Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Good thermochemical stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidation-resistant interfacial coating for fiber-reinforced ceramic

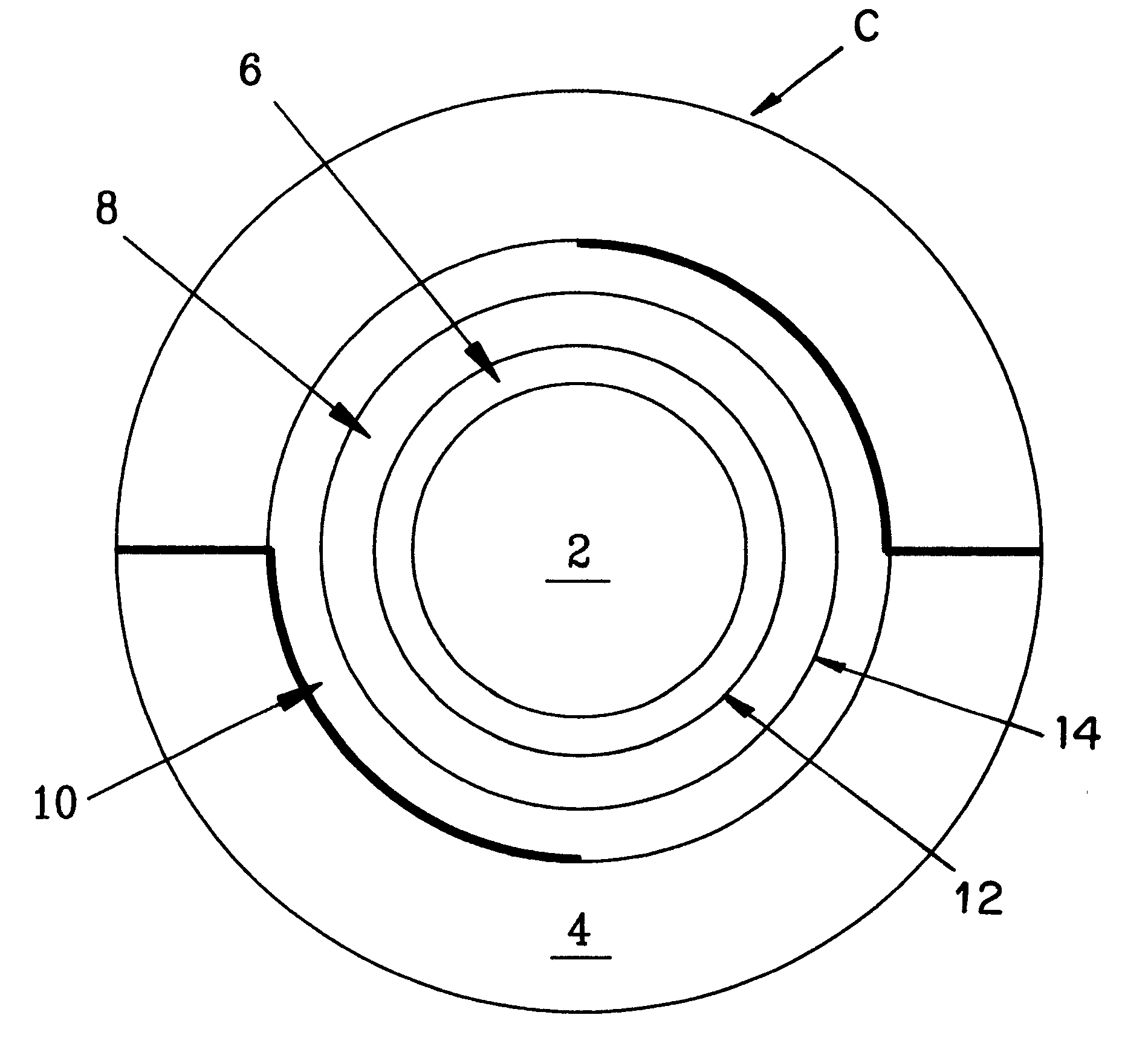

InactiveUS6322889B1Promoting preferential crack deflection and debondingGood thermochemical stabilityGlass/slag layered productsYarnThermal expansionOxidation resistant

A ceramic-matrix composite having a multilayered interfacial coating adapted to protect the reinforcing fibers from long-term oxidation, while allowing these to bridge the wake of advancing cracks in the matrix, is provided by selectively mismatching materials within adjacent layers of the interfacial coating, the materials having different coefficients of thermal expansion so that a low toughness interface region is created to promote crack deflection either within an interior layer of the mismatched interfacial coating or between adjacent layers of the mismatched interfacial coating.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

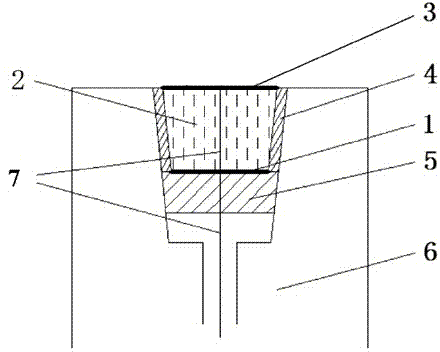

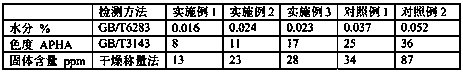

Refrigerating machine oil combination and preparation method thereof

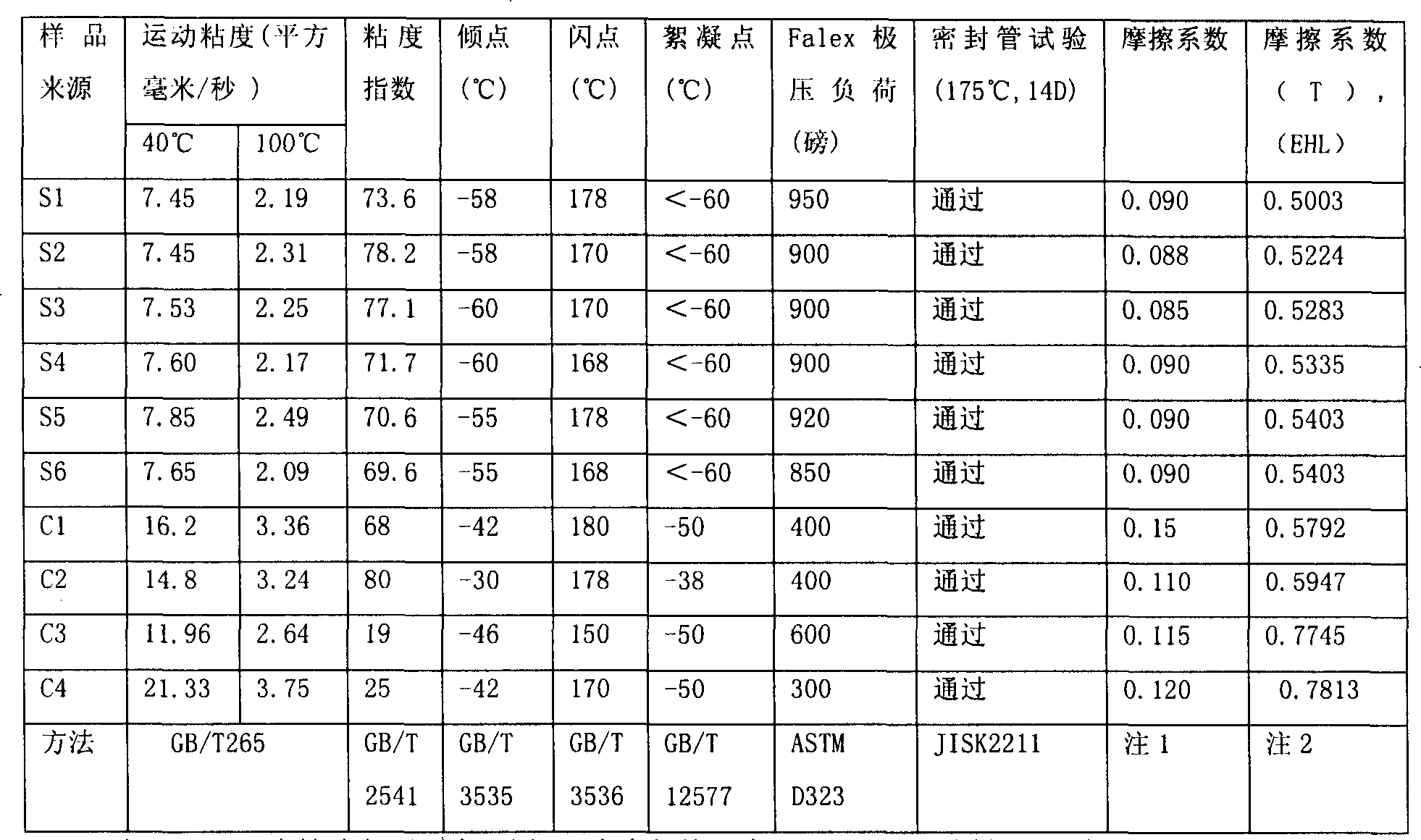

ActiveCN101177643AImprove solubilityGood fluidity at low temperatureLiquid hydrocarbon mixtures productionBase-materialsAlkaneSolubility

The invention relates to a refrigerant machine oil composition, comprising a mixed Alpha olefin polymer oil which is adopted as base oil and additive, wherein, a viscosity of the mixed Alpha olefin polymer oil at 40 DEG C ranges from 3 square millimeter per second to less than 6 square millimeter per second; the mixed Alpha olefin polymer oil is C15-C22 mixed isoolefine, C15-C22 mixed isoparaffin or the mixture of C15-C22 mixed isoolefine and C15-C22 mixed isoparaffin. The refrigerant machine oil composition provided by the invention has the advantages that: (1) good solubility with R600A refrigerating fluid, and floc point being lowered to minus 70 DEG C; (2) excellent fluidity in low temperature, with a pour point lowering to minus 70 DEG C, and a kinematic coefficient of the viscosity being less than 500 square millimeter per second at minus 40 DEG C; (3) comparatively apparent energy saving effect which is respectively higher than the refrigerant machine oil with a viscosity of 22 and 10 square millimeter per second by 14 percent and 4 percent at 40 DEG C.

Owner:BEIJING FRIENDLINK PETROCHEM T&D CO LTD

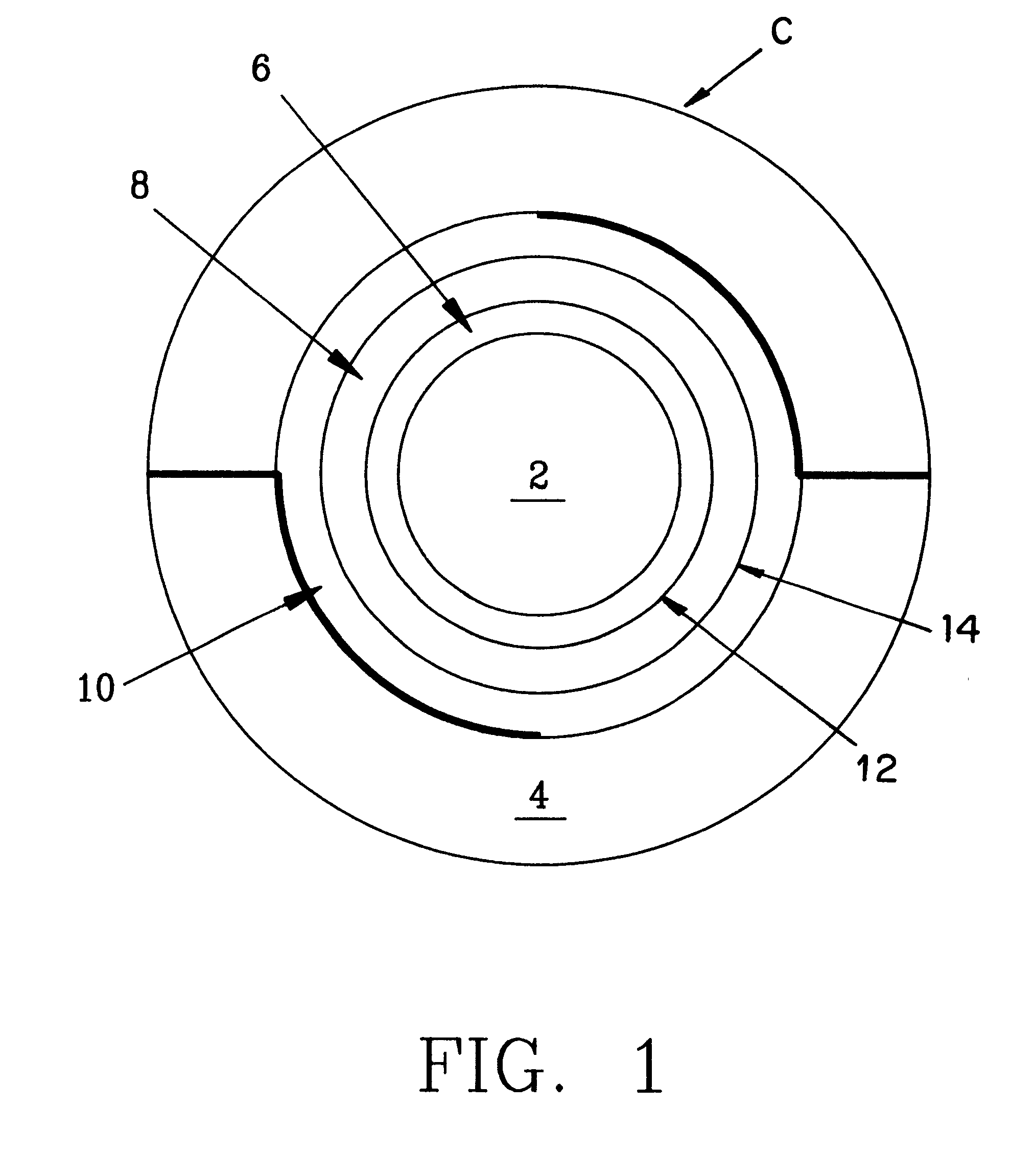

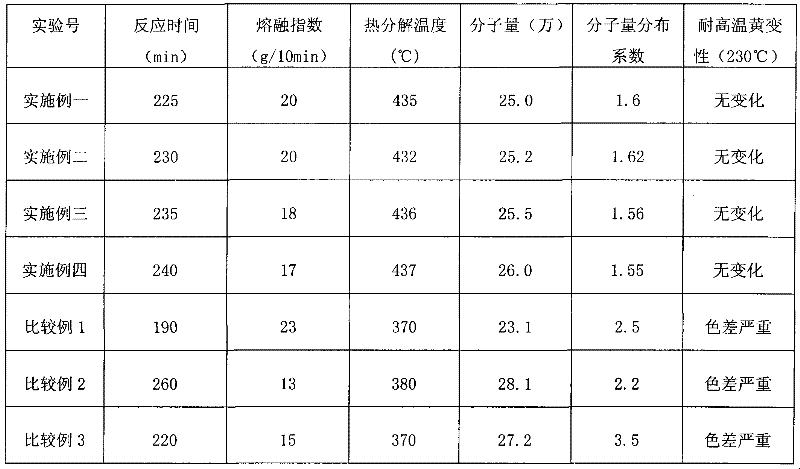

Preparation method for polyvinylidene fluoride with high molten fluidity

ActiveCN102134292AImprove regulation efficiencyImprove melt fluidityPowdery paintsEnd-groupPolyvinylidene difluoride

The invention relates to a preparation method for polyvinylidene fluoride with high molten fluidity. The initiator used for the polymerization is an organic initiator comprising organic hydrogen peroxide and organic peroxide with a molar ratio of 1-5, and the used conditioning agent is an ester conditioning agent with high dispensing efficiency for the system; the addition way of the initiator and the conditioning agent is a continuous addition way; the polymerization condition is mild; the polymerization product has a stable end group and a moderate molecular weight with a narrow distribution coefficient; and the product has high molten fluidity, good thermochemical stability, and significantly improved mechanical properties and weatherability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

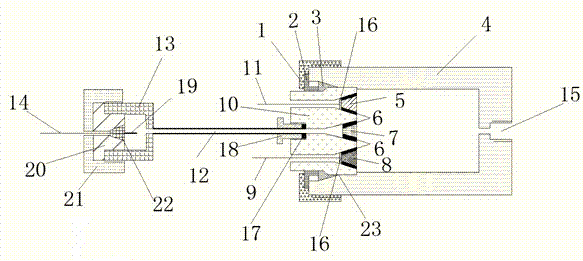

Three-electrode electrochemical measurement system for high-pressure hydrothermal systems and preparation method of three-electrode electrochemical measurement system

ActiveCN104777210AModerate hardnessGood thermochemical stabilityMaterial analysis by electric/magnetic meansElectricityEngineering

The invention discloses a three-electrode electrochemical measurement system for high-pressure hydrothermal systems and a preparation method of the three-electrode electrochemical measurement system. An electrode base is fixed in a mounting hole of a high-temperature high-pressure cavity through a metal sealing ring, a sealing ring compression ring and a compression nut; three conical holes which are communicated with three through holes at the outer end are formed in the axial inner end of the electrode base; a circular truncated cone-shaped working electrode, a circular truncated cone-shaped auxiliary electrode and a circular truncated cone-shaped porous ceramic are respectively mounted in the three conical holes; the through hole which is communicated with the conical hole which is provided with the circular truncated cone-shaped porous ceramic is communicated with a reference electrode capillary tube; the other end of the reference electrode capillary tube is communicated with an electrode chamber which is formed by a reference electrode nut, a reference electrode shell, a reference electrode compression ring and a circular truncated cone-shaped reference electrode. According to the three-electrode electrochemical measurement system, the working electrode, the reference electrode and the auxiliary electrode are capable of bearing high temperature and pressure under high-pressure electrochemical condition through a formed conical self-tightening type sealing mechanism, and good sealing efficiency and insulating property are provided.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

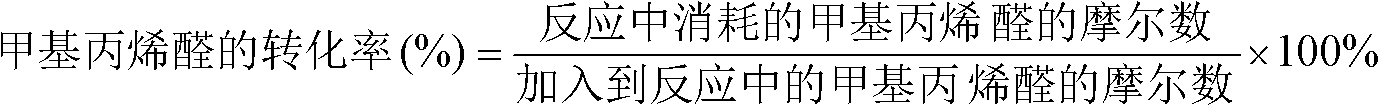

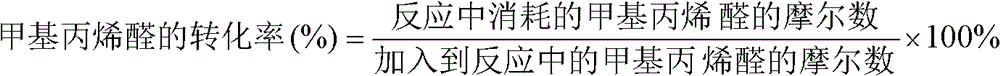

Preparation method of catalyst for synthesizing methacrylic acid

ActiveCN102553624AHigh activityHigh mechanical strengthPhysical/chemical process catalystsOrganic compound preparationGas phasePhosphoric acid

The invention relates to a preparation method of a catalyst for synthesizing methacrylic acid. The preparation method comprises the following steps: preparing a heteropoly compound catalyst by adopting an ionic liquid and metal salt step-by-step precipitation method; performing a reaction on a molybdenum-containing compound, a vanadium-containing compound and phosphoric acid to obtain solution orslurry A; preparing imidazolium ionic liquid into solution B; preparing alkali metal nitrate, transition metal nitrate and lanthanide nitrate into mixed aqueous solution C; adding the B and the C into the A in a step-by-step precipitation and aging mode; and then obtaining the catalyst by concentrating, drying, forming and roasting. The catalyst prepared by the method has high activity and high selectivity for the reaction of preparing methacrylic acid by carrying out gas-phase oxidation on methylacrolein and has high mechanical strength and high thermochemical stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

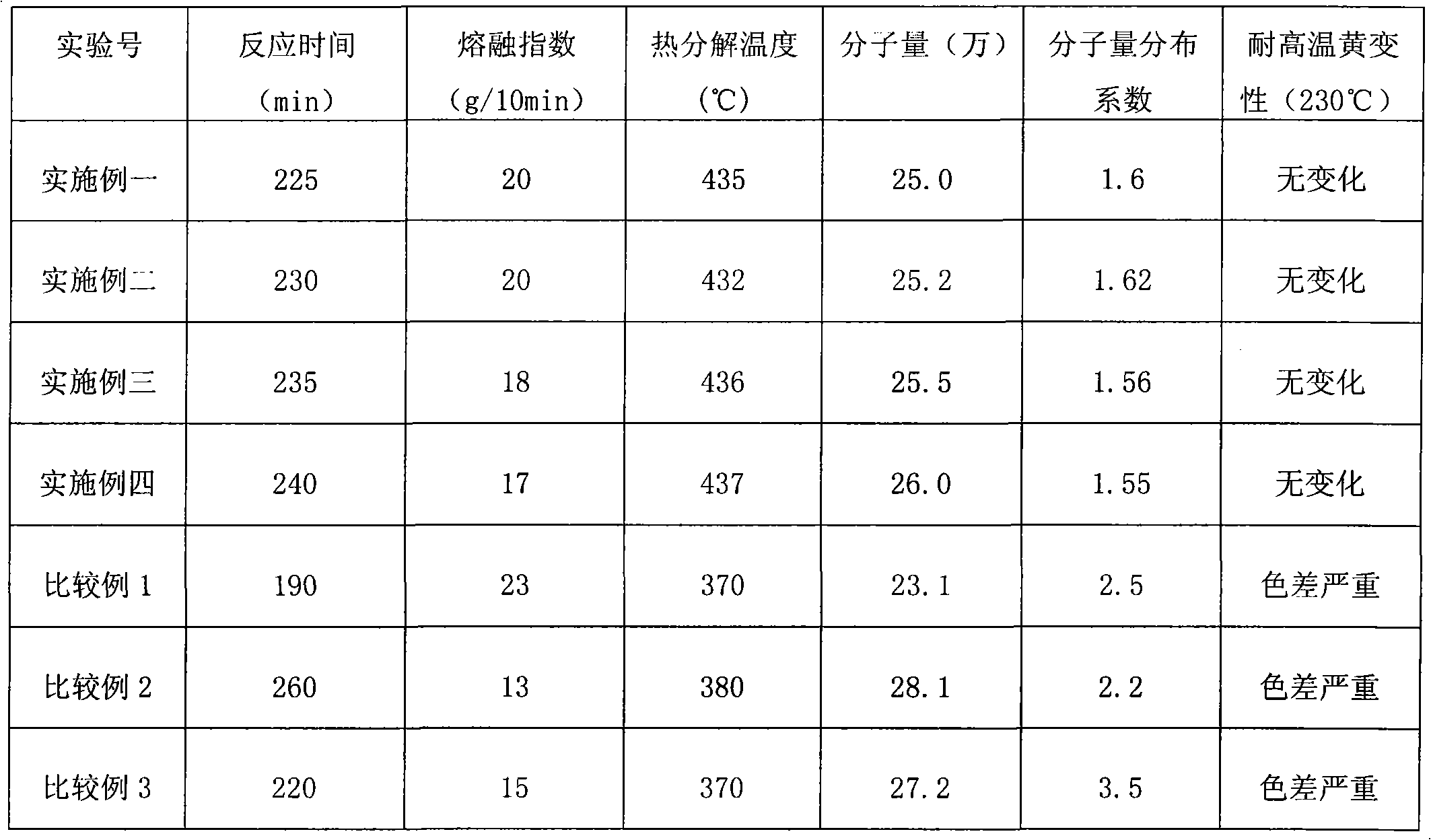

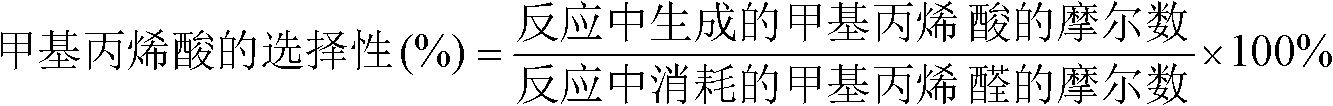

Platinum electrode for high-temperature high-pressure hydrothermal system and preparation method thereof

ActiveCN104749234AGood mechanical strength at high temperatureModerate hardnessMaterial electrochemical variablesPlatinumOptoelectronics

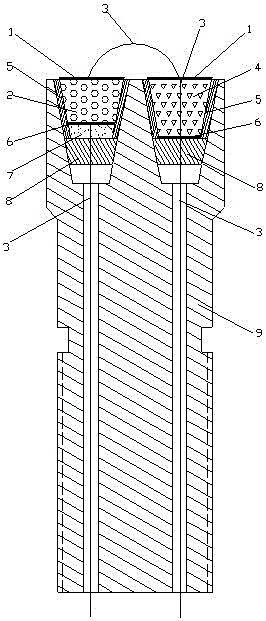

The invention discloses a platinum electrode for a high-temperature high-pressure hydrothermal system and a preparation method of the platinum electrode. The platinum electrode is composed of a substrate (6), a circular truncated cone shaped high-temperature insulating mat (5), a high-temperature insulating taper sleeve (4), a circular truncated cone shaped high-temperature insulating ceramic (2), an inert metal sheet (1), a spongy inert metal layer (3) and an electrode lead wire (7), wherein one end of the substrate is provided with a taper hole and the other end of the substrate is provided with an axis through hole; the convergent end of the taper hole is provided with the circular truncated cone shaped high-temperature insulating mat, the divergent end of the taper hole is provided with the high-temperature insulating taper sleeve and the circular truncated cone shaped high-temperature insulating ceramic, the electrode lead wire and the spongy inert metal layer are arranged on the axis and the large circular surface of the circular truncated cone shaped high-temperature insulating ceramic, and the inert metal sheet is arranged between the circular truncated cone shaped high-temperature insulating mat and the circular truncated cone shaped high-temperature insulating ceramic. Compared with the existing various high-pressure hydrothermal platinum electrodes, the platinum electrode solves the difficult problems that the existing cold-sealing type platinum electrode at home and abroad has poor stability and reliability and the hot-sealing type platinum electrode cannot be used in a high-pressure hydrothermal environment at higher than 400 DEG C.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Refrigerant oil composition

InactiveCN104194899AImprove abrasion resistanceReduce coefficient of frictionLubricant compositionParaffin waxRefrigeration compressor

The invention provides a refrigerant oil composition, comprising base oil and an additive. The refrigerant oil composition is suitable for lubricating a refrigeration compressor taking a hydrocarbon working medium as a refrigerant; the viscosity of the refrigerant oil composition at 40 DEG C is 2.0-7.5mm<2> / s; and the refrigerant oil composition comprises 90-99.5wt% of base oil and 0.5-10wt% of additive. The refrigerant oil composition is characterized in that the base oil is paraffinic oil and alkyl benzene oil; and the additive mainly is a phosphide functional agent. The refrigerant oil composition provided by the invention has excellent low temperature resistance and good refrigerant compatibility, and enough antiwear property and scratch protecting property, can keep stable performance for a long period of time, and does not block a capillary tube in a refrigerating cycle.

Owner:WUHAN UN LUBRICANT TECH

Internal-heated integrated evaporation boat with aluminum oxide porous structure buffering layer

InactiveCN107326330ASolve Oxidation ProblemsHigh bonding strengthVacuum evaporation coatingSputtering coatingPorosityStress relieving

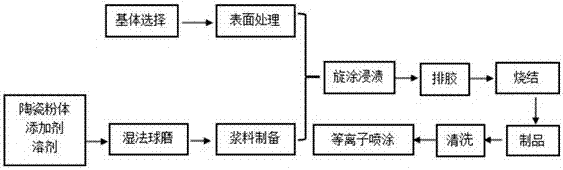

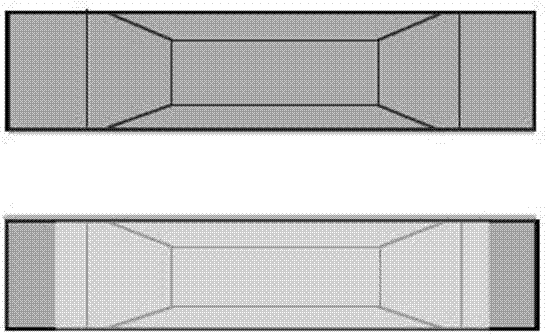

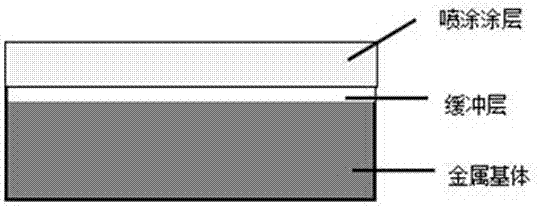

The invention discloses an internal-heated integrated evaporation boat with an aluminum oxide porous structure buffering layer. Surface coatings of the evaporation boat totally comprise two layers. The inner layer is the Al2O3 buffering layer of a loose porous structure, and the outer layer is the compact low-porosity corrosion-resistantAl2O3 coating. Firstly, through a rotary-coating steeping technique, the Al2O3 buffering layer with the thickness being 0.1-0.3 mm is prepared on the surface of a matrix; and then through a plasma spraying technology, the Al2O3 corrosion-resistantlayer with the thickness being 0.5-1 mm is sprayed and prepared on the evaporation boat with the buffering layer. According to the composite technique, the evaporation boat with the Al2O3 coatings of different microstructures is prepared; in service, the buffering layer of the porous structure can achieve the stress relieving effect and can further prevent the problem of matrix oxidization caused by later spraying; and the compact low-porosity Al2O3 coating brings excellent corrosion resistance into play and can be widely applied to the technical field of vacuum evaporation metal thin films.

Owner:FUZHOU UNIV

Oxygen chemical sensor for high-temperature and high-pressure hydrothermal system and preparation method of oxygen chemical sensor

ActiveCN105004777AImprove corrosion resistanceGood mechanical strength at high temperatureMaterial analysis by electric/magnetic meansOxygen sensorMetal sheet

The invention discloses an oxygen chemical sensor for a high-temperature and high-pressure hydrothermal system and a preparation method of the oxygen chemical sensor. The oxygen chemical sensor comprises a base, circular platform-shaped high-temperature-resistant insulating conical pads, a solid oxygen buffer agent, high-temperature-resistant insulating conical sleeves, circular platform-shaped solid electrolyte ceramic, circular platform-shaped high-temperature-resistant insulating ceramic, spongy inert metal layers, inert metal sheets and electrode leads. The oxygen chemical sensor, namely an oxygen sensor based on an electrochemical cell, is formed by combining all the components into a conical self-tightening mechanism, and can be utilized for in-situ direct measurement of the oxygen fugacity or the oxygen activity in the high-temperature (250 to 700 DEG C) and high-pressure (normal pressure to 100 MPa) hydrothermal system, so as to solve the problems that various conventional oxygen chemical sensors for a high-pressure hydrothermal system are low in operating temperature and operating pressure (the operating temperature and the operating pressure can hardly exceed 400 DEG C and 40 MPa simultaneously), low in response speed, and low in reliability when being applied to a complex concentrated water fluid sample.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Method of compositing nanocellulose with nano silver wires to prepare transparent conductive fiber

ActiveCN106222773ASmall coefficient of thermal expansionHigh strengthElectroconductive/antistatic filament manufactureMonocomponent cellulose artificial filamentFiberAcrylic resin

The invention discloses a method of compositing nanocellulose with nano silver wires to prepare transparent conductive fiber. The method includes: a), extracting nanocellulose from wood powder; b), preparing a nanocellulose / nano silver wire compound c), performing miscible compositing on the nanocellulose / nano silver wire compound and acrylic resin; d), adopting a wet mixing extrusion method to prepare the transparent conductive composite fiber. The method has the advantages that the nanocellulose is low in coefficient of thermal expansion, high in strength and Young modulus and excellent in thermochemical stability; a transparent conductive material made from the nano silver wires is high in transparency, low in haze, high in bending resistance and low in impedance, and a simplified preparation process is adopted; nanocellulose / nano silver wire composite conductive wires are high in light transmittance and low in haze value.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

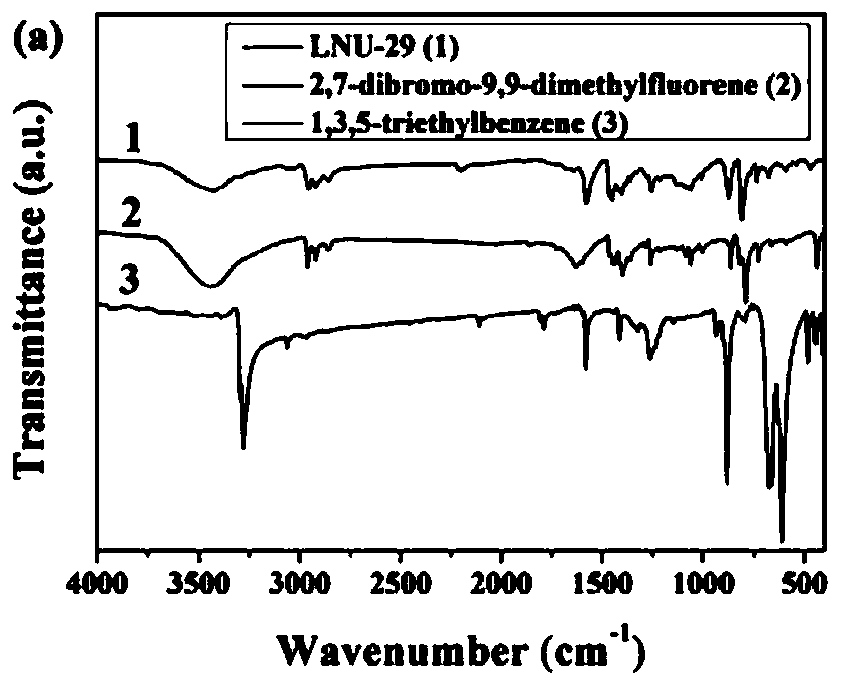

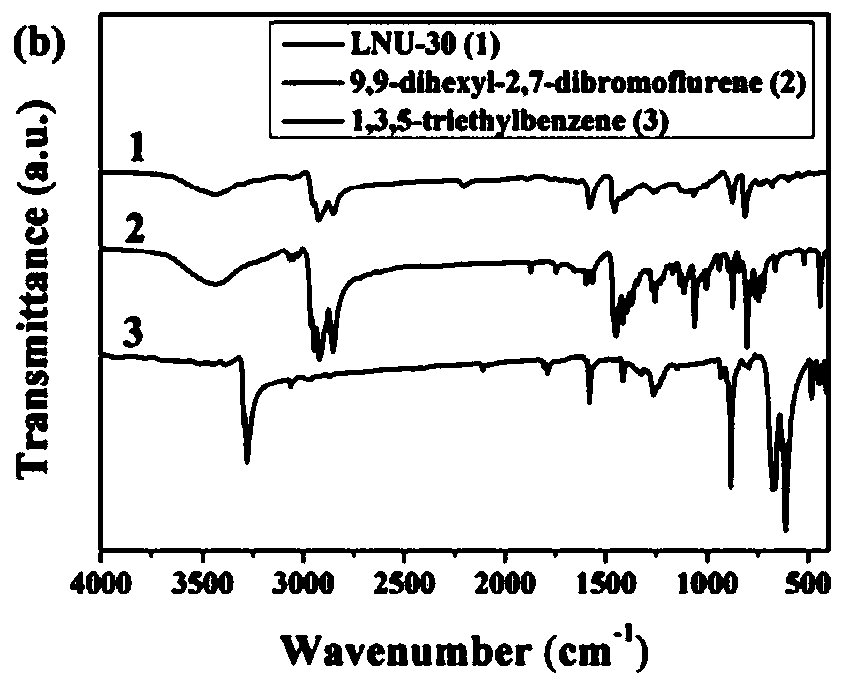

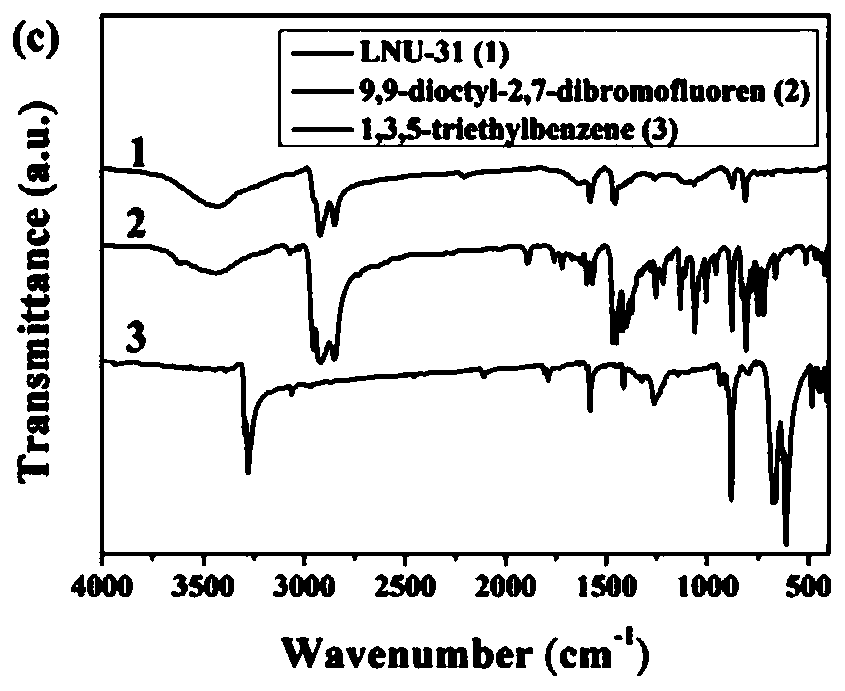

Super-hydrophobic porous organic polymer containing alkyl chains and preparation method and application of super-hydrophobic porous organic polymer containing alkyl chains

InactiveCN110437425AImprove hydrophobicityMild reaction conditionsFatty/oily/floating substances removal devicesOther chemical processesPolyesterOrganic compound

The invention discloses a super-hydrophobic porous organic polymer containing alkyl chains and a preparation method and application of the super-hydrophobic porous organic polymer containing the alkylchains. 1,3,5-triethynylbenzene and organic compounds containing the different alkyl chains serve as a construction unit, copper iodide and tetrakis(triphenylphosphine)palladium serve as catalysts, reaction is conducted for 72 h at 80 DEG C through a Sonogashira-Hagihara coupling reaction, and thus the super-hydrophobic porous organic polymer LNUs containing the alkyl chains is obtained. According to the preparation method, raw materials are easy to obtain, operation is easy, the environmentally friendly and efficient effects are achieved, and the reaction conditions are mild. The prepared super-hydrophobic porous organic polymer containing the alkyl chains is good in thermal stability and excellent in hydrophobic property. Prepared super-hydrophobic polyester fabric has the stable hydrophobic ability in various environments, and has great application prospects in the sewage treatment fields such as oil-water separation, and adsorption of leaked crude oil or organic solvents.

Owner:LIAONING UNIVERSITY

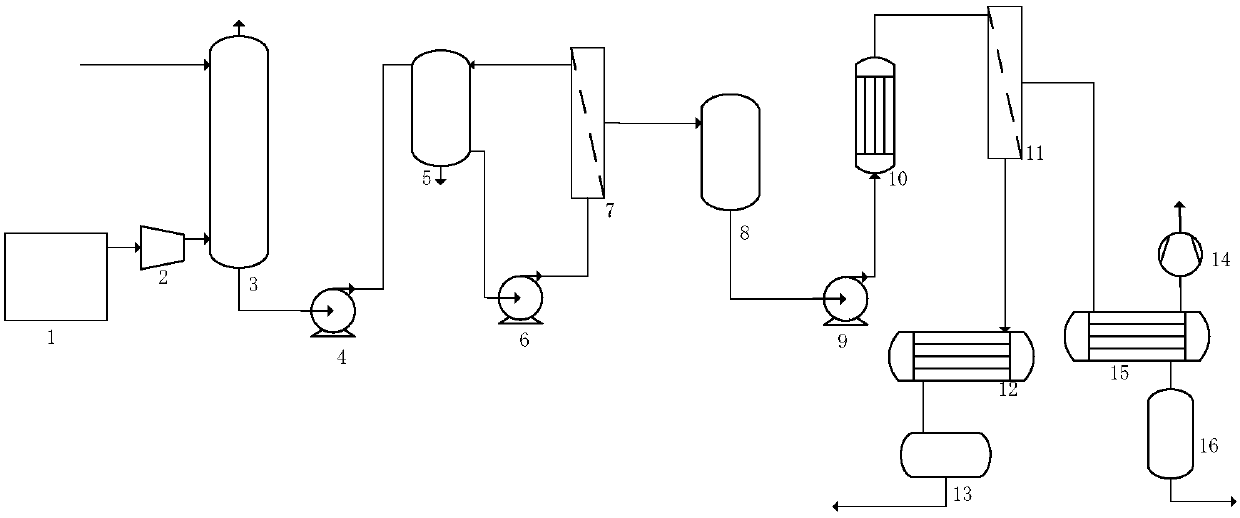

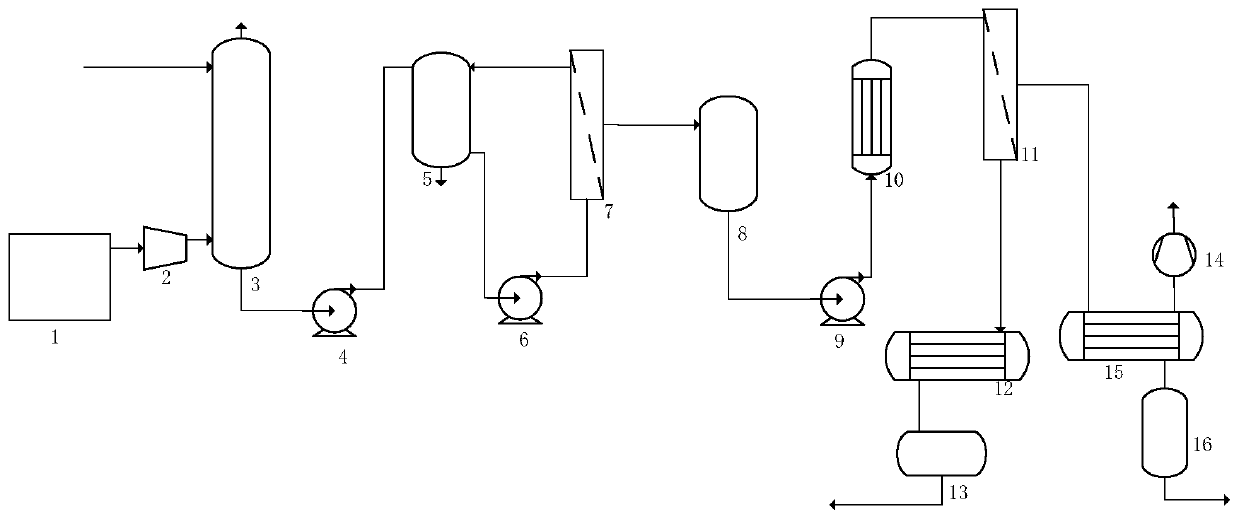

Method and device for recovering NMP (N-methyl pyrrolidone) waste gas in lithium battery production with membrane separation method

ActiveCN107626186AReduce energy consumptionAvoid the problem of easy ingress of airSemi-permeable membranesDispersed particle separationPole pieceImpurity

The invention relates to a technology for recovering NMP (N-methyl pyrrolidone) waste gas in lithium battery production with a membrane separation method and belongs to the technical field of organicwaste gas recovery. The technology comprises steps as follows: NMP waste gas in a lithium battery pole piece drying box is fed into an absorption tower by blast apparatus and absorbed by utilizing water as a solvent, NMP effluent is formed at the bottom of the absorption tower and enters a porous ceramic filtering membrane separator through a circulating pump, NMP and water penetrate through a porous ceramic filtering membrane under the action of pressure difference before and after NMP and water penetrate through the porous ceramic filtering membrane, an NMP-water clear liquid is formed on the rear side of the porous ceramic filtering membrane, and an intercepted liquid returns to a circulating tank; the NMP-water clear liquid is stored in a clear liquid tank and enters a heater for heating under the action of a feed pump; when the heated clear liquid passes through a pervaporation membrane, water penetrates through the membrane while NMP is intercepted, and accordingly, NMP and waterare separated. The operating temperature is lower than the boiling point of an NMP recovered liquid in the recovery process, recovered NMP does not need high temperature and negative pressure and haslow probability of producing new impurities, energy consumption is low, operation is simple, and the technology is a green NMP waste gas recovery technology.

Owner:NANJING MEMBRANE IND TECH RES INST CO LTD

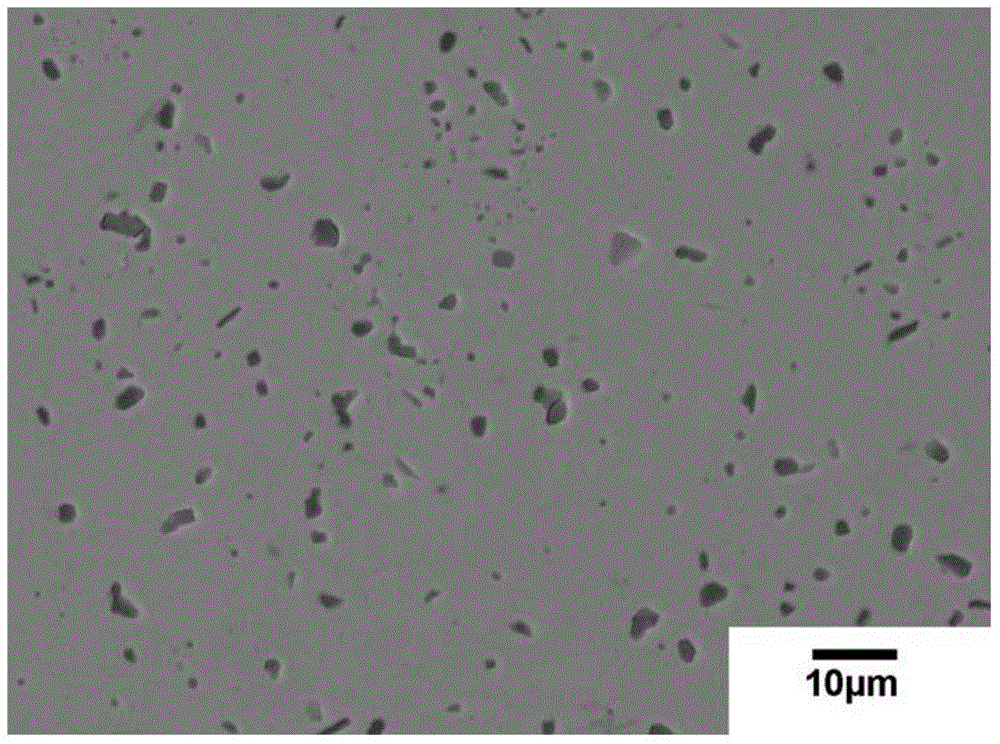

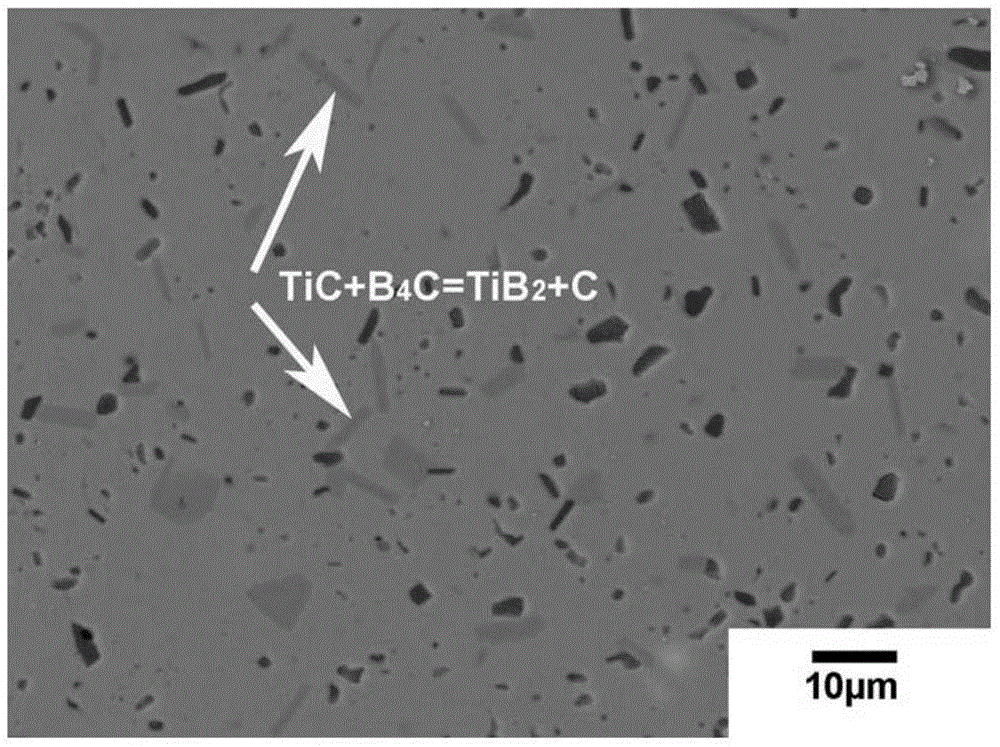

Preparation method of highly-densified titanium carbide ceramic

InactiveCN105481365AReduce contentDoes not affect high temperature performanceTitanium carbideCeramic

The invention relates to a preparation method of highly-densified titanium carbide ceramic. The method comprises: 1) taking TiC powder and a sintering aid, and performing mixing, molding, and debinding treatment to obtain TiC ceramic biscuit, wherein the sintering aid is at least one of WC, B4C, Cr3C2, VC, and C; and 2) sintering the TiC ceramic biscuit prepared in the step 1) under a normal pressure, at a temperature of 2100-2500 DEG C, and in an inert gas atmosphere to obtain the densified titanium carbide ceramic.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

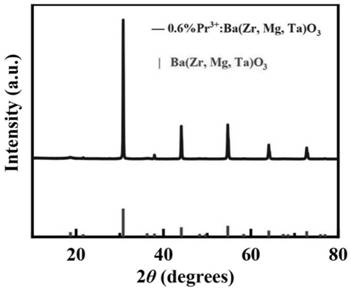

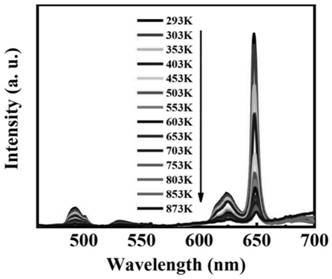

Fluorescence temperature measurement method suitable for ultra-wide temperature measurement range

PendingCN113390529AHigh luminous intensityHigh temperature limitThermometers using physical/chemical changesFluorescence spectraPhysical chemistry

The invention relates to the technical field of fluorescence temperature measurement, in particular to a fluorescence temperature measurement method suitable for an ultra-wide temperature measurement range. The fluorescence temperature measurement method comprises the following steps of: (a) establishing a standard curve of a fluorescence peak intensity ratio of Pr < 3 + >-based 3P1-to-3F2 transition and 3P0-to-3F2 transition of a fluorescence temperature sensing material along with temperature change; and (b) placing the fluorescence temperature sensing material in an environment of which the temperature is to be measured, measuring the fluorescence spectrum of the fluorescence temperature sensing material, calculating the fluorescence peak intensity ratio of Pr < 3 + >-based 3P1-to-3F2 transition and 3P0-to-3F2 transition, substituting the fluorescence peak intensity ratio into the standard curve, and calculating to obtain a temperature measurement value of the to-be-measured environment, the fluorescence temperature sensing material being Pr < 3 + >-doped oxide transparent ceramic, and the molar doping concentration of Pr < 3 + > being 0.1%-10%. According to the temperature measurement method, a higher temperature measurement limit and a wider temperature measurement range can be realized.

Owner:SONGSHAN LAKE MATERIALS LAB +1

Titanium alloy composite capable of resisting high temperature oxidation and hot salt corrosion and preparation method thereof

InactiveCN109023479AReduce internal stressGood chemical stabilitySurface reaction electrolytic coatingMicro arc oxidationAlloy substrate

The invention discloses a titanium alloy composite capable of resisting high temperature oxidation and hot salt corrosion and a preparation method thereof. The titanium alloy composite comprises a titanium alloy substrate; a ceramic transition layer and an enamel coating are arranged on the surface of the titanium alloy substrate; the ceramic transition layer is located between the titanium alloysubstrate and the enamel coating; the ceramic transition layer is a micro-arc oxidation ceramic layer; and the enamel coating and the ceramic transition layer form a high-temperature protection gradient composite coating on the titanium alloy substrate. The titanium alloy composite is excellent in resistance to high temperature oxidation and high temperature hot salt corrosion and the gradient composite coating is good in chemical stability.

Owner:SICHUAN ENG TECHN COLLEGE

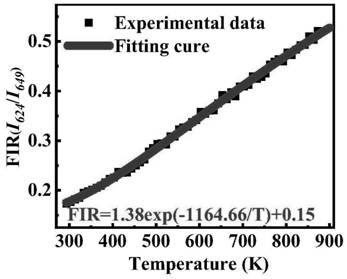

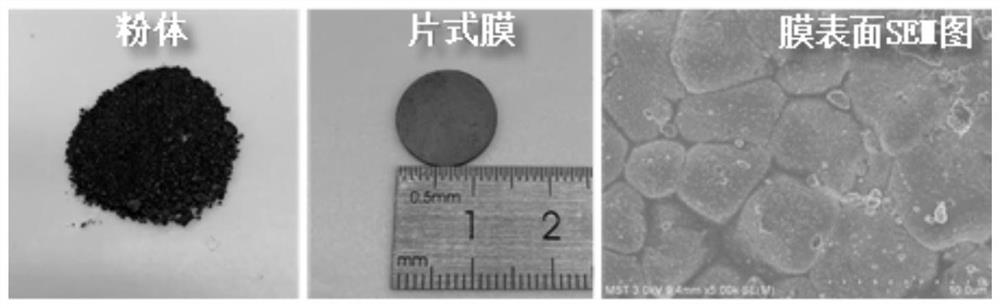

High-entropy perovskite membrane and application in oxygen separation and membrane reactor

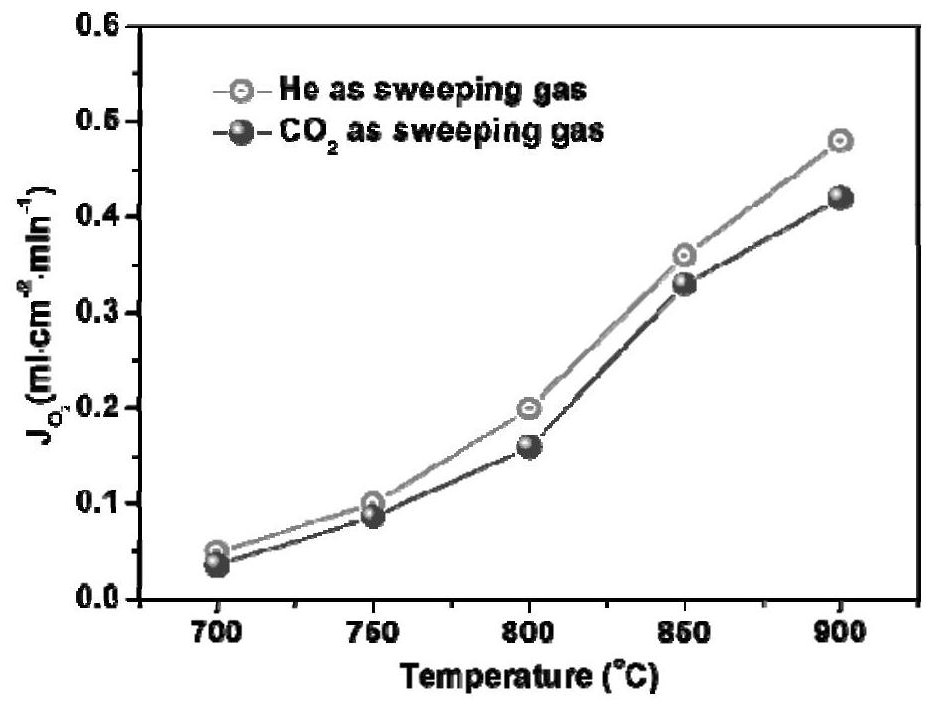

ActiveCN113967413AExcellent oxygen permeabilityGood thermochemical stabilitySemi-permeable membranesDispersed particle separationAlkaline earth metalElectrical conductor

The invention discloses a high-entropy perovskite membrane and application in oxygen separation and membrane reactors, and belongs to the field of mixed conductor high-entropy perovskite membrane materials. According to the high-entropy perovskite membrane material, the high-entropy perovskite membrane has a general formula (Ax1A'x2... A<(m-1)>'xm)(By1B'y2... B<(n-1)>'yn) O3-delta, at least one of site A and site B is a multi-element with five or more elements, delta is oxygen lattice defect number, A is one or more of alkali metal, alkaline earth metal or rare earth metal elements, B is one or more of transition metal elements, x1 +... + xm is equal to 1, y1 +... + yn1 is equal to 1, delta is more than or equal to 0 and less than 3, and the material is prepared by using a solid-phase reaction method. The membrane material provided by the invention can effectively improve the thermal stability and oxygen permeability of the material, also has excellent CO2 resistance, can be applied for a long time in the fields of oxygen separation and membrane reactors, and meets the requirements of industrial application.

Owner:JIANGNAN UNIV

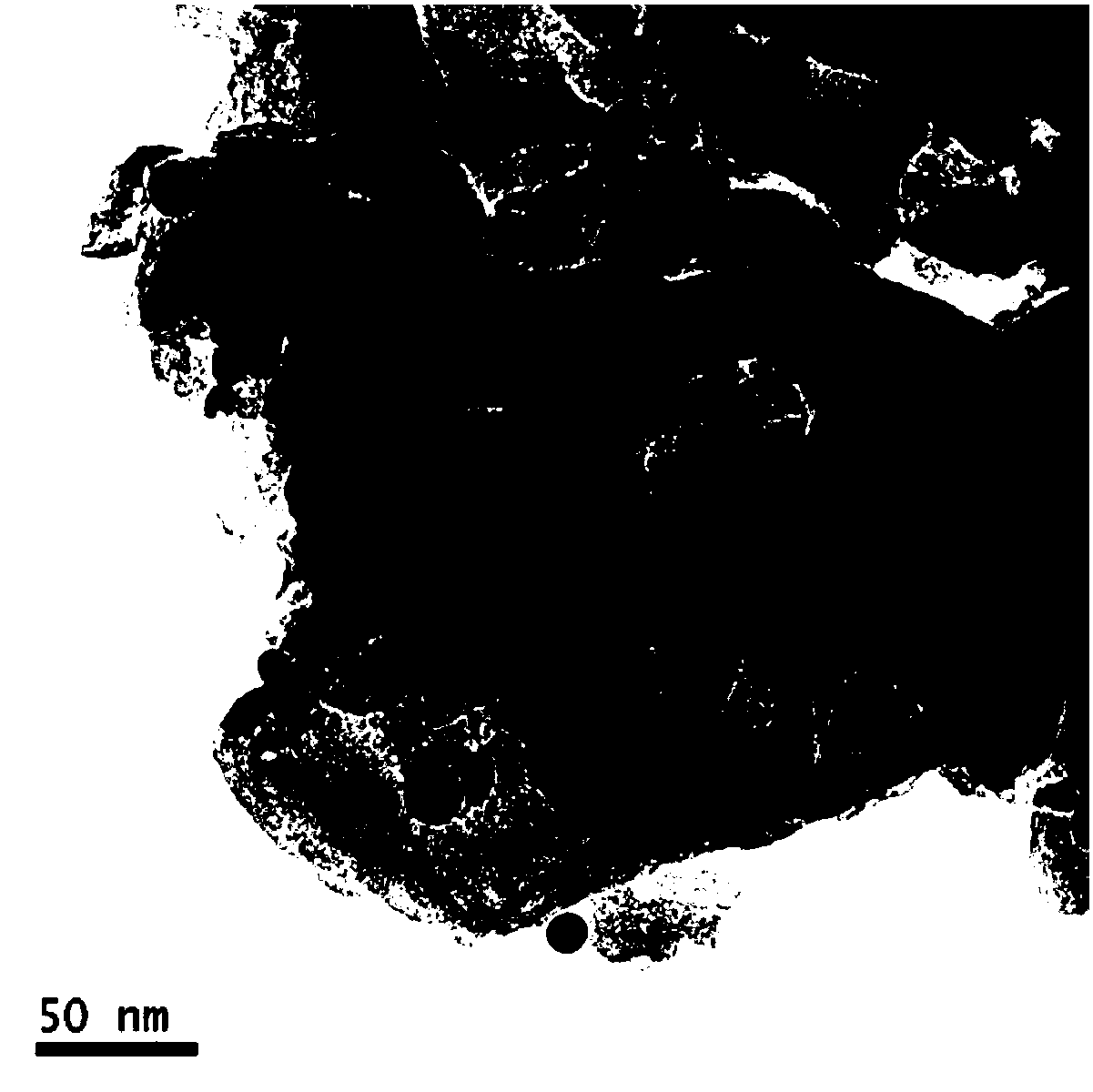

Method for treating nitro aromatic hydrocarbon substances by polydopamine reduced carbon nitride supported nano-gold catalyst

ActiveCN108404993ALarge specific surface areaIncrease loadOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsGold particlesCarbon nitride

The invention discloses a method for treating nitro aromatic hydrocarbon substances by polydopamine reduced carbon nitride supported nano-gold catalysts. The nano-gold catalysts are added into the nitro aromatic hydrocarbon substances and mixed solution containing BH4- salt, and degradation is performed. The nano-gold catalysts include polydopamine-carbon nitride supporters and nano-gold particles, the polydopamine-carbon nitride supporters are formed by automatically polymerizing dopamine on the surface of carbon nitride, the nano-gold particles are reduced by polydopamine on the supporters,the polydopamine coats the flaky carbon nitride in an amorphous form, the nano-gold particles are supported on the surfaces of the polydopamine-carbon nitride supporters, the mass ratio of the nano-gold particles to the polydopamine-carbon nitride supporters is (1-4):30, and the mass ratio of the polydopamine to the carbon nitride is (0.8-1.2):1. The method has the advantages of simplicity in operation, rapidness in reaction, easiness in recycling of the catalysts, high degradation efficiency and the like, and can be widely applied to treatment of nitro aromatic hydrocarbons.

Owner:HUNAN UNIV

Preparation method of catalyst for synthesizing methacrylic acid

ActiveCN102553624BHigh activityHigh mechanical strengthPhysical/chemical process catalystsOrganic compound preparationGas phasePhosphoric acid

The invention relates to a preparation method of a catalyst for synthesizing methacrylic acid. The preparation method comprises the following steps: preparing a heteropoly compound catalyst by adopting an ionic liquid and metal salt step-by-step precipitation method; performing a reaction on a molybdenum-containing compound, a vanadium-containing compound and phosphoric acid to obtain solution or slurry A; preparing imidazolium ionic liquid into solution B; preparing alkali metal nitrate, transition metal nitrate and lanthanide nitrate into mixed aqueous solution C; adding the B and the C into the A in a step-by-step precipitation and aging mode; and then obtaining the catalyst by concentrating, drying, forming and roasting. The catalyst prepared by the method has high activity and high selectivity for the reaction of preparing methacrylic acid by carrying out gas-phase oxidation on methylacrolein and has high mechanical strength and high thermochemical stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Scrubbable illite photocatalyst spraying liquid

InactiveCN106221418AHigh temperature resistanceImprove securityAntifouling/underwater paintsPaints with biocidesPolyvinyl alcoholPolyethylene glycol

The invention discloses scrubbable illite photocatalyst spraying liquid. The main points of the technical scheme are that ingredients consist of illite, acidified attapulgite clay, high-viscosity attapulgite clay, nano-titanium dioxide, white carbon black, nano-silver-loaded antibacterial powder, nano-magnesium oxide, nano-zirconium dioxide, nano-aluminium oxide, nano-zinc oxide, polyvinyl alcohol, polyethylene glycol, polydimethylsiloxane and water. The scrubbable illite photocatalyst spraying liquid is prepared by stirring, dispersing, emulsifying and grinding the ingredients first, then performing dispersion again, and performing homogenization, grinding and canning. The scrubbable illite photocatalyst spraying liquid is suitable to be sprayed onto the surface of a building or a decorative material, can continuously adsorb and degrade pollutants, such as formaldehyde, ammonia and benzene, under the irradiation of light, and has extremely good functions of sterilization, deodorization, mould prevention and air purification; a thin film which is formed by spraying the scrubbable illite photocatalyst spraying liquid onto the surface of the building or the decorative material can present a saturated state after being used for a long time, and can be scrubbed with a cleaning rag.

Owner:蒋文兰

Inorganic silicon resin/basalt fiber composite high-temperature-resistant coating and preparation method thereof

PendingCN114133774AImprove uniformityGood storage stabilityFireproof paintsAlkali metal silicate coatingsSilicic acidBasalt fiber

The invention discloses an inorganic silicon resin / basalt fiber composite high-temperature-resistant coating and a preparation method thereof. The preparation method comprises the following steps: firstly, taking a lithium silicate aqueous solution as a raw material, adding a silane coupling agent to prepare modified inorganic silicon resin, then sequentially adding a certain amount of fumed silica, basalt chopped fibers and high-temperature-resistant ceramic powder at different stirring speeds, and uniformly stirring to obtain the inorganic silicon resin / basalt fiber composite high-temperature-resistant coating. The coating is uniformly blade-coated on a base material such as a steel plate and the like to obtain an inorganic silicon resin / basalt fiber composite high-temperature-resistant coating layer. The preparation method disclosed by the invention is simple and easy to operate, and the prepared high-temperature coating has good high-temperature resistance, heat insulation, corrosion resistance, ablation resistance and the like, and can be used as a high-temperature-resistant and heat-insulation protective coating.

Owner:PEKING UNIV

Base oil for refrigerated machine oil composition, refrigerated machine oil composition, composition for refrigerating, and refrigerating method

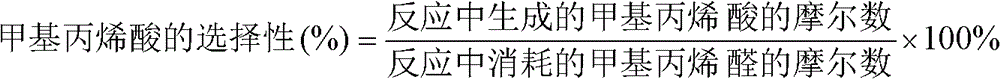

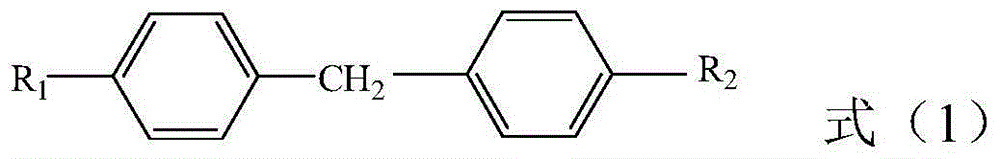

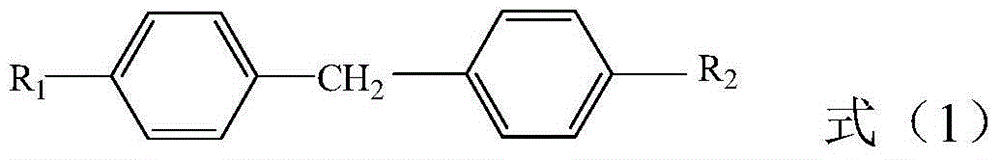

The invention discloses base oil for a refrigerated machine oil composition; the base oil disclosed by the invention is characterized in that the kinematic viscosity of the base oil at 40 DEG C is below 3 SM / S; the base oil is a mixture of an aromatic compound represented by the formula (1) and alkylbenzene with the total carbon atom number of 12-15 and / or isoparaffin with the total carbon atom number of 14-18, wherein R1 and R2 are independently H or C1-C4 alkyl respectively; and R1 and R2 are same or different. The invention further provides a refrigerated machine oil composition, a composition for refrigerating, and a refrigerating method. The refrigerated machine oil composition provided by the invention not only has good intermiscibility and thermal and chemical stability of an R600 A refrigerating agent, but also has lower viscosity, higher flashing point, good low-temperature fluidity, good lubricity and lower friction coefficient; and thus, the base oil has the obvious energy-saving effect. The formula I is as shown in the specification.

Owner:BEIJING FRIENDLINK PETROCHEM T&D CO LTD

Nano titanium dioxide photocatalyst

InactiveCN110152742AWide variety of sourcesImprove catalytic performanceGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic effectChloride

The invention discloses a nano titanium dioxide photocatalyst. The photocatalyst comprises the following components in parts by weight: 10-20 parts of nano titanium dioxide, 1-3 parts of a dispersingagent, 2-4 parts of nano-silver, 3-6 parts of nano-silica, 3-9 parts of nano zirconia, 4-10 parts of nano-zinc oxide, 12-22 parts of deionized water, 4-10 parts of ferric chloride and 5-12 parts of polyvinylpyrrolidone. The preparation method is simple, the raw material source is wide, and the prepared photocatalyst is excellent in catalytic effect, does not produce corrosion, and is high in oxidizing ability, high in bactericidal ability and long in preservation time.

Owner:四川净入环境工程有限公司

Multifunctional fireproof door core plate and preparation method thereof

The invention discloses a multifunctional fireproof door core plate and belongs to the technical field of fireproof doors. The multifunctional fireproof door core plate is prepared from the following raw materials in parts by weight: 40-50 parts of magnesium oxide, 1-2 parts of kyanite, 30-40 parts of pearlite, 3-6 parts of carbon fibers, 4-7 parts of glass fibers, 17-22 parts of asbestos powder, 2-5 parts of nano zirconium dioxide, 1-4 parts of traditional Chinese medicine decoction dregs, 1-2 parts of flavoring essence, 4-5 parts of foamer and 3-5 parts of binder. The invention further discloses a preparation method of the multifunctional fireproof door core plate. The multifunctional fireproof door core plate is simple to prepare, high in strength and good in fireproof performance, is free of off odors, can bring delicate fragrance to surroundings and is also beneficial to health preserving of people.

Owner:合肥市旺友门窗有限公司

Preparation of high-amylose regularity polyvinylidene fluoride

The invention relates to a preparation methof of chained polyvinylidene fluoride with high tacticity degree. An initiator used in the polymerization is a redox initiator, an oxidant thereof, i.e., cumene peroxide end group is stable, a reducer thereof, i.e., sodium hypochlorite does not influence the color of a product, and the mol ratio between the oxidant and the reducer is 1:1 to 1:3; the polymerization condition is moderate, the chain of the polymerization product has high tacticity degree and stable end group, therefore, the thermo-chemical stability is good, and the mechanical performance and weathering resistance are significantly improved.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

A method and device for recovering n-methylpyrrolidone waste gas from lithium battery production by membrane separation

ActiveCN107626186BGood chemical stabilityHas removedSemi-permeable membranesDispersed particle separationEngineeringPole piece

Owner:江苏旭一高科技有限公司

A method for treating nitroaromatic hydrocarbons with a carbon nitride-supported nano-gold catalyst reduced by polydopamine

ActiveCN108404993BLarge specific surface areaIncrease loadOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsGold particlesCarbon nanotube

The invention discloses a method for treating nitroaromatic hydrocarbons using a polydopamine-reduced carbon nitride-loaded nano-gold catalyst. The nano-gold catalyst is added to nitroaromatic hydrocarbons and BH-containing substances. 4 - In a mixed solution of salts, degradation treatment is performed; the nano-gold catalyst includes a polydopamine-carbon nitride carrier formed by the self-polymerization of dopamine on the carbon nitride surface, and nano-gold particles reduced by polydopamine on the carrier, The polydopamine is in an amorphous state coating sheet-like carbon nitride, the gold nanoparticles are loaded on the surface of the polydopamine-carbon nitride carrier, and the mass ratio of the gold nanoparticles to the polydopamine-carbon nitride carrier is 1~ 4:30, the mass ratio of polydopamine to carbon nitride is 0.8~1.2:1. The method of the present invention has the advantages of simple operation, rapid reaction, easy recovery and reuse of the catalyst, and high degradation efficiency. It is a method that can be widely used for treating nitroaromatic hydrocarbons.

Owner:HUNAN UNIV

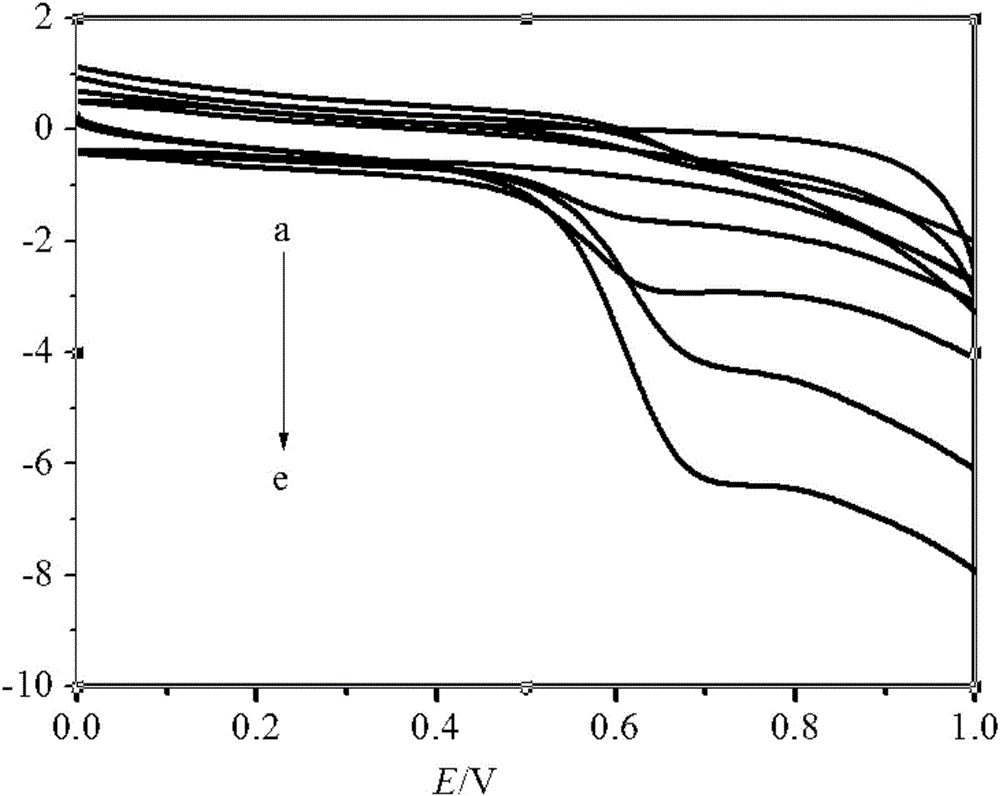

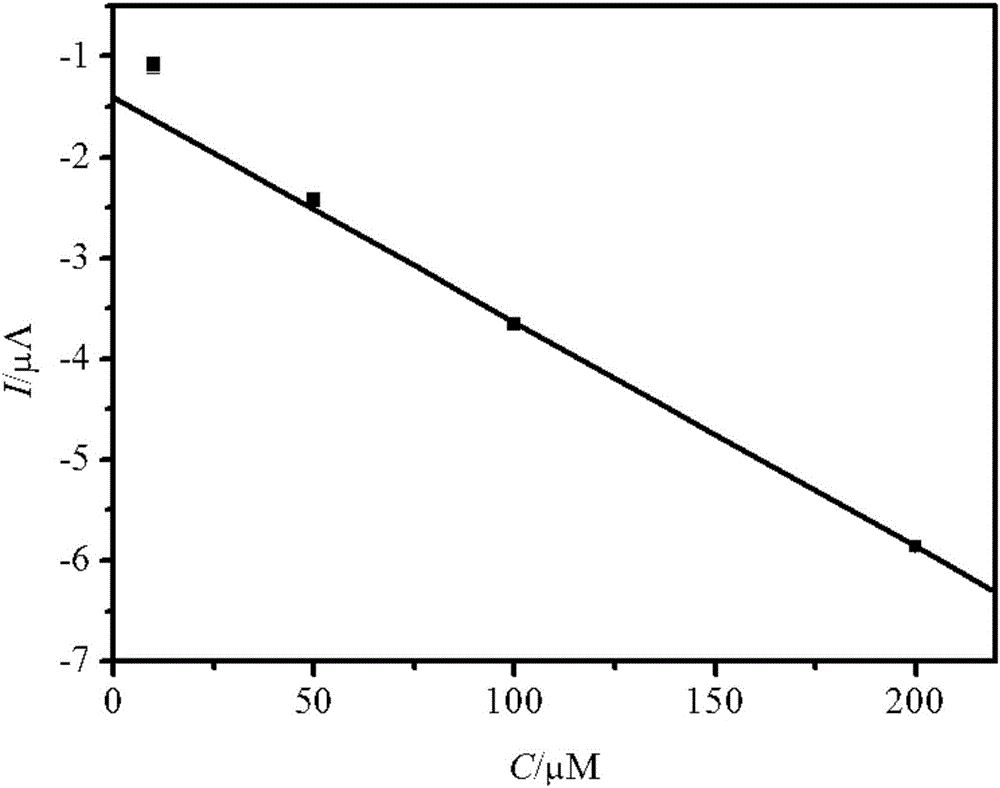

Method for detecting concentration of resorcinol in solution

ActiveCN106290543AFast transfer rateImprove stabilityMaterial electrochemical variablesQuantumGraphene quantum dot

The invention discloses a method for detecting the concentration of resorcinol in solution. The resorcinol in the to-be-detected solution is detected by three-electrode systems by the aid cyclic voltammetry, the concentration of the resorcinol in the to-be-detected solution is acquired according to linear equations of the resorcinol, and working electrodes of the three-electrode systems are modified and treated by the aid of aminated graphene quantum dots and are glassy carbon electrodes. The method has the advantages that the method is easy to implement and high in sensitivity, the concentration of the resorcinol can be quickly detected by the aid of the method, and the resorcinol in the mixed sample solution can be identified in a high-sensitivity manner by the aid of the method.

Owner:广西恒沁检测科技有限公司

Scrubbing-resistant paint

InactiveCN106189446AImprove adhesionGood scrub resistanceFireproof paintsAnti-corrosive paintsSodium BentonitePhosphoric acid tributyl ester

The invention discloses scrubbing-resistant paint, and relates to the technical field of building materials. The paint is prepared from, by weight, 60-80 parts of vinyl versatate, 6-8 parts of hydroxyethyl cellulose water solution with weight ratio of 3%, 15-20 parts of nanometer zirconium oxide, 15-25 parts of glass beads, 10-15 parts of talcum powder, 5-10 parts of bentonite, 0.1-0.2 part of tributyl phosphate and 40-65 parts of deionized water. The problem that existing building materials are poor in scrubbing resistance is solved.

Owner:LIUZHOU YITING TRADE

Refrigerated machine oil composition

One kind of refrigerator oil compounding, this compounding includes base oil and the additive, the the base oil include the mix alpha alkene polymerized oil which decomposed by the wax, among them, the viscosity of the mix alpha alkene polymerized oil is smaller than 10 mm2 / s at 40 degree C. The refrigerator oil compounding provided by this invention has the following merits: (1) the R600A refrigerant has fine solubility, the flocculation point may reach lower than -60 degree C; (2)it has obvious energy conservation effect, compares with the refrigerator which viscosity is 22 mm2 / s oils conserves energy 6% in 40 degree Cviscosity, it can economize on energy 6%, compares with the refrigerator which viscosity is 10 mm2 / s at 40 degree C, it can economize on energy 2%.

Owner:BEIJING FRIENDLINK PETROCHEM T&D CO LTD

Preparation method for polyvinylidene fluoride with high molten fluidity

ActiveCN102134292BImprove regulation efficiencyImprove melt fluidityPowdery paintsEnd-groupPolyvinylidene difluoride

The invention relates to a preparation method for polyvinylidene fluoride with high molten fluidity. The initiator used for the polymerization is an organic initiator comprising organic hydrogen peroxide and organic peroxide with a molar ratio of 1-5, and the used conditioning agent is an ester conditioning agent with high dispensing efficiency for the system; the addition way of the initiator and the conditioning agent is a continuous addition way; the polymerization condition is mild; the polymerization product has a stable end group and a moderate molecular weight with a narrow distribution coefficient; and the product has high molten fluidity, good thermochemical stability, and significantly improved mechanical properties and weatherability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com