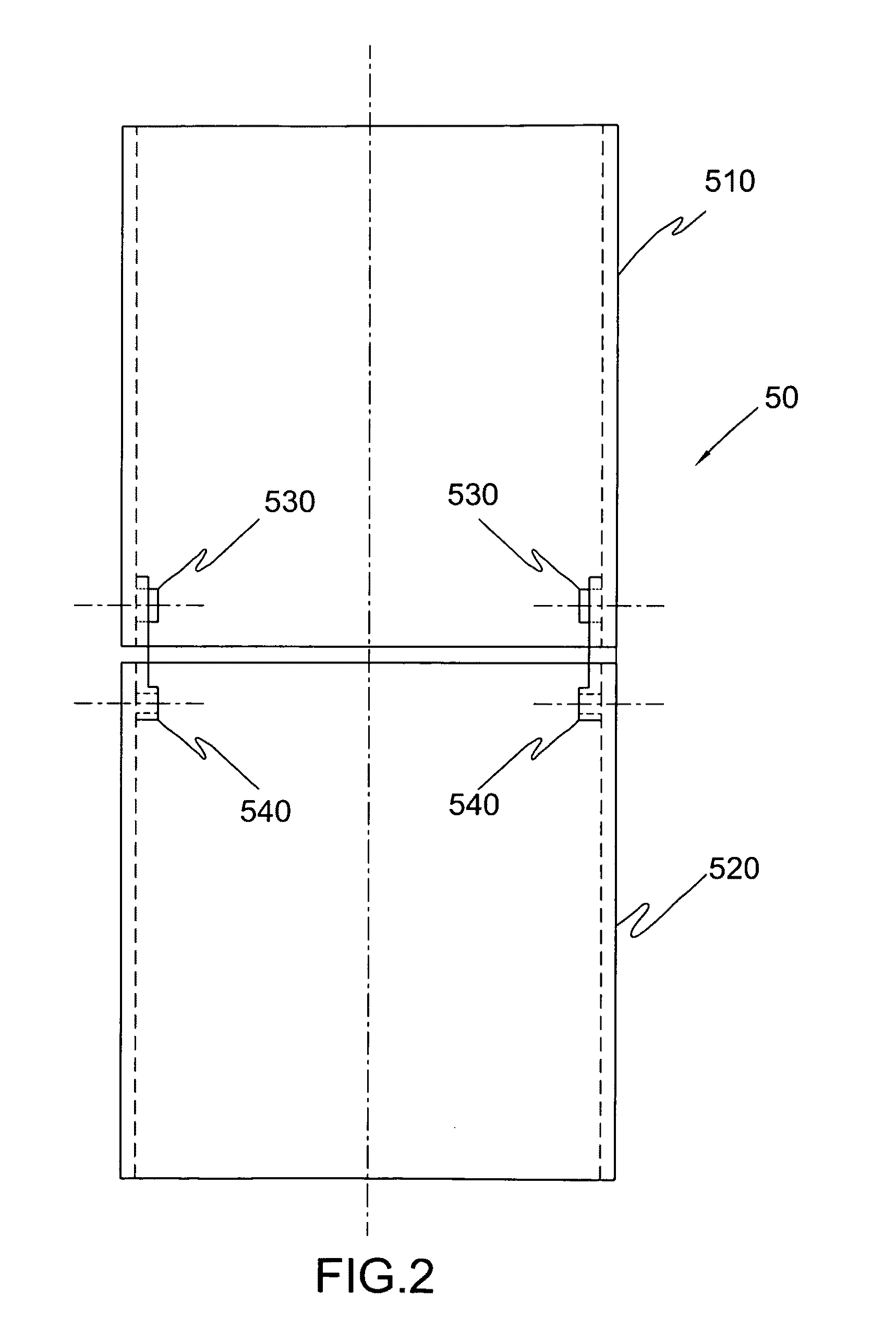

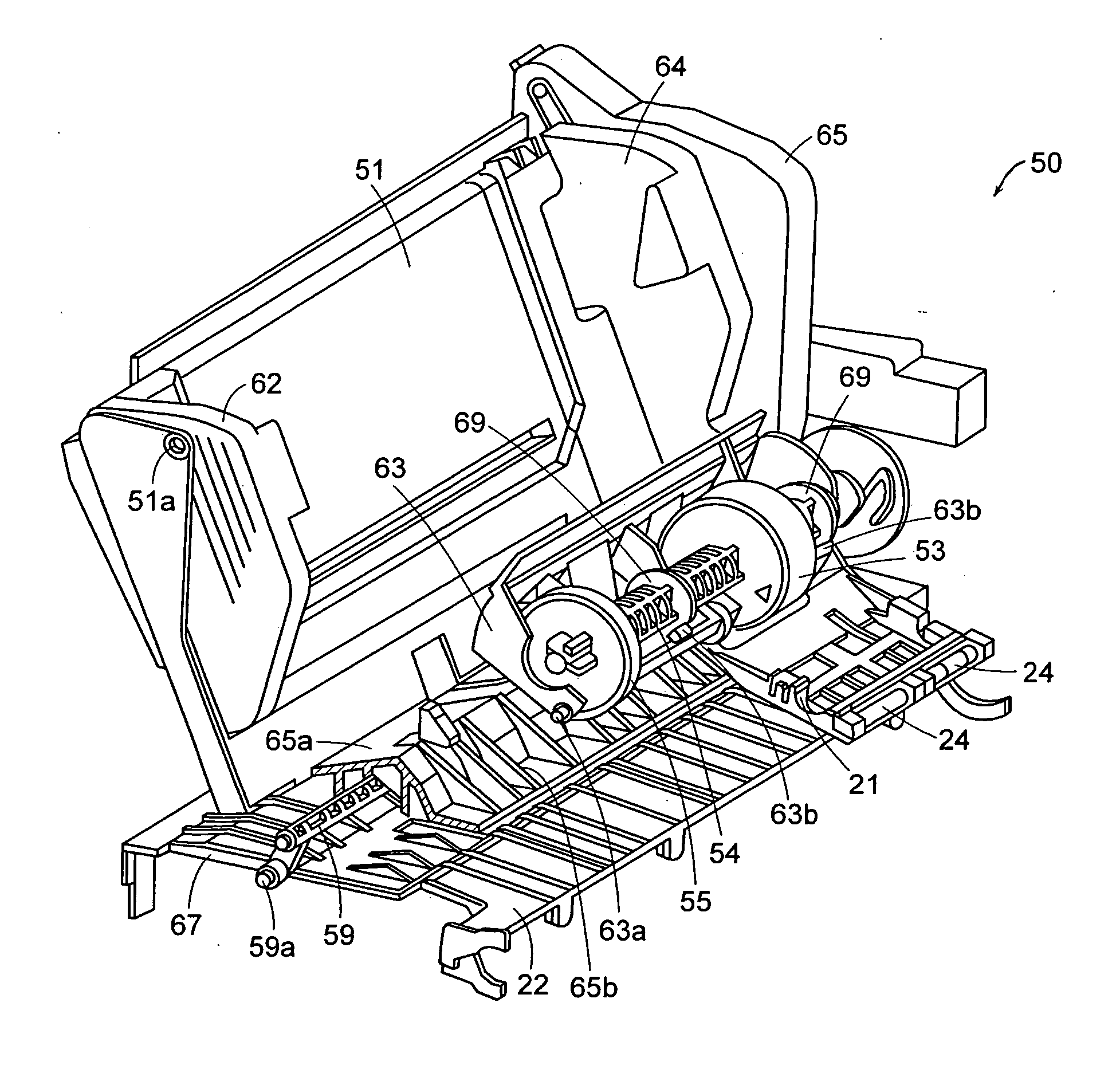

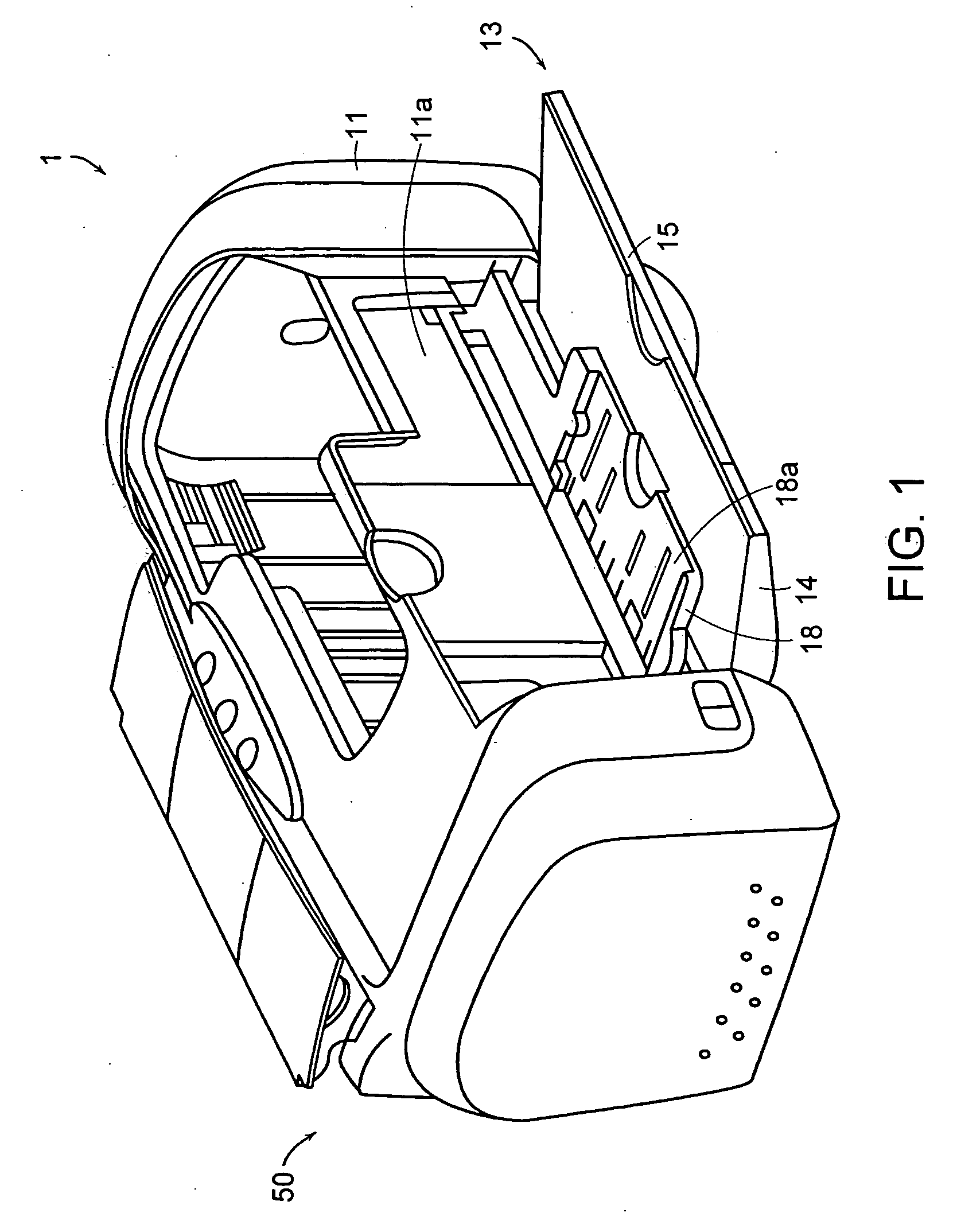

Earth working digging tool and system for digging holes in ground

InactiveUS20110232551A1Prevent avalancheEfficient and effectivePlantingFurrow making/coveringEngineeringScrew conveyor

This invention was intended to develop an earth working equipment and system for digging holes in ground particularly in agricultural soils for needs including but not limited to transplanting of seedlings of flowers, vegetables, fruits, bushes, and shrubs; and for making holes for other purposes where hollow-cylindrical shapes are desired. One very important feature of the equipment is the provision of a removable or embeddable cylindrical retaining wall around the hole being dug thus preventing hole-deforming avalanches of soils, common in trowel assisted hole digging that results in V-shaped rather than cylindrical shaped holes. This provision and other features of the equipment ensure formation of consistent hollow-cylindrical holes effectively, efficiently and economically. The equipment consists of a tilling tool to loosen the soil, a screw conveyor to dig into and transport the soil away, and a cylindrical retaining wall to maintain cylindrical shape of the hole by preventing soil avalanches.

