Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Does not constitute pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

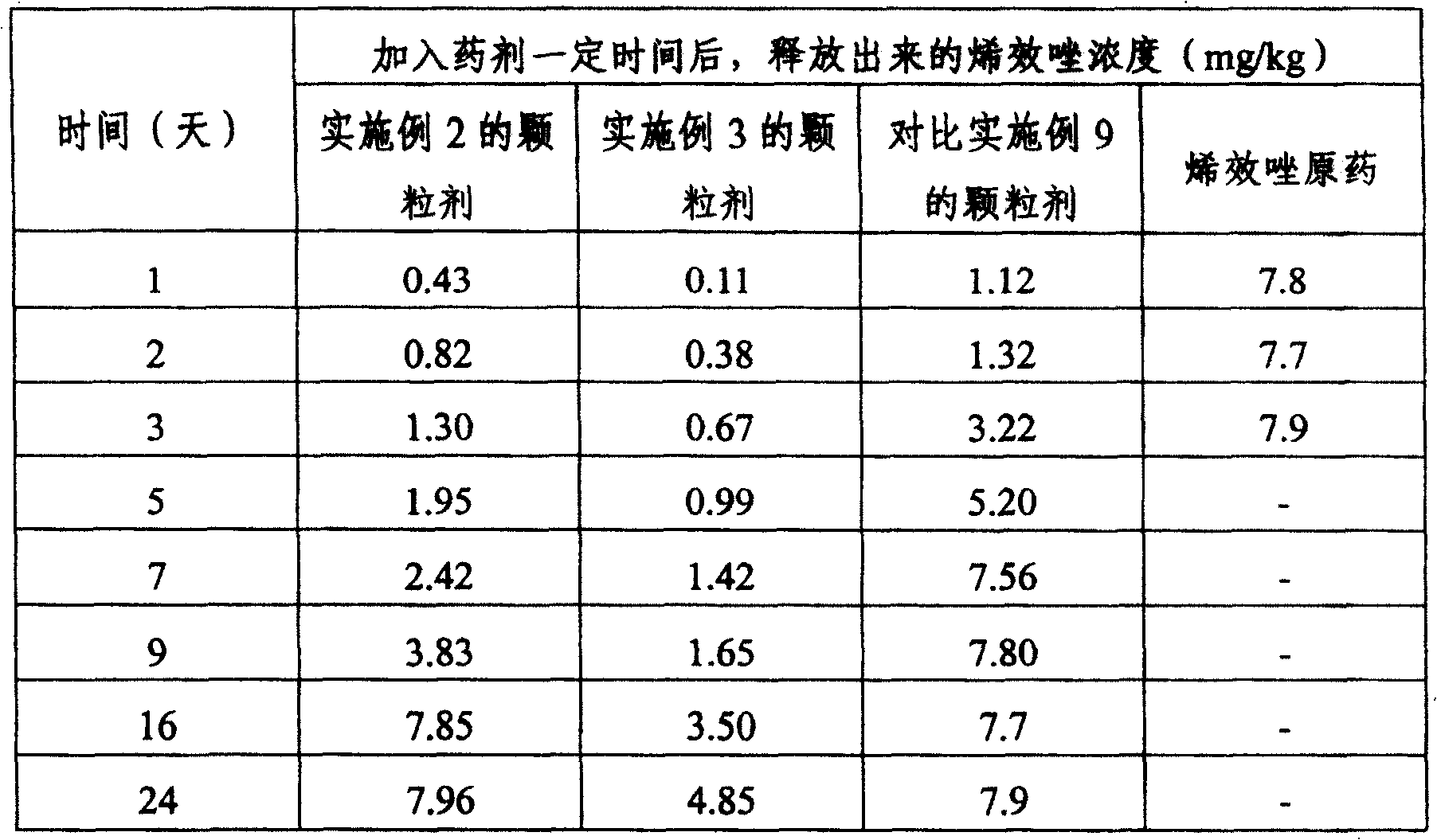

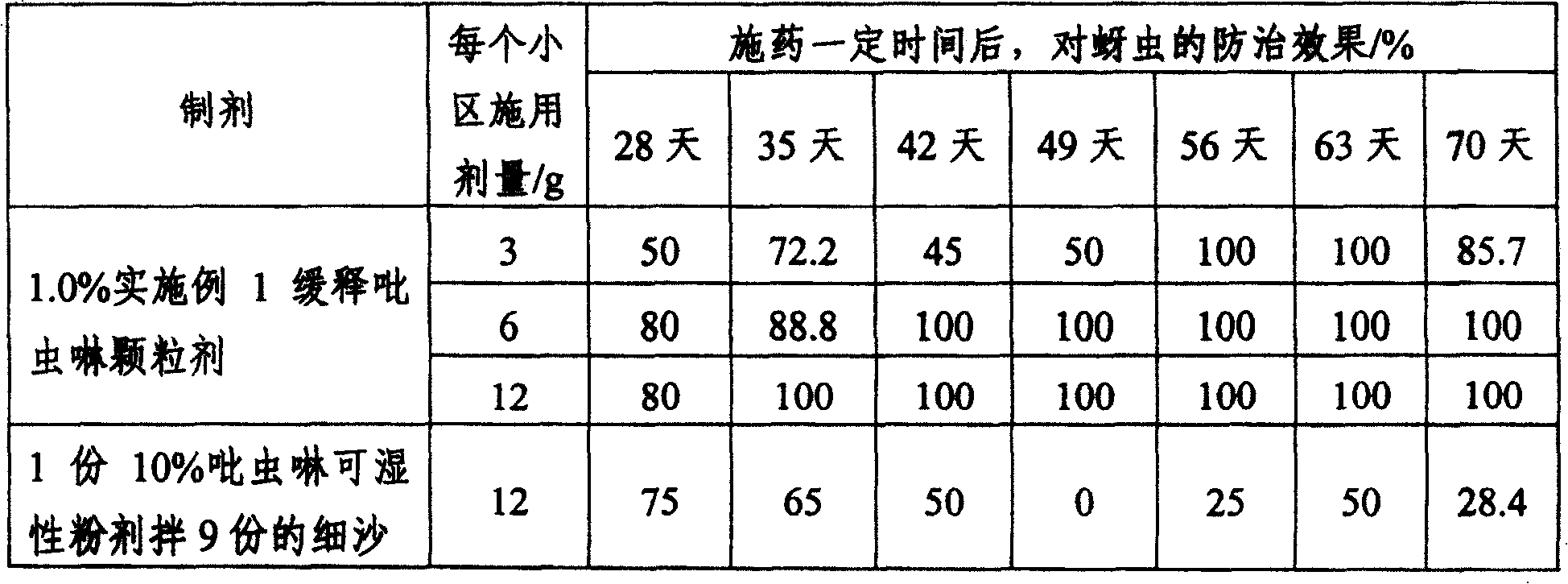

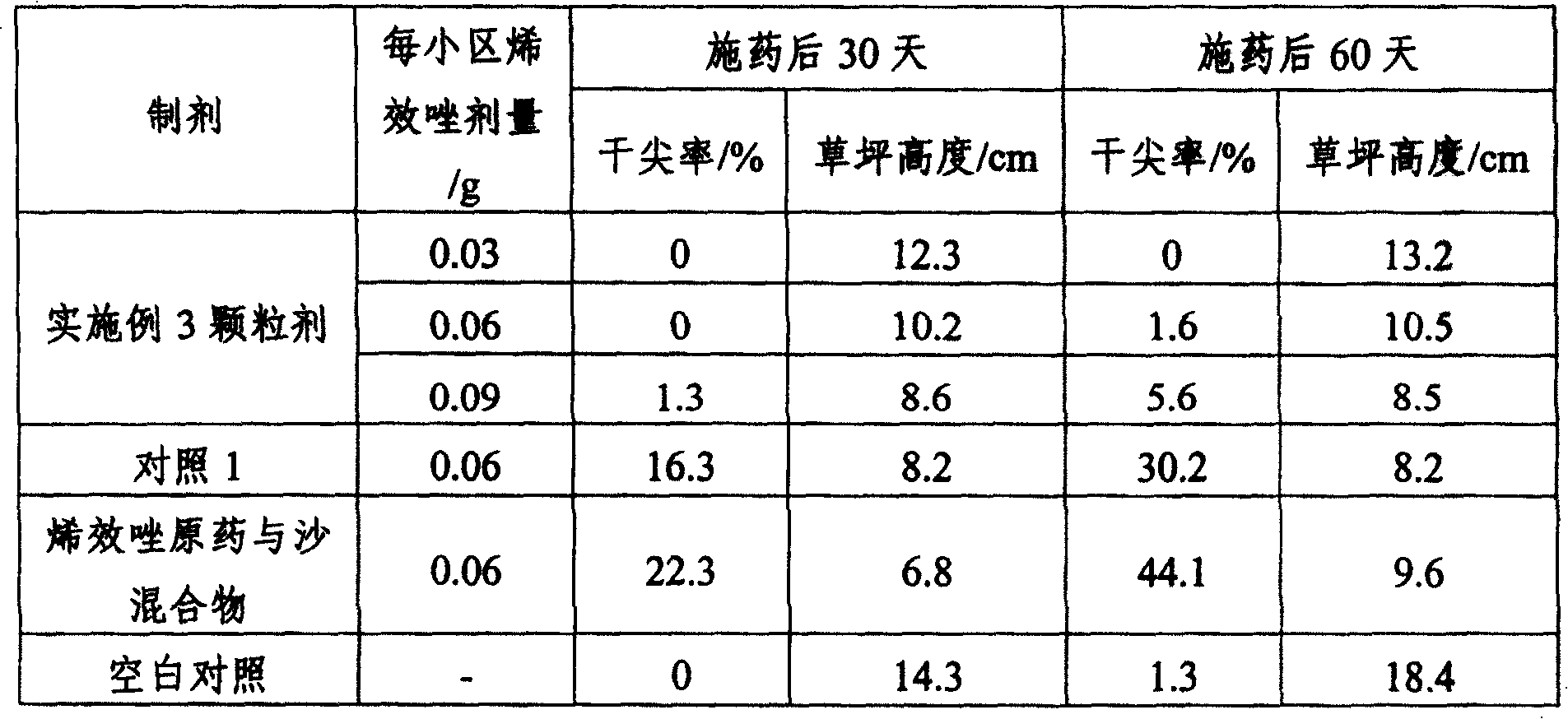

Sustained releasing pesticide granule

InactiveCN1951186ALong durationDoes not constitute pollutionBiocideAnimal repellantsActive componentBiology

The invention relates to a slow-release pesticide granula, formed by pesticide active compound, modify amidon, powder and assist agents. Wherein, the invention also provides relative application; the granula can control the active component to be released to condition at preset speed; therefore, the invention can function the plant one time to control their growth in whole season.

Owner:BEIJING AGRI TECH PROMOTION STATION

Organic bentonite pesticide sustained-release granular formulation and preparation method thereof

InactiveCN102578081AGood compatibilityDoes not constitute pollutionBiocideFungicidesChemical structureControl release

