Recycling process of remaining interstall pillars of two-step mining method

A mining method and process technology, which is applied in the recovery process field of the leftover pillars of the two-step mining method, can solve the problems of the leftover pillars, the deterioration of safety conditions, the reduction of resource recovery rate and production efficiency, etc., and achieve low dilution loss, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

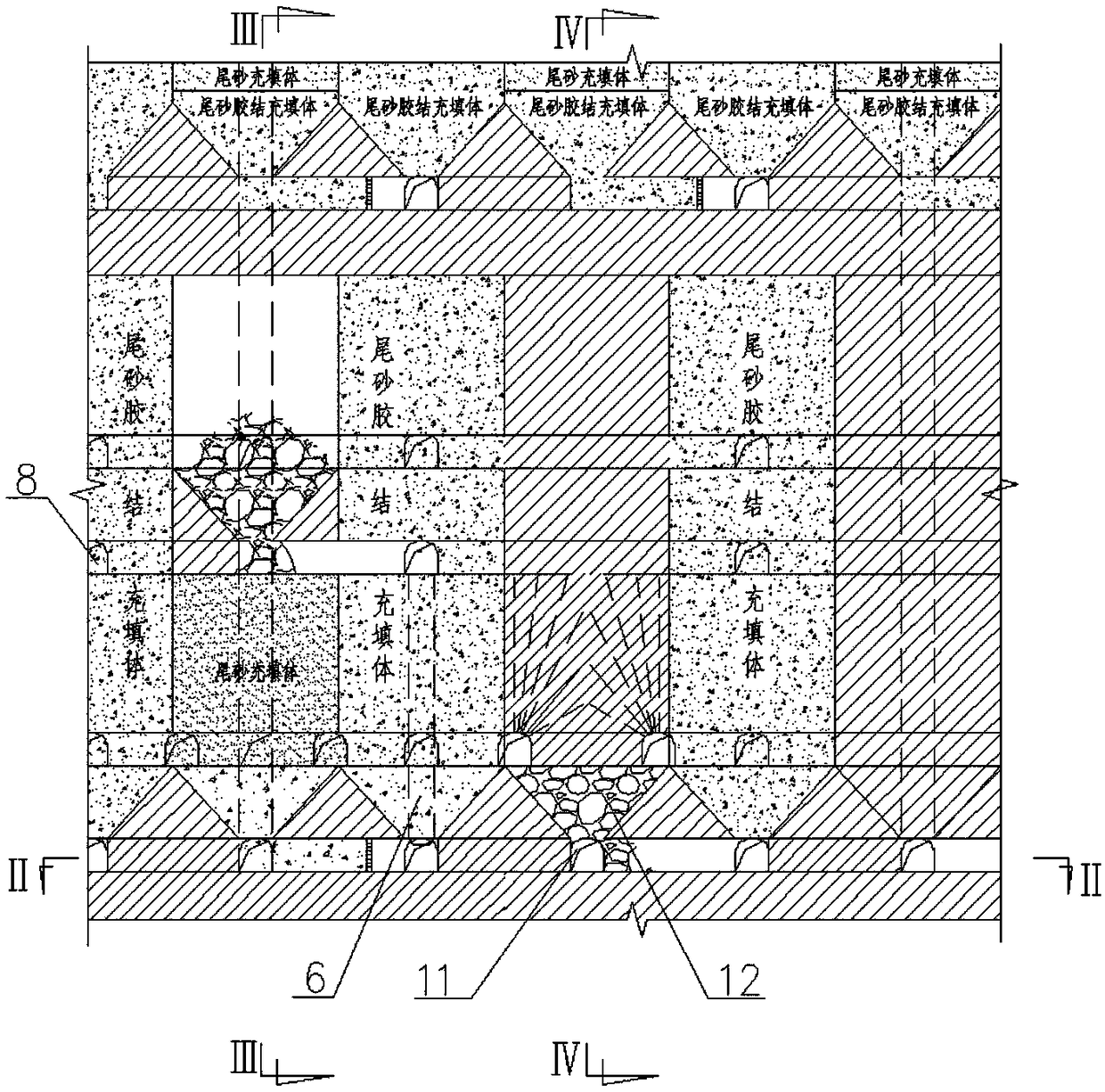

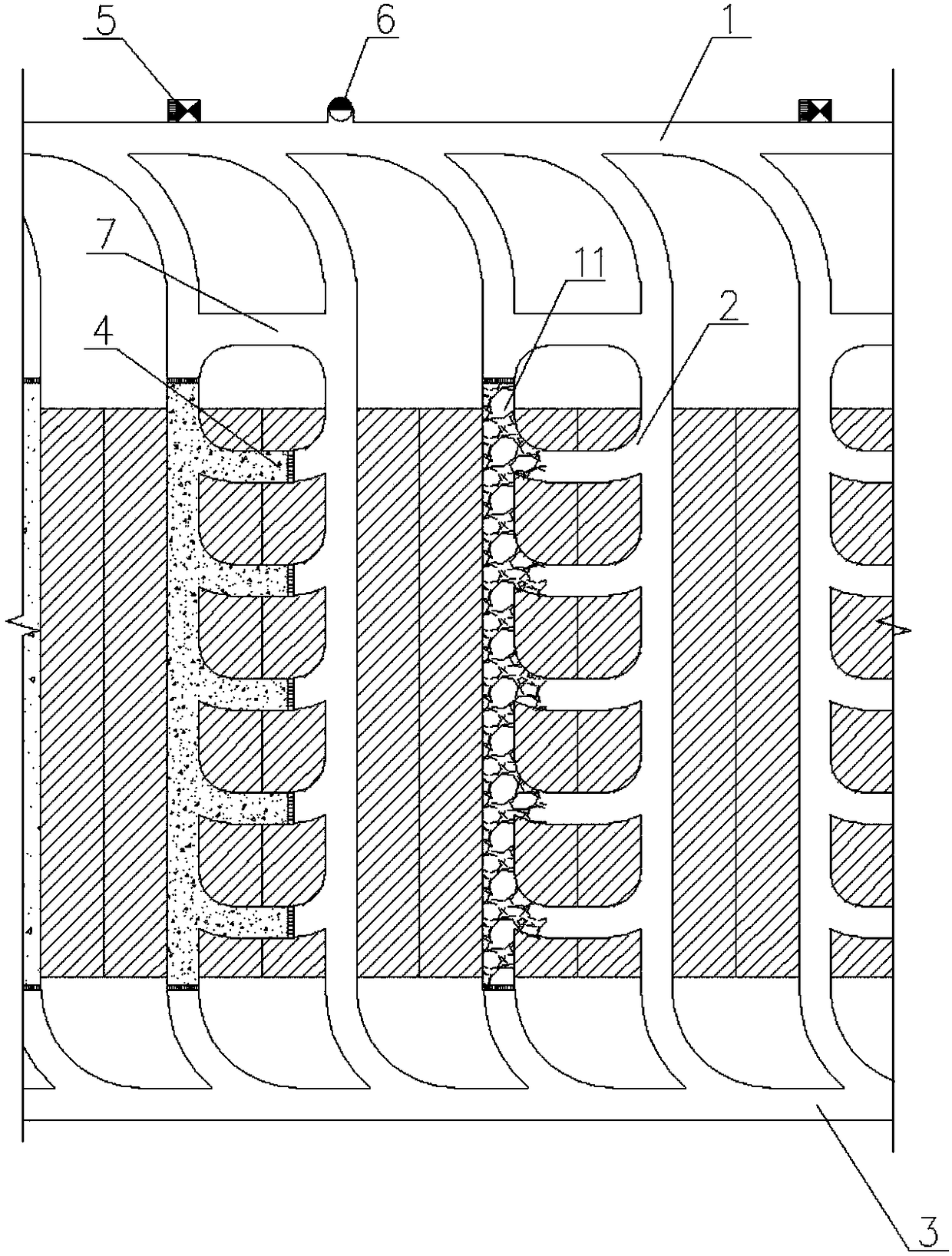

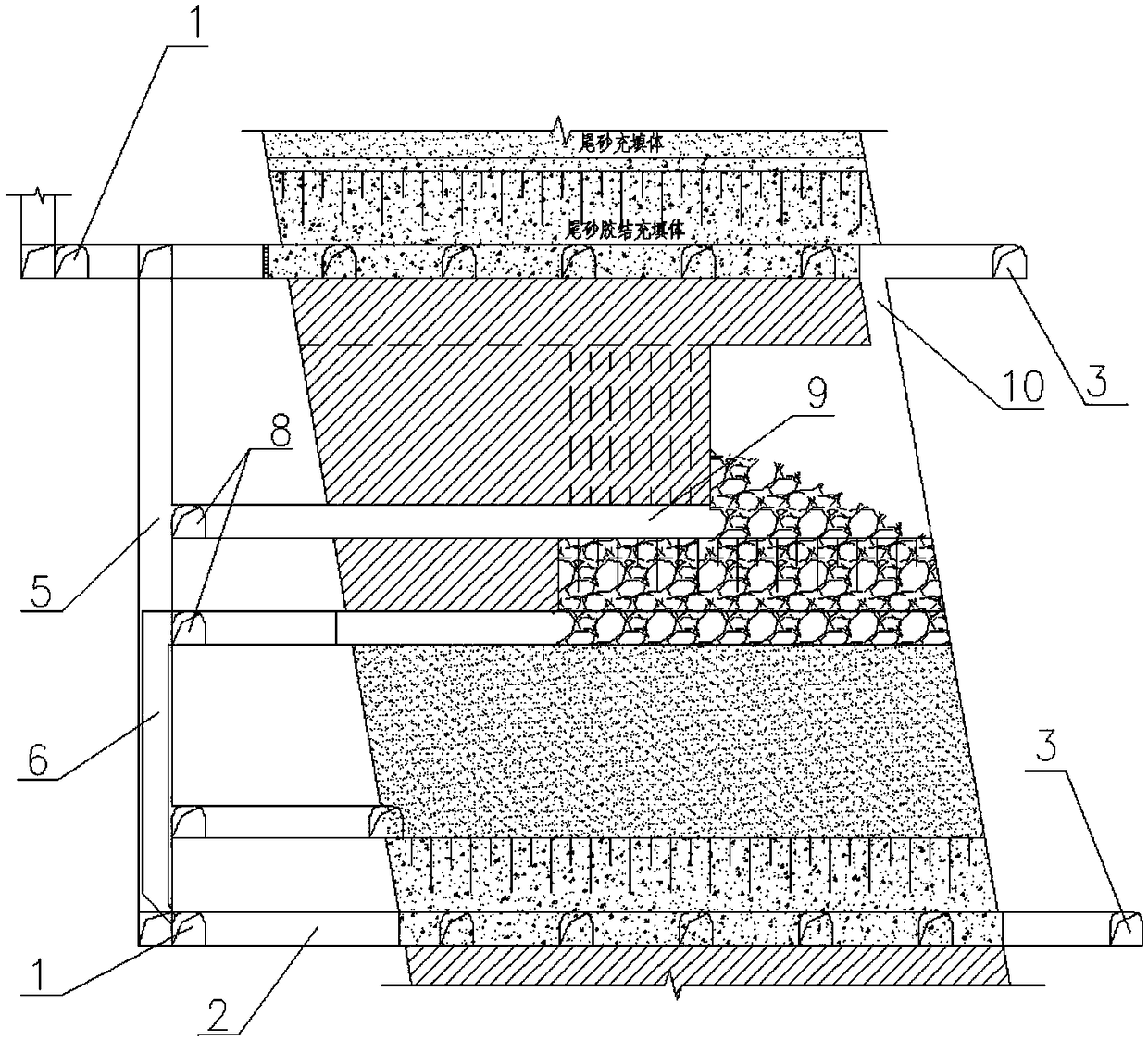

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] A copper-iron ore mining area in Hubei is adjacent to Daye Lake, with developed karst, abundant sources of groundwater supply, and complex hydrogeological conditions, but the ore body is thick and rich in grade. A series of technical research and practice have been carried out for the two-step inter-pillar recovery, and the goal of safe and efficient recovery of thick and large ore body inter-pillars under complex conditions has been achieved. Specific steps are as follows:

[0039] (1) Determination of stope structure

[0040] The stope is arranged vertically to the direction of the ore body, the length is the horizontal thickness of the ore body, the height of the middle section is 50m, the height of the section is 22.5m, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com