Owner:HAQUE EKRAMUL

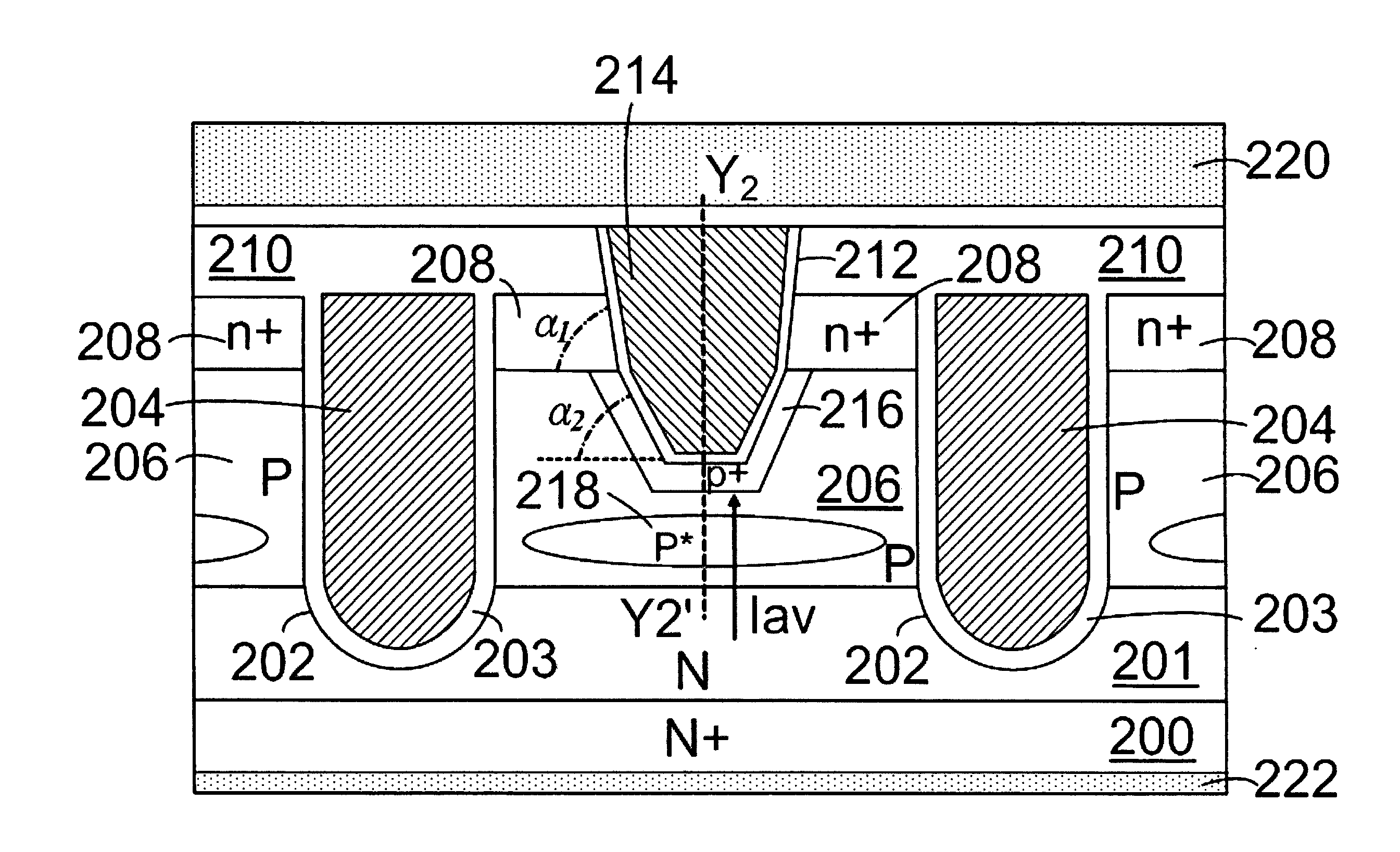

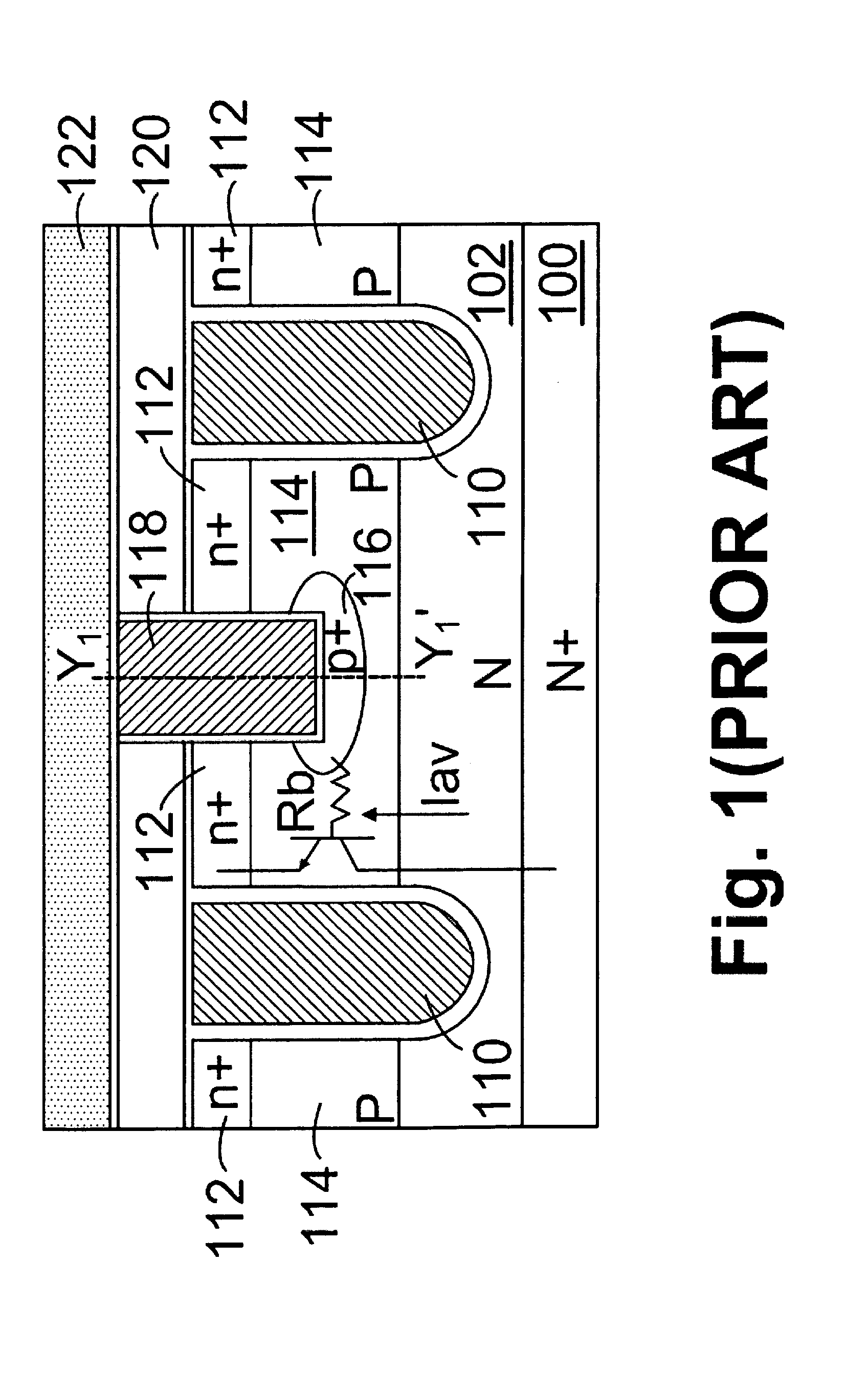

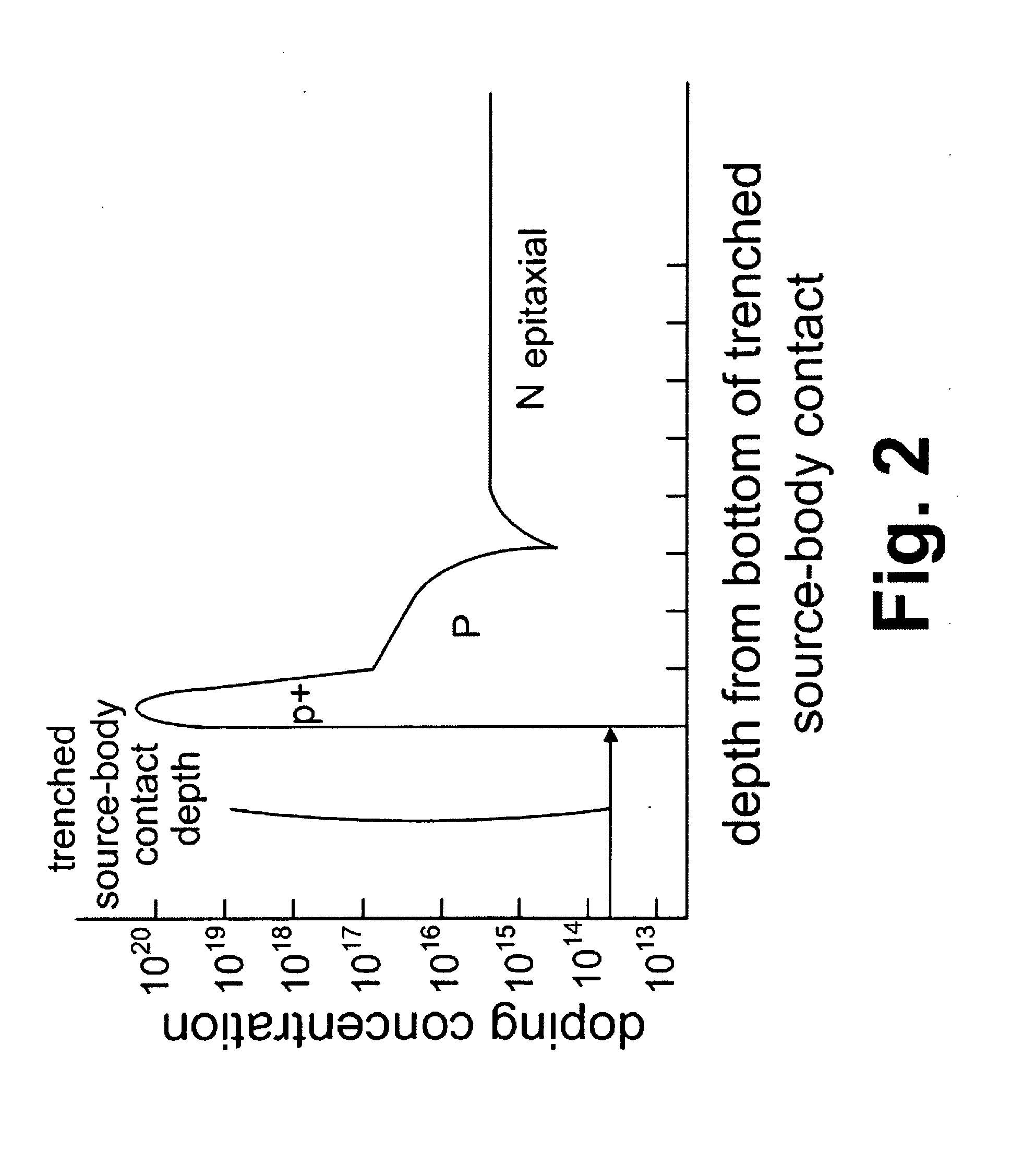

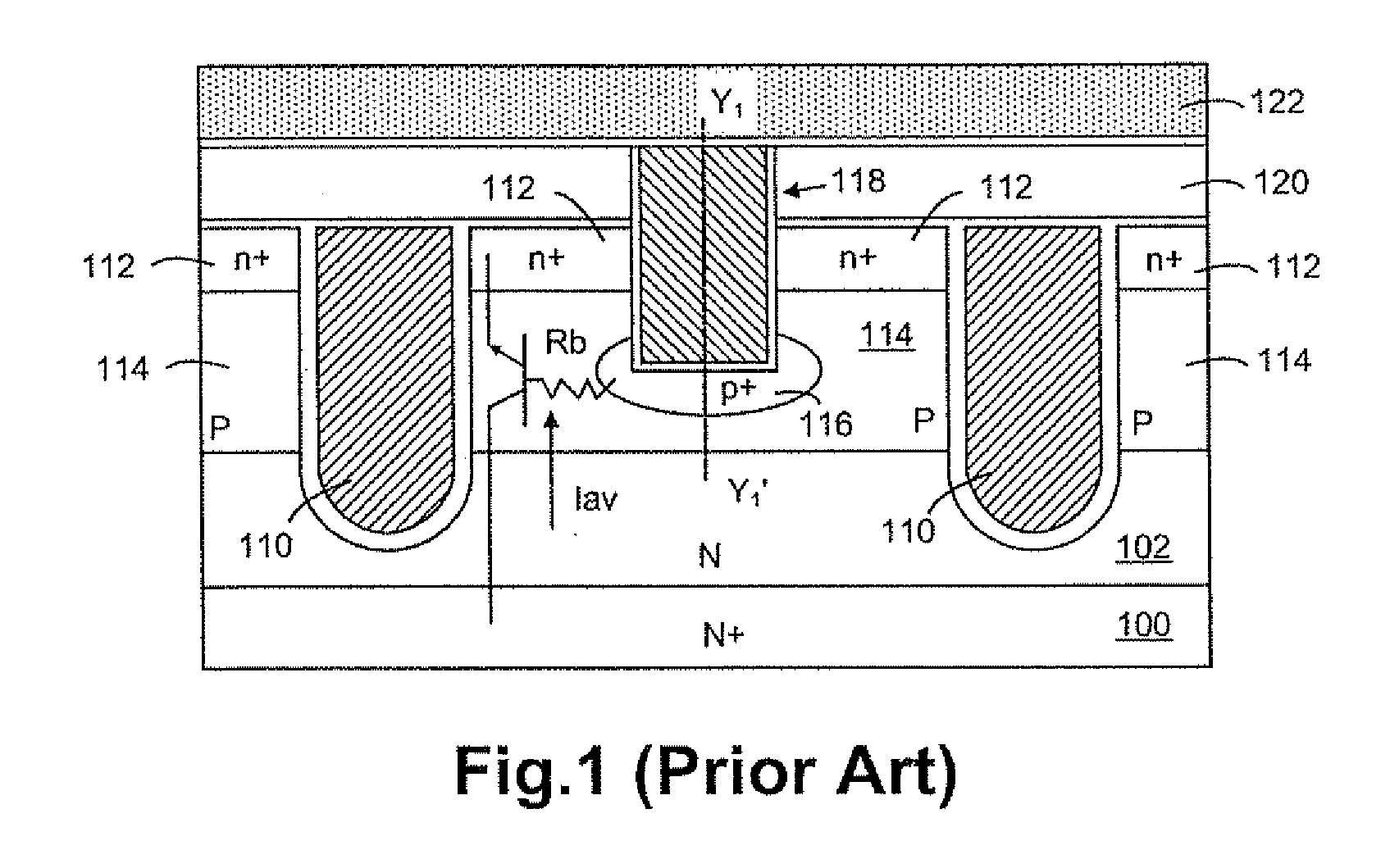

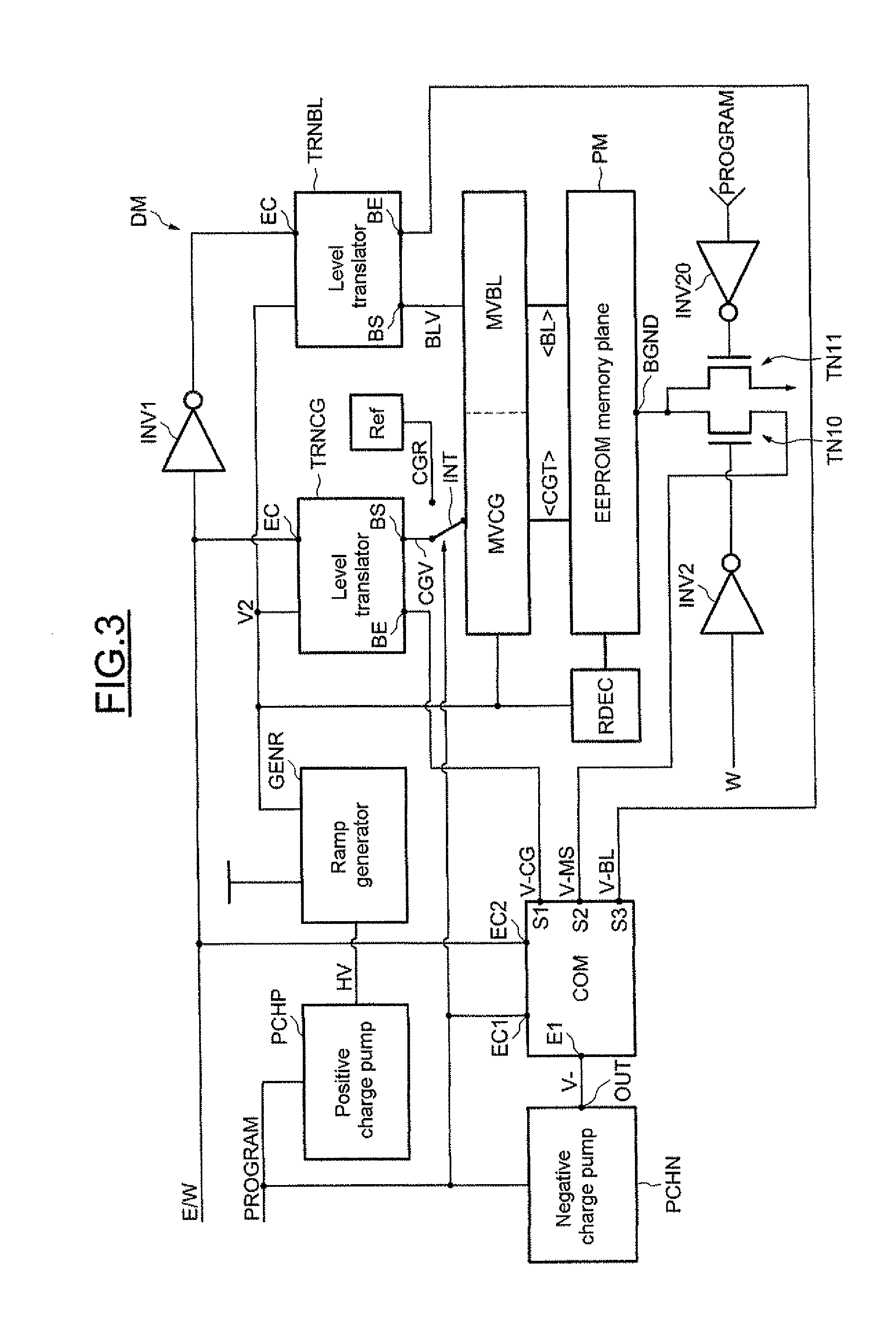

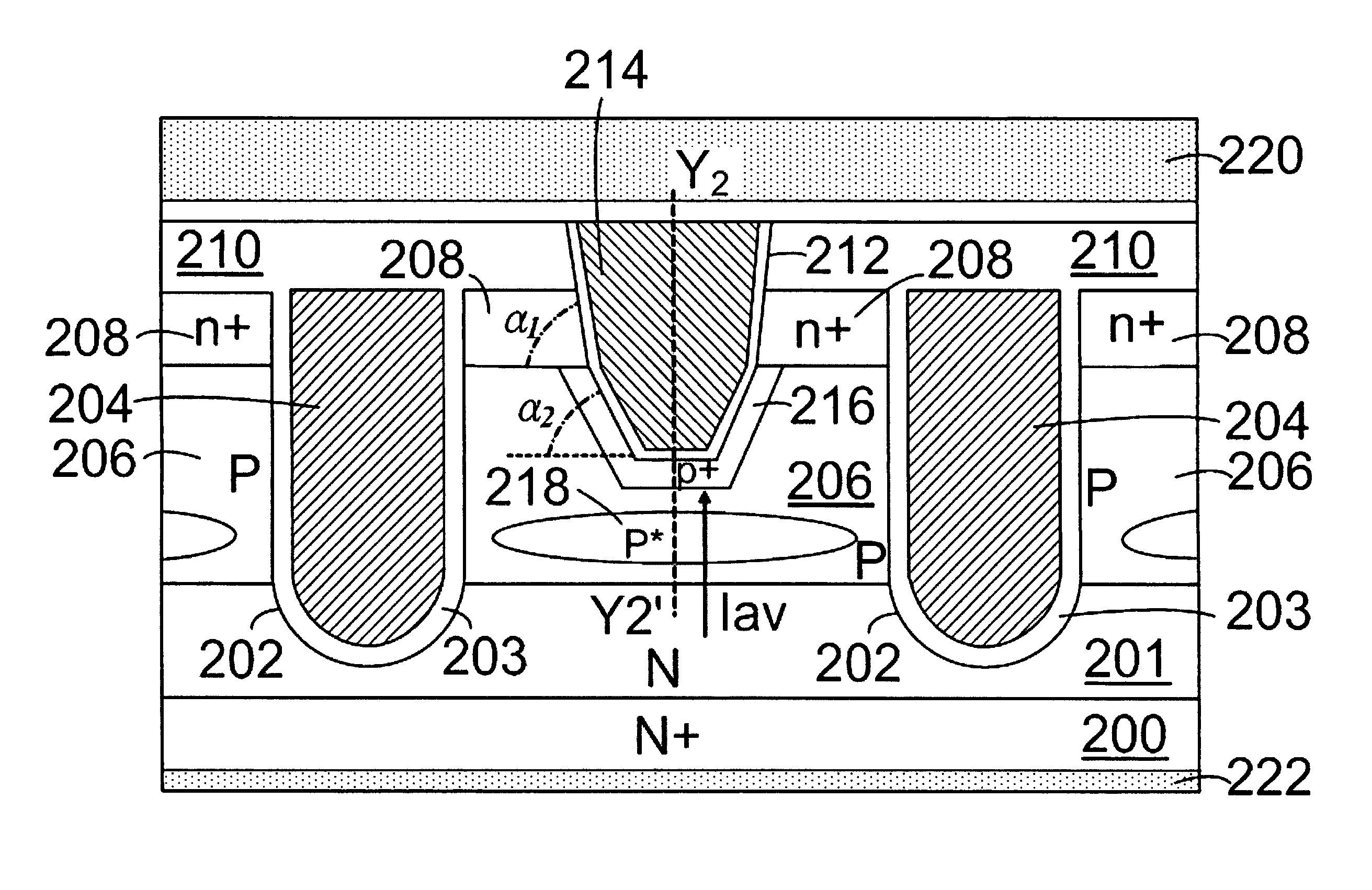

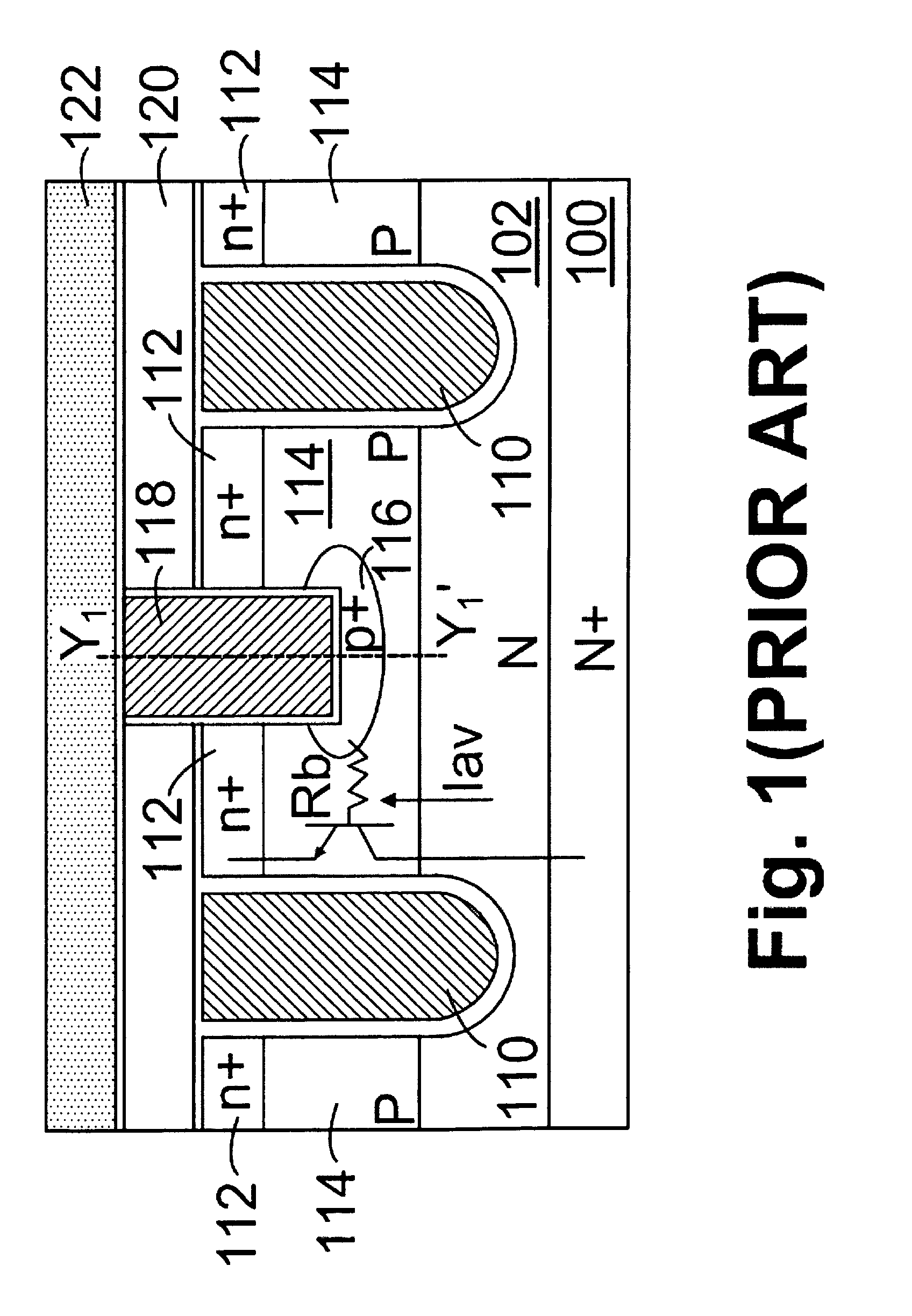

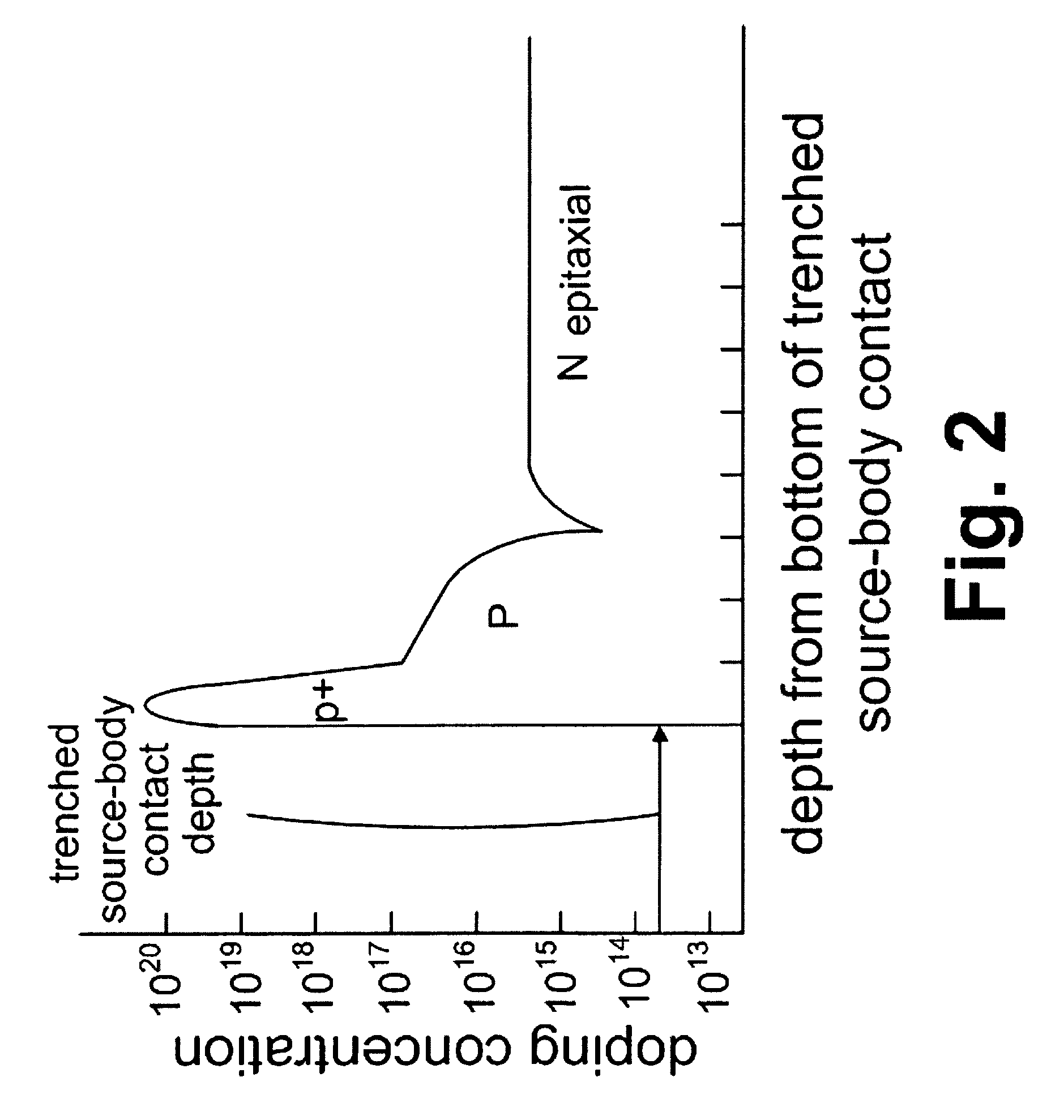

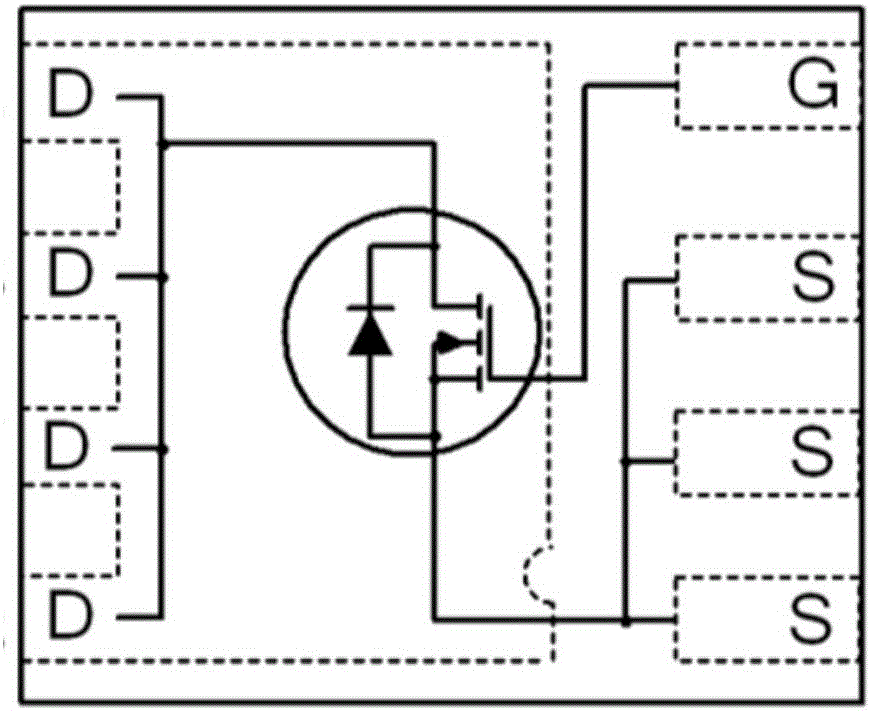

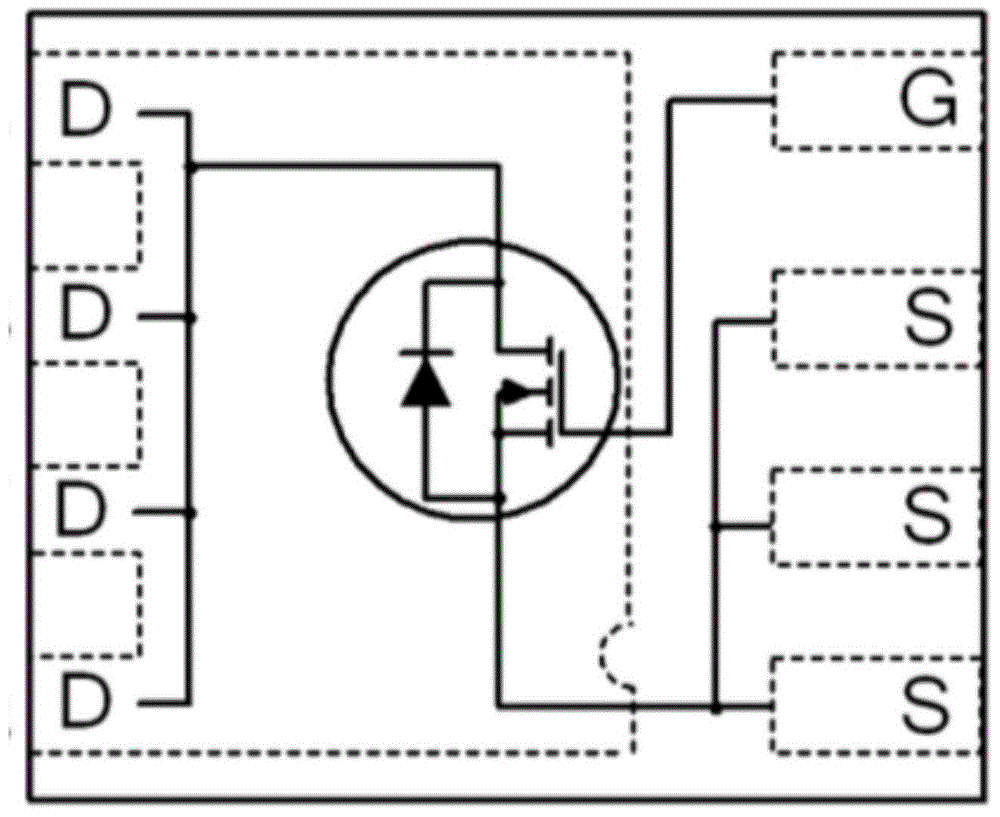

Avalanche capability improvement in power semiconductor devices

ActiveUS20110233606A1Prevent avalancheImprove performanceTransistorThyristorPower semiconductor devicePower flow

A power semiconductor device with improved avalanche capability structures is disclosed. By forming at least an avalanche capability enhancement doped regions with opposite conductivity type to epitaxial layer underneath an ohmic contact doped region which surrounds at least bottom of trenched contact filled with metal plug between two adjacent gate trenches, avalanche current is enhanced with the disclosed structures.

Owner:FORCE MOS TECH CO LTD

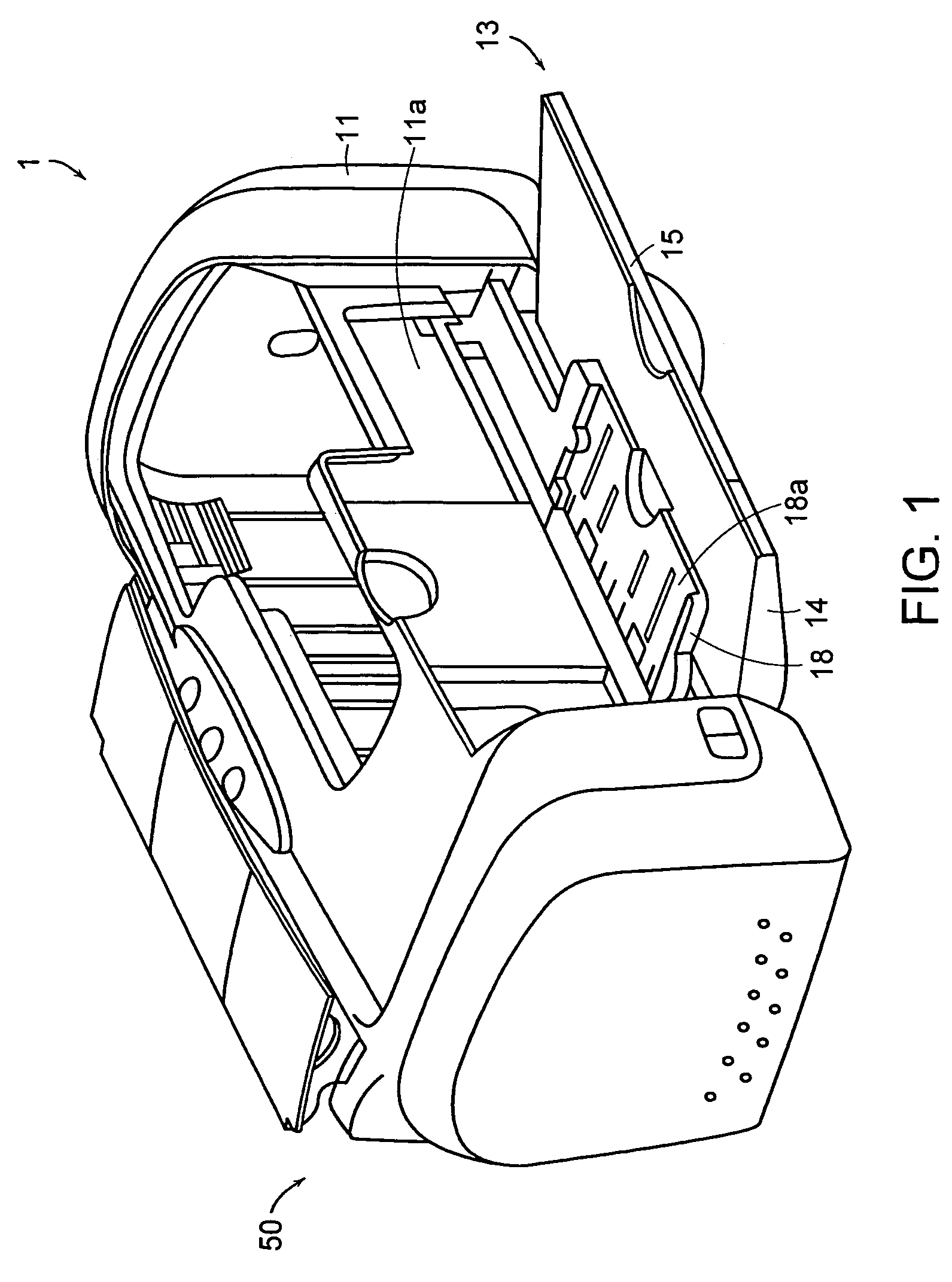

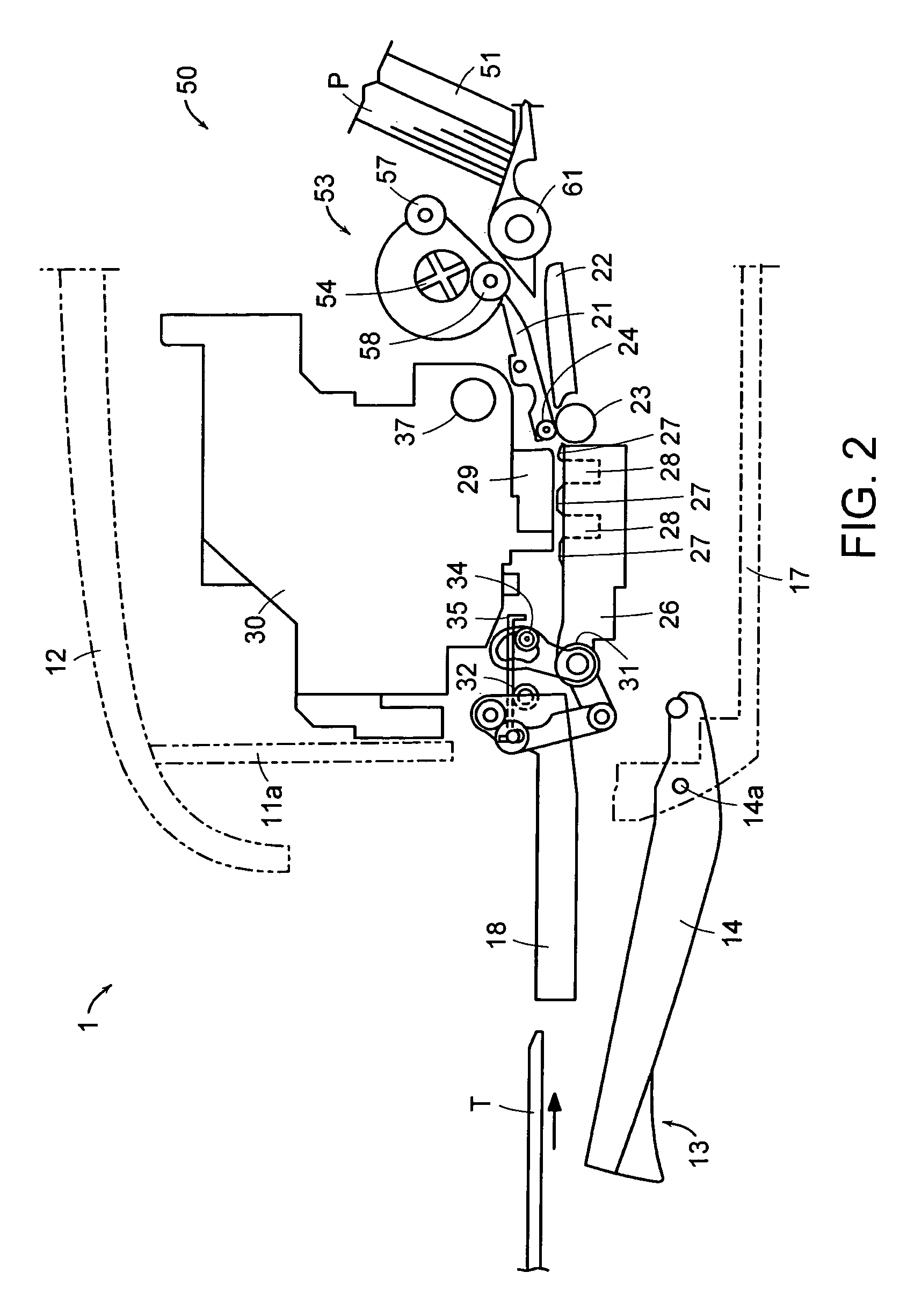

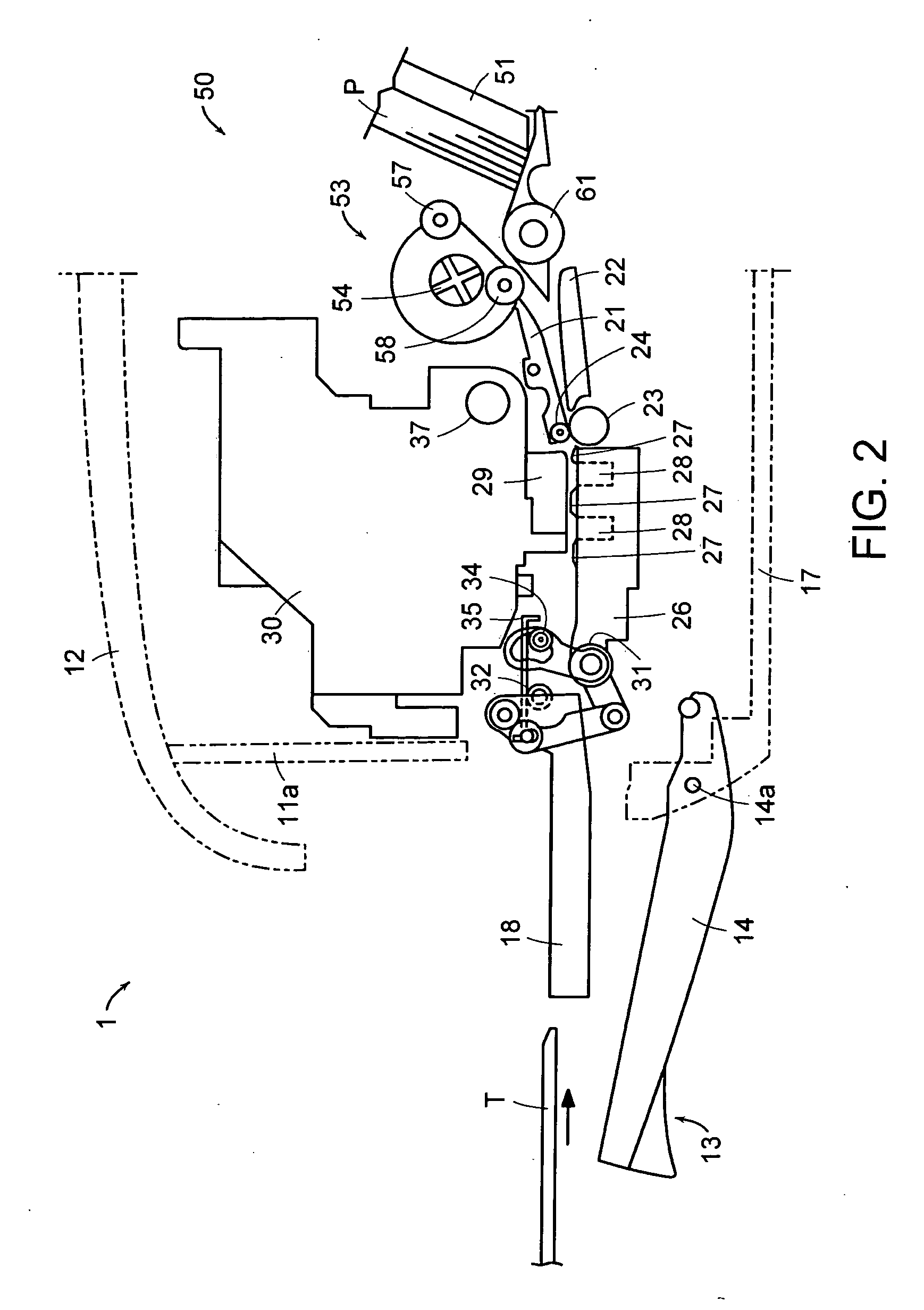

Recording medium feeding apparatus, recording apparatus, liquid ejecting apparatus

