Multifunctional compression-shear testing machine

A testing machine, multi-functional technology, applied in the field of comprehensive testing system, can solve problems such as complex structure of press shears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

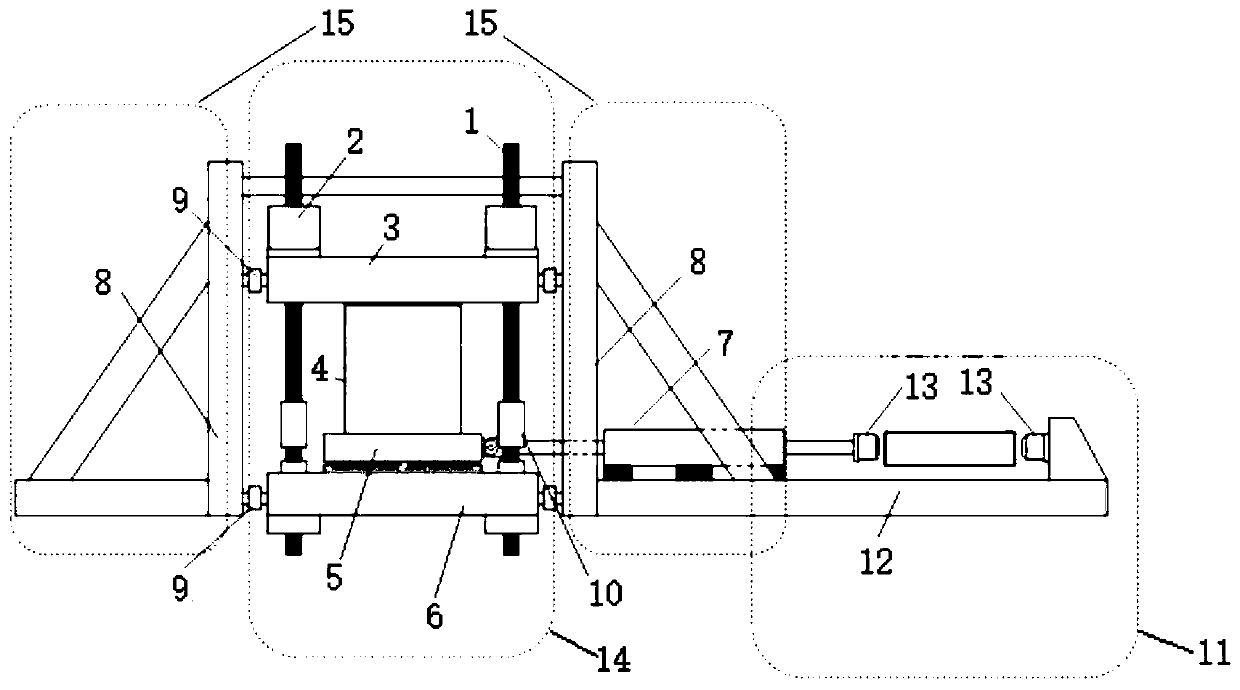

[0108] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

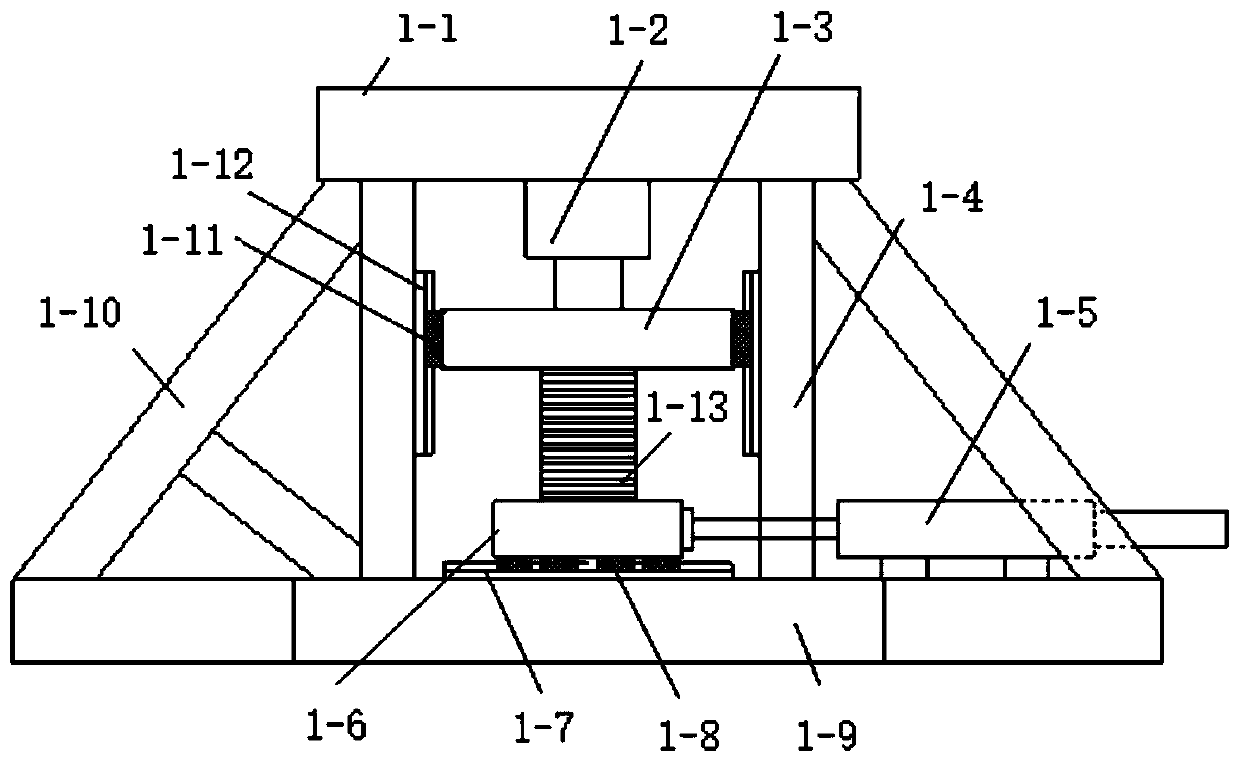

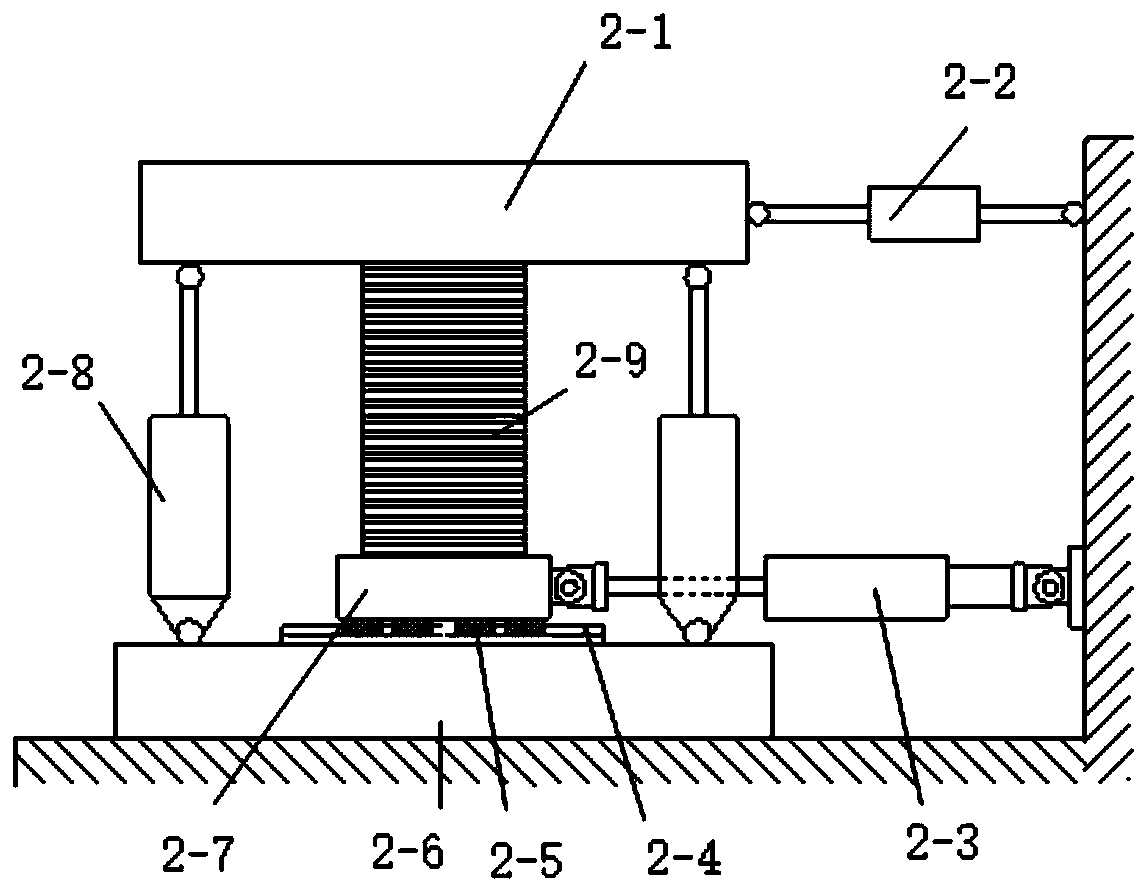

[0109] Such as image 3 As shown, a multifunctional compression-shear testing machine includes a vertical loading part 14, a lateral support part 15 and a function expansion device 11;

[0110] The vertical loading part 14 includes a column 1, a vertical loading actuator 2, an upper loading platform 3, a test piece 4, a lower loading platform 5, a loading base 6 and a horizontal actuator 7; the top of the column 1 or The bottom end is provided with a vertical loading actuator 2 that can apply a vertical force. An upper loading platform 3 is installed on the upper part of the column 1. Below the upper loading platform 3 is the loading space for the test piece 4. Below the test piece 4 is the lower loading space. Loading platform 5, the lower loading platform 5 is equipped with sliders at the bottom, and is installed on the loading base 6 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com