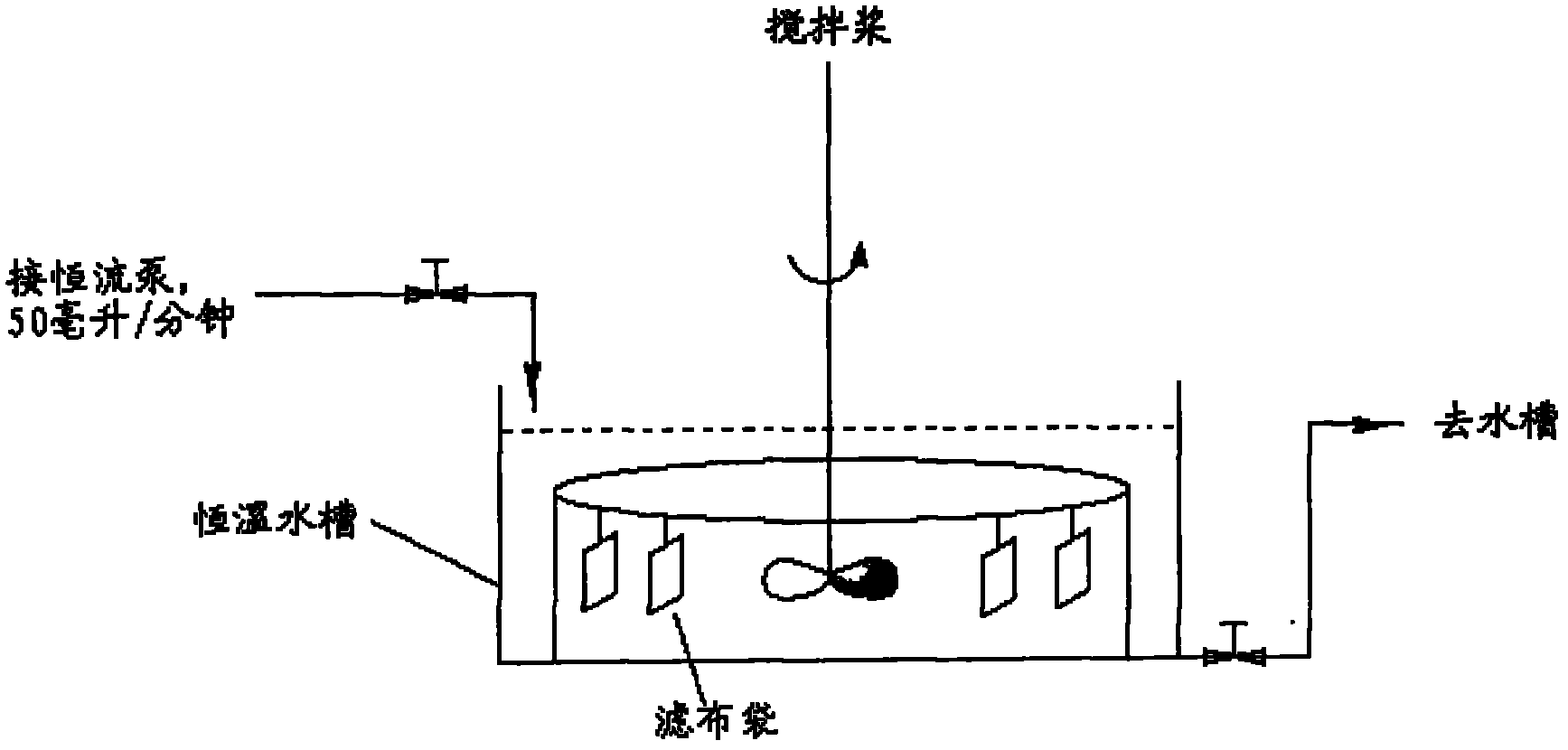

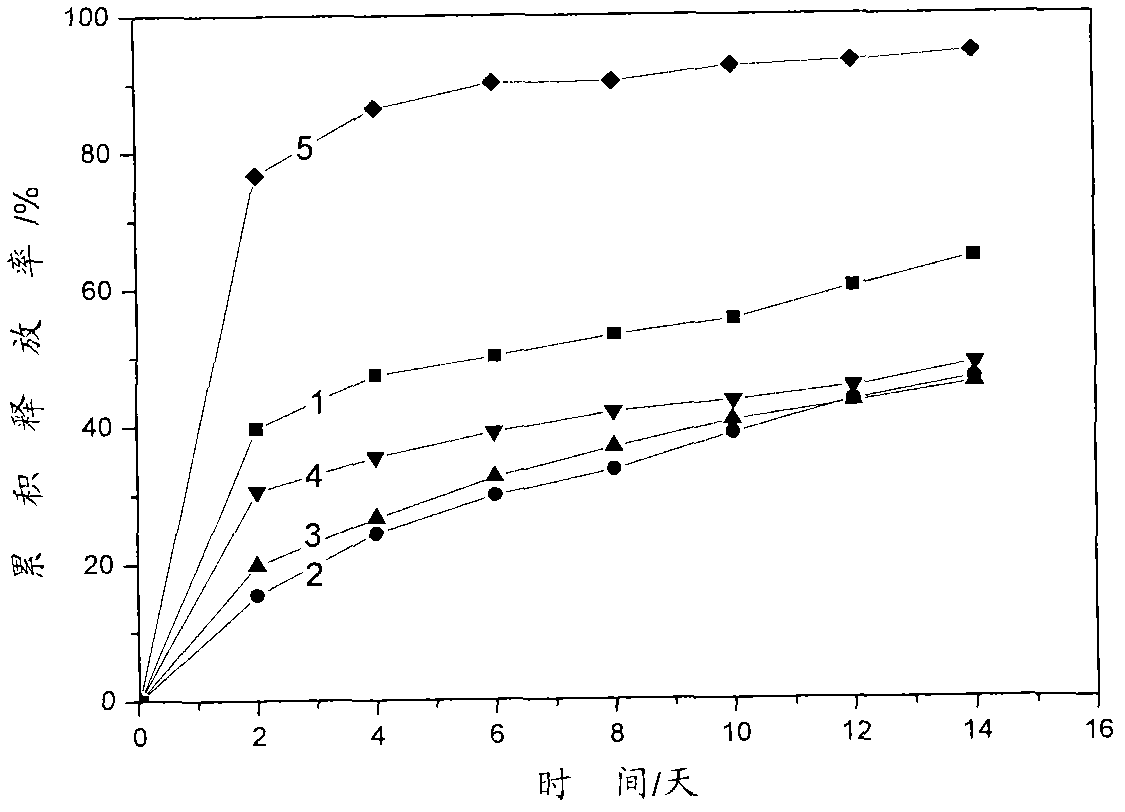

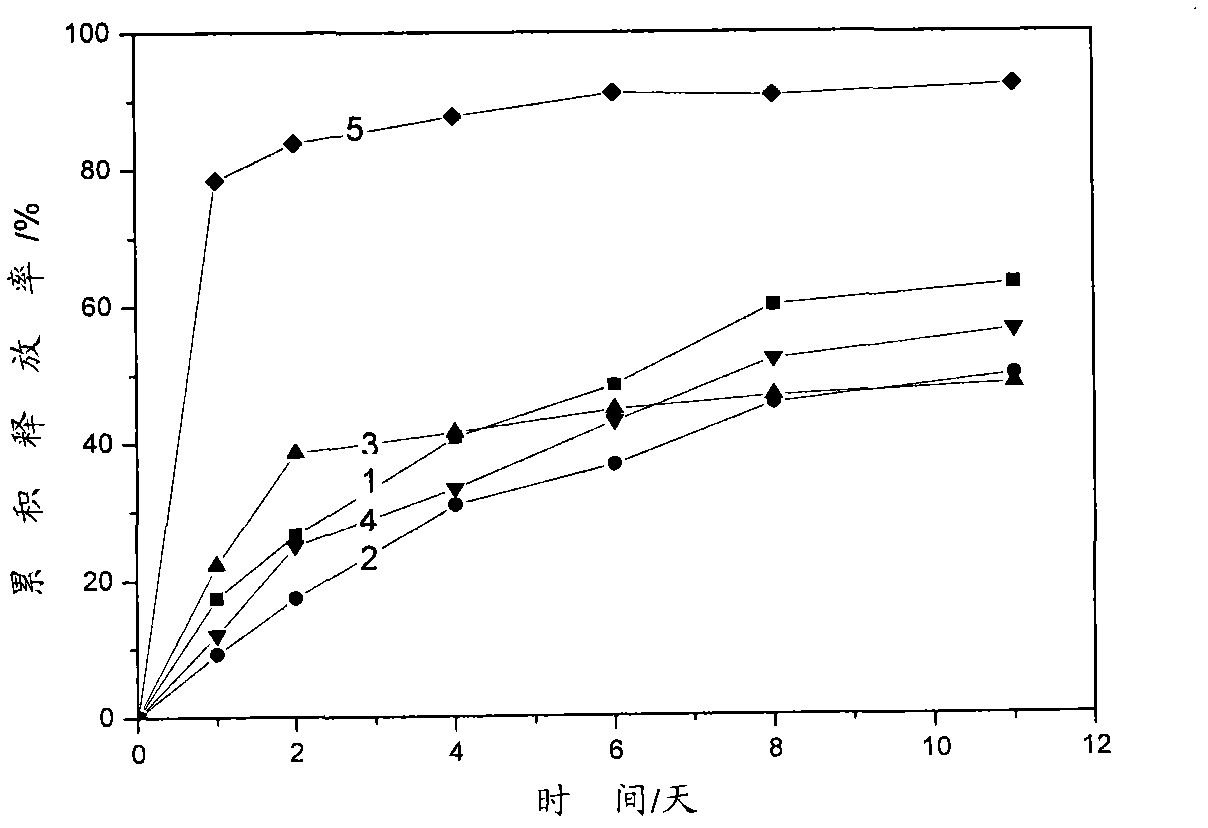

The invention relates to a sustained-release granular formulation for preventing and treating crop diseases and insect pests and a preparation method thereof. The pesticide sustained-release granular formulation comprises bentonite, an organic modifier, pesticide active ingredients, an inert filler and a binding agent, and is prepared by the preparation method comprising the steps of: (1) with the bentonite as a basic material, modifying the bentonite by the organic modifier to obtain organic bentonite; (2) loading the pesticide active ingredients on the organic bentonite to prepare medicine-carrying organic bentonite; and (3) mixing the medicine-carrying organic bentonite, the inert filler and the binding agent proportionally, and pelleting to obtain the sustained-release granular formulation. The preparation method of the sustained-release granular formulation, provided by the invention, not only overcomes the defect of low pesticide loading rate of the natural bentonite, but also realizes the controlled release of the pesticide by adjusting a chemical structure and the amount of the modifier, so that the sustained-release granular formulation is coincident with an occurrence rule of the plant diseases and insect pests, and the pesticide sustained-release granular formulation is used safely, reasonably, economically and effectively.

Owner:GAUNGXI TIANYUAN BIOCHEM +1

Molybdenum disulfide diaphragm of lithium-sulfur battery and preparation method therefor

InactiveCN107068944AImprove cycle lifeDoes not constitute pollutionLi-accumulatorsCell component detailsFiltrationSpectroscopy

The invention discloses a molybdenum disulfide diaphragm of a lithium-sulfur battery and a preparation method therefor, belonging to the field of lithium-sulfur batteries. According to the molybdenum disulfide diaphragm of the lithium-sulfur battery, the molybdenum disulfide diaphragm has high lithium conductivity, and is capable of inhibiting the migration of polysulfides between a positive electrode and a negative electrode so as to improve a cycle life of the lithium-sulfur battery. In addition, the high-temperature resistance of molybdenum disulfide is used to improve the overall temperature resistance of the diaphragm; a vacuum filtration method is used to deposit a molybdenum disulfide nanosheet on the surface layer of the lithium-sulfur battery diaphragm; and a relative position of pore size of a funnel on the surface of the molybdenum disulfide diaphragm is relatively small in thickness under the vacuum filtration condition, so that good air permeability can be achieved, and battery capacity is not affected. The MoS2 / Celgard prepared is applied to the lithium-sulfur battery; an electrochemical impedance spectroscopy result shows that the lithium ion conductivity of the MoS2 / Celgard diaphragm is about 2.0*10<-1> mS.cm<-1>, thereby substantially prolonging the cycle life of the lithium-sulfur battery. The whole preparation method is short in process flows, the conditions are simple, the cost is low, and no pollution is caused to the environment, so that a requirement of cleaner production can be achieved.

Owner:NORTHWEST NORMAL UNIVERSITY

Method for leaching selenium in acid mud by using sodium sulfite

ActiveCN102583264AHigh extraction rateEasy to smeltElemental selenium/telluriumSulfite saltDistillation

The invention discloses a method for leaching selenium in acid mud by using sodium sulfite. The method comprises the following steps: selenium-containing acid mud and industrial water are mixed into pulp, and the pulp is put into a stirring groove for water washing till the acid mud is neutral; the neutral acid mud is mixed with the sodium sulfite and the industrial water into pulp, the pulp is put into a high-pressure reactor, nitrogen is introduced for reaction, the pressure and the temperature are reduced after the reaction is finished, the material is taken out and filtered, and the filtrate is sodium selenate solution; the sodium selenate solution is put into an acidizing groove, and sulfuric acid is added under the stirring condition; after the acidification is finished, temperature rise is started, the mixture is continuously stirred and then filtered, and the filter residue is selenium powder with the content of more than or equal to 97.0%; the selenium is leached by using the industrial sodium sulfite in the process of extracting the selenium in the acid mud, and the leached selenium is acidized to obtain the selenium powder with the content of more than or equal to 97.0%; and sodium sulfate produced in the technical process is effectively recycled by a distillation and crystallization method. The method has the characteristics of low cost, easiness in industrialization and low-carbon environmental protection.