ActiveUS7111934B2Prevent avalancheReduce loadRecording apparatusTypewritersLiquid jetMechanical engineering

Owner:SEIKO EPSON CORP

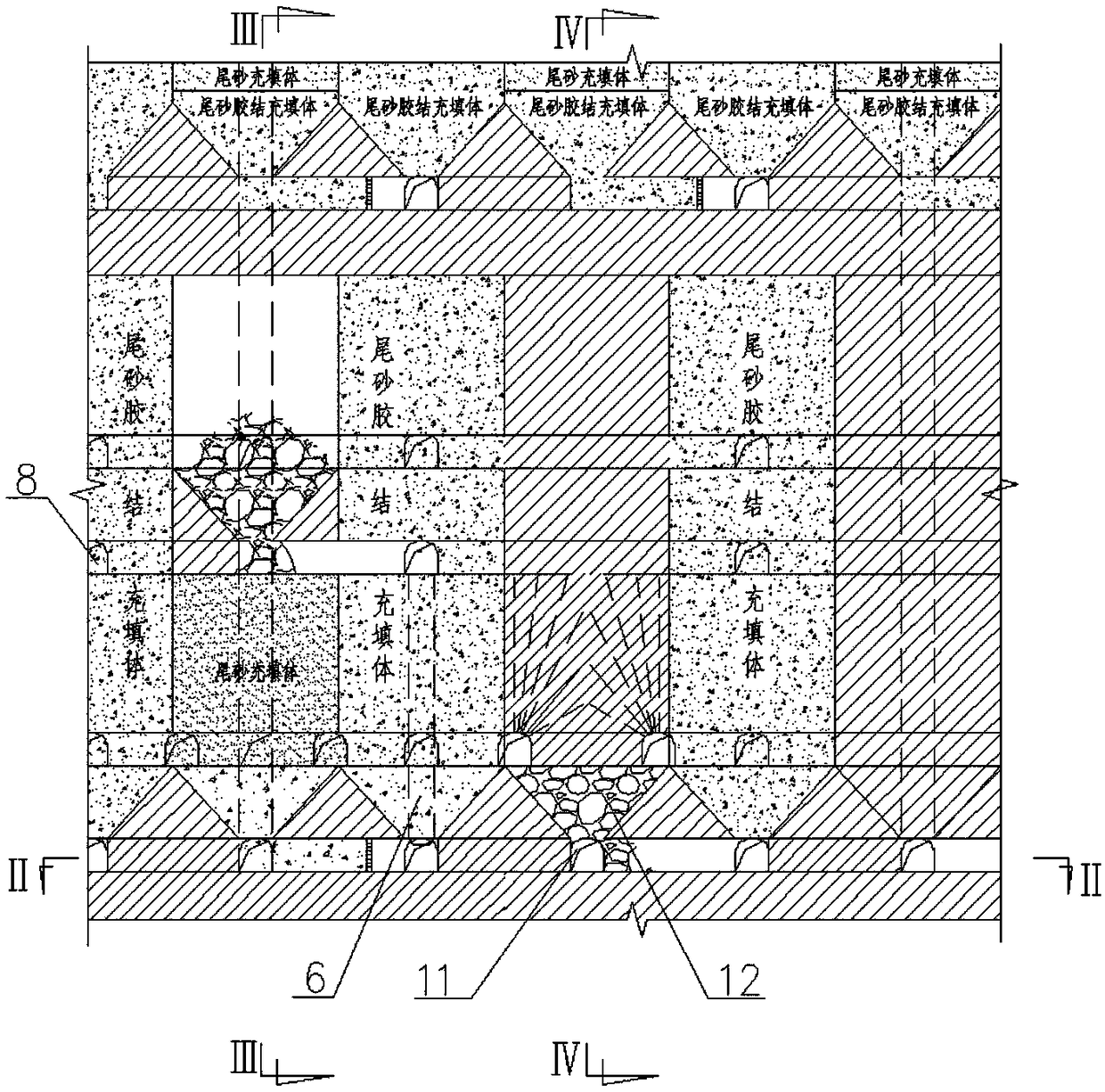

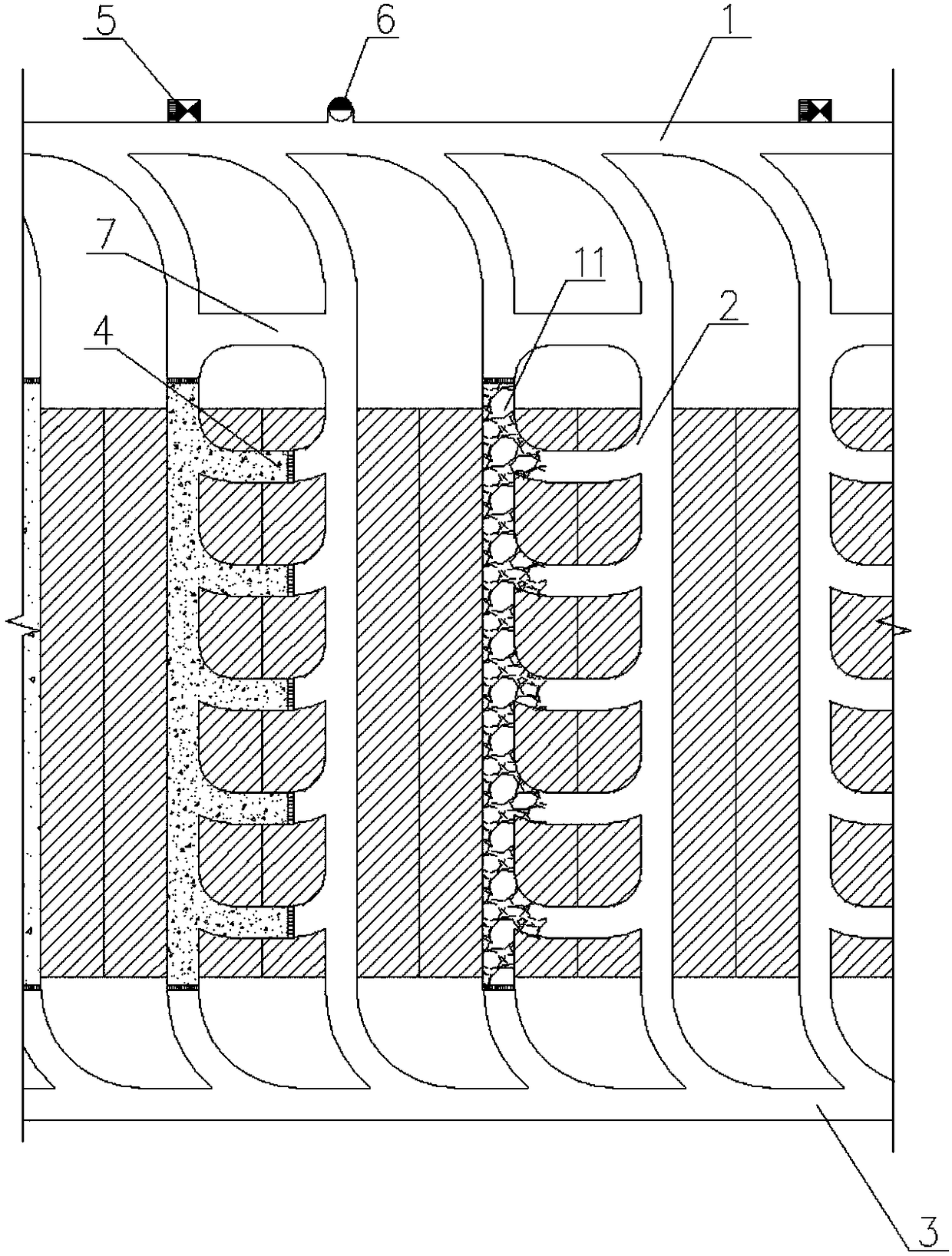

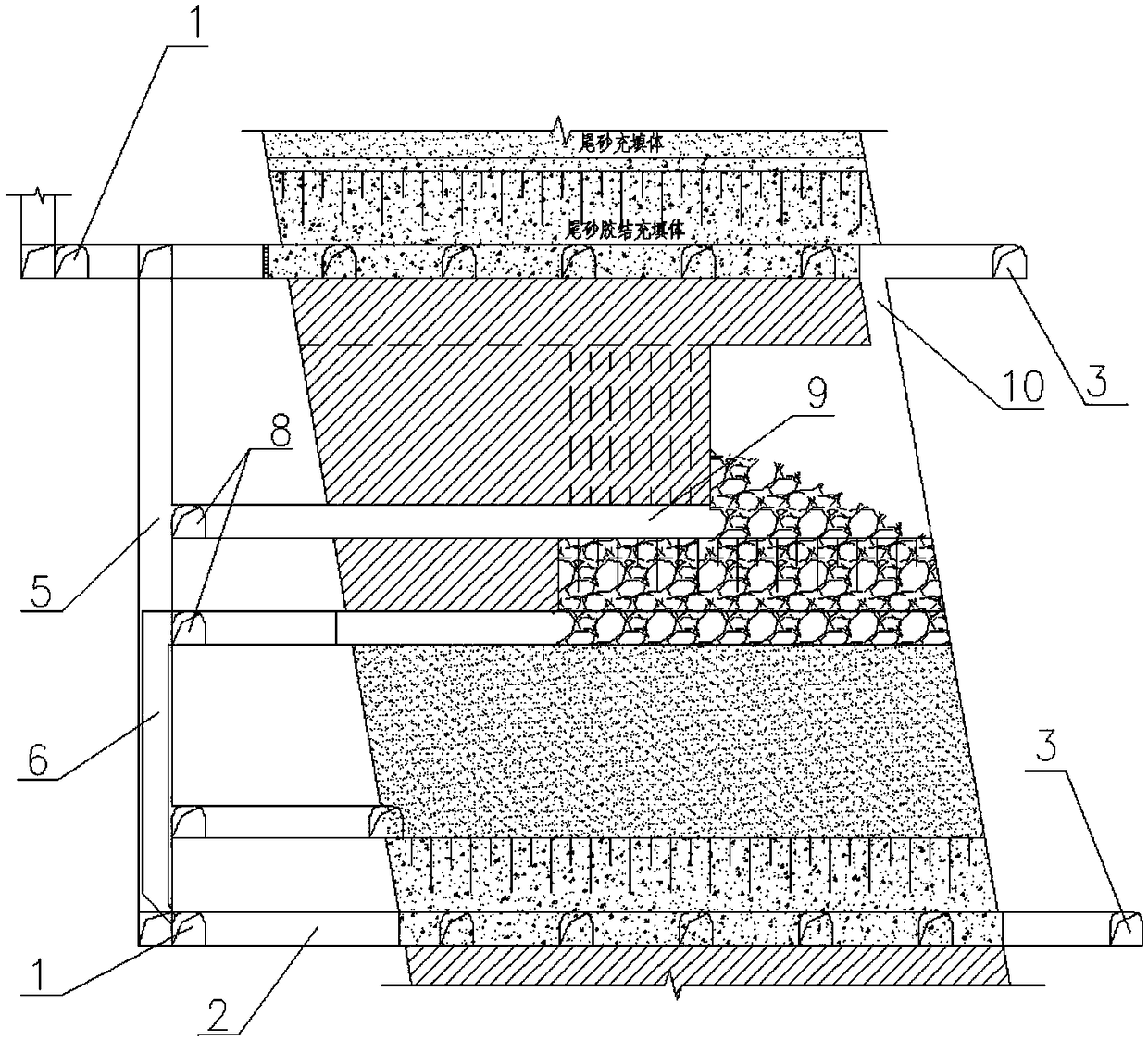

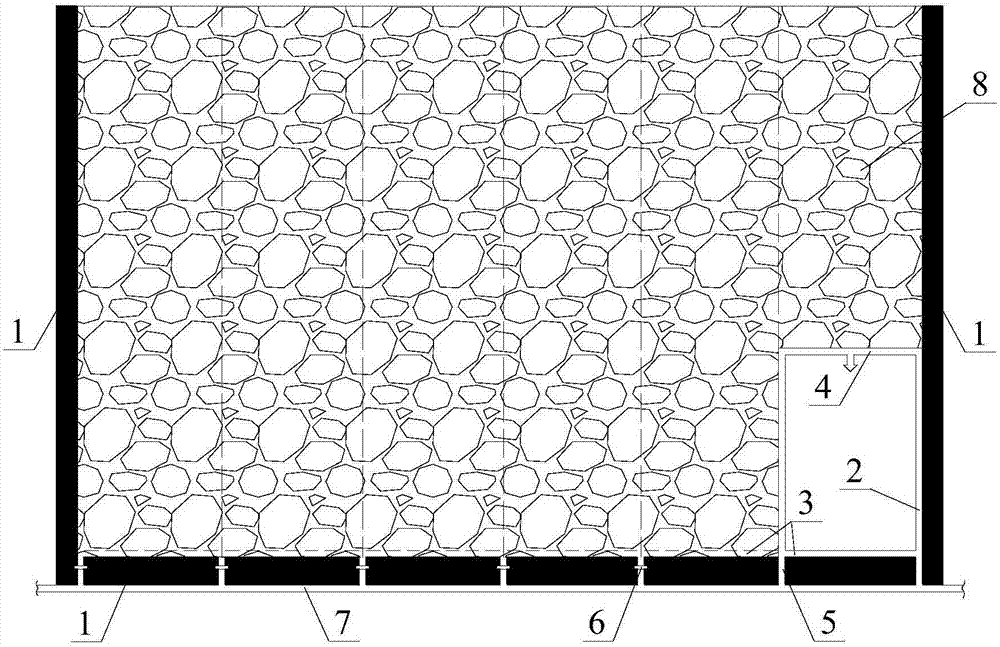

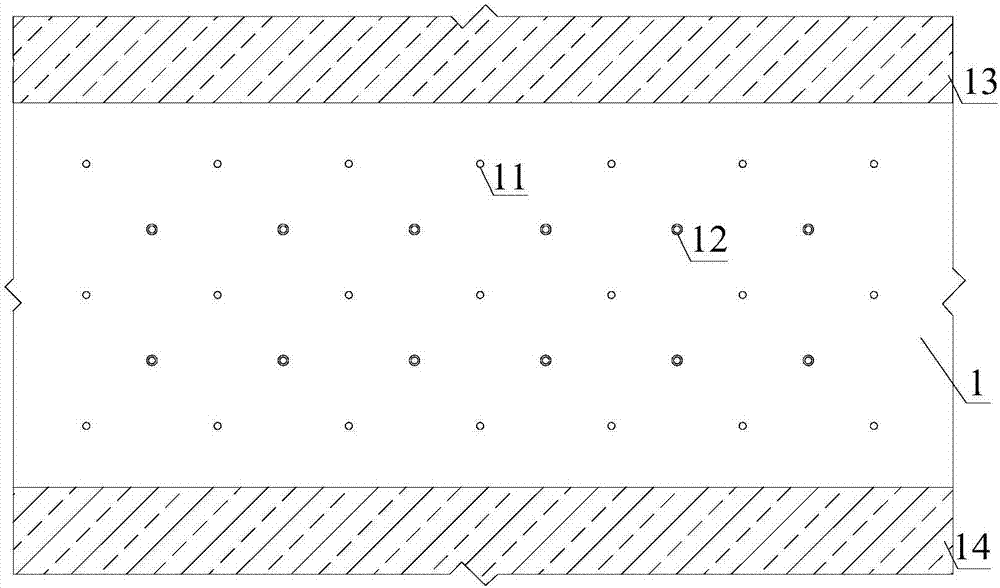

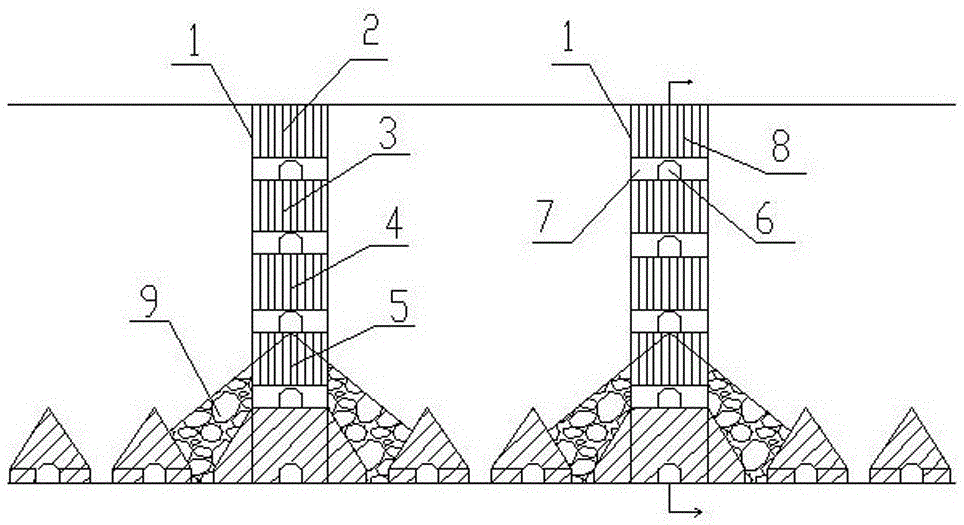

Recycling process of remaining interstall pillars of two-step mining method

InactiveCN108547618AReduce exposure heightPrevent avalancheUnderground miningSurface miningMining engineeringLower grade

The invention discloses a recycling process of remaining interstall pillars of a two-step mining method. The recycling process comprises two circulations of stoping and filling, so as to reduce the exposure height of filling bodies and surrounding rock of the top wall and the bottom wall, and to prevent dilapidation of the filling bodies and the surrounding rock of the top wall and the bottom wall. Bilateral entrance drilling-blasting is adopted. Places near the filling bodies of a mining room adopt a short delay presplitting blasting method which requires drilling more holes and filling fewerexplosives to reduce shaking of and destruction to the filling bodies of the mining room caused by explosion. A part of the ore, to be used as a temporary support, is retained in diggings during stoping. Rock drilling and ore removal are conducted in a roadway. Staff does not need to enter into the stope, so stoping safety is good, and production capability of ore blocks is high. The stoping is conducted from bottom to top, and then cemented filling is carried out with low-grade ore tailings. The recycling process effectively controls ground pressure in the mining stope. The stope roof, the top wall and the bottom wall and the filling bodies basically remain stable in the process of stoping and filling. The recycling process has the characteristics of being safe, efficient, low in cost and low in dilution loss, so the recycling process is especially suitable for the recycling of remaining interstall pillars which are difficult to exploit by using the two-step filling method for thickand large ores of metal mines with complex conditions.

Owner:CINF ENG CO LTD

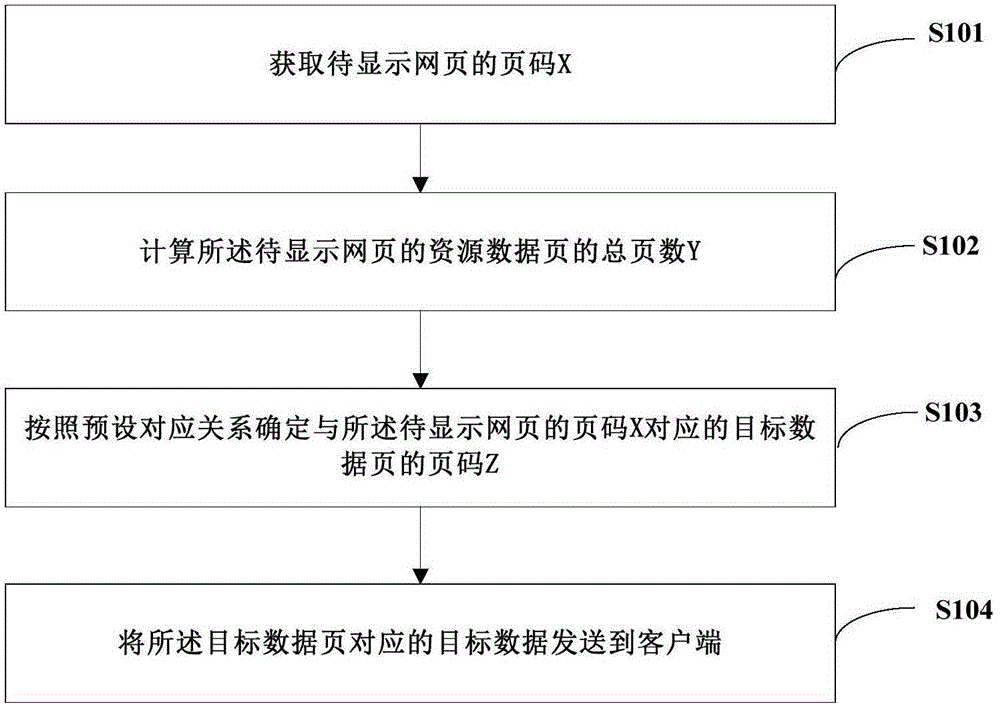

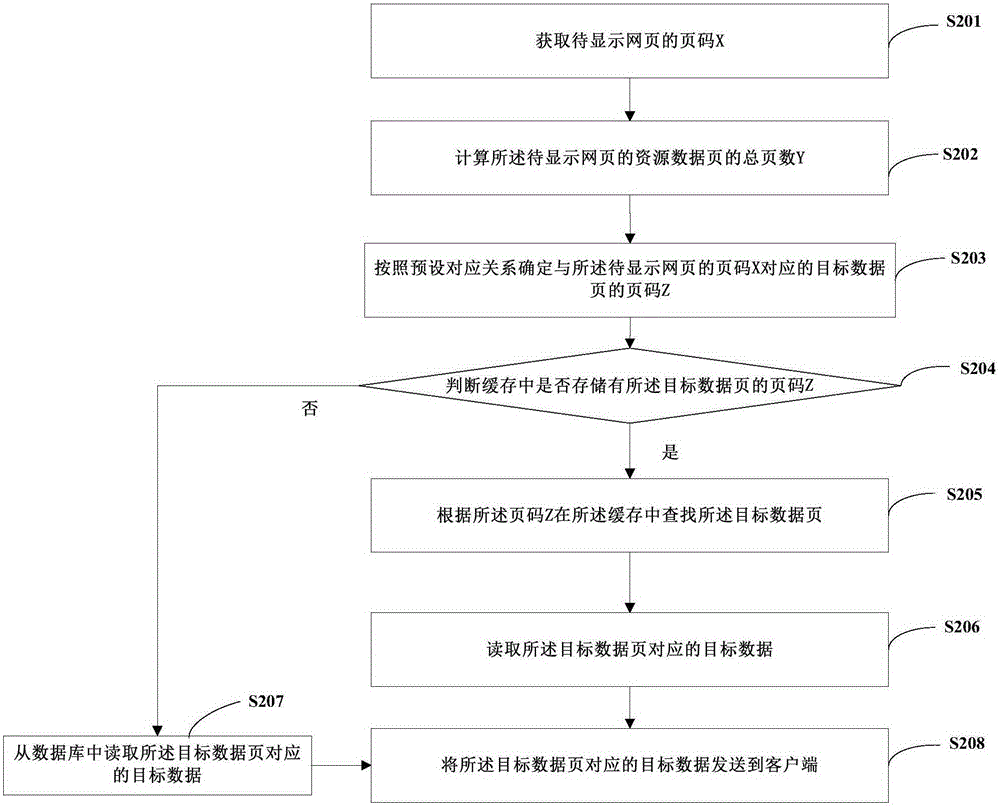

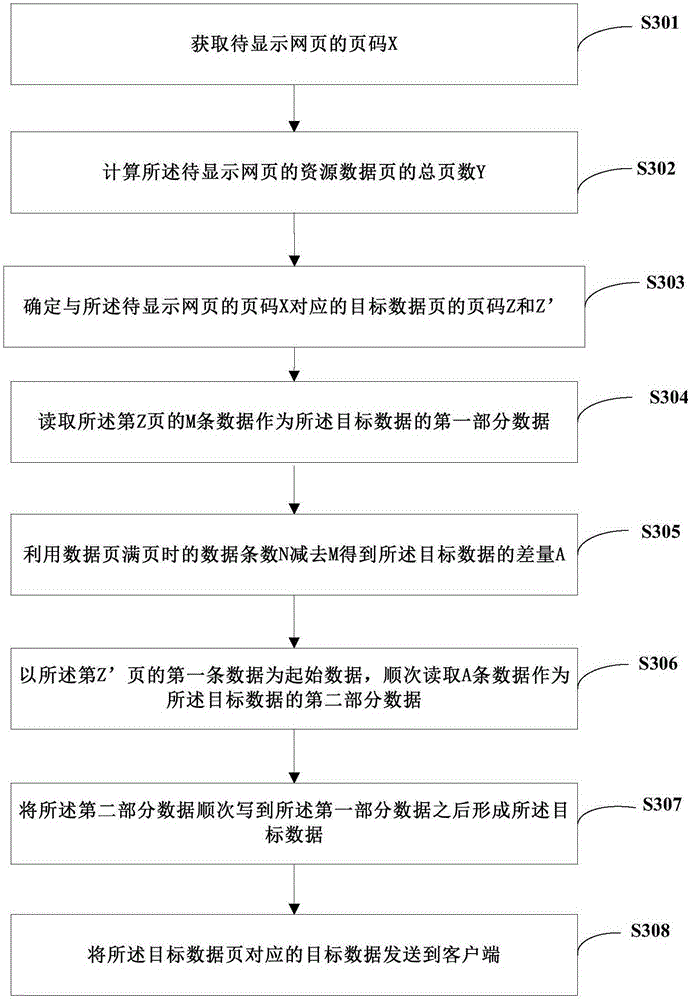

Data paging method and apparatus

ActiveCN105183764APrevent avalancheImprove cache hit ratioSpecial data processing applicationsPage countCache hit rate

The invention discloses a data paging method. The method comprises: obtaining a page code X of a to-be-displayed webpage; calculating the total page number Y of resource data pages of the to-be-displayed webpage; determining a page code of a target data page corresponding to the page code X of the to-be-displayed webpage according to a preset corresponding relationship; and sending target data corresponding to the target data page to a client. Correspondingly, the invention further discloses a data paging apparatus. Compared with the prior art, the technical scheme provided by the invention can avoid the occurrence of an avalanche phenomenon of a cache, so that the cache hit ratio of data in each page can be increased, and the performance and data loading efficiency of the cache are improved.

Owner:ALIBABA (CHINA) CO LTD

Coal mine underground reservoir and multi-layer grouting anti-seepage reinforcement method for reservoir dam

The invention provides a coal mine underground reservoir and a multi-layer grouting anti-seepage reinforcement method for a reservoir dam and belongs to the field of coal mine underground construction. According to the multi-layer grouting anti-seepage reinforcement method, the area of the underground reservoir and the location of the coal pillar dam are determined and set through the volume; two side tunnels and withdrawal tunnels of the underground reservoir are drilled, concrete grout and silica sol are sequentially sprayed on the tunnel walls, and concrete and silica sol spray layers are formed; a plurality of shallow grouting holes are constructed in the sides, near the coal pillar dam, of the two side tunnels and the withdraw tunnels and the holes are sealed for grouting, and then a plurality of deep grouting holes are constructed and sealed for grouting; and finally, an artificial water retaining dam is constructed for sealing the tunnels, and accordingly the closed coal mine underground reservoir is formed. The multi-layer grouting anti-seepage reinforcement method has the double effects of reinforcement and sealing on the coal pillar of the coal mine underground reservoir; and nano-scale, inorganic, green and efficient materials are selected, the anti-seepage safety of the coal pillar dam can be ensured, and the coal mine underground reservoir is made durable and stable.

Owner:CHINA UNIV OF MINING & TECH

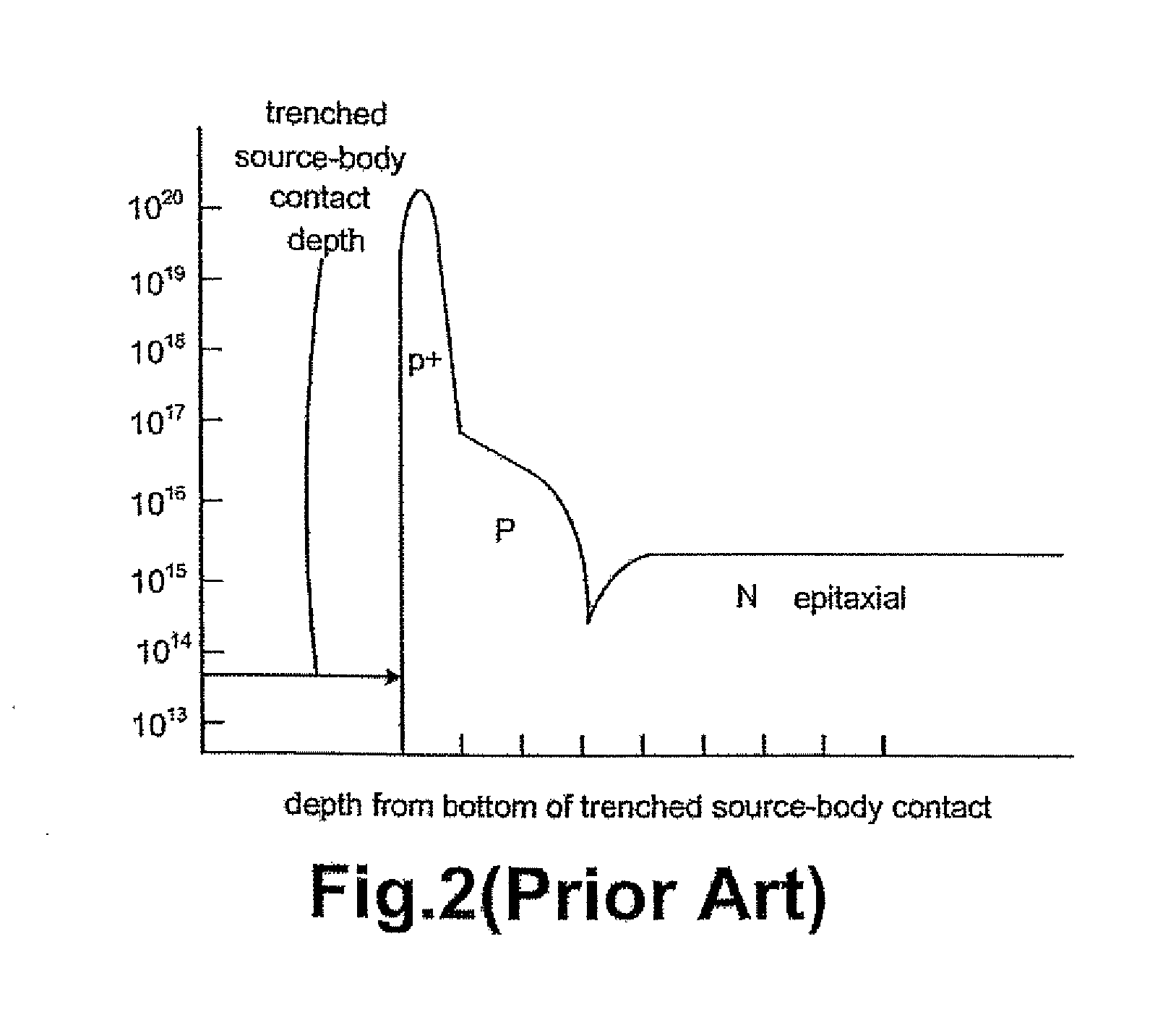

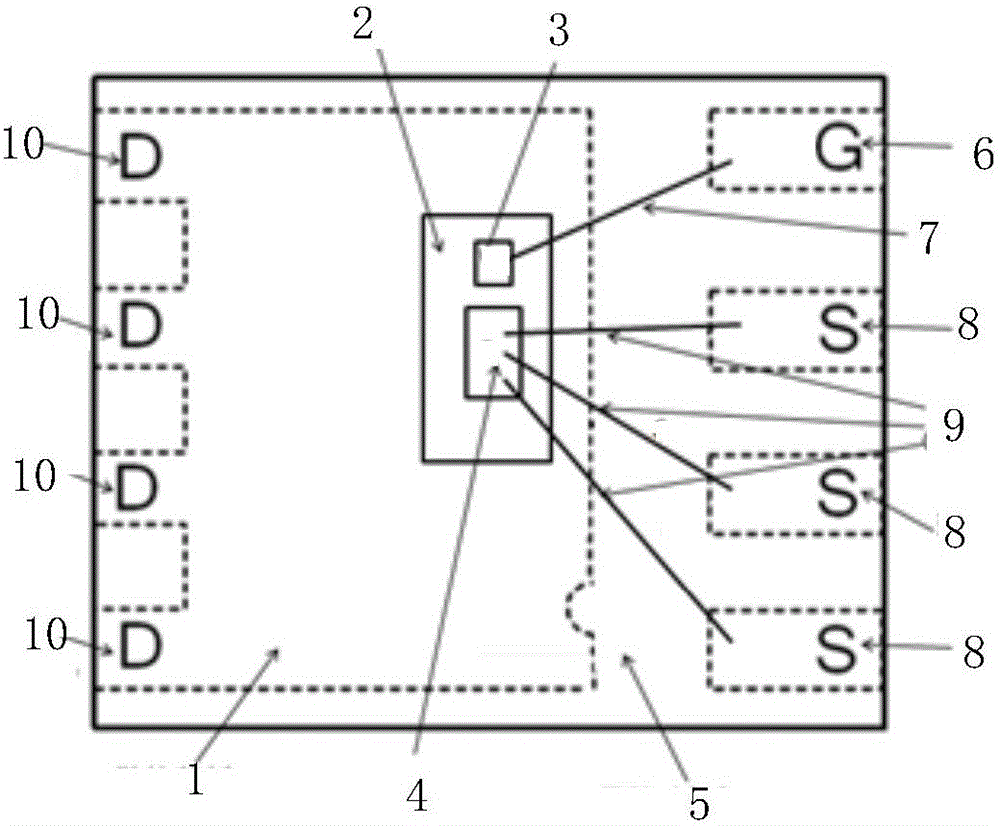

Avalanche capability improvement in power semiconductor devices using three masks process

ActiveUS20140048872A1Improve avalanche capabilityImproved avalanche capabilityThyristorSemiconductor/solid-state device manufacturingPhysicsPower semiconductor device

A power semiconductor device with improved avalanche capability is disclosed by forming at least one avalanche capability enhancement doped region underneath an ohmic contact doped region. Moreover, a source mask is saved by using three masks process and the avalanche capability is further improved.

Owner:HSIEH FU YUAN +1

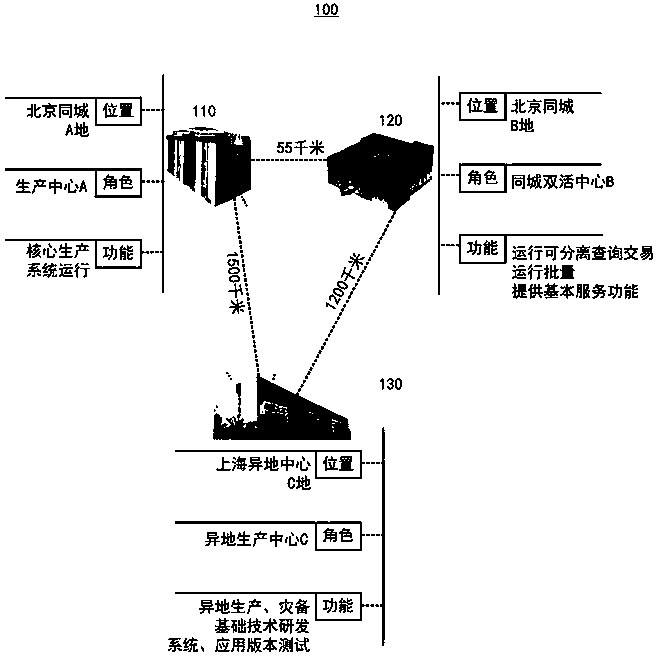

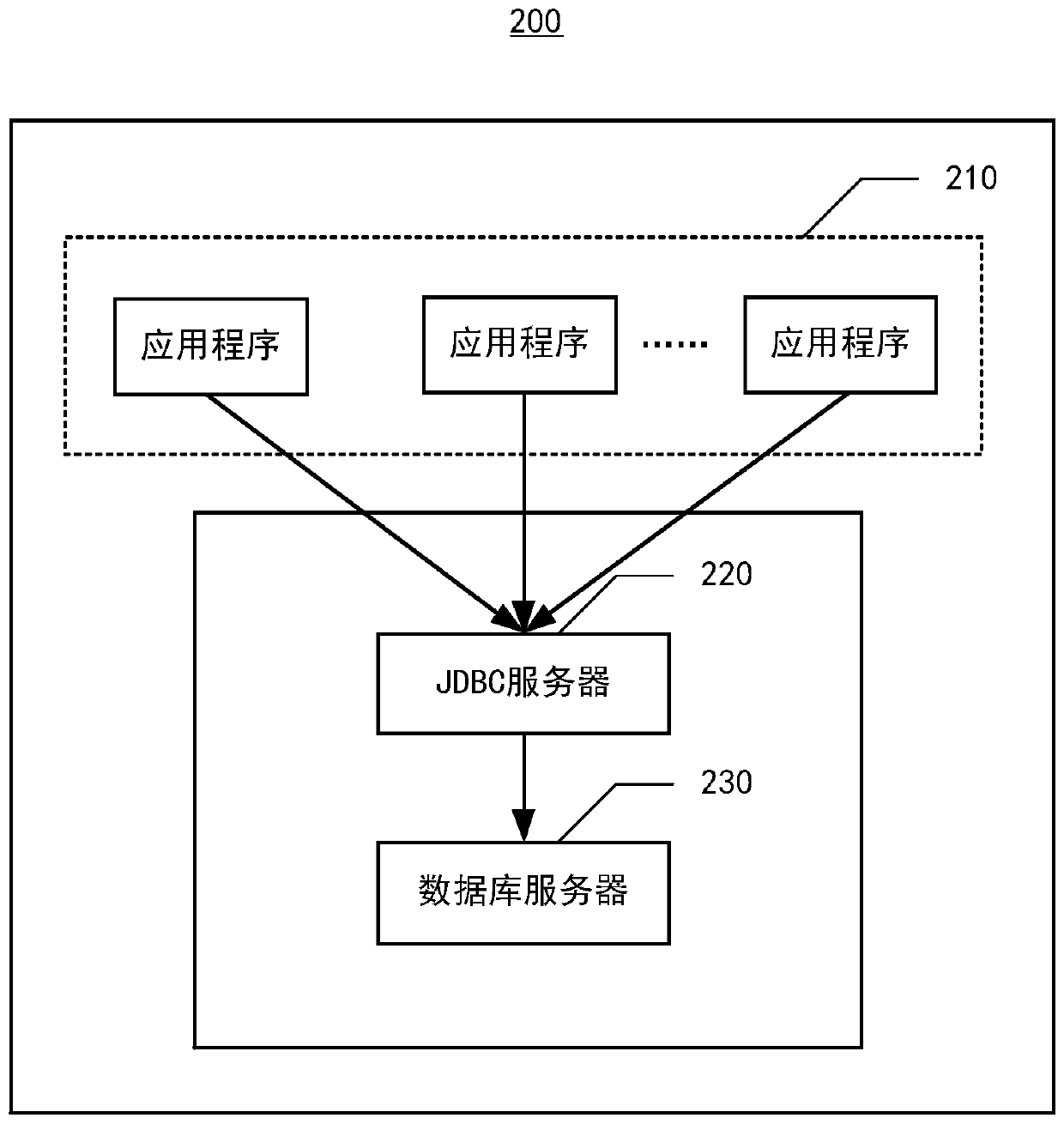

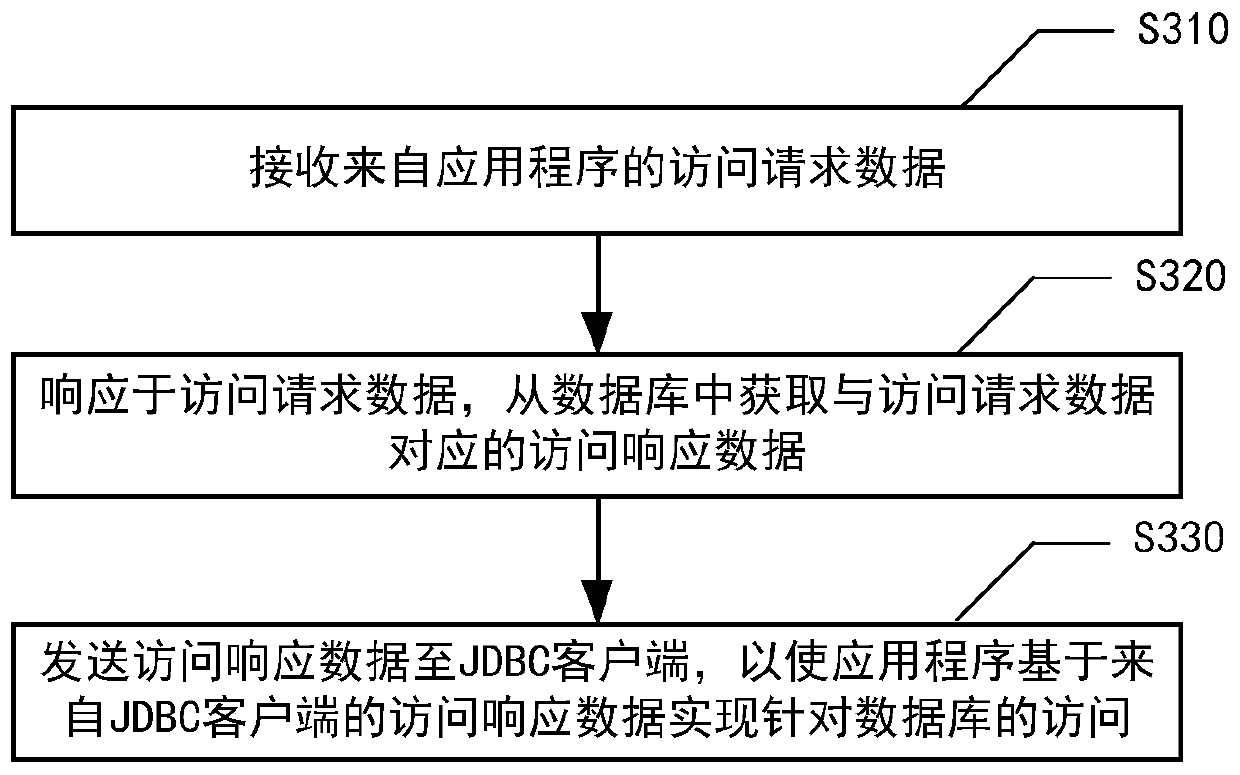

Database access method and device, electronic equipment and medium

ActiveCN110413676AOvercome Performance Loss and Security HazardsReduce network overheadDatabase management systemsSpecial data processing applicationsClient-sideApplication software

The invention provides a database access method. The method is executed by a Java database connection (JDBC) server. The JDBC server and the database are deployed in the same network area; the methodcomprises the following steps: receiving access request data from an application program, wherein the access request data is sent by the JDBC client in response to an access request of an applicationprogram for a database, and the access request data is obtained by encrypting and / or compressing a structured query statement and an access parameter carried in the access request by the JDBC client;in response to the access request data, obtaining access response data corresponding to the access request data from a database; and sending the access response data to the JDBC client, so that the application program realizes access to the database based on the access response data from the JDBC client. The invention further provides a database access device which is applied to the JDBC server, electronic equipment and a computer readable storage medium.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

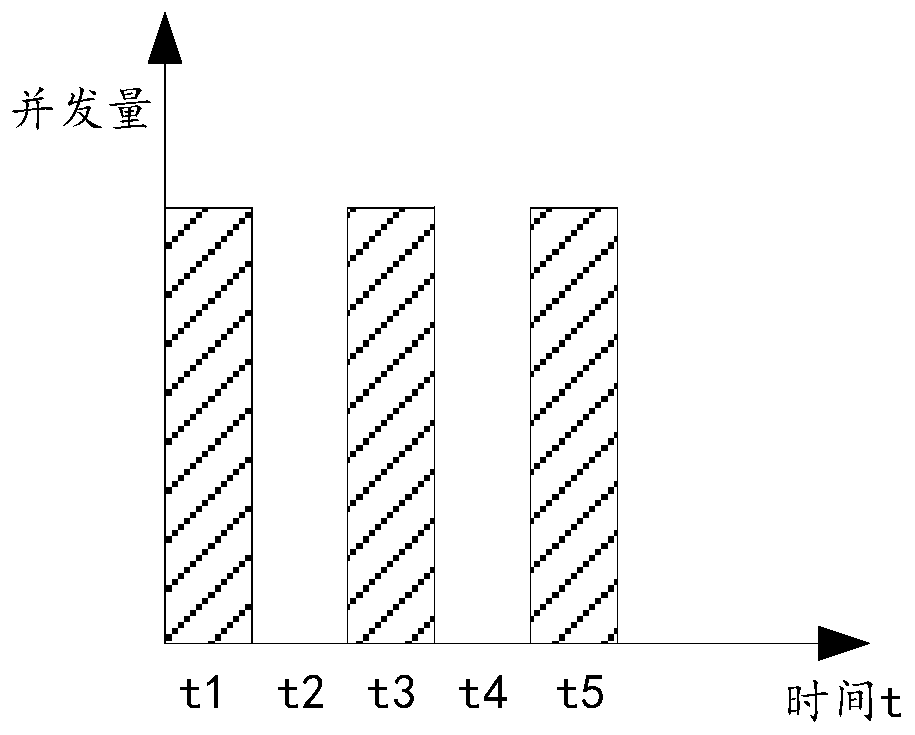

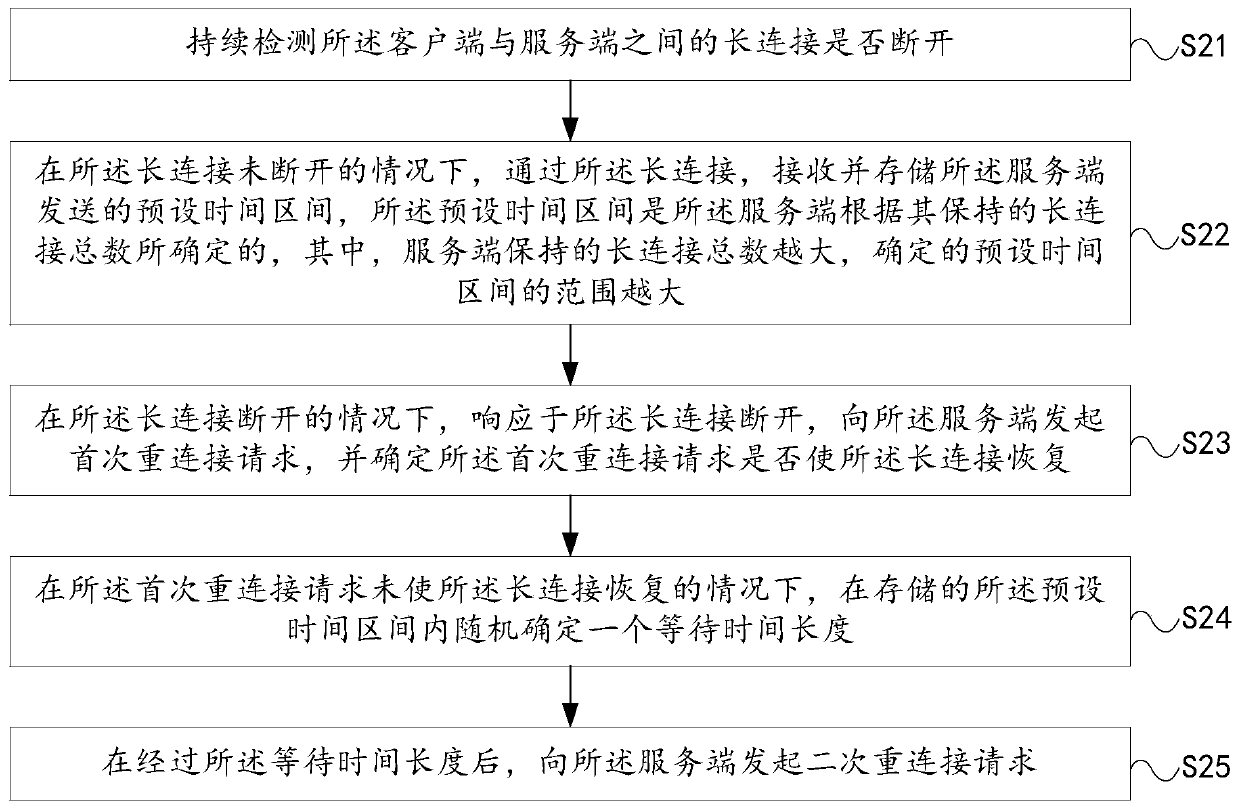

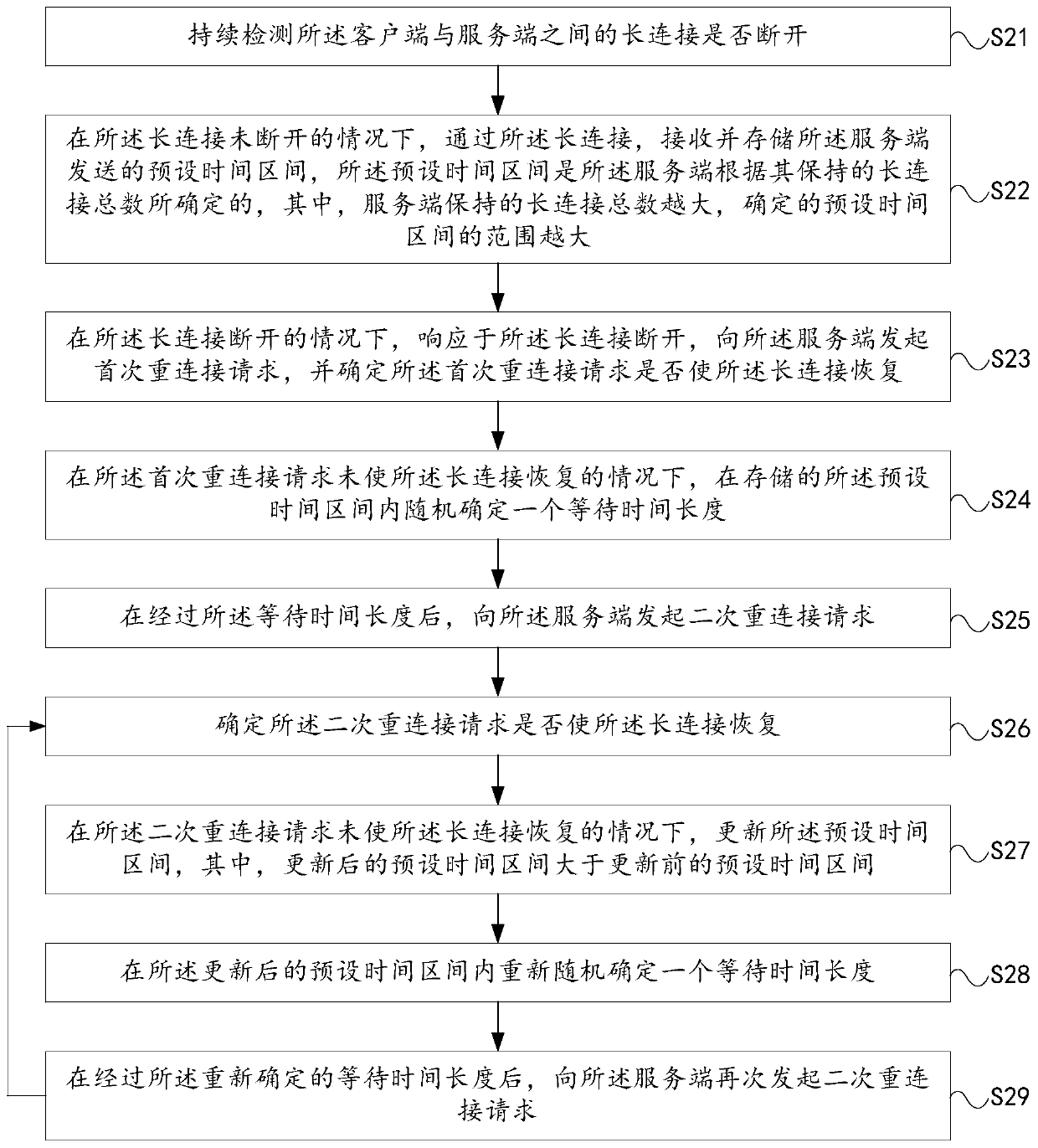

Long connection recovery method, system and device, electronic equipment and storage medium

The embodiment of the invention provides a long connection recovery method, system and device, electronic equipment and a storage medium, and aims to relieve the high concurrency condition of a reconnection request on a server side and improve the long connection recovery efficiency. The method is applied to a client, and the method comprises the following steps: continuously detecting whether thelong connection between the client and a server is disconnected or not; under the condition that the long connection is not disconnected, receiving and storing a preset time interval sent by the server through the long connection; under the condition that the long connection is disconnected, initiating a first reconnection request to the server in response to the disconnection of the long connection, and determining whether the first reconnection request enables the long connection to be recovered or not; under the condition that the long connection is not recovered by the first reconnectionrequest, randomly determining a waiting time length in the stored preset time interval; after the waiting time length, initiating a secondary reconnection request to the server.

Owner:TAIKANG LIFE INSURANCE CO LTD

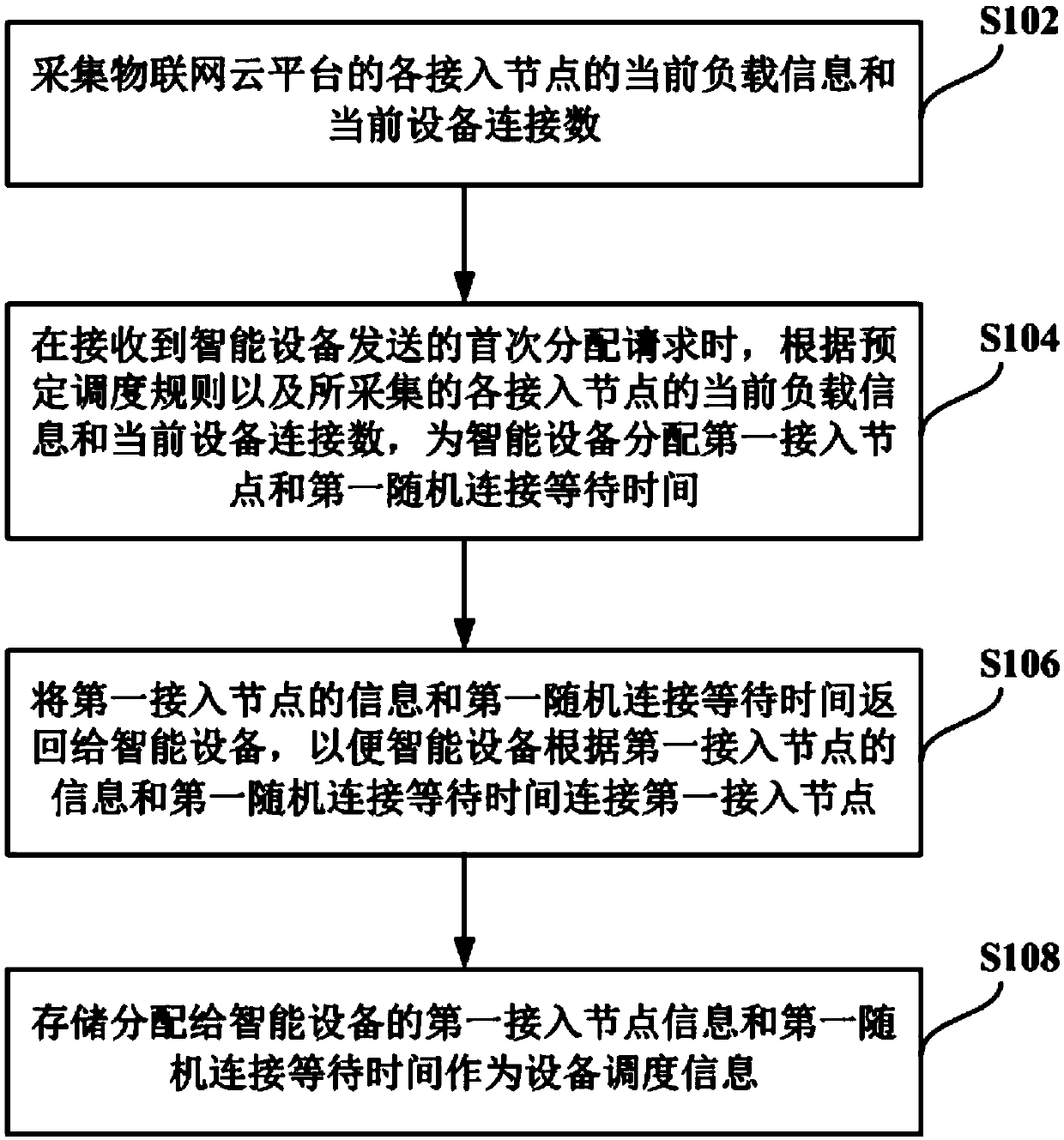

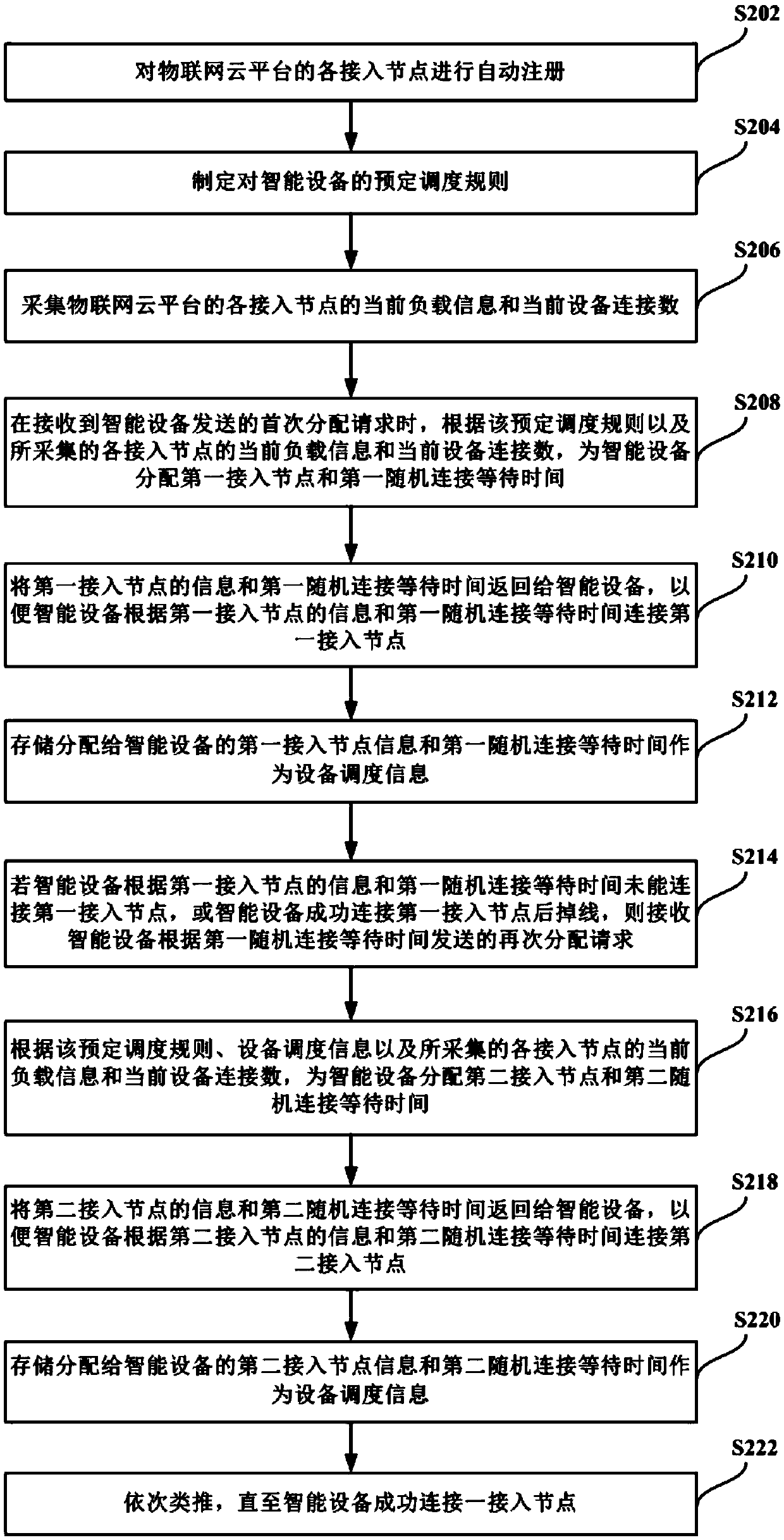

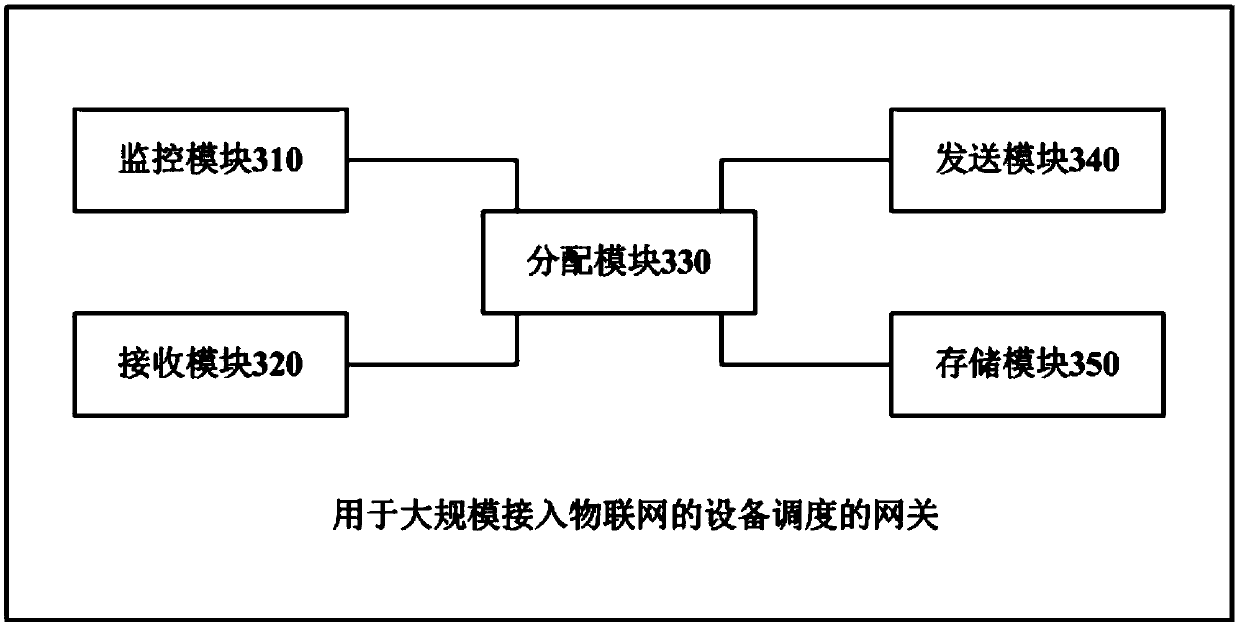

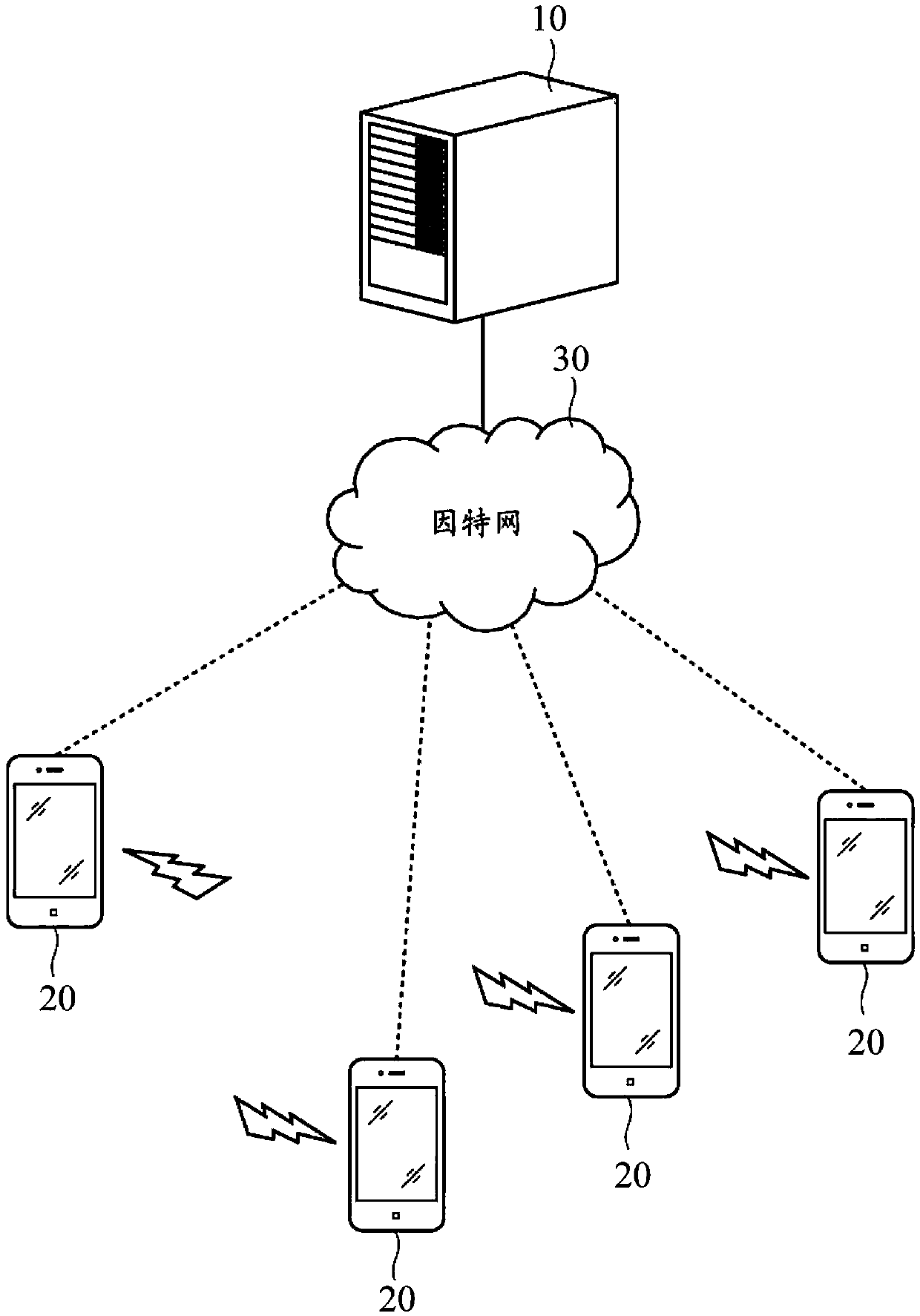

Device scheduling method, gateway and system for large-scale access to Internet of Things

ActiveCN111083181ASolve the problem of high loadLoad balancingData switching by path configurationThe InternetEngineering

The invention provides a device scheduling method, gateway and system for large-scale access to the Internet of Things. The method comprises the following steps: acquiring current load information andcurrent device connection number of each access node of an Internet of Things cloud platform; when a first allocation request sent by an intelligent device is received, according to a predetermined scheduling rule, the current load information of each access node and the current device connection number, allocating a first access node and a first random connection waiting time to the intelligentdevice, and returning an allocation result to the intelligent device, so that the intelligent device is connected with the first access node according to the allocated information of the first accessnode and the first random connection waiting time; and storing the first access node information and the first random connection waiting time allocated to the intelligent device as device scheduling information. According to the invention, resources of device access nodes are intelligently and dynamically allocated, the problem that large-scale device accesses the Internet of Things cloud platformis solved, and automatic operation and maintenance of device access management are realized.

Owner:BEIJING QIHOO TECH CO LTD

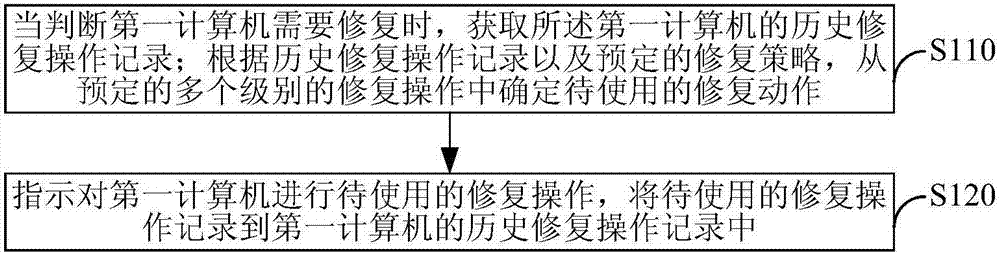

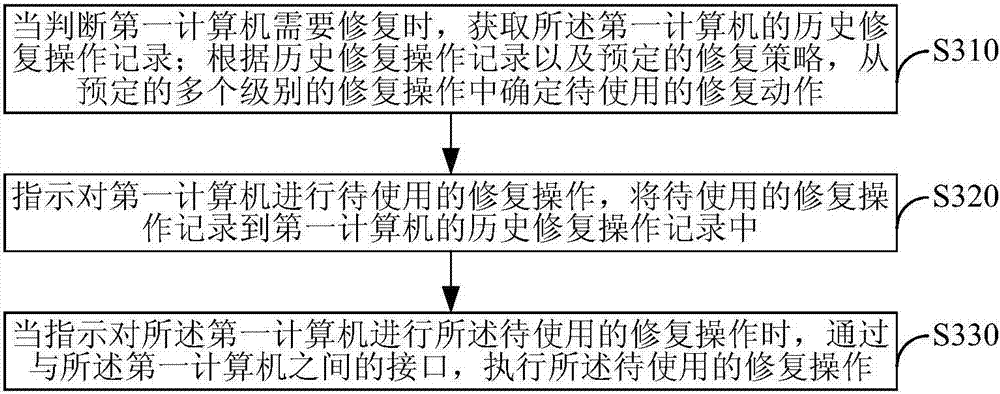

Computer repair control method and system, and repairing method and system

ActiveCN107122254ANo human intervention requiredPrevent avalancheNon-redundant fault processingRepair methodReliability engineering

The invention provides a computer repair control method and system, and a repairing method and system. The repair control method comprises the steps of obtaining a historical repair operation record of a first computer when it is judged that the first computer needs to be repaired; determining a to-be-used repair operation from predetermined multiple-level repair operations according to the historical repair operation record and a predetermined repair strategy; and indicating to perform the to-be-used repair operation on the first computer, and recording the to-be-used repair operation record in the historical repair operation record of the first computer. By virtue of the repair control method, the problem that the repair operation cannot be adjusted according to an actual condition and the problem of overhigh dependency on one-machine monitor accuracy can be solved.

Owner:ALIBABA GRP HLDG LTD

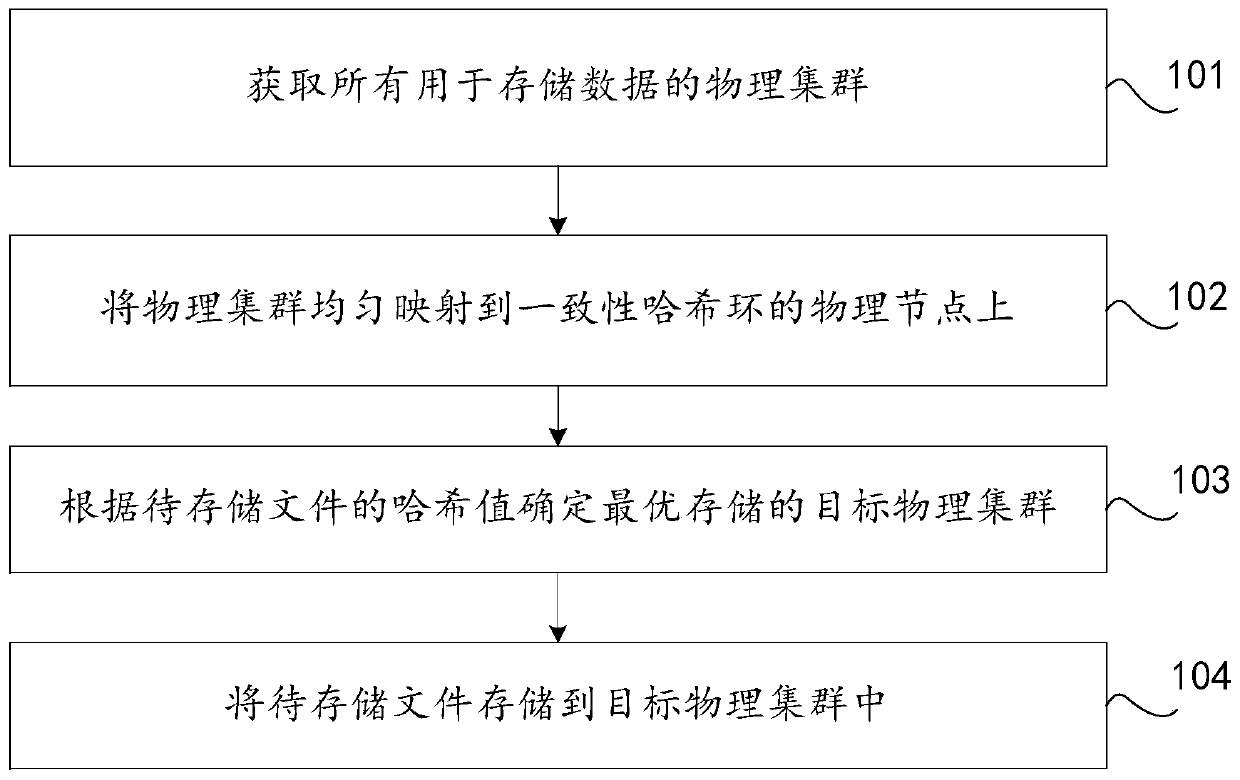

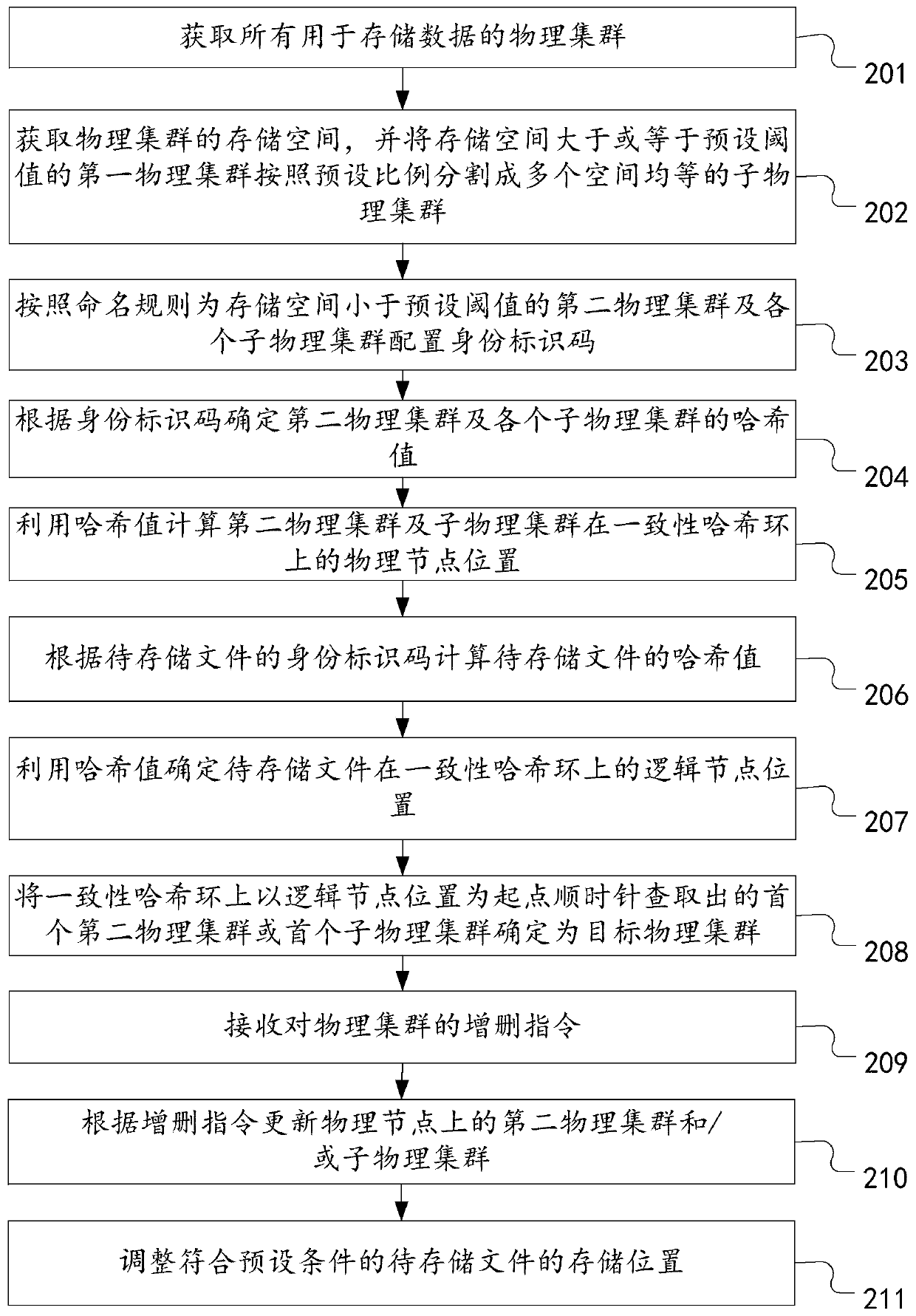

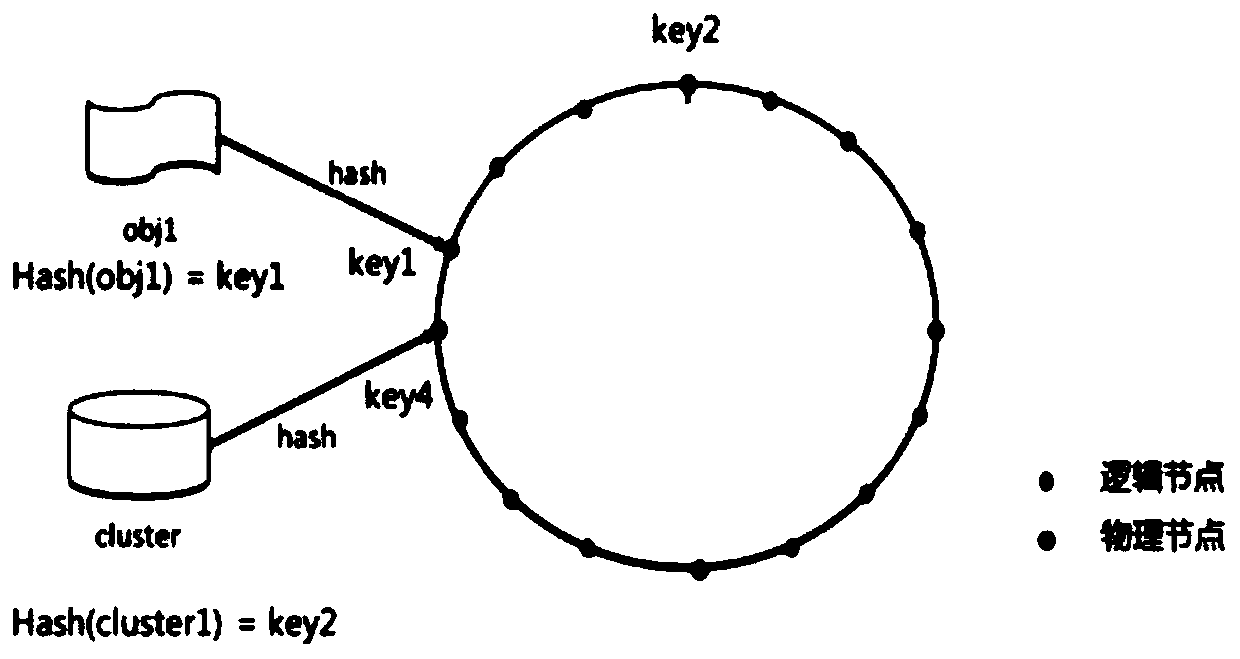

Data cluster storage method and device and computer equipment

ActiveCN110489059AReduce complexityLow costInput/output to record carriersComputer equipmentData processing

The invention discloses a data cluster storage method and device and computer equipment, relates to the field of data processing, and can solve the problems that when a cluster is used for data storage, rule storage of data in the cluster cannot be guaranteed, the data storage position cannot be quickly positioned, and consequently the storage performance is poor. The method comprises the steps ofobtaining all physical clusters used for storing data; uniformly mapping the physical clusters to physical nodes of a consistent hash ring; determining an optimally stored target physical cluster according to the hash value of the to-be-stored file; and storing the to-be-stored file in the target physical cluster. The application is suitable for cluster storage of data.

Owner:PING AN TECH (SHENZHEN) CO LTD

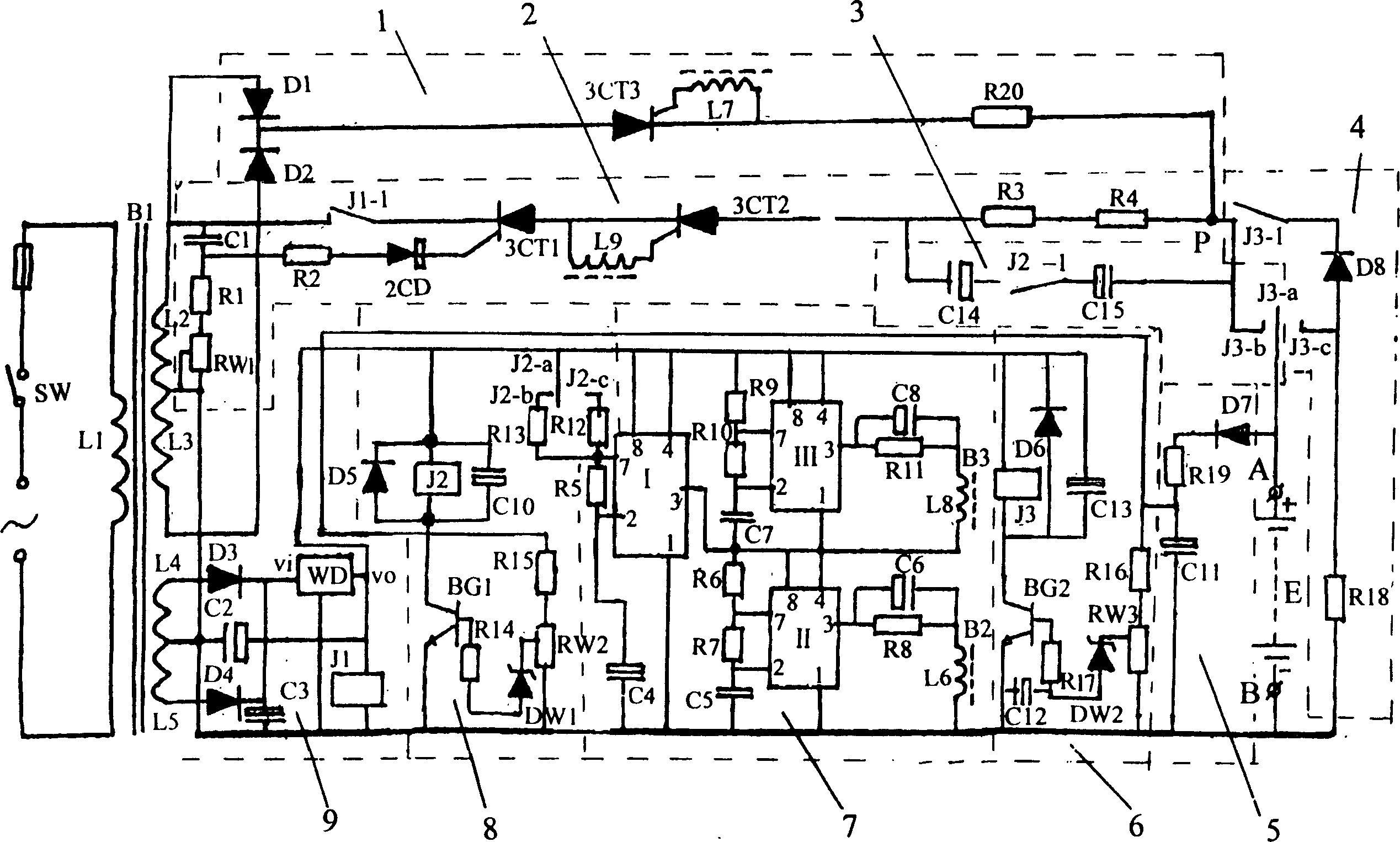

Method and apparatus for repairing high-capacity waste lead accumulator by variable combined pulse

InactiveCN1866662AReduce power consumptionEliminate generationBatteries circuit arrangementsElectric powerCharge and dischargeElectric energy

The invention discloses an accumulator charging technology and equipment, which is characterized by the following: 1) proceeding charging at 65-75 percent of combination pulse of normal positive and negative pulse charging time dutycycle; 2) increasing negative-pulse charging time in the combination pulse from 80-90 percent through new positive and negative pulse charging time dutycycle; 3) discharging the accumulator in the negative pulse charging condition; 4) repeating 1), 2), 3) charging and discharging courses until the accumulator voltage stabilizes over certain value of standard voltage to finish restoring. The invention can restore combination pulse charging waste lead accumulator of single positive and negative pulse dutycycle, which improves power utility rate.

Owner:刘庆丰

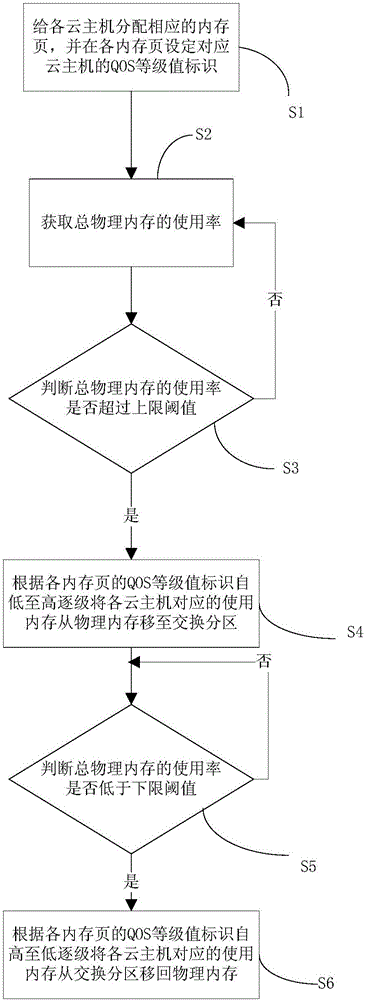

Memory control method and system of physical computer with multi-cloud host

InactiveCN106126345AGuaranteed memory usagePrevent avalancheResource allocationOperating systemUtilization rate

A memory control method of a physical computer with multi-cloud hosts comprises the following steps: S1, allocating corresponding memory pages for each cloud host, and setting QOS rank value identifications corresponding to cloud hosts in each memory page; S2, obtaining the total physical memory utilization rate; S3, determining whether the total physical memory utilization rate exceeds an upper limit threshold value or not; if yes, executing step4; if not, returning to step2; S4, gradually transferring used memory corresponding to each cloud host from the physical memory to an exchange partition according to a rising order of the QOS rank value identifications in each memory page. The method and system can gradually transfer memories of the cloud hosts with different QOS rank values in the rising order, thus preferably ensuring memory usage of the cloud hosts with high level, and preventing system avalanche caused by overloading.

Owner:GUANGDONG EFLYCLOUD COMPUTING CO LTD

Recording medium feeding apparatus, recording apparatus, liquid ejecting apparatus

ActiveUS20050168501A1Prevent avalancheReduce loadRecording apparatusTypewritersEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

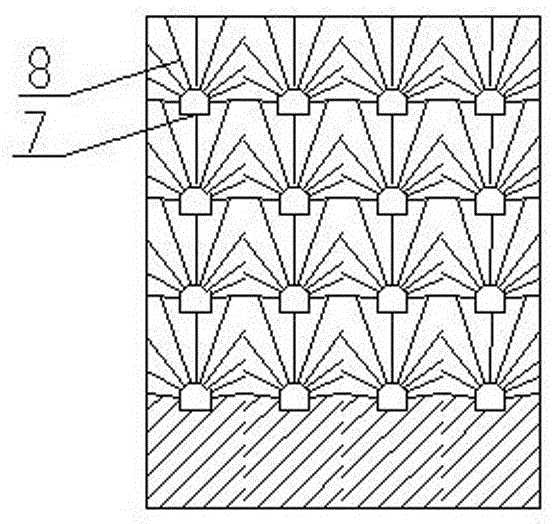

Method for blasting centralized recovery lag jambs in several times

The invention provides a method for blasting centralized recovery lag jambs in several times. The method mainly comprises the steps that the recovered jambs are divided into four sections in the height direction, a drilling drift is dug in the length direction of the jambs, a plurality of drilling crossdrifts perpendicular to the drilling drift are dug in the width direction of the jambs, and the drilling crossdrifts penetrate through the jambs; sector-shaped blasting holes which radiate upwards with the cross sections of the drilling crossdrifts as the circle center are formed above the drilling crossdrifts, and the mined areas on the two sides of the jambs are used as the free faces of blasting; the highest section is blasted first, caved mineral ores are used as a buffering layer, and ore removal is not conducted temporally; then secondary blasting is conducted, the rest sections are blasted at a time; and ore removing is conducted after blasting is over. The jambs are spallationd in several sections and times, the mineral ore buffering layer is formed first, secondary blasting is conducted to cave the upper mineral ores at a time under the protection of the buffering layer, and potential safety hazards caused by large-scale mineral ore caving and ore dilution caused by collapse of hanging side and heading side surrounding rock are also avoided.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

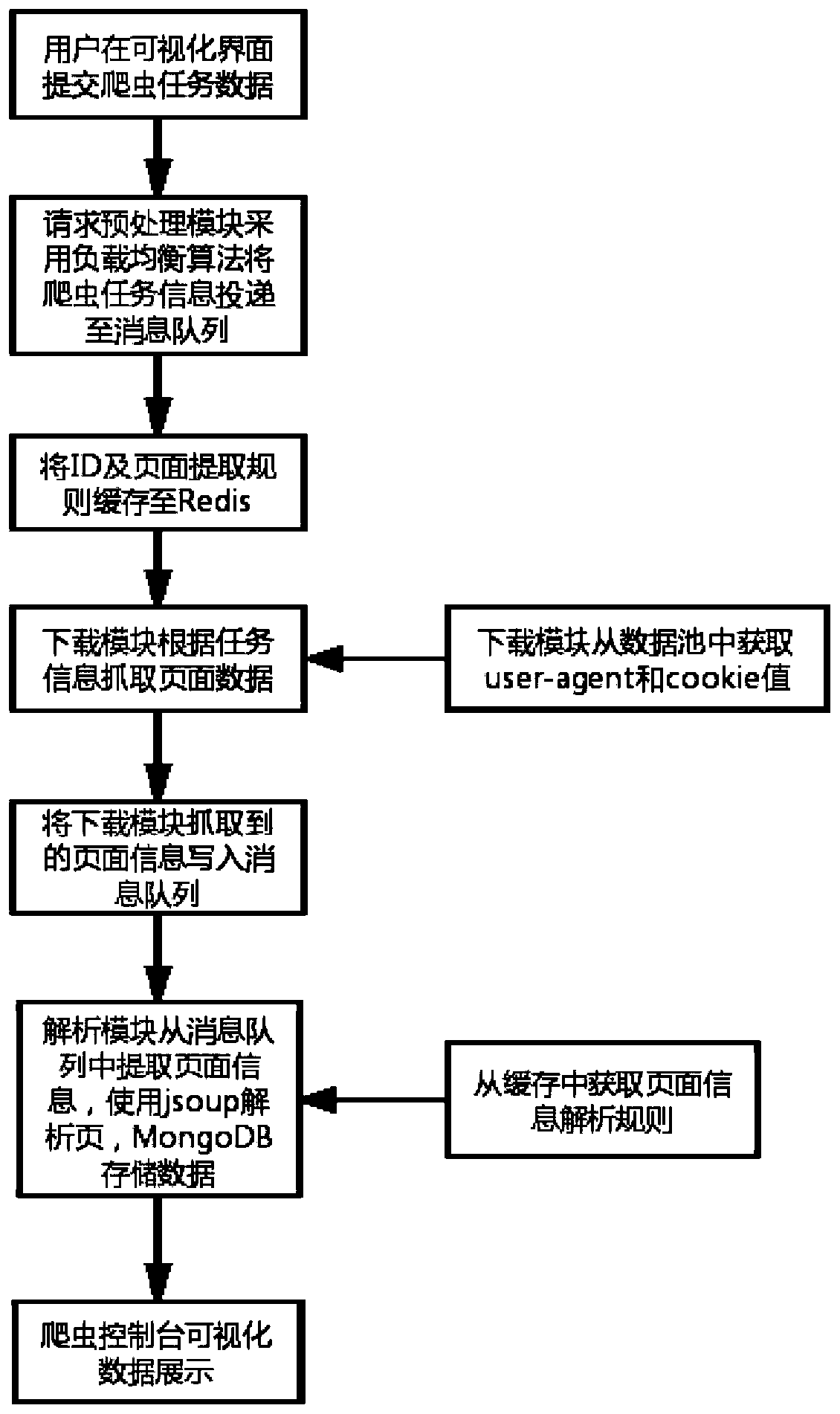

Distributed web crawler data extraction system and method based on micro-service architecture

InactiveCN111222027AClear divisionPrevent avalancheResource allocationWeb data indexingData ingestionWeb crawler

The invention provides a distributed web crawler data extraction system and method based on a micro-service architecture. A leading-edge micro-service architecture concept in the current industry is used; the whole crawler system is split into a data extraction module; based on the system and the cloud architecture, a user can realize quickquickquickquick deployment of the distributed crawler system, support horizontal expansion and containerized deployment, and greatly improve the expandability and quickquickquickquick deployment capability of the crawler system.

Owner:NANJING UNIV OF POSTS & TELECOMM

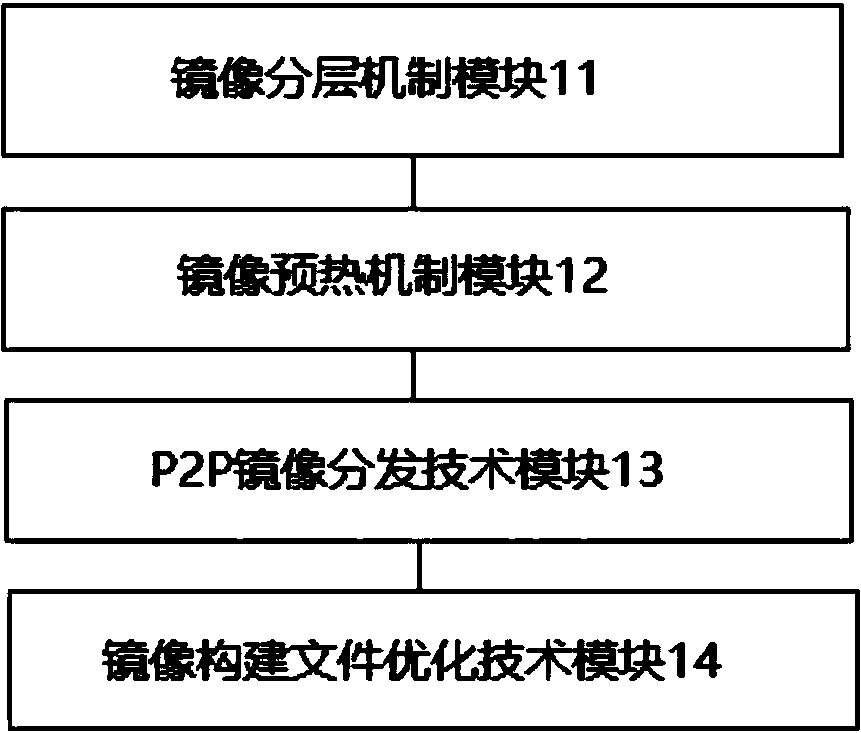

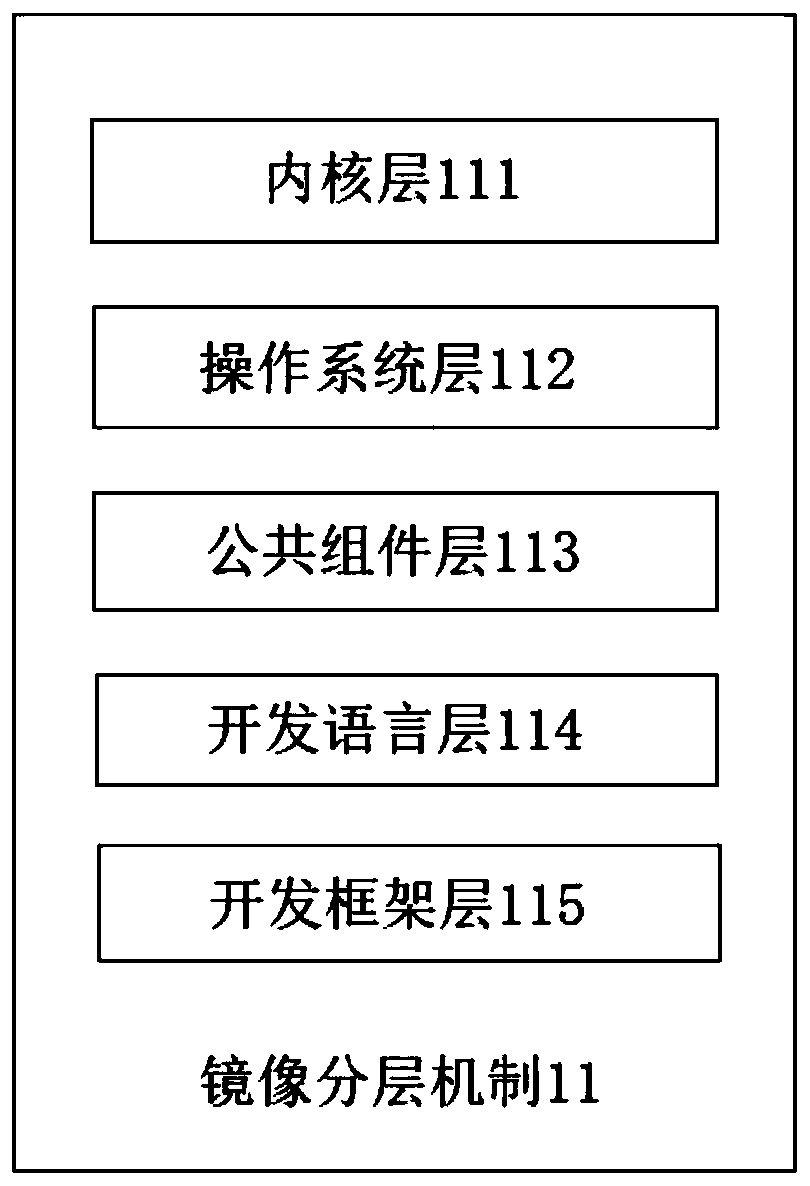

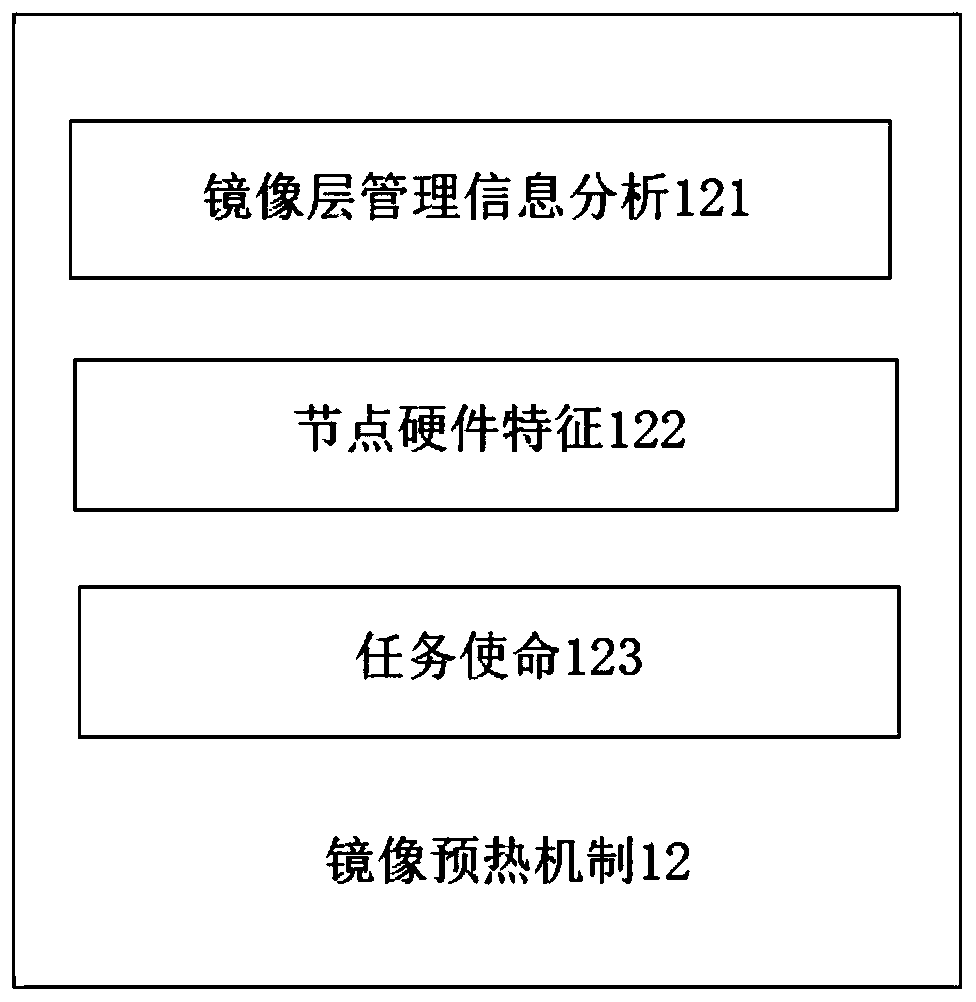

Lightweight resource virtualization method and lightweight resource virtualization device for server

PendingCN111459668AChange the status quoImprove distribution speedResource allocationSoftware simulation/interpretation/emulationOperational systemResource virtualization

The invention provides a lightweight resource virtualization method and a lightweight resource virtualization device for a server. The method comprises the following steps: 1, preparing raw materials;the method comprises the following steps of: (A) setting a container public mirror image which is provided with a kernel layer, an operating system layer, a public component layer, a development language layer and a development framework layer; and (B) analyzing node hardware characteristics and / or task missions according to mirror image layer management information, and preloading a necessary basic common mirror image layer, wherein the kernel layer, the operating system layer, the common component layer, the development language layer and the development framework layer are arranged from bottom to top.

Owner:中科边缘智慧信息科技(苏州)有限公司

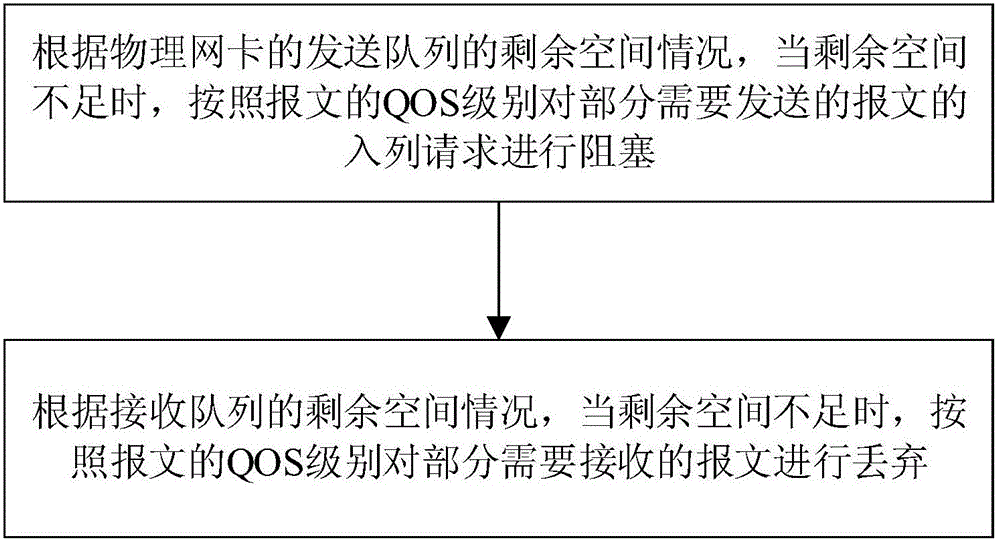

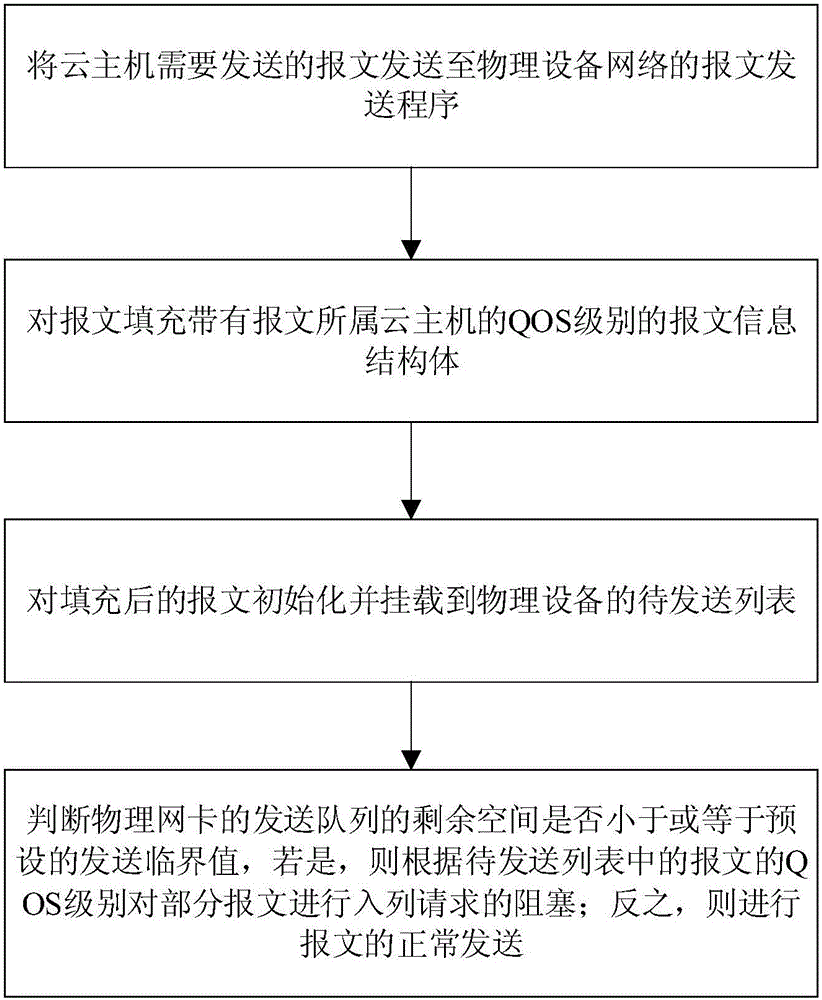

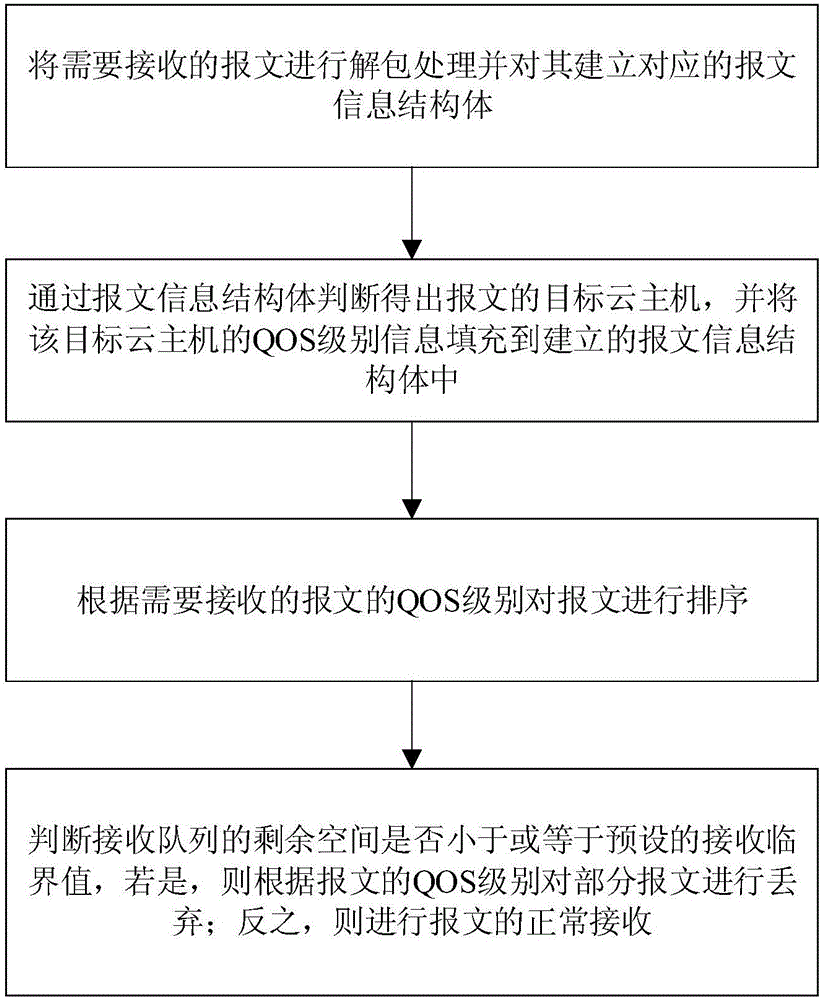

Method and system for ensuring communication queue of cloud host based on QoS (Quality of Service)

InactiveCN106101014AEasy to usePrevent avalancheData switching networksQuality of serviceNetwork data

This invention discloses a method and system for ensuring a communication queue of a cloud host based on QoS. The method comprises a message scheduling sending stage, and a message scheduling receiving stage. The system comprises a message scheduling sending unit and a message scheduling receiving unit. Through judging residual spaces of a sending queue and a receiving queue, the message scheduling can be adjusted in advance according to the QOS level, so that the network congestion can be avoided and the message is not abandoned randomly due to insufficient queue space; thus, the network data of the cloud host with a higher QOS level can be used smoothly, and the avalanche of the cloud host system can be effectively prevented. The method and the system can be widely applied to the cloud host technology.

Owner:GUANGDONG EFLYCLOUD COMPUTING CO LTD

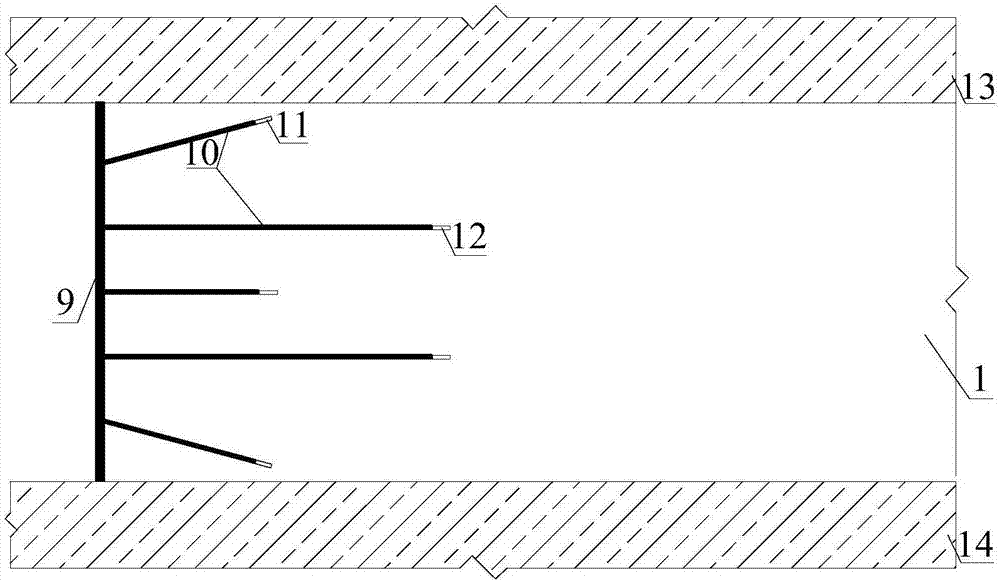

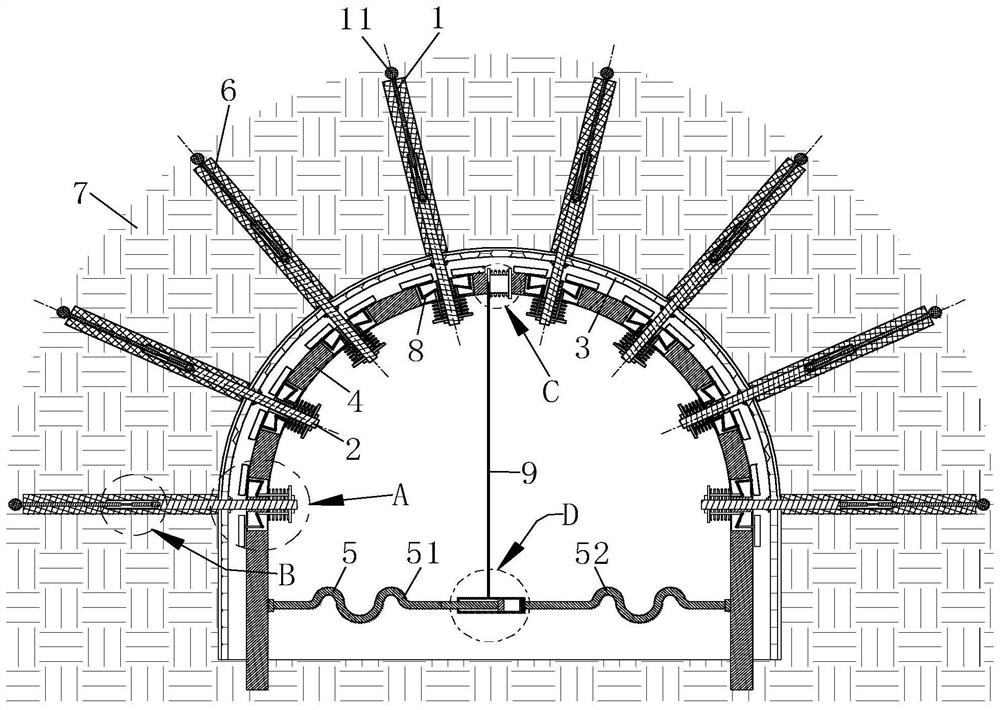

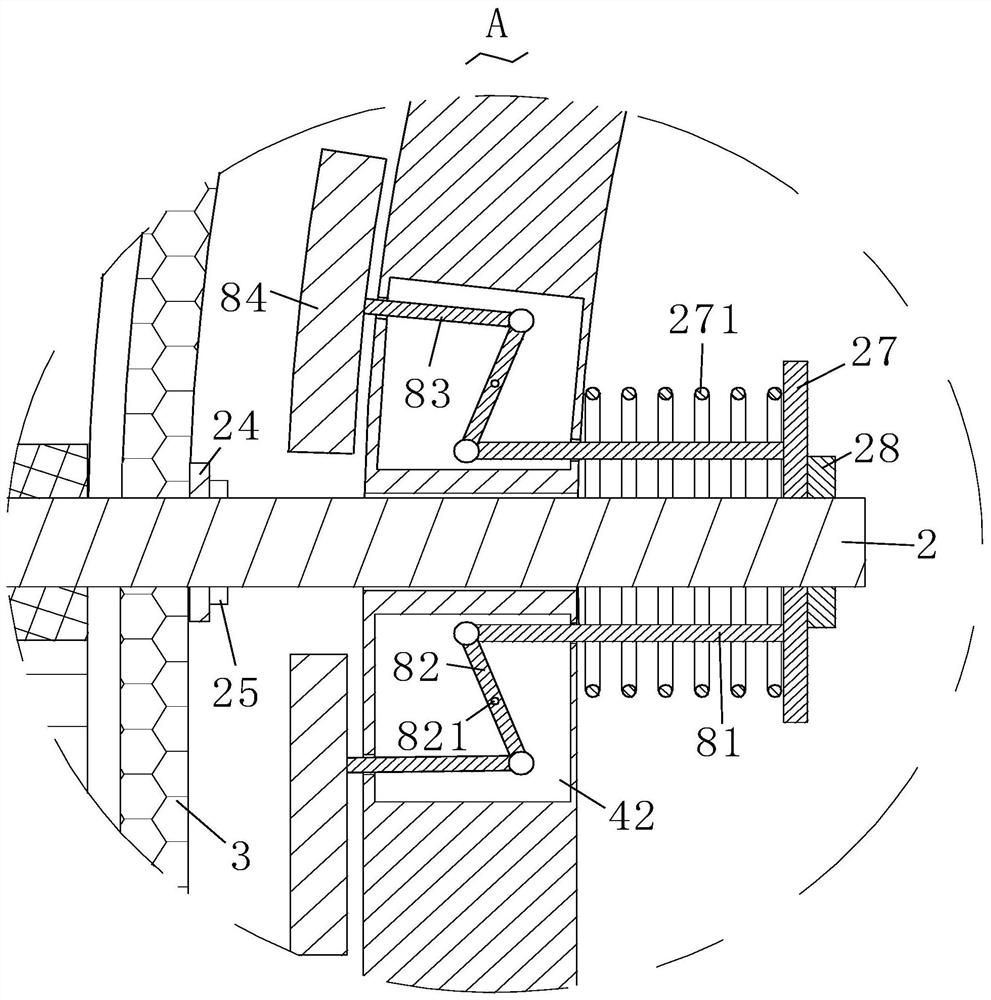

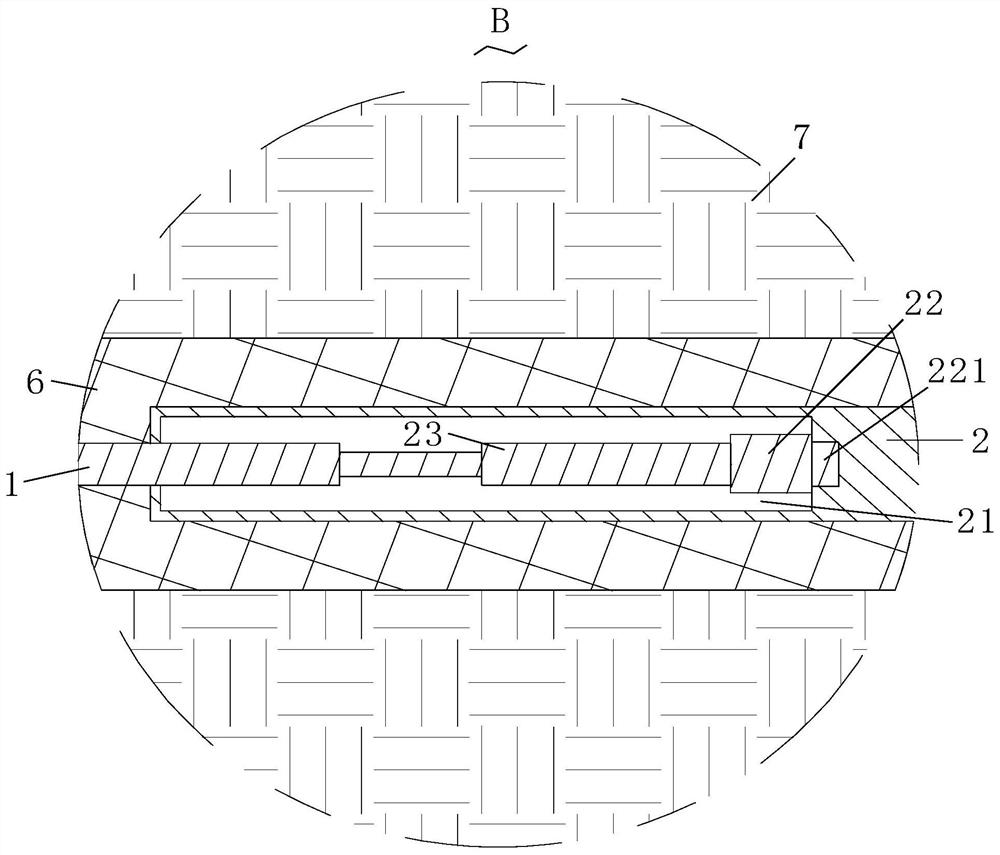

Monitoring and coupling integrated protection device for deep mine rock burst

InactiveCN113250723AAvoid breakingStrengthen surrounding rockMining devicesPump controlHydraulic pumpClassical mechanics

The invention belongs to the field of mine supporting equipment, and particularly discloses a monitoring and coupling integrated protection device for deep mine rock burst. The monitoring and coupling integrated protection device comprises an anchor cable, an anchor rod, an anchor net, arc-shaped steel and a supporting beam, the arc-shaped steel and the supporting beam play a supporting role, the anchor cable and the anchor rod are inserted into a drill hole poured with cement grout in a rock wall, one end of the anchor cable is fixedly provided with a stress sensor used for monitoring rock stratum rock burst, the other end of the anchor cable extends into a first cavity formed in one end of the anchor rod, a hydraulic telescopic rod is installed in the first cavity, and one side of a hydraulic pump is electrically connected with a PLC. The change condition of rock wall rock burst near a mine is monitored in real time through the stress sensor, when the rock burst is increased, the hydraulic pump drives the hydraulic telescopic rod to extend, so that the anchor rod and the anchor cable integrally extend, force unloading is carried out, the anchor rod and the anchor cable are prevented from being fractured due to overlarge stress, when the rock burst is reduced, the hydraulic pump drives the hydraulic telescopic rod to shorten, so that the anchor rod and the anchor cable integrally shorten, and surrounding rock of a roadway is further reinforced.

Owner:ANHUI UNIV OF SCI & TECH

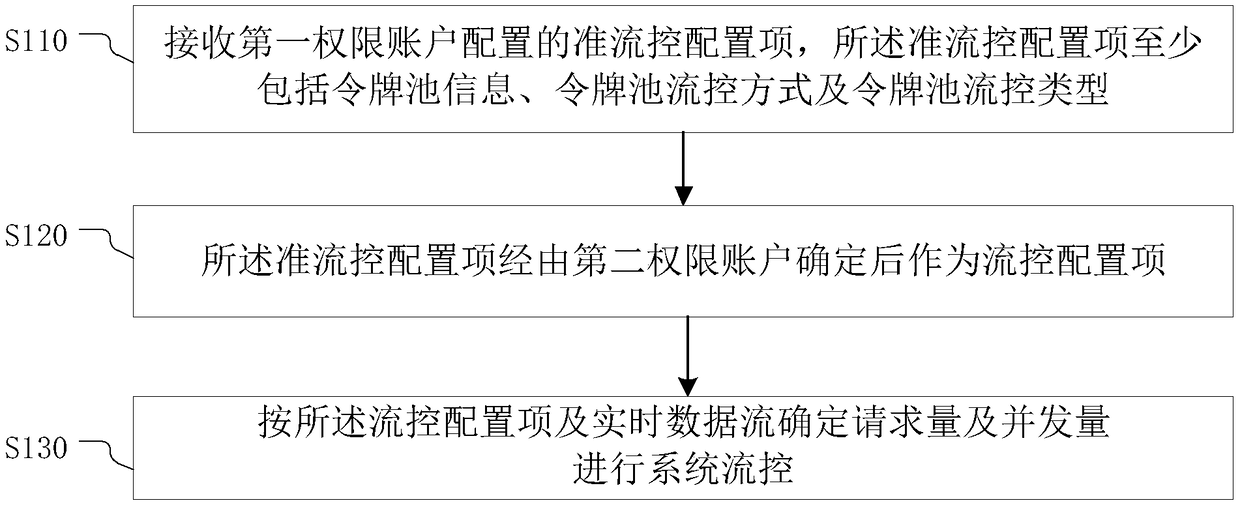

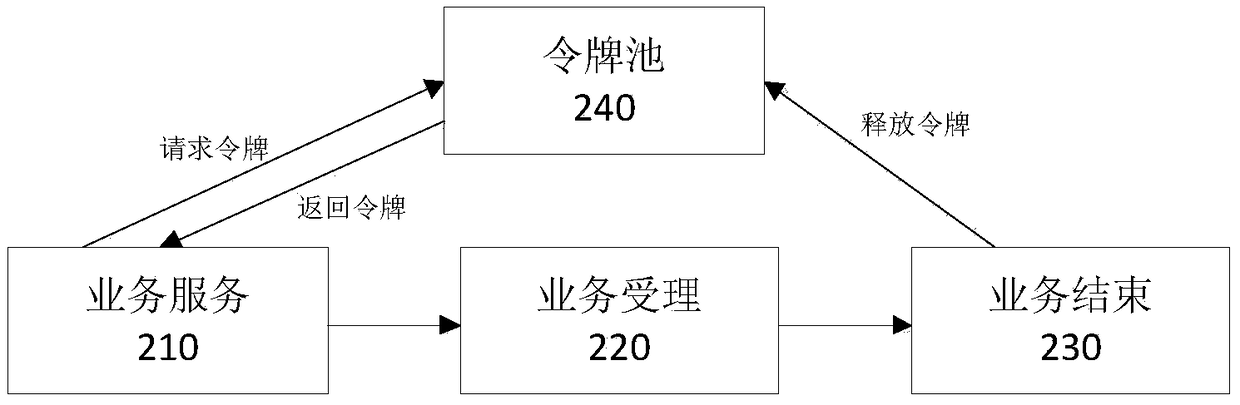

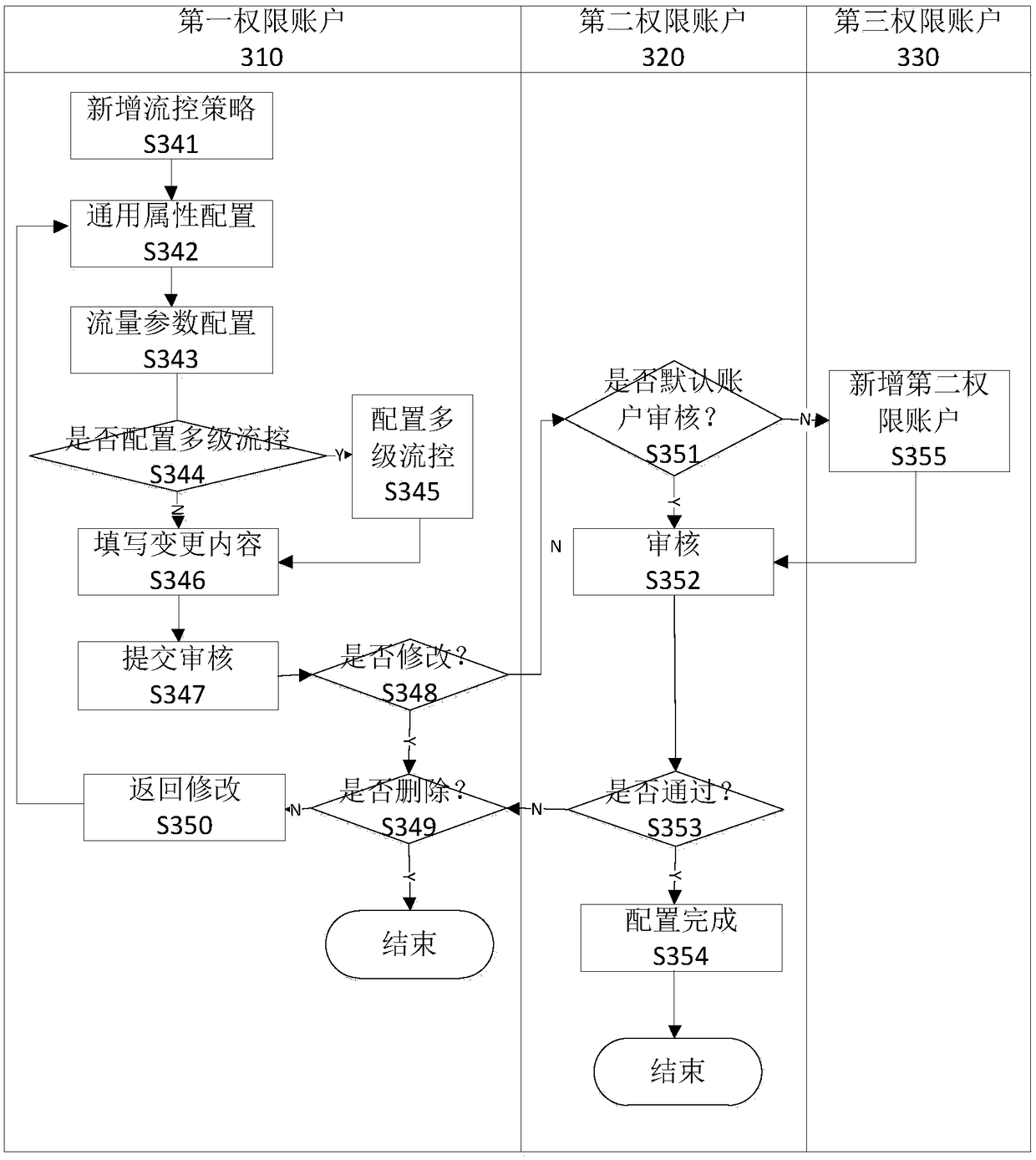

Token-based system flow control method and device, electronic equipment and storage medium

ActiveCN109412967APrevent avalancheImprove experienceData switching networksReal-time dataData stream

The invention provides a token-based system flow control method and device, electronic equipment and a storage medium. The token-based system flow control method includes: receiving quasi flow controlconfiguration items configured by a first authority account, wherein the quasi-flow control configuration items include at least token pool information, a token pool flow control manner and a token pool flow control type; using the quasi-flow control configuration items as flow control configuration items after determination from a second authority account; and determining request quantity and concurrence quantity according to the flow control configuration items and real-time data flow for system flow control. The method and the device provided by the invention ensure stability of a system,reduce downtime risks, enhance robustness of services, and improve user experience.

Owner:JIANGSU MANYUN SOFTWARE TECH CO LTD

Resource allocation method and device, computer equipment and storage medium

ActiveCN110489227APrevent avalancheGuaranteed uptimeResource allocationResource poolResource utilization

The invention relates to a resource allocation method and device, computer equipment and a storage medium. The method comprises the steps of obtaining a resource configuration file; wherein the resource configuration file comprises resource division information; when a target request initiated based on a target micro-service system is received, applying for idle resources from a first resource area in the resource pool according to the resource division information; when the idle resources do not exist in the first resource area, determining a resource partition corresponding to the target request in a second resource area of the resource pool according to the resource division information, and applying for the idle resources from the resource partition; and responding to the target request based on the applied idle resources. The method can improve the resource utilization rate.

Owner:招联消费金融股份有限公司

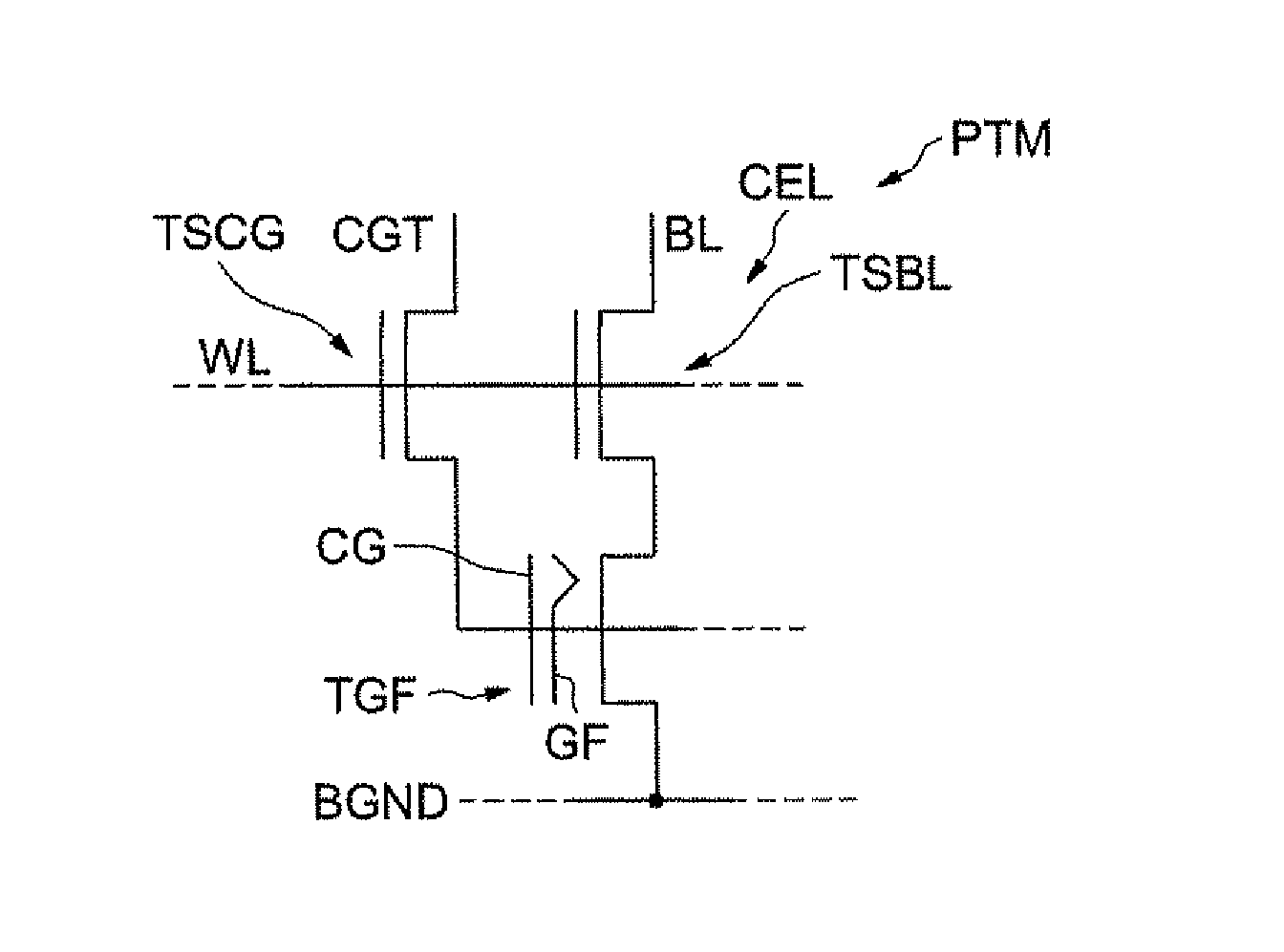

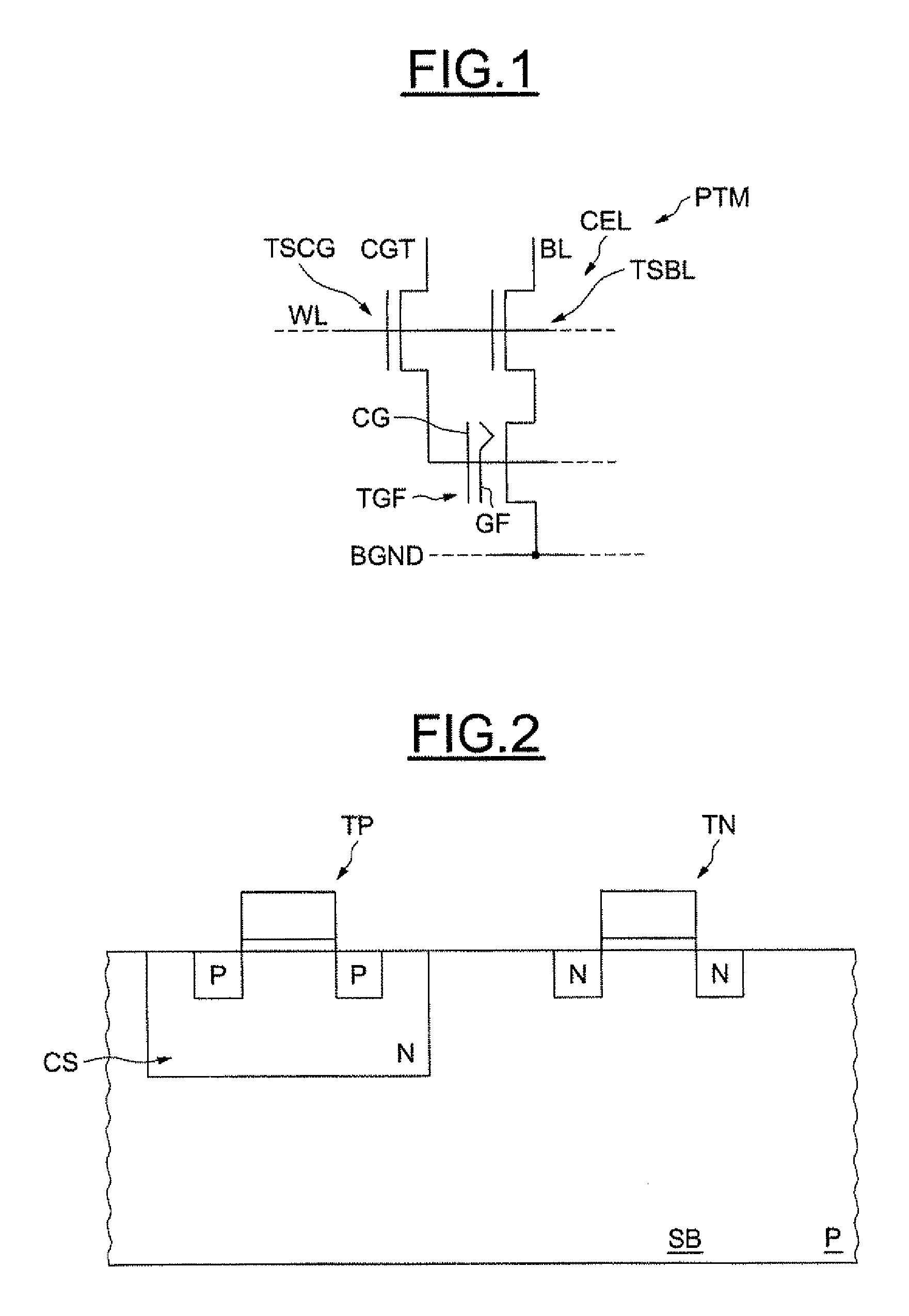

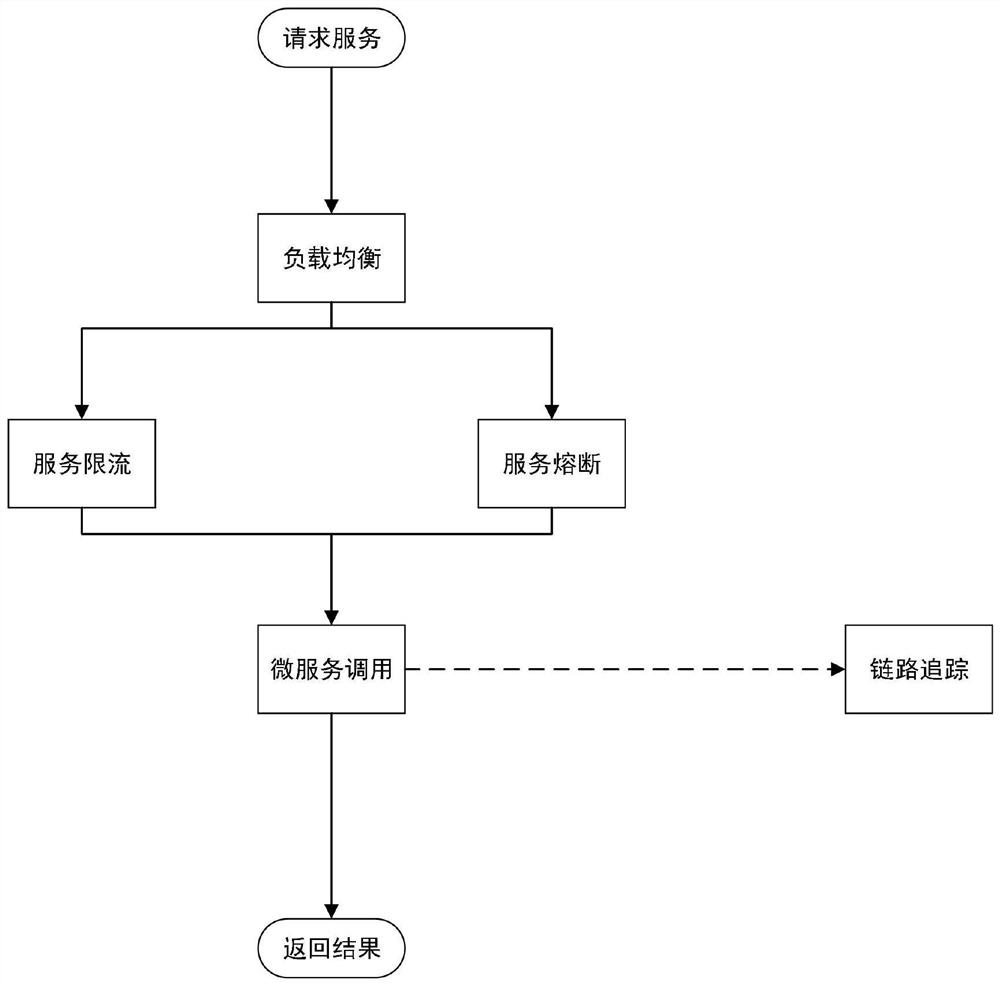

Method of programming an electrically programmable and erasable non-volatile memory point, and corresponding memory device

ActiveUS20110141805A1Prevent avalancheReduce chanceRead-only memoriesDigital storageBit lineGround line

An electrically programmable and erasable non-volatile memory point may have at least one floating-gate transistor connected to a bit line and to a ground line, and may be programmed with a programming voltage. In an erase phase of the memory point, a first, negative, voltage may be applied to the bit line and to the ground line. The absolute value of the first voltage may be smaller than a threshold value of a PN diode. A second positive voltage which is smaller than the programming voltage may be applied to the control gate of the floating-gate transistor. The difference between the second voltage and the first voltage may be equal to the programming voltage, and, in a writing phase, the first negative voltage may be applied to the control gate of the floating-gate transistor, and the second voltage may be applied to the bit line.

Owner:STMICROELECTRONICS (ROUSSET) SAS

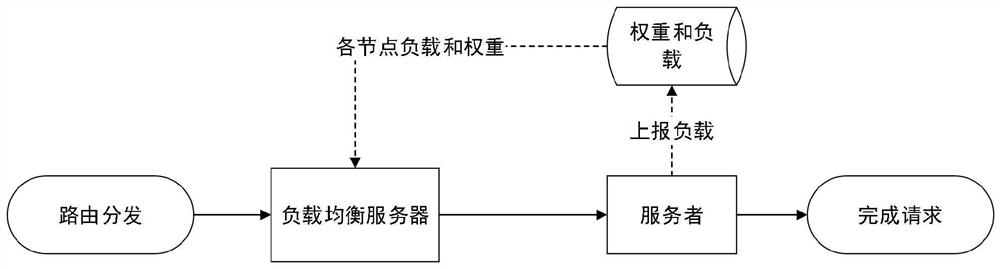

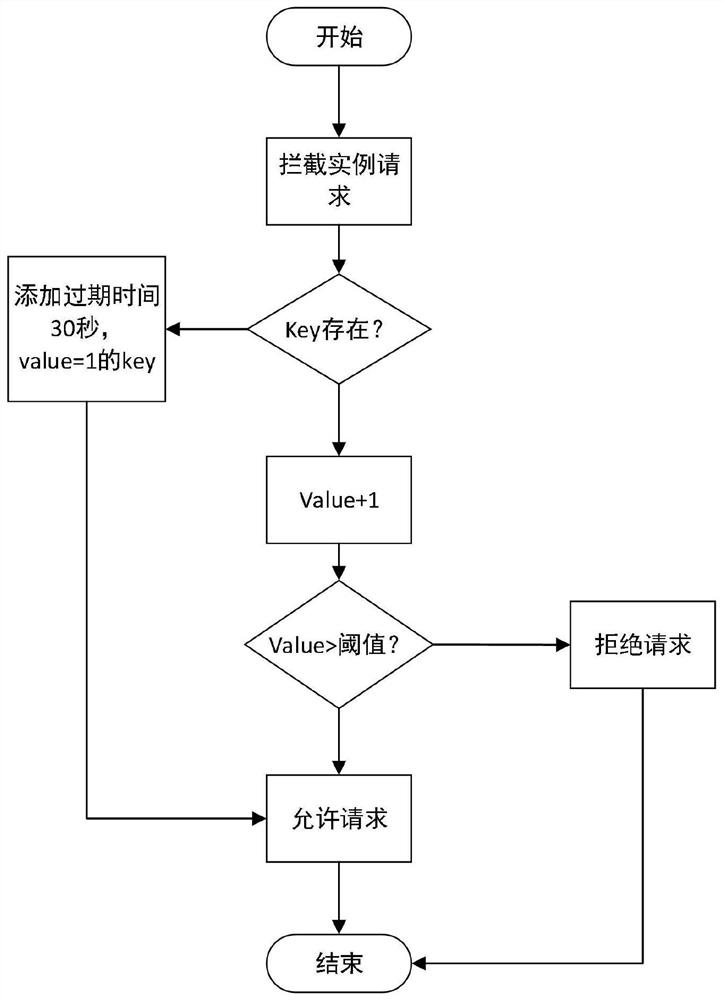

Micro-service governance system and method

ActiveCN113382080AReal-time adjustment of load balancing weightsPressure balanceNon-redundant fault processingEnergy efficient computingNegative feedbackManagement system

The invention provides a micro-service management system and method. The system comprises a load balancing module, a service current limiting module, a link tracking module and a fusing degradation module. According to the micro-service governance method, the pressure of the micro-service node is balanced through a negative feedback control load balancing strategy, and a link tracking identifier is generated through a snowflake algorithm and is implicitly transmitted to the whole link, so that a calling link of the micro-service is completely known; and service current limiting and fusing in a distributed cluster environment are completed by using a current limiting scheme capable of automatically degenerating into single-machine current limiting and a distributed fusing method capable of automatically detecting and reconnecting, so that the availability of a micro-service system is improved.

Owner:中关村智慧城市产业技术创新战略联盟

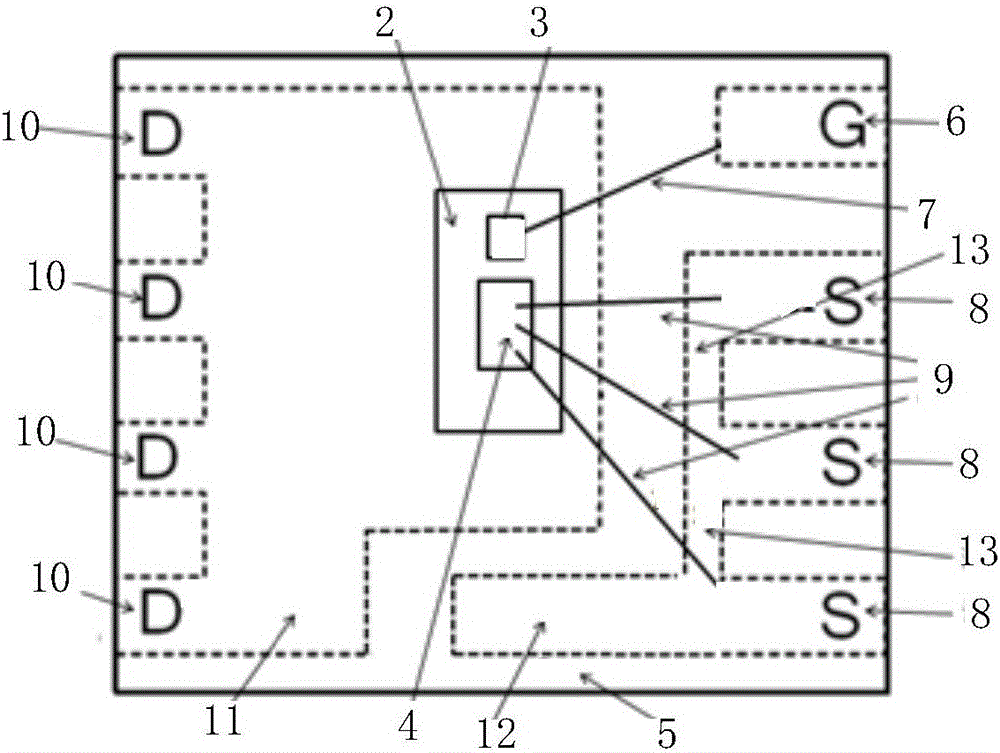

Avalanche capability improvement in power semiconductor devices

ActiveUS8264035B2Prevent avalancheImprove performanceTransistorThyristorPower semiconductor devicePower flow

A power semiconductor device with improved avalanche capability structures is disclosed. By forming at least an avalanche capability enhancement doped regions with opposite conductivity type to epitaxial layer underneath an ohmic contact doped region which surrounds at least bottom of trenched contact filled with metal plug between two adjacent gate trenches, avalanche current is enhanced with the disclosed structures.

Owner:FORCE MOS TECH CO LTD

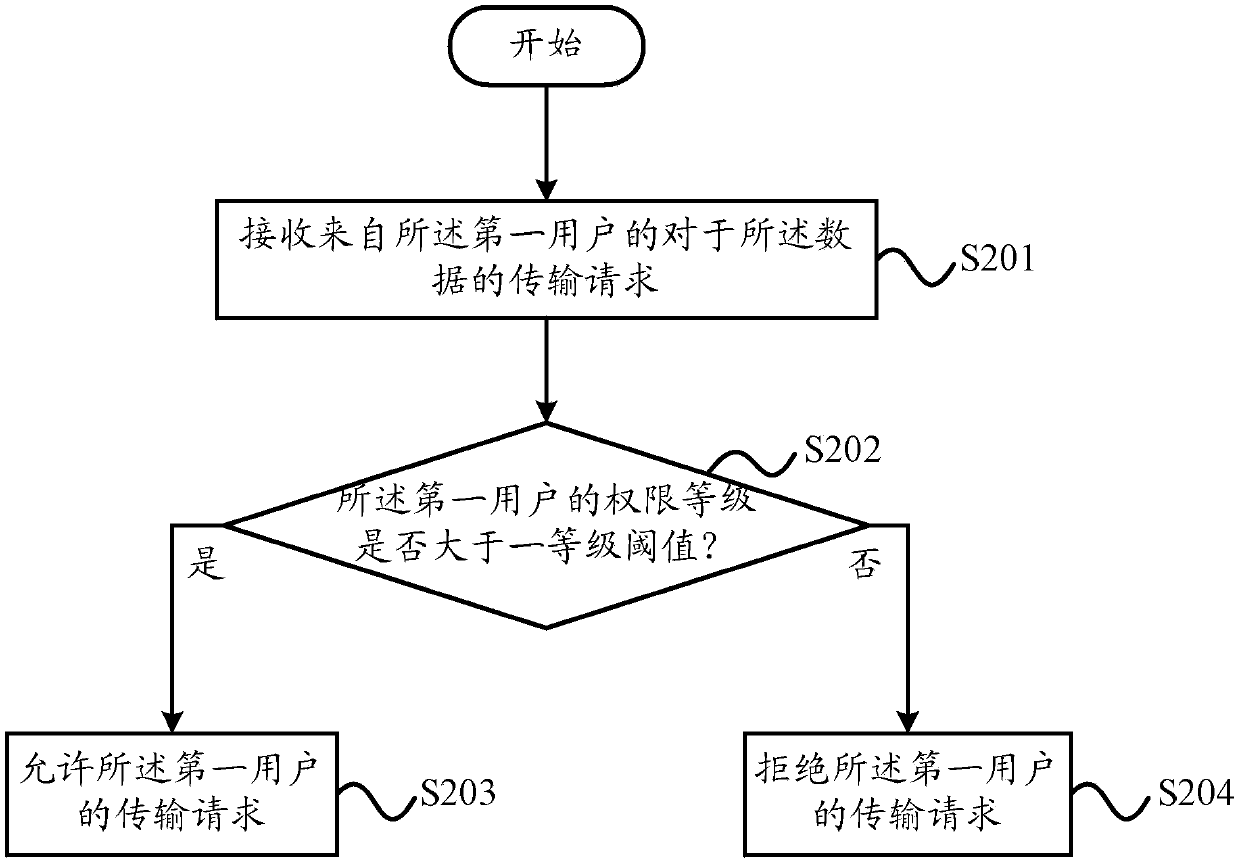

Gray scale control method and device for data transmission and medium

ActiveCN110213218AControl Transmission BreadthEffective controlPayment circuitsData switching networksInternet privacySocial behavior

The invention discloses a grayscale control method and device for data transmission and a medium. The grayscale control method for data transmission comprises the following steps: receiving a use request for data transmitted by a first user from a second user; allowing the second user to use the data; and if the second user does not have the authority level, based on the social behavior of transmitting the data to the second user by the first user, and setting an authority level of the second user, and when a transmission request for the data from the second user is received, determining whether to allow the transmission request based on the authority level of the second user so as to realize gray scale control for the data transmission.

Owner:TENCENT TECH (SHENZHEN) CO LTD

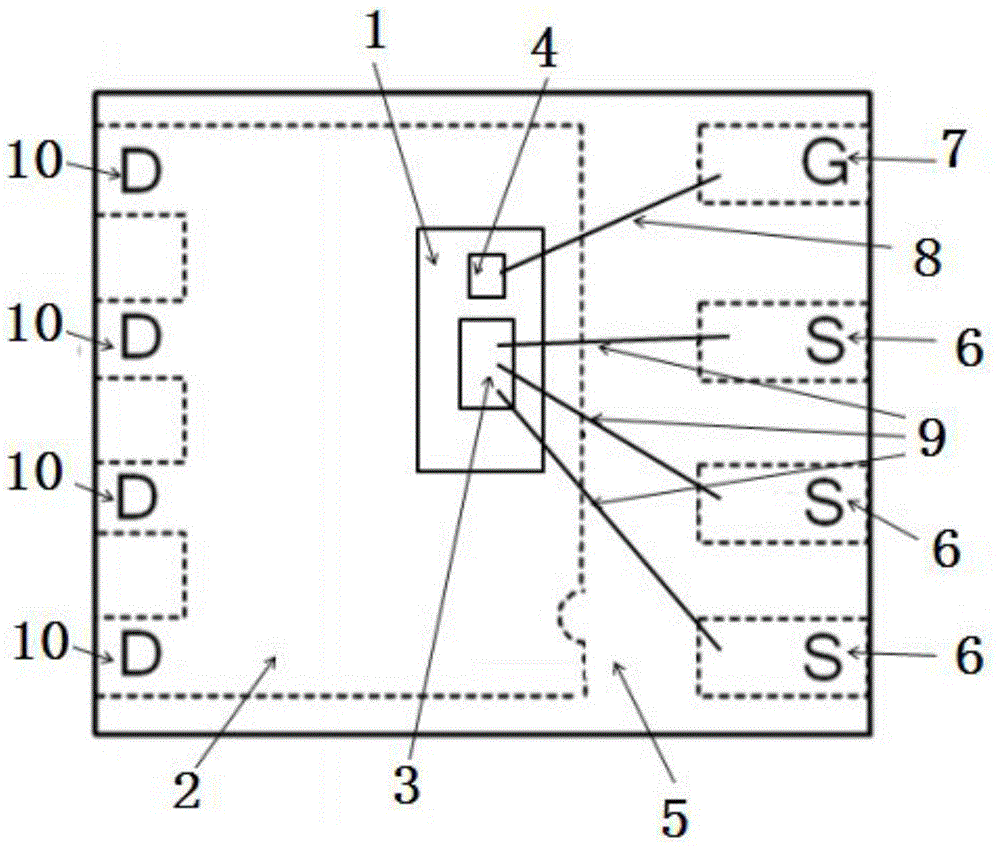

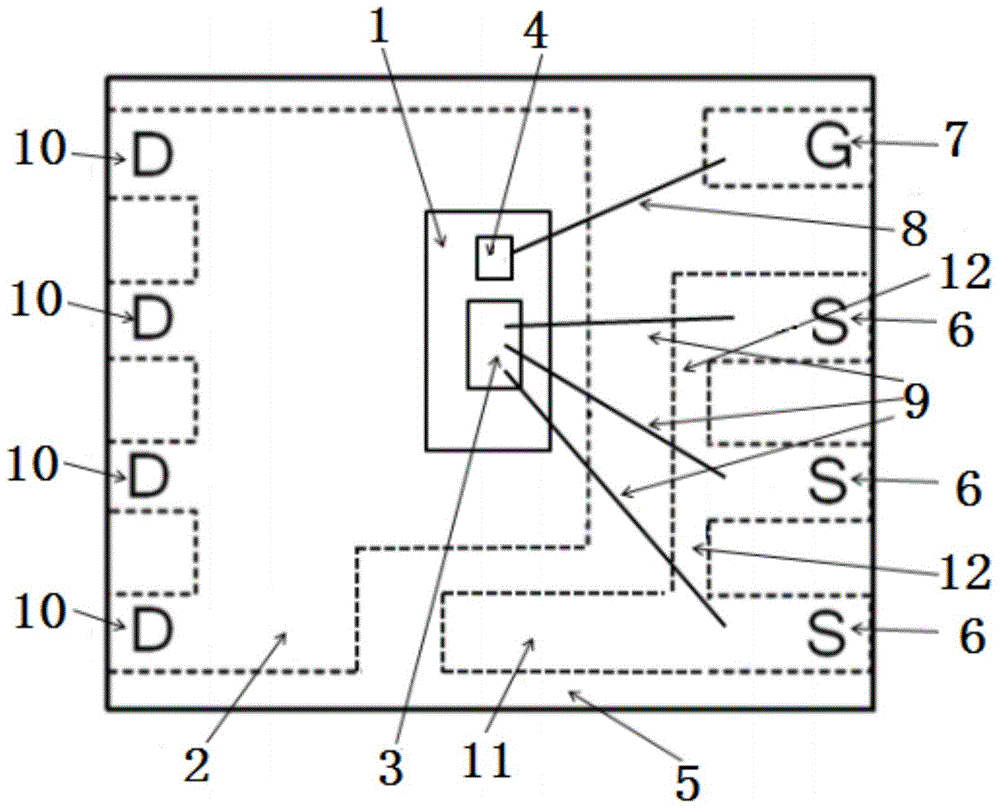

Fast charging MOSFET packaging structure for improving heat dissipation efficacy

InactiveCN106298703AGuaranteed uptimeTimely exclusionSemiconductor/solid-state device detailsSolid-state devicesMOSFETFast charging

The invention provides a fast charging MOSFET packaging structure for improving heat dissipation efficacy. The packaging structure includes a power device, a first heat dissipation substrate and a second heat dissipation substrate. The power device is arranged on the first heat dissipation substrate. The power device has a collector electrode which is connected to the first heat dissipation substrate and a source electrode which is connected to the second heat dissipation substrate. The packaging structure also includes a supporting plate which is provided with the first heat dissipation substrate and the second heat dissipation thereon. The first heat dissipation substrate has an area larger than that of the second heat dissipation substrate. According to the invention, the heat initially generated by the power device is timely eliminated, so that the power device can operate in a low temperature environment, and packaging structure can also maintain blocked impedance and higher power conversion efficiency.

Owner:武汉晶亮电子科技有限公司

Efficient heat dissipation paster type packaging structure

InactiveCN105140196AFixed Impedance HighAvoid avalanchesSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical impedance

The invention provides an efficient heat dissipation paster type packaging structure, comprising a first heat dissipation substrate, a second heat dissipation substrate and a chip, wherein the chip is provided with a collector, a source electrode and a gate electrode; the collector is in connection with the first heat dissipation substrate; the source electrode or the gate electrode is in connection with the second heat dissipation substrate. The efficient heat dissipation paster type packaging structure also comprises a supporting plate, on which the first heat dissipation substrate and the second heat dissipation substrate are arranged; and a plurality of collector pins which are in connection with the first heat dissipation substrate. The first heat dissipation substrate and the second heat dissipation substrate can timely discharge the heat initially generated by the chip, maintain the operation of the chip under the low temperature environment, and keep blocked impedance and higher power conversion efficiency; the efficient heat dissipation paster type packaging structure can maintain the operation of the chip under the low temperature environment, avoid avalanche, protect elements, and prolong the service life of the elements.

Owner:SHANGHAI JINGLIANG ELECTRONICS TECH

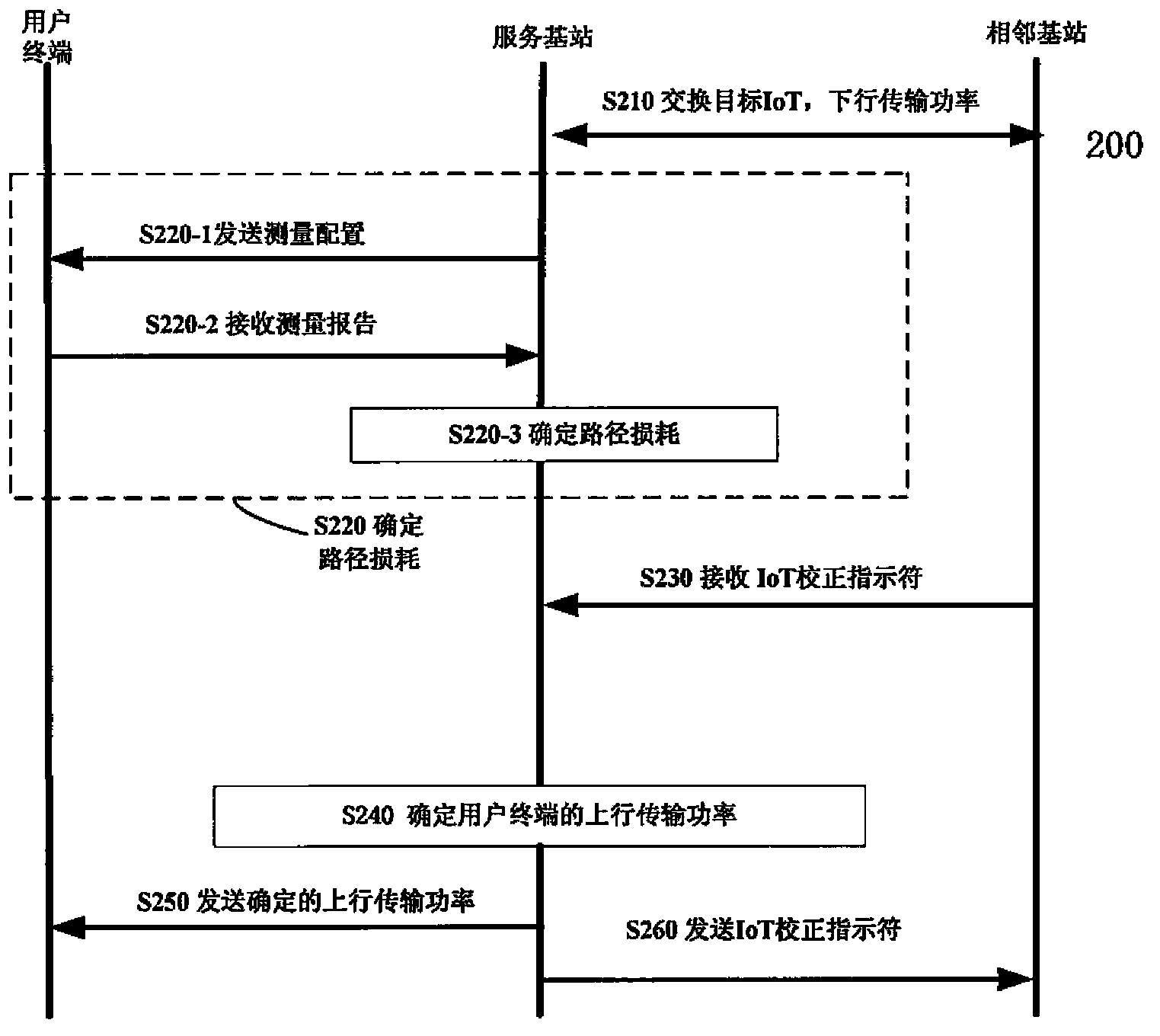

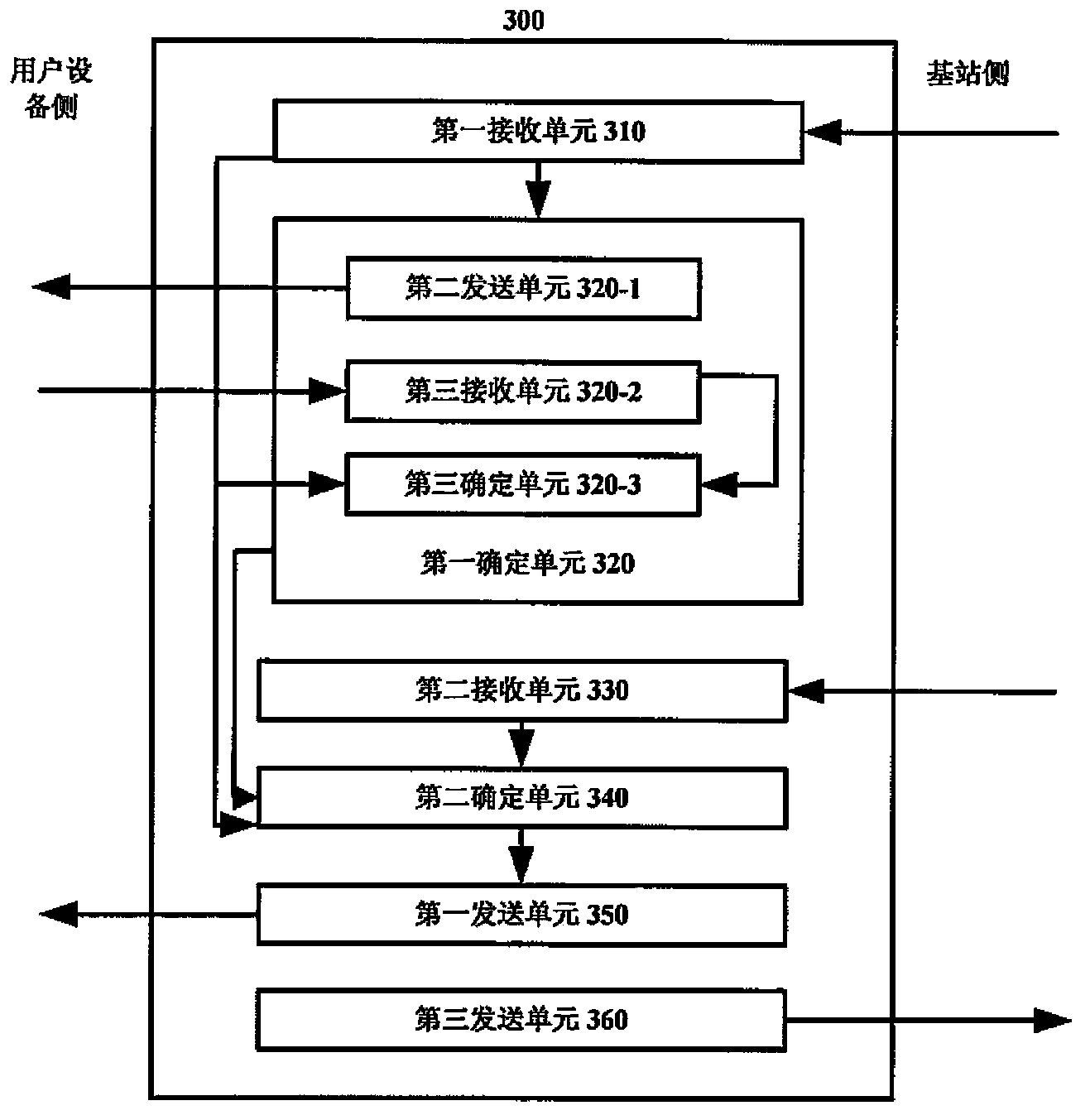

Method and device for controlling uplink transmission power of user terminal

ActiveCN104144483AControl the IoT levelPrevent avalanchePower managementUplink transmissionClosed loop

The invention provides a method and device for controlling the uplink transmission power of a user terminal. The method comprises the steps that the target interference and thermal noise IoT level of an adjacent cell is received from the adjacent cell; path loss from the user terminal in a service cell to the service cell and the adjacent cell is determined; an IoT calibration indicator is received from the adjacent cell; the uplink transmission power of the user terminal is determined regarding the path loss from the user terminal to the adjacent cell, the IoT calibration indicator received from the adjacent cell and the target IoT level of the adjacent cell; the determined uplink transmission power of the user terminal is sent to the user terminal. According to the method and device, the IoT level of each cell can be controlled correctly, and the problem of avalanche of closed-loop uplink transmission power control can be avoided.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

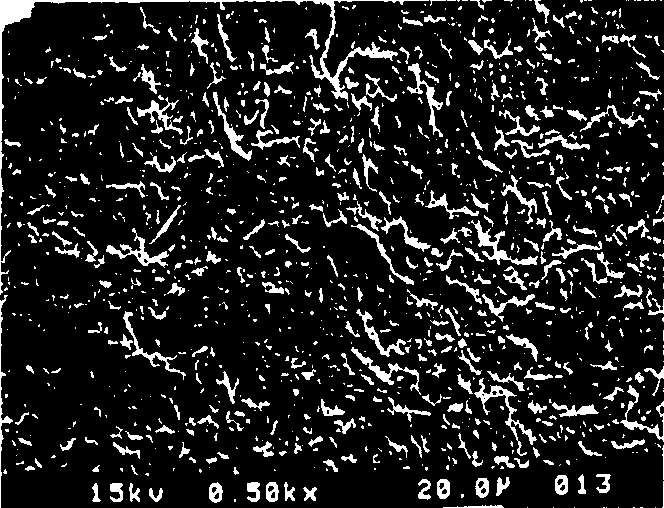

Sputtering target and manufacture thereof

InactiveCN1407128AReduce or even eliminate avalancheShort lifeVacuum evaporation coatingSemiconductor/solid-state device manufacturingOptoelectronicsLaser

The invention provides a sputtering target in which initial arcing can be prevented and initial stability can be greatly improved and which can be manufactured at a low cost, and provides its manufacturing method. Burr and abrasive dust occurring at working such as grinding and further dust and particles may be removed by sublimation, or the like, by the application of surface treatment using a laser outputted at <=100 mu sec pulse width.

Owner:MITSUI MINING & SMELTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com