Owner:KUNMING METALLURGY INST

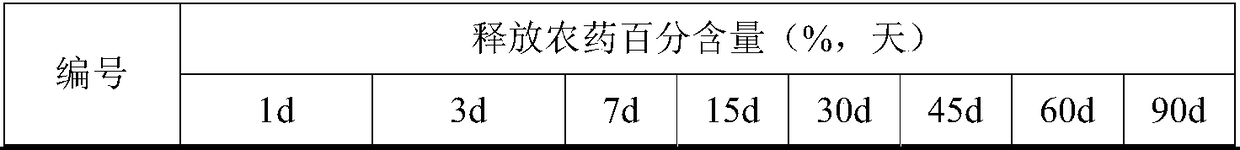

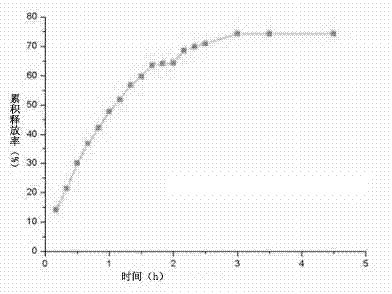

Application of beewax in controlled release pesticide and method for preparing controlled release pesticide by taking beewax as matrix

InactiveCN108935457ALong durationReduce the frequency of sprayingBiocideAnimal repellantsControl releaseRelease time

The invention discloses application of beewax in a controlled release pesticide and a method for preparing the controlled release pesticide by taking the beewax as a matrix and belongs to the technical field of controlled release pesticides. The controlled release pesticide taking the beewax as the matrix is prepared by utilizing pesticide active molecules, an adsorbent, beewax or modified beewax,a surfactant, a controlled release regulator and a filler. According to pesticide granules prepared by the method, the pesticide active molecules in the pesticide granules can be released in a certain period of time according to crop needs, the uncontrollability of release time of the conventional controlled release pesticide is solved, and an excellent effect of controlling crop pests is achieved. Moreover, the preparation process is simple, the raw materials are cheap, and the preparation cost is low.

Owner:GAUNGXI TIANYUAN BIOCHEM +1

Nano photolysis-resistant controlled-release pesticide taking lignin as coating matrix and preparation method thereof

ActiveCN110946133AHigh drug loadingSimple preparation processBiocideAnimal repellantsSulfonateLignosulfonates

The invention discloses a nano photolysis-resistant controlled-release pesticide taking lignin as a coating matrix. According to the preparation method, water-soluble lignosulfonate is taken as a coating substrate, intermolecular crosslinking is carried out on the lignosulfonate by using a crosslinking agent, and then active molecules of a pesticide active compound are coated in lignin molecules,so that the nano photolysis-resistant controlled-release pesticide taking lignin as the coating matrix can be obtained. The nano photolysis-resistant controlled-release pesticide provided by the invention has very good photolysis-resistant and antioxidant effects and very good slow-release effect, and has the advantages of high and controllable drug loading capacity and simple preparation process.

Owner:GAUNGXI TIANYUAN BIOCHEM

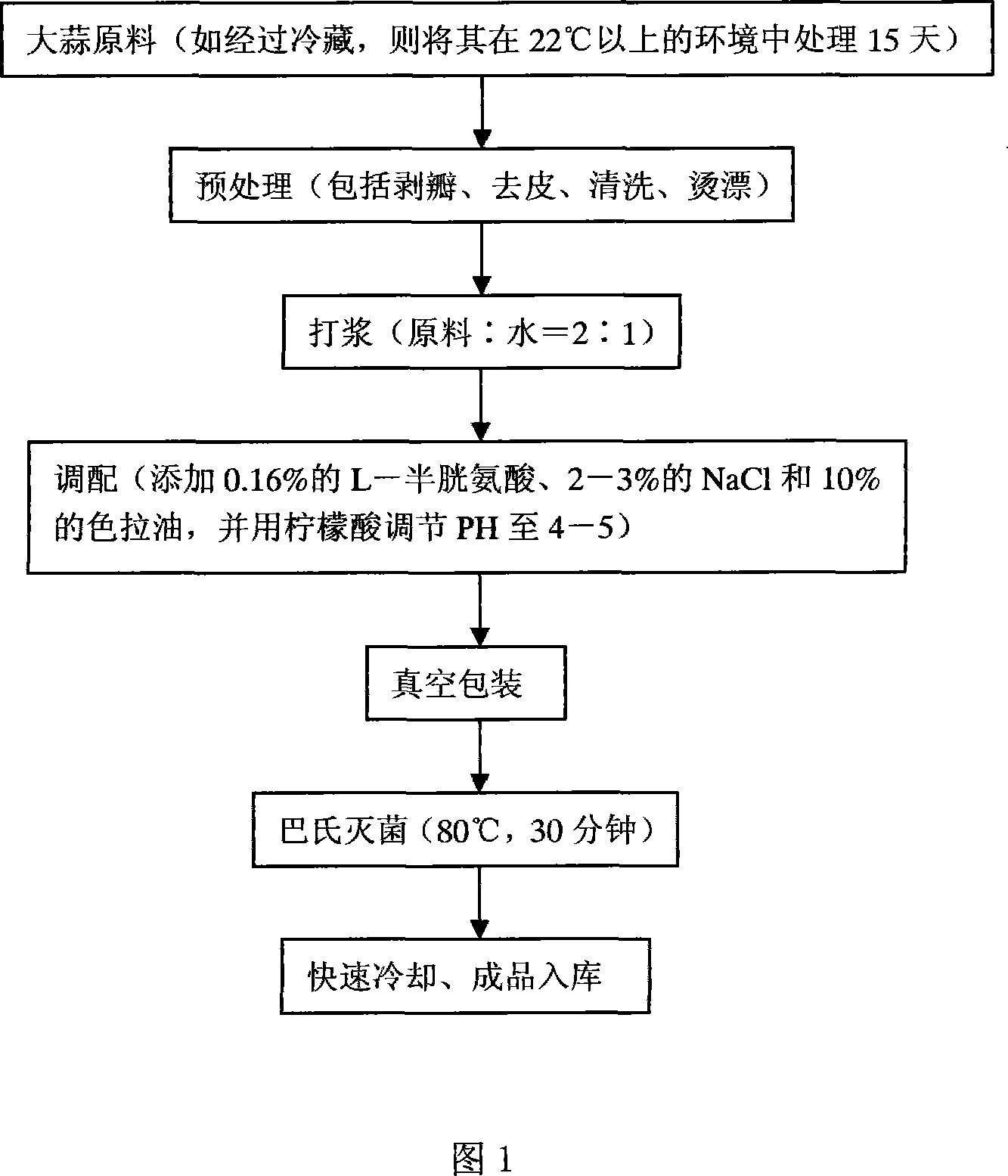

Mushed garlic producing process with control on greening and its product

The present invention relates to mashed garlic producing process capable of preventing greening and its product, and belongs to the field of agricultural product processing technology. The process includes the steps of material treatment, separating into garlic flakes, eliminating coat, washing, blanching while adding L-cysteine in 0.16 wt%, preparing mashed garlic, blending, packing and sterilizing. The garlic material is garlic without passing through cold storage or garlic passing through cold storage and treatment at 22-35 deg.c for 15 days. The process is efficiency and safe, and has white mashed garlic product with well maintained nutritious components and flavor and high quality.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

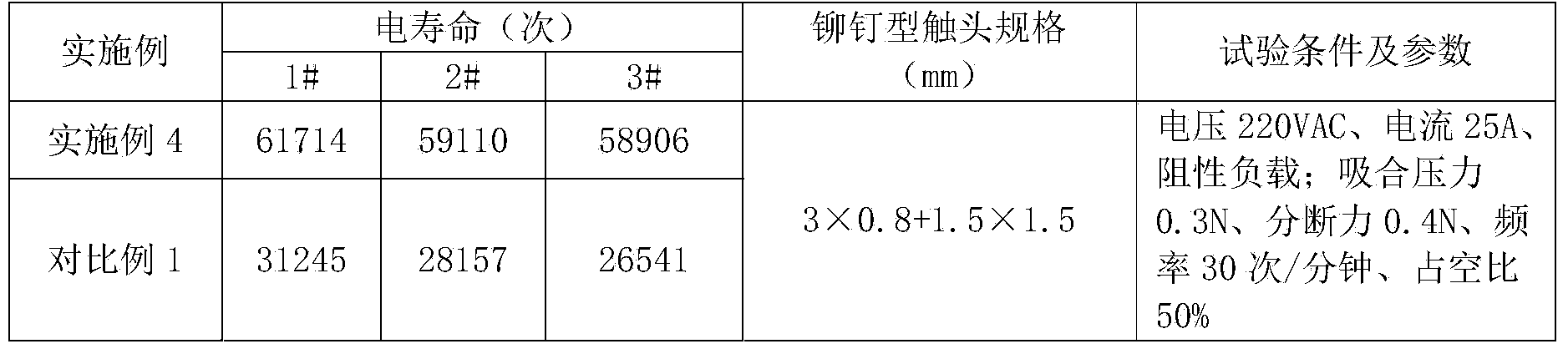

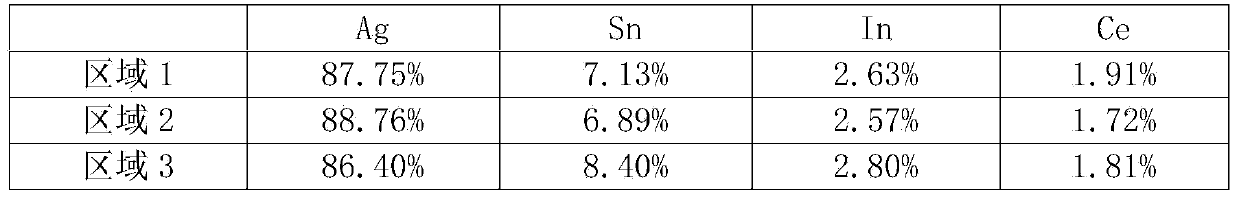

Preparation method of atomized silver and zinc oxide electrical contact materials containing additives

The invention discloses a manufacturing method of atomized silver and zinc oxide electrical contact materials containing additives. The method comprises the following steps that (1), according to the material ratio of silver and zinc oxide electrical contacts needing preparing, the dosages of needed pure silver blocks, needed pure zinc blocks and needed salt-class compounds containing the additives are calculated, and the needed pure silver blocks, and the needed pure zinc blocks and the needed salt-class compounds containing the additives are weighed for the standby; (2), the pure silver blocks and the pure zinc blocks are atomized to be silver and zinc alloy powder; (3), the salt-class compounds containing the additives are prepared to form a water solution or an ethyl alcohol solution, the silver and zinc alloy power is added into the solution to be mixed, and silver and zinc alloy powder slurry with the salt-class compounds containing the additives evenly distributed is obtained; (4), the slurry is dried and smashed, and silver and zinc alloy powder with the salt-class compounds containing the additives evenly distributed is obtained; (5), pre-oxidation processing, isostatic pressing formation, sintering and extrusion are carried out on the alloy powder so as to obtain the atomized silver and zinc oxide electrical contact materials containing the additives. The method well solves the problem of segregation of the additives caused by a traditional atomization and power mixing process, and improves the degree of densification, the processing performance, the material yield and the electrical property of the materials.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

In-situ starch solidifying formation process to prepare ceramic biscuit

The in-situ starch solidifying formation process to prepare ceramic biscuit includes adding starch in 1-15 wt% into ceramic slurry with solid content over 50 vol% and water as dispersing medium to prepare pH 3-10 ceramic slurry through homogeneous mixing; casting into mold, heating to 60-85 deg.c for solidification to fix powder particle in ceramic slurry and drying to make ceramic biscuit; and heating to oxidize and eliminate the introduced starch organic matter or carbonizing the organic matter into ceramic biscuit component. The present invention is practical, simple in production process, wide in material source, low in cost, without environmental pollution and high in product performance.

Owner:WUHAN UNIV OF TECH

Low-melting-point glass powder, preparation method and application thereof and method of utilizing same to prepare composite glass column

The invention relates to the technical field of chemical engineering and electronics, in particular to low-melting-point glass powder, a preparation method and application thereof and a method of utilizing the same to prepare a composite glass column, and aims to solve the problem that existing glass powder is poor in chemical stability, high in cost and incapable of guaranteeing high airtightness in sealing connection of electronic packaging members. The low-melting-point glass powder is composed of, by mass part, stannous oxide, phosphorus pentoxide, zinc oxide, sodium oxide, barium oxide, potassium oxide, silicon dioxide, indium oxide, magnesium oxide, iron oxide, aluminum oxide and strontium oxide. The low-melting-point glass powder is high in chemical stability, proper in linear expansion coefficient, lead-free and environment-friendly, is low in melting point and especially suitable for airtight sealing connection of lead terminals of phased array radar T / R modules and high-precision instruments.

Owner:허난징타이에어로우스페이스하이테크머터리얼스테크놀로지컴퍼니리미티드

Method for recycling rare and precious metals from acid mud

ActiveCN105803209ADoes not constitute pollutionReduce manufacturing costProcess efficiency improvementElemental selenium/telluriumSulfite saltSodium salt

The invention provides a method for recycling rare and precious metals from acid mud, and relates to the technical field of recycling and reusing of precious metals from the acid mud. The method comprises the following steps: acid mud pretreatment, copper recycling, lead recycling and selenium recycling. The method is particularly suitable for the acid mud with the following features: Pb 30-50%, Se 2-15%, Bi 1-5%, Cu 2-10%, Au 2-10 g / t and Ag 30-200 g / t. The method has the beneficial effects that by acid mud washing, copper metal in the acid mud is recycled and is leached by mixed acid, by high accumulation ability of lead to gold, silver and bismuth, lead-bismuth alloy is prepared by pyrogenic-process smelting, the rare and precious metals such as the bismuth, the gold and the silver are recycled to a maximum extent, selenium powder is prepared in a reducing manner by sulfur dioxide, and compared with a sodium sulfite technology, the method has the feature that sodium salt wastewater or sodium sulfate crystal cannot be formed. Solid waste generated in the technology is mainly from two-time solid-liquid separation, filter residues of solid-liquid separation are rich in lead element, the lead element is used for pyrogenic-process smelting of lead to form the lead-bismuth alloy, therefore, a closed cycle system is formed in a whole technological process, the environment is not polluted, production costs are reduced, and environmentally friendly and clean production is realized.

Owner:甘肃高能中色环保科技有限公司

Etching method of single crystal silicon material for solar cell

InactiveCN102255002ARealize automatic controlImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesSulfur hexafluorideOxygen

The invention provides an etching method of a single crystal silicon material for a solar cell. The etching method comprises the steps of: introducing a reaction gas to a vacuum reaction cavity filled with a single crystal silicon material, applying high-frequency electricity to the reaction cavity at a certain pressure, wherein the reaction gas is a mixed gas of oxygen or one or more gases selected from nitric acid gas, chlorine, sulfur hexafluoride and alkali metal hydroxides. According to the single crystal silicon material prepared by adopting the etching method, the photoelectric conversion efficiency of the solar cell can be greatly increased; and according to the method provided by the invention, liquid acid and alkaline are fully eliminated, zero emission is realized, no any pollution is produced to the environment, and a large quantity of manufacture cost is saved.

Owner:陈必雄

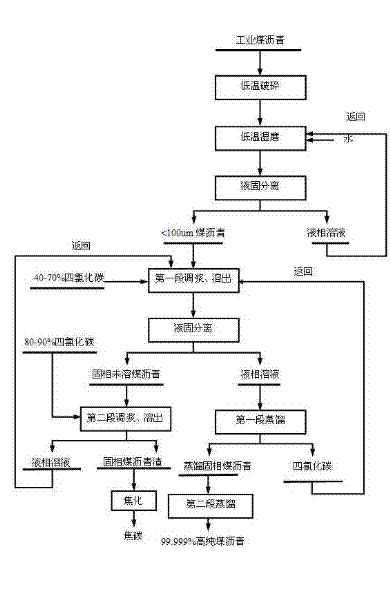

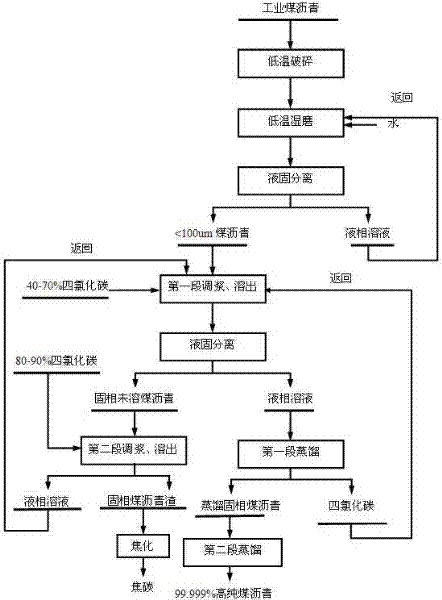

Preparation method of high-purity coal tar pitch from industrial coal tar pitch

ActiveCN102226093ASolve the deficiency of physical purification methodEfficient removalWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionPurification methodsGranularity

The invention relates to a preparation method of high-purity coal tar pitch from industrial coal tar pitch. Industrial coal tar pitch is cracked at a low temperature of 0-15 DEG C, ground wet and treated with liquid-solid separation to obtain coal tar pitch with a granularity less than 100[mu]m. The coal tar pitch with a granularity less than 100[mu]m reacts with carbon tetrachloride with a concentration of 40-70%, and is treated with liquid-solid separation after the reaction. A liquid phase solution enters into a first distillation operation until carbon tetrachloride does not distill into a condensation receiver. Obtained distilled solid coal tar pitch enters into a second distillation operation, and high-purity coal tar pitch is obtained after distillation, wherein a total ash content is less than 0.0008%, and an impurity content is less than 0.0005%. The invention solves insufficiency of a traditional industrial coal tar pitch physical purification method, and enables effective removal of impurities such as zinc, aluminium, titanium and iron etc. in industrial coal tar pitch.

Owner:KUNMING METALLURGY INST

Control method of greenish appearance of mashed garlic during processing process

InactiveCN105876385AControl green changeImprove qualityClimate change adaptationFood preservationAllium sativumFood flavor

The invention relates to a control method of greenish appearance of mashed garlic during processing processes, and belongs to the technical field of agricultural product processing. The control method of greenish appearance of the mashed garlic during the processing processes comprises the following steps: treating raw materials, namely carrying out pre-treating processes, including separating the raw-material garlic into cloves, peeling the separated garlic cloves, washing the peeled garlic cloves, blanching the washed garlic cloves and so on; preparing the mashed garlic; blending the prepared mashed garlic; packaging the blended mashed garlic, and carrying out sterilizing. The non-refrigerated fresh garlic is selected as the raw material, or the refrigerated garlic which has been treated at 22-35 DEG C for 15 days before the processing is used as the raw material. During the blending process, L-thioserine is added into the mashed garlic, wherein the mass of the L-thioserine accounts for 0.16% of the mass of the mashed garlic. The control technology of greenish appearance of mashed garlic provided by the invention is highly effective, safe and low in cost; and the prepared mashed garlic product is white in color as well as good in nutrition and flavor; thus, the product meets the export standards.

Owner:重庆市涪陵区渝杨榨菜(集团)有限公司

Process for preparing bamboo pulp cotton

The invention discloses a process for preparing bamboo pulp cotton, comprising the following steps of preparation of bamboo glue, preparation of a sponge and posttreatment. The process is characterized in that the bamboo glue is prepared by the steps of soaking bamboo fibers in an alkaline liquor, then ageing, yellowing and carrying out post-dissolution; the sponge is prepared by mixing ripened glue and sodium sulfate decahydrate, adding a colorant, evenly stirring, putting into an appointed mold and heating for curing and forming, wherein the ripening ammonium chloride value reaches 7+ / -0.5ml, and the weight of the sodium sulfate decahydrate is 3-5 times of the weight of the glue; and the posttreatment comprises the following steps of: washing the formed sponge 1-3 times to remove most of sodium sulfate decahydrate in the sponge, then carrying out acid-washing, desulfuring and alkali-washing, then washing to be neutral with tap water, and carrying out moisturizing and fungus-resisting treatment to obtain the finished product of the bamboo pulp cotton. The bamboo pulp cotton prepared by adopting the process disclosed by the invention is clean and environment-friendly and has durable antibiosis and bacteriostasis effects.

Owner:JIAXING JEHONN CLEANING PRODS

Sustained releasing pesticide granule

InactiveCN100442975CLong durationDoes not constitute pollutionBiocideAnimal repellantsLow speedPlant roots

The invention provides a novel sustained-release pesticide granule, which is prepared from the following components: pesticide active compound, modified starch, powder and auxiliary materials. The invention also provides a method for using the slow-release pesticide granule. The granules of the present invention can control the active ingredient so that it is released into the surrounding environment at a predetermined speed or at a lower speed in a predetermined time, so they are particularly suitable for controlling the entire growing season around the rhizosphere of a plant once applied (or Period) pests or excessive growth, especially suitable for controlling the growth of lawn.

Owner:BEIJING AGRI TECH PROMOTION STATION

Control method of mushed garlic producing process with control on greening and its product

InactiveCN101019681BControl green changeImprove qualityFood preservationFood preparationBiotechnologyAgricultural science

Owner:JIANGSU ACAD OF AGRI SCI

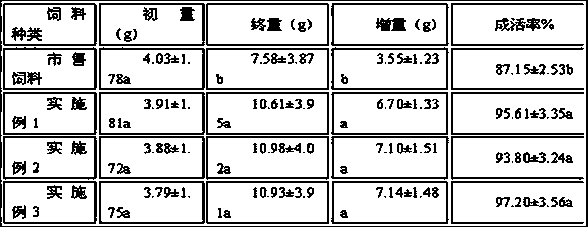

Compound feed being efficient and low in cost for young anguilla rostrata and preparation method of compound feed

InactiveCN108041340ABoost taste budsLike to eatClimate change adaptationAnimal feeding stuffHermetia illucensGracilaria verrucosa

The invention discloses a compound feed being efficient and low in cost for young anguilla rostrata and a preparation method of the compound feed. The compound feed for the young anguilla rostrata consists of the following raw materials in parts by weight: hermetia illucens powder, vital wheat gluten, white fish meal, maggot powder, silkworm chrysalis powder, yellow mealworm powder, whey powder, blood powder, corn flour, high gluten flour, soybean flour, gracilaria verrucosa powder, lecithin, multiple vitamins, multiple minerals, methionine, glutamic acid and choline. According to the compoundfeed for young anguilla rostrata, the components are green and environment-friendly raw materials, healthy and environmental-friendly, and the raw materials are environment-friendly raw materials, thereby guaranteeing that products are free from residue of toxin and harmful substances, do not damage health of human, and are free from potential pollution to health of human, human and environment.In addition, the compound feed is low in cost, the growth rate of the young anguilla rostrata is increased, and the compound feed also contain substances having effect of improving the immunity, so that the compound feed can exert the corresponding effect, further, the disease resistance of the young anguilla rostrata can be improved, and the survival rate of the young anguilla rostrata can be increased.

Owner:JIMEI UNIV

Manufacturing method of crib

InactiveCN105479763ADoes not constitute pollutionCorrosion resistantCoatingsNatural resourceCompressive strength

The invention discloses a manufacturing method of a crib. The manufacturing method includes the following steps that corresponding molds are designed according to components of the crib, the components of the crib comprise two side bars, two bedsides and a bed board, the components are arranged linearly, the molds are opened, the temperature of the molds ranges from 25 DEG C to 35 DEG C, the raw materials are injected into the molds, the molds are combined and stand still for 9 minutes to 11 minutes, then the molds are opened, the components, formed in the molds, of the crib are taken out, the two bedsides and the two side bars are fixed through screws, and the crib is obtained after the bed board is mounted. According to the manufacturing method, a wood-imitation material or plastic is adopted, and the crib has the beneficial effects of being free of rust, resistant to corrosion, low in mass, insulating, balanced in density distribution, good in compressive strength, good in dimensional stability, free of cracking, free of maintenance, resistant to flame, free of mildew, long in service life, environment-friendly, free of pollution to the surroundings, free of consumption of a great number of natural resources, good in water resistance and high in safety coefficient.

Owner:陈同云

Environment-friendly flame-retardant insulating material

PendingCN112300474AGood compatibilityHigh breaking strengthPlastic/resin/waxes insulatorsCalcium silicatePolypropylene

The invention discloses an environment-friendly flame-retardant insulating material. The material comprises the following raw materials in parts by weight: 25-40 parts of polyethylene, 20-40 parts ofan ethylene-vinyl acetate copolymer, 10-20 parts of graphene, 13-18 parts of magnesium hydroxide, 10-15 parts of polypropylene reinforced fibers, 10-15 parts of aromatic polyamide fibers, 12-19 partsof aluminum oxide, 5-7 parts of polyamide, 10-15 parts of calcium silicate, 2-7 parts of a plasticizer, 0.5-3.0 parts of an accelerant, 10-20 parts of a flame retardant, 1-5 parts of an antioxidant, 2-5 parts of a lubricant, 2-3 parts of a compatilizer, 3-7 parts of a toughening compatibilizer, wherein the outer side of each of the toughening compatibilizer and the graphene is coated with an insulating coating layer. According to the environment-friendly flame-retardant insulating material disclosed by the invention, the compatibility among the components is improved through the ethylene-vinylacetate copolymer and the maleic anhydride graft, so that the breaking strength and the elongation of the environment-friendly flame-retardant insulating material are improved; and the environment-friendly insulating material provided by the invention is long in service life, improves the use safety, adopts halogen-free environment-friendly raw materials, does not generate toxic gas during incineration, does not pollute a human body and the environment, and is green and environment-friendly.

Owner:太湖华强科技有限公司

Halogen-free environmentally-friendly high temperature nylon

The invention relates to an organic polymer composite material, specifically speaking, relates to a halogen-free environmentally-friendly high temperature nylon. The halogen-free environmentally-friendly high temperature nylon comprises the following raw materials by weight ratio: 35.5-75% of high temperature nylon, 5-25% of halogen-free alkali-free glass fiber, 0.1-8% of filler, 0.1-3.0% of heat stabilizer, 0.1-3.0% of glass fiber processing agent, 0.2-2.5% of lubricant, 0.1-0.5% of other auxiliary agents and 1-5% of active carbon. The halogen-free environmentally-friendly high temperature nylon has the beneficial effects of using a halogen-free environmentally-friendly technology, reducing the halogen in plastic and generating no toxic gas during burning, and has advantages of no pollution on human body and environment as well as environmental protection.

Owner:SUZHOU IND PARK XINFENGLIN PLASTIC TECH

Slow-release pesticide granule

Owner:HENAN GOODDAYS BIOLOGY DEV CO LTD

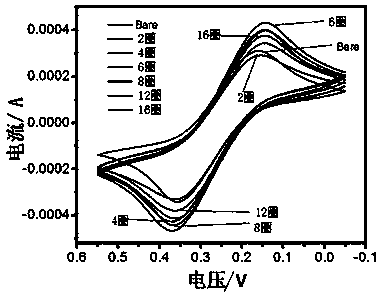

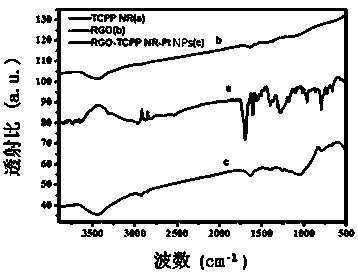

A kind of reduced graphene oxide/porphyrin/platinum nanocomposite material and its preparation and application

ActiveCN106955739BImprove photocatalytic performanceDoes not constitute pollutionMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPlatinumDehydrogenation

The invention discloses a reduced graphene oxide / porphyrin / platinum nanocomposite material and its preparation and application, and belongs to the technical field of photocatalysis. The present invention uses reduced graphene oxide with good electrical conductivity as the anchoring group molecule, and uses rod-shaped 5,10,15,20-tetrakis (4-carboxyphenyl) porphyrin with the best photocatalytic performance among porphyrins. The reduced graphene oxide film is modified, and finally platinum nanoparticles, which are the best catalytic hydrogen evolution materials, are loaded on the modified reduced graphene oxide film through photoreduction method. The prepared ITO‑RGO‑TCPP NR‑PtNPs nanocomposite has It has good photocatalytic performance and can be used as a catalyst in the photocatalytic hydrogen production process. The entire method has a short process flow, simple experimental conditions, low cost, and does not cause pollution to the environment, meeting the requirements of clean production.

Owner:深圳市睿烯新材料科技有限公司

Method for preparing silver tin oxide electrical contactor material containing additives

ActiveCN103695696AEvenly distributedImprove segregation and other phenomenaContactsTin dioxideElectrical performance

The invention discloses a method for preparing silver tin oxide electrical contactor material containing additives. The method comprises the following steps: (1) calculating the dosages of needed tin dioxide powder, silver powder and salt compounds containing adding elements according to the compounding ratio of the silver tin oxide electrical contactor material needed to be prepared, and weighing for reserve; (2) preparing the salt compounds containing the adding elements into aqueous solution or ethanol solution, adding the tin dioxide powder or silver powder, mixing materials to obtain alloy powder sizing agents in which the salt compounds containing the adding elements are distributed evenly; (3) drying and smashing the sizing agents to obtain the alloy powder in which the salt compounds containing the adding elements are distributed evenly; (4) evenly mixing the obtained alloy powder and the silver powder or the tin dioxide powder, and performing the processes of isostatic pressing, sintering and extruding. In the method, the additives are added to matrices in a special mode, the problem of additive aliquation caused by the conventional powder mixing technology is resolved, and the densifying degree, the processing performance, the yield and the electrical performance of the materials are increased.

Owner:桂林金格电工电子材料科技有限公司

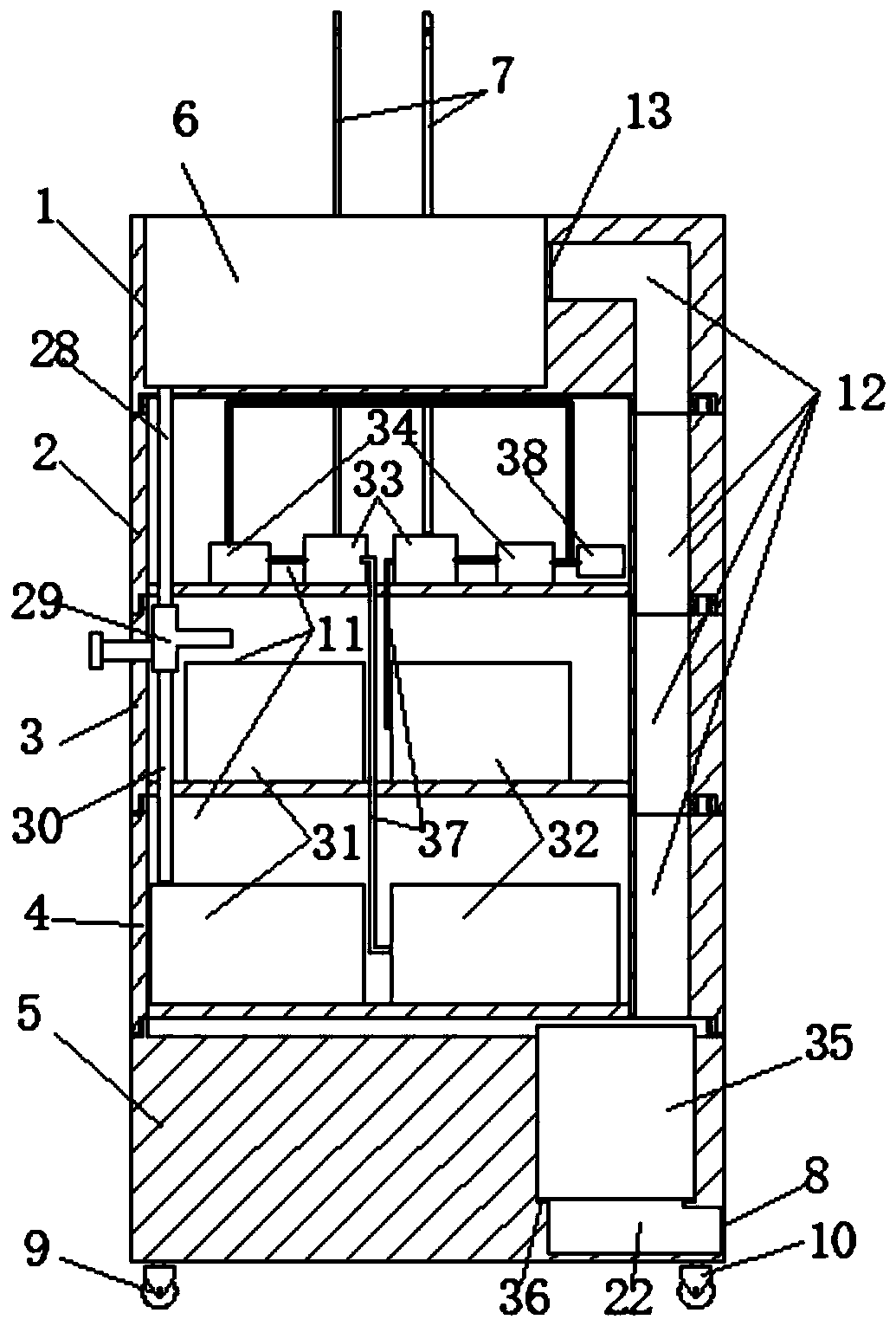

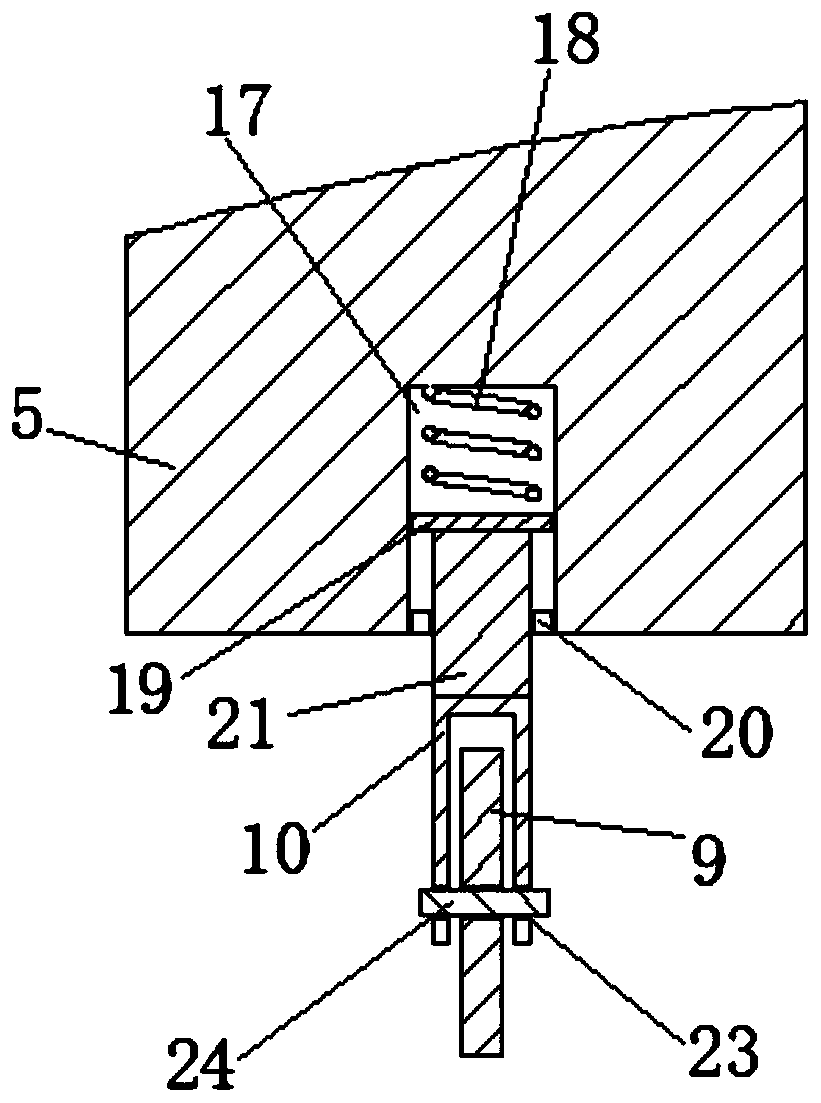

Automatic supply and discharge system and purification device for medical liquid reagent

ActiveCN110255635AEasy to handleTimely processDispersed particle filtrationTreatment control/steeringPulp and paper industryMedical device

The invention relates to the technical field of medical devices and in particular relates to an automatic supply and discharge system and purification device for a medical liquid reagent. The automatic supply and discharge system and purification device comprises a base block; a placing groove is formed in one side of the top end of the base block; an air outlet channel is formed in the side of the base block; a fourth block body is placed on the top end of the base block; a third block body is placed on the top end of the fourth block body; a second block body is placed on the top end of the third block body; a first block body is placed on the top end of the second block body; a waste liquid recovery pool is formed in one side of the top end of the first block body; a sealing ring is adhered to a position, relative to an air suction channel, at the bottom end of the first block body; storage grooves are formed in top ends of the first block body, the second block body, the third block body and the fourth block body; a liquid delivery working pump is placed in the storage groove of the second block body; the input end of the liquid delivery working pump communicates with a liquid inlet pipe, and the other end of the liquid inlet pipe is inserted into a liquid delivery vessel; the bottom end of the waste liquid recovery pool communicates with a first waste liquid recovery pipe; the outside of the waste liquid working pump is connected with a control mechanism; and the output end of the liquid delivery working pump communicates with a liquid feeding pipe. The automatic supply and discharge system and purification device is simple in structure and worthy of popularization.

Owner:孝感市爱普丽生电子科技有限公司

Method for preparing atomizing silver tin oxide electrical contactor material containing additives

The invention discloses a method for preparing atomizing silver tin oxide electrical contactor material containing additives. The method comprises the following steps: (1) calculating the dosages of needed pure silver ingots, pure tin ingots and salt compounds containing adding elements according to the compounding ratio of the silver tin oxide electrical contactor material needed to be prepared, and weighing for reverse; (2) atomizing the pure silver ingots and the pure tin ingots into silver tin alloy powder; (3) preparing the salt compounds containing the adding elements into aqueous solution or ethanol solution, adding the silver tin alloy powder, mixing materials to obtain silver tin alloy powder sizing agents in which the salt compounds containing the adding elements are distributed evenly; (4) drying and smashing the sizing agents to obtain the silver tin alloy powder in which the salt compounds containing the adding elements are distributed evenly; (5) performing the processes of pre-oxidizing, isostatic pressing, sintering and extruding for the obtained silver tin alloy powder. According to the method, the problem of additive aliquation caused by the traditional atomization and powder mixing technology is well solved, and the densifying degree, the processing performance, the yield and the electrical performance of the materials are improved.

Owner:桂林金格电工电子材料科技有限公司

Adult Japanese flounder feed additive and preparation method thereof

InactiveCN105029112ABoost taste budsLike to eatFood processingAnimal feeding stuffFish oilMazus japonicus

The invention relates to an aquatic culture animal feed additive, in particular to an adult Japanese flounder feed additive, and further relates to a preparation method of the adult Japanese flounder feed additive. The adult Japanese flounder feed additive is composed of, by mass, 6-10 parts of silkworm chrysalis, 6-10 parts of earthworm, 6-8 parts of eclipta alba, 6-8 parts of ligustrum lucidum ait, 4-6 parts of ulva, 4-6 parts of shepherdspurse herb, 4-6 parts of carrot, 4-6 parts of herba houttuyniae, 3-5 parts of purslane, 3-5 parts of fructus xanthii, 3-5 parts of watermelon peel, 3-5 parts of Japanese pearlwort herb, 3-5 parts of mazus japonicus, 3-5 parts of astragalus sinicus, 1-3 parts of fresh ginger, 2-4 parts of honey, 2-4 parts of olive oil and 2-4 parts of fish oil. By means of the adult Japanese flounder feed additive, the growth of Japanese flounder can be promoted, the immunity of Japanese flounder can be improved, and Japanese flounder is high in specific growth rate and survival rate after eating the adult Japanese flounder feed additive.

Owner:QINGDAO HAIZHIYUAN INTELLIGENT TECH

A kind of preparation method of silver-nickel material for electric contact

ActiveCN102800513BEnhanced interface bindingImprove electrical performanceElectric switchesLow voltageLanthanum

The invention relates to a preparation method for preparing silver nickel materials by means of electrical contacts. The preparation method is characterized by comprising the following steps of: performing surface ultrasonic chemical coating processing on Ni powder of which the purity is more than 99 percent, wherein elements for coating processing are one or more of zinc, copper, silver and lanthanum, the processing temperature is controlled to be between 60 and 100 DEG C, and the coating amount is between 1 and 30 percent; mixing the coated N powder with Ag powder and trace metal oxide; performing a sintering-extruding process subsequently; and drawing materials into finished products. The preparation method has the key point that a layer of transition element which is used as a contact bridge between Ag and Ni is coated in the surface of the Ni powder, and the interface combination between the Ag and the Ni is improved, so that the contact between the Ag and the Ni is not simple mechanical contact, and Ag and the Ni are well blended together, the densification of materials is facilitated, the sintering temperature is reduced, the machining performance of materials is improved, the electrical life of the materials is prolonged, and the silver nickel materials can be widely used for switches, relays, circuit breakers and the like in low-voltage electrical appliances.

Owner:佛山通宝精密合金股份有限公司

A kind of low-melting-point glass powder, its preparation method and application, and the method for preparing composite glass column by using low-melting-point glass powder

The invention relates to the technical field of chemical engineering and electronics, in particular to low-melting-point glass powder, a preparation method and application thereof and a method of utilizing the same to prepare a composite glass column, and aims to solve the problem that existing glass powder is poor in chemical stability, high in cost and incapable of guaranteeing high airtightness in sealing connection of electronic packaging members. The low-melting-point glass powder is composed of, by mass part, stannous oxide, phosphorus pentoxide, zinc oxide, sodium oxide, barium oxide, potassium oxide, silicon dioxide, indium oxide, magnesium oxide, iron oxide, aluminum oxide and strontium oxide. The low-melting-point glass powder is high in chemical stability, proper in linear expansion coefficient, lead-free and environment-friendly, is low in melting point and especially suitable for airtight sealing connection of lead terminals of phased array radar T / R modules and high-precision instruments.

Owner:허난징타이에어로우스페이스하이테크머터리얼스테크놀로지컴퍼니리미티드

Process for preparing bamboo pulp cotton

Owner:JIAXING JEHONN CLEANING